An Adaptive Parameterization for

"How to efficiently measure BRDFs with a goniophotometer"

Jonathan Dupuy

Wenzel Jakob

Unity Technologies

EPFL

This presentation is an overview of our SIGGRAPH Asia 2018 paper

"An Adaptive Parameterization for Efficient Material Acquisition and Rendering".

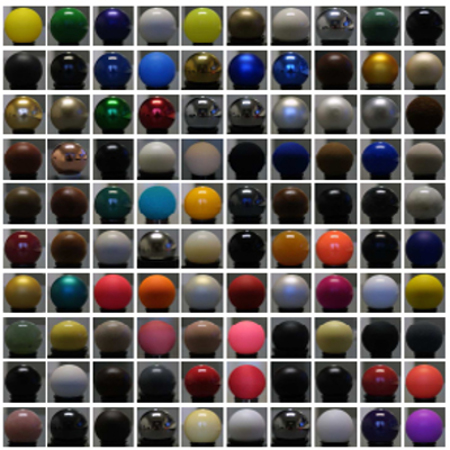

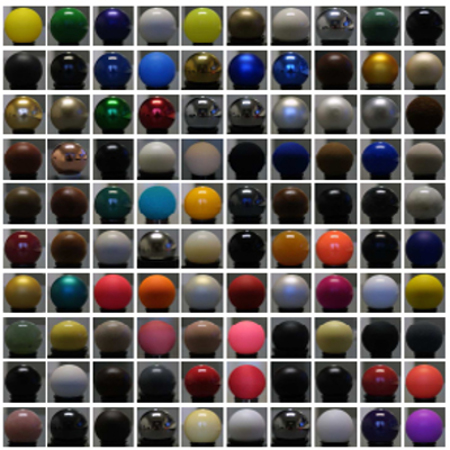

57 BRDFs (10 anisotropic)

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

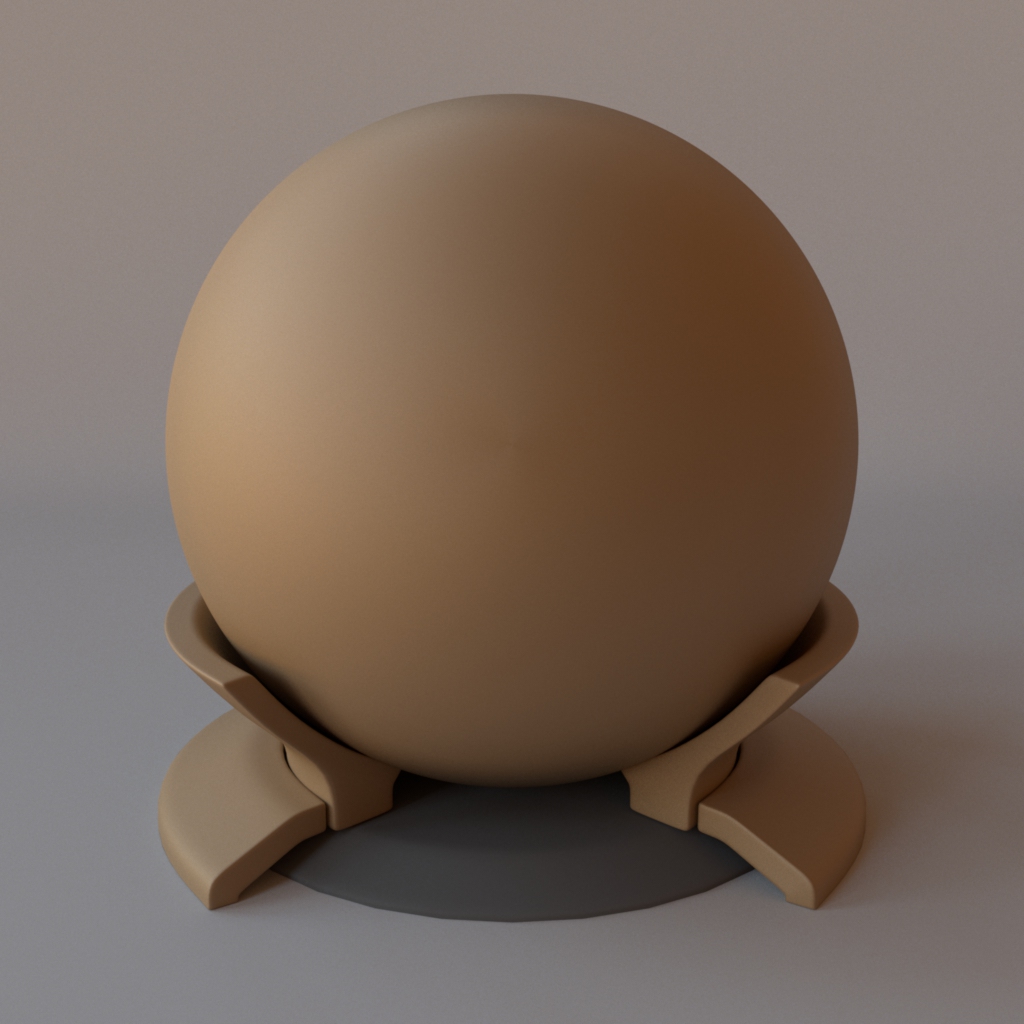

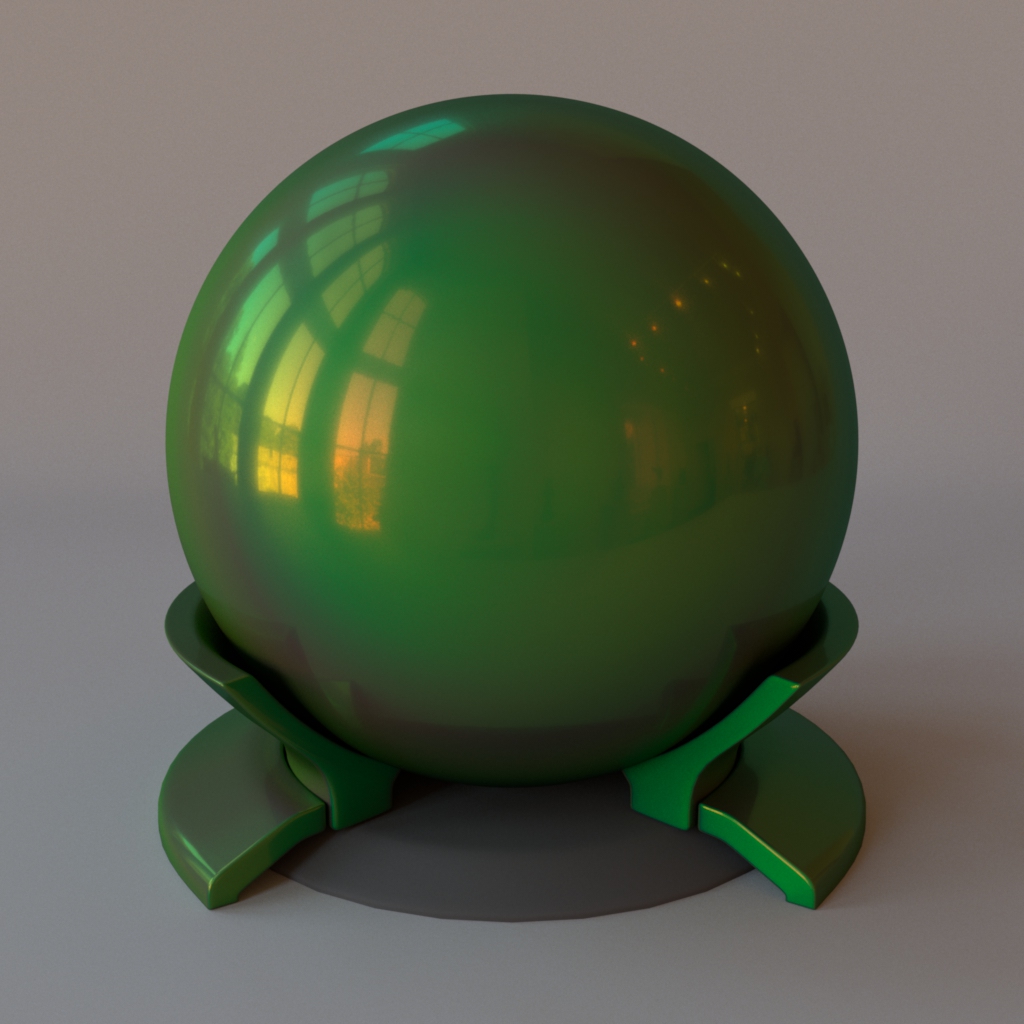

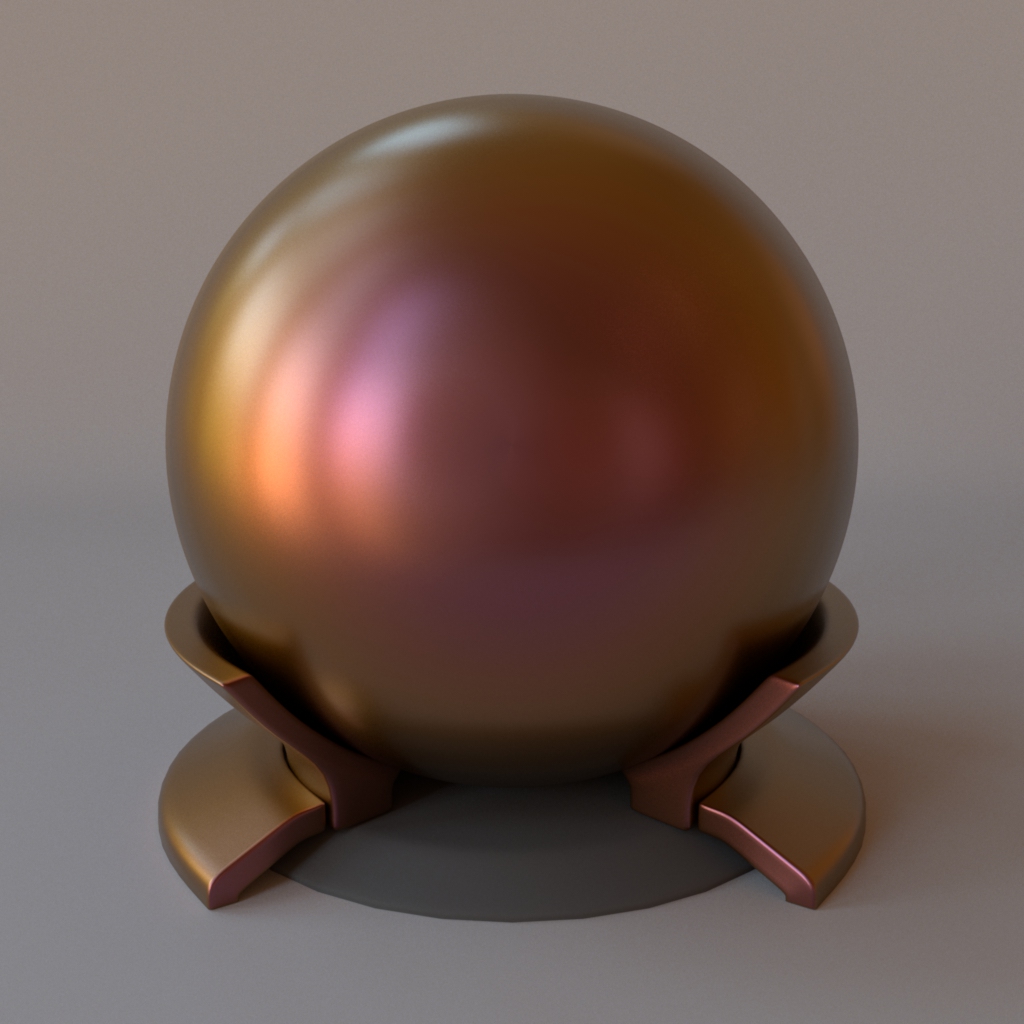

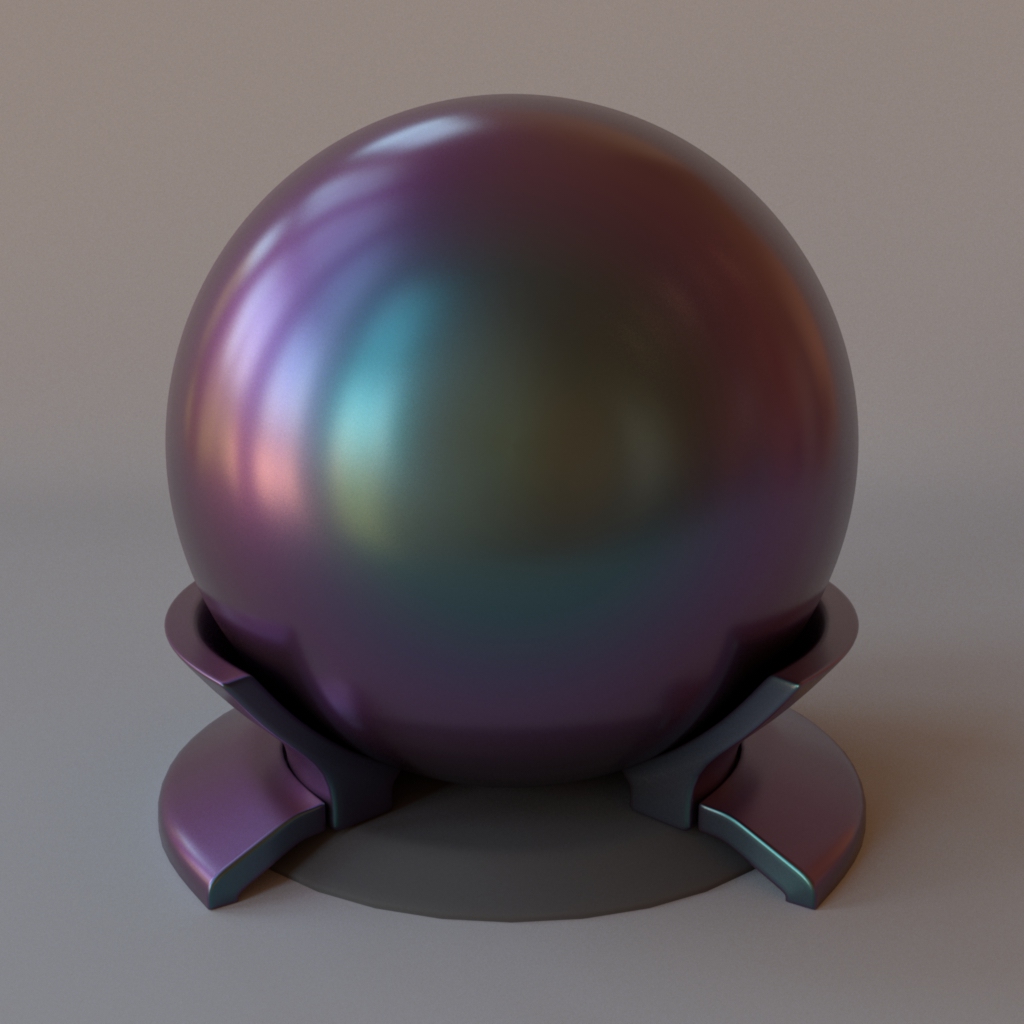

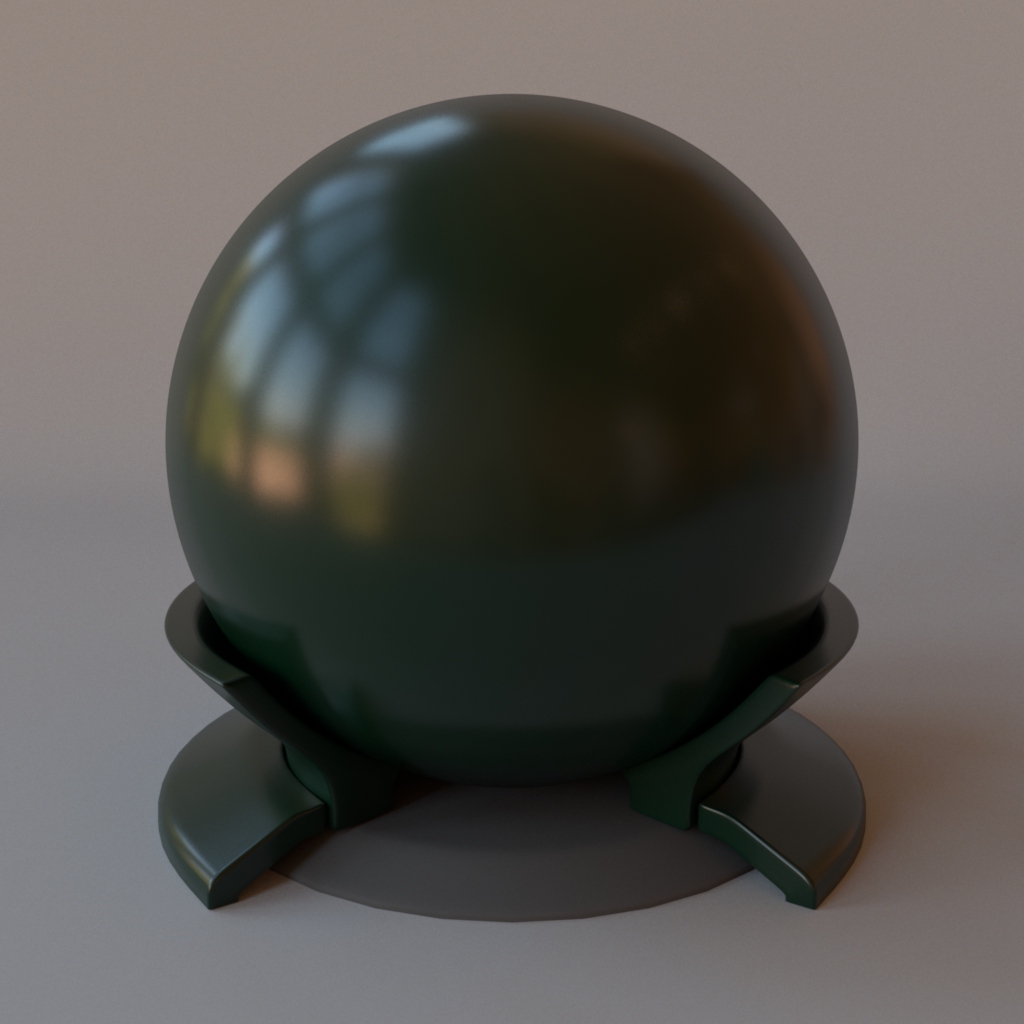

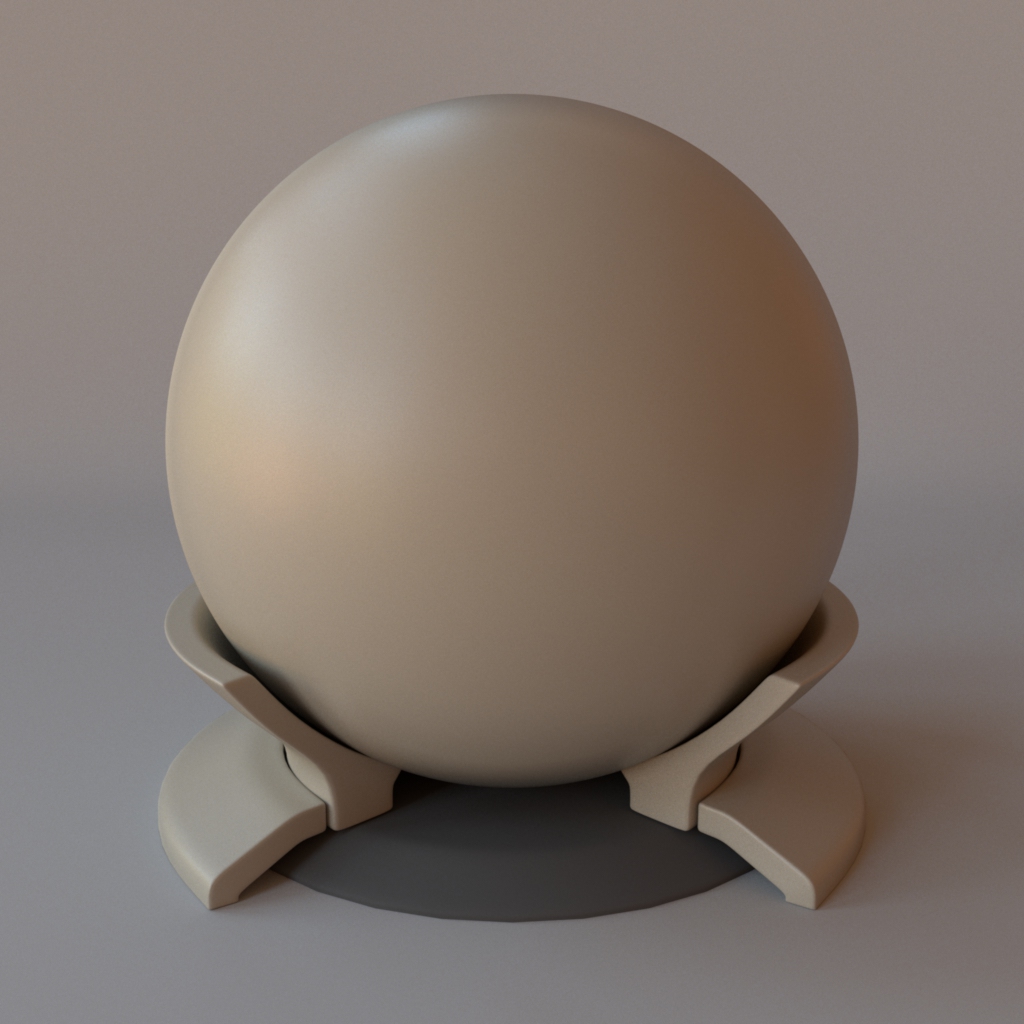

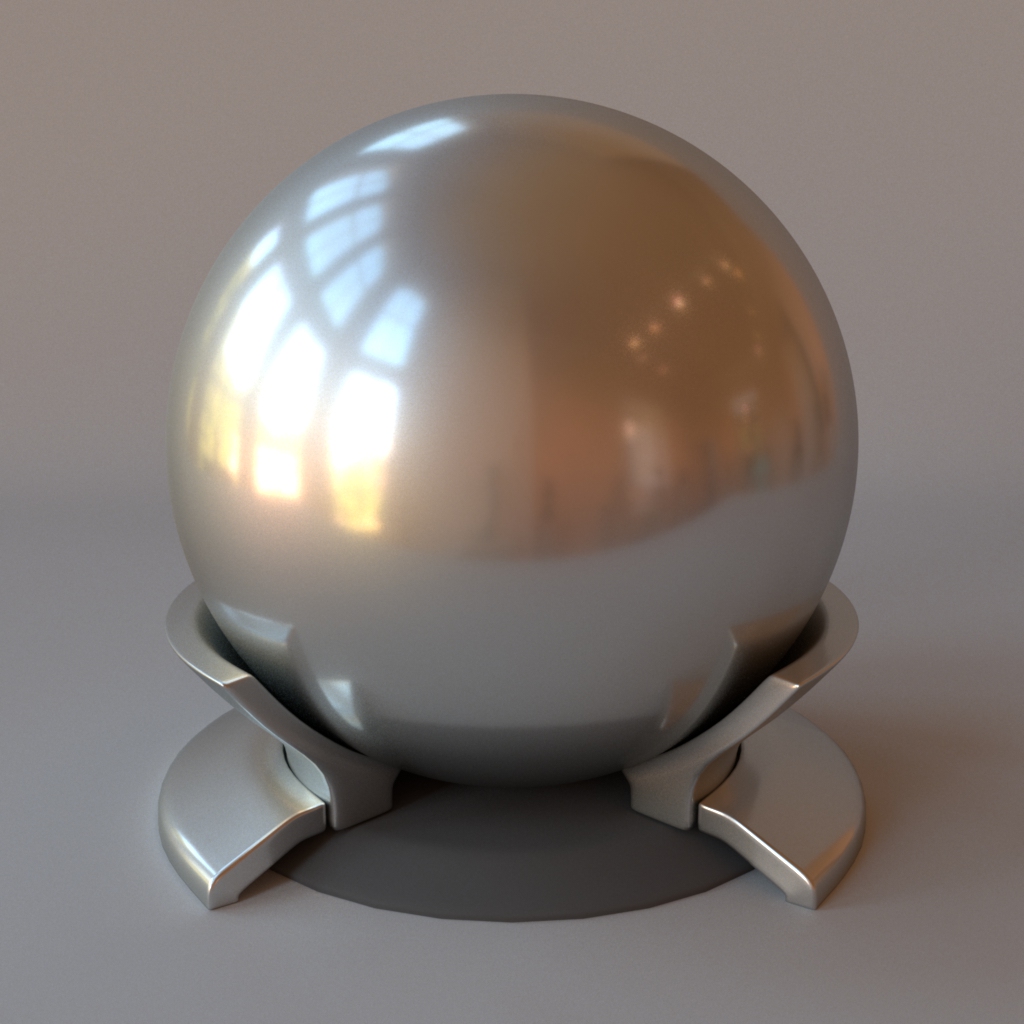

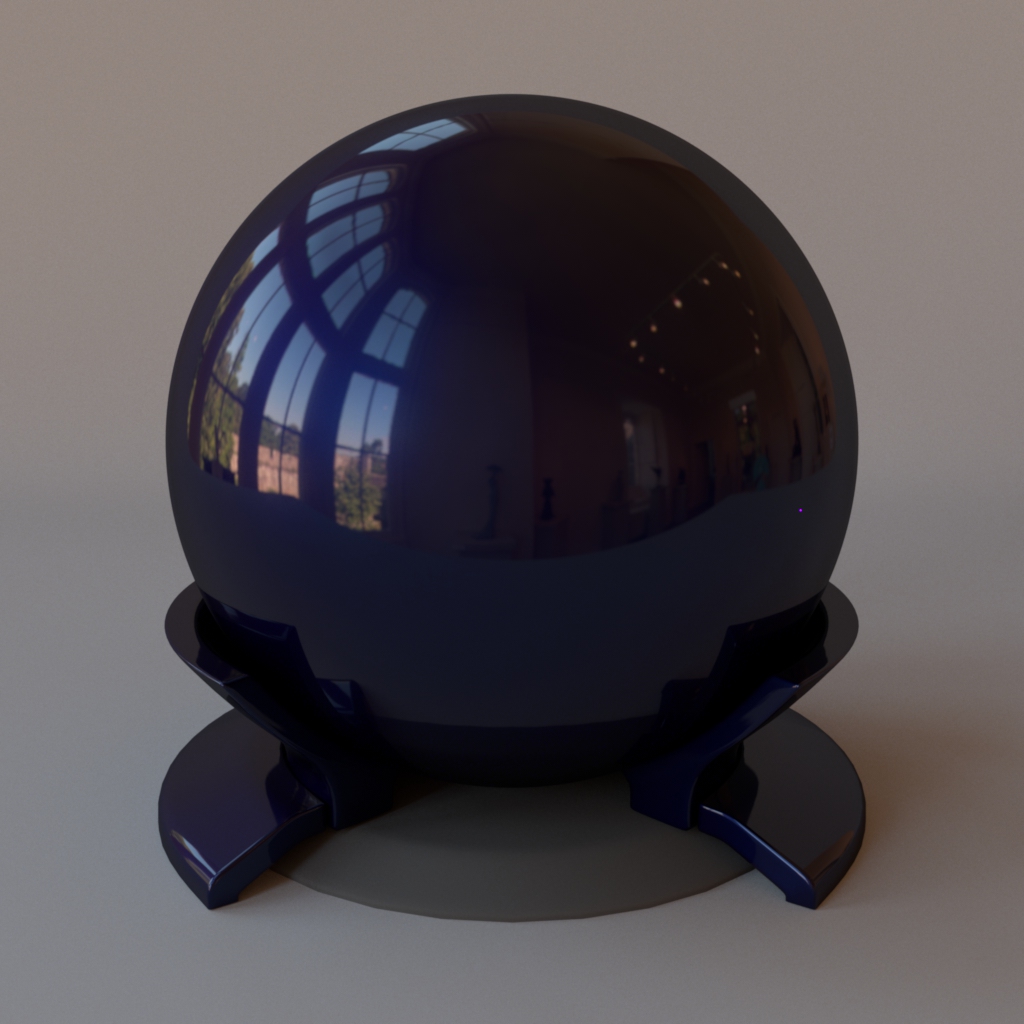

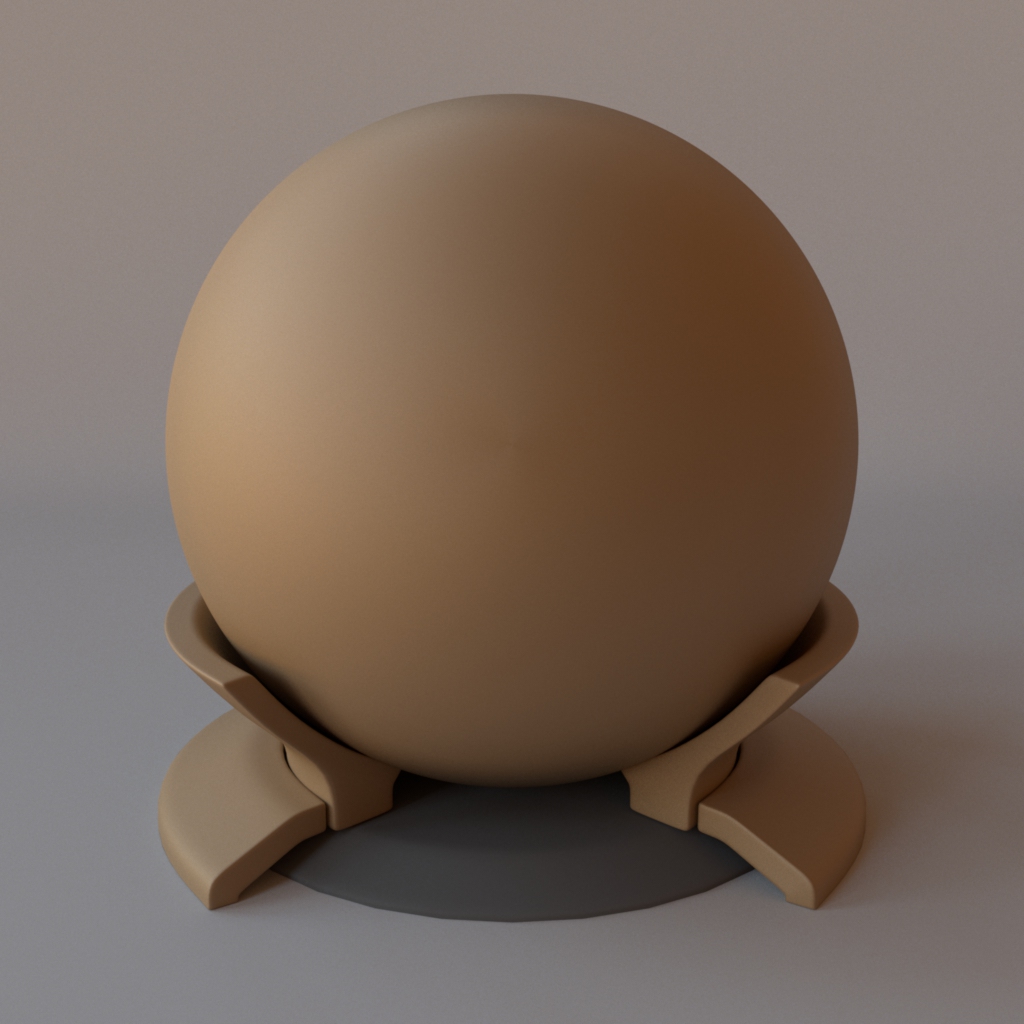

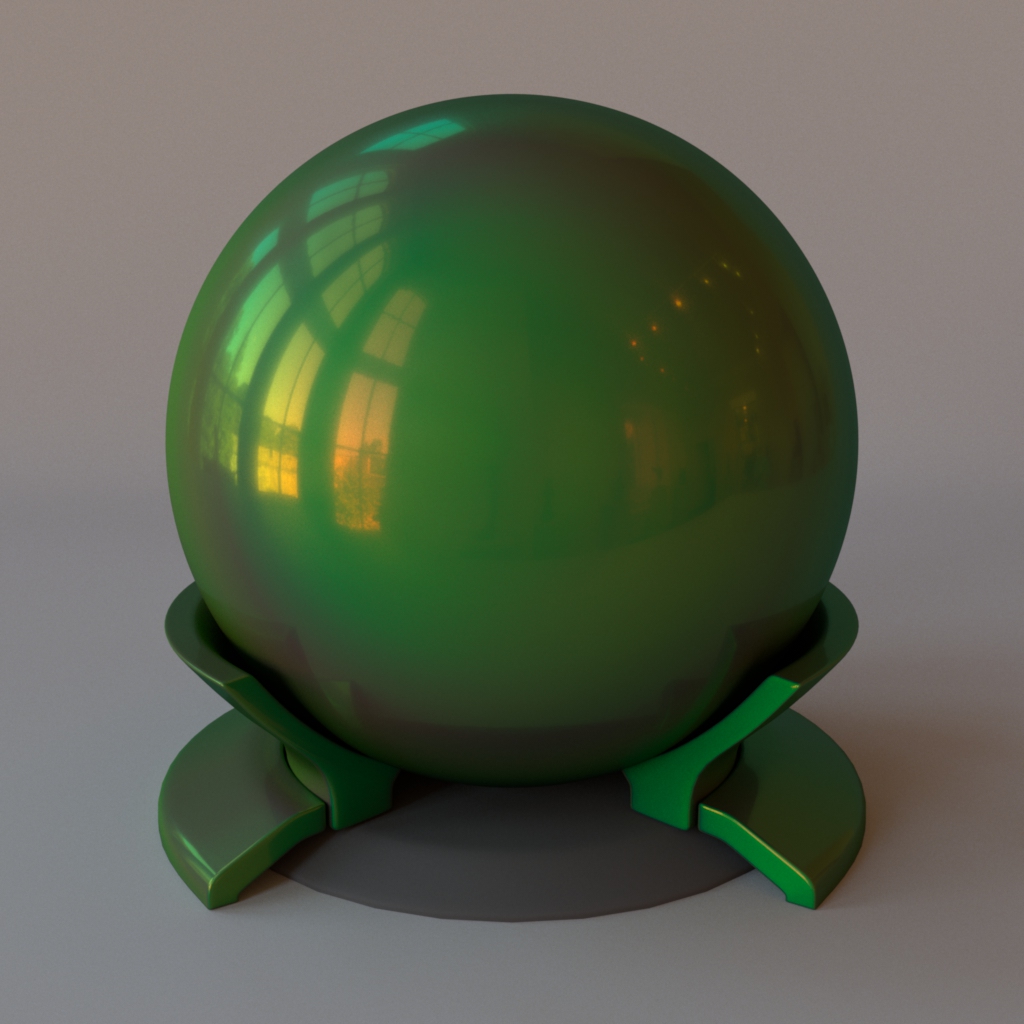

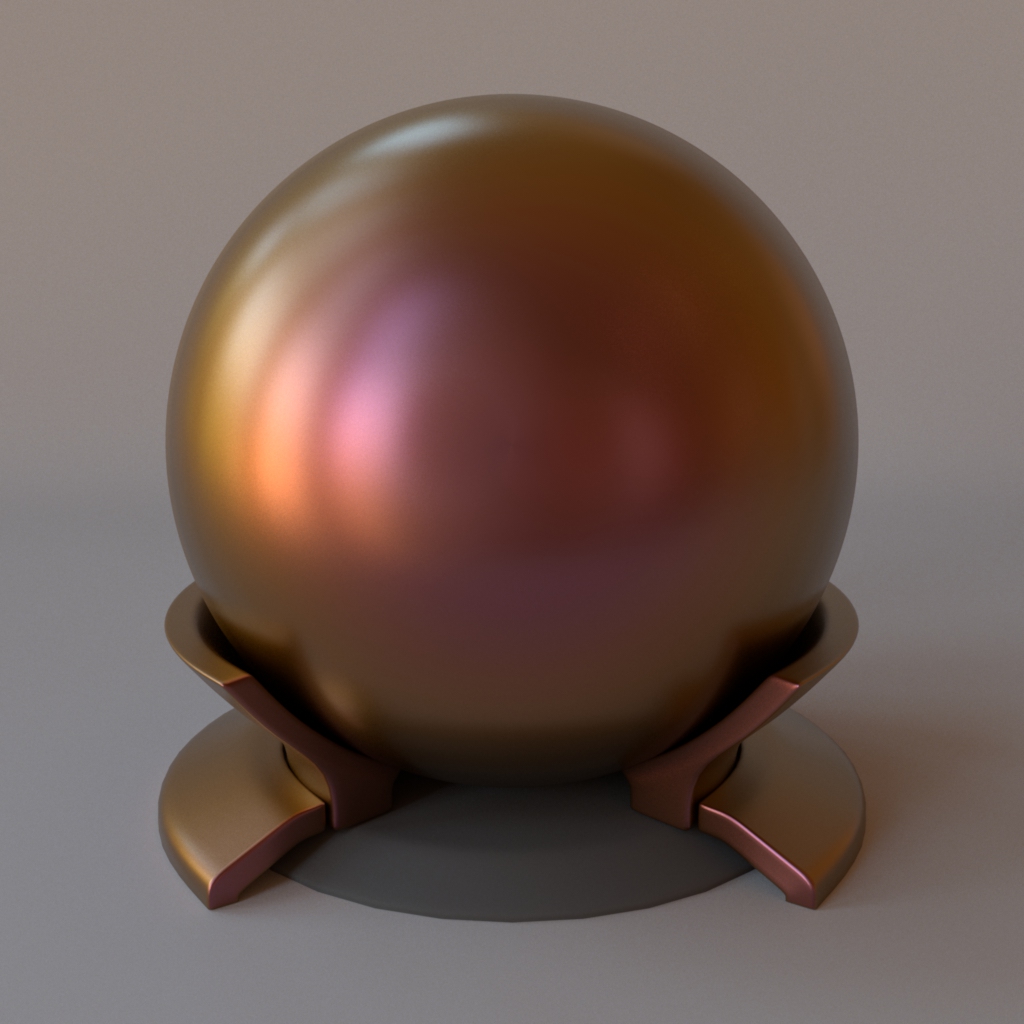

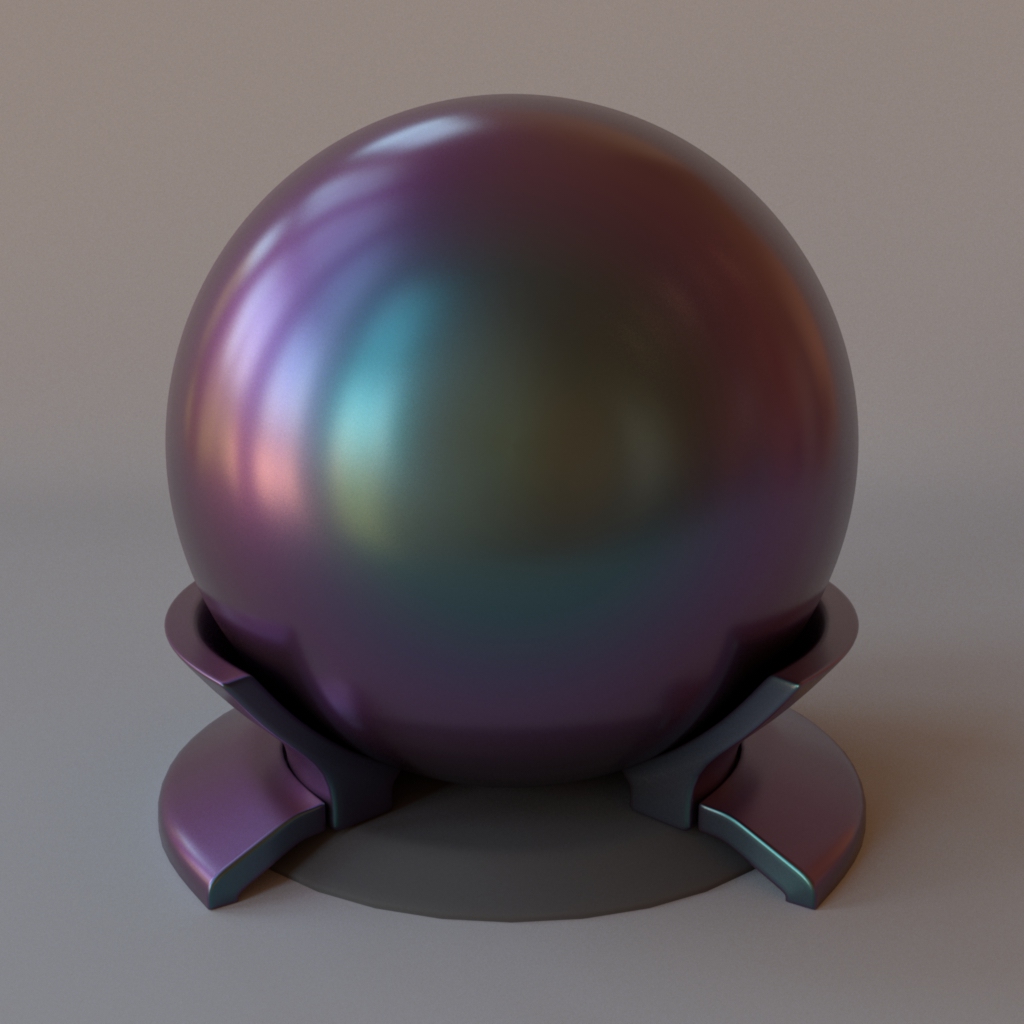

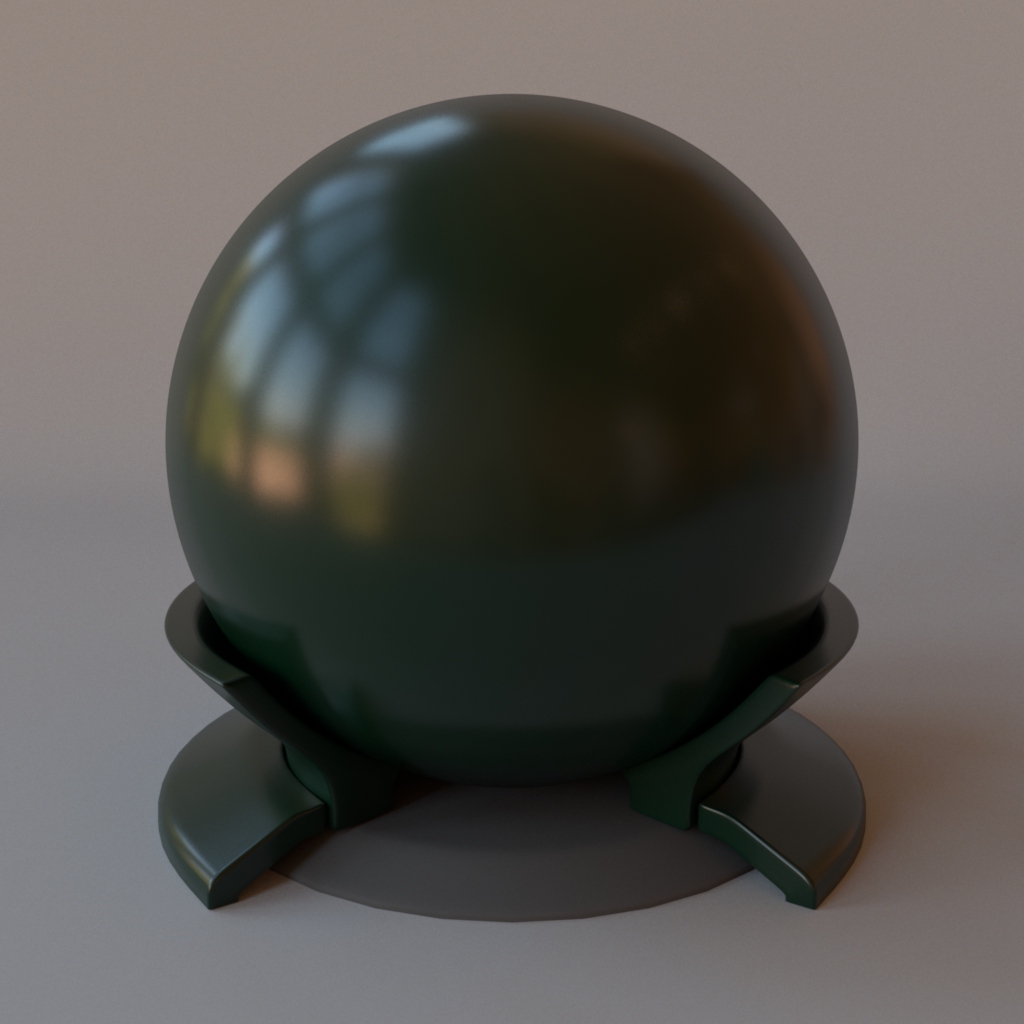

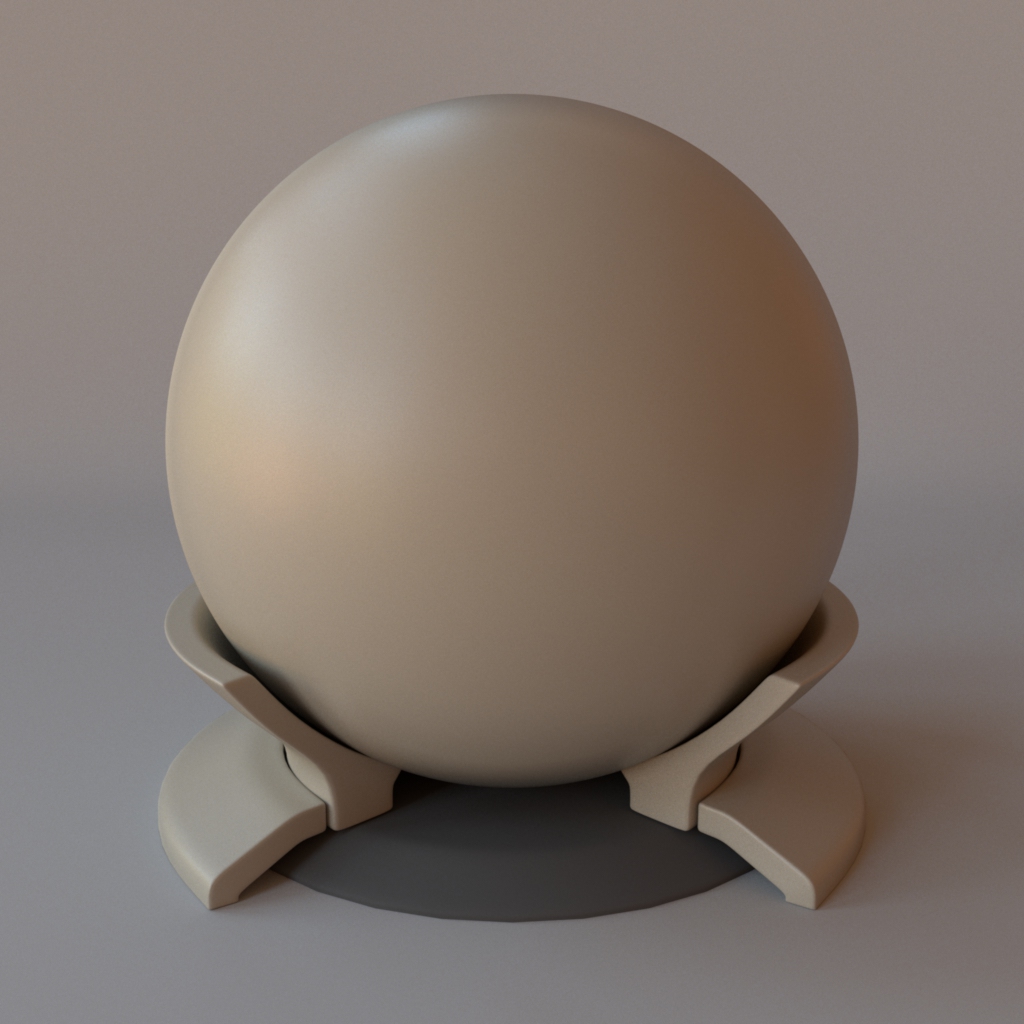

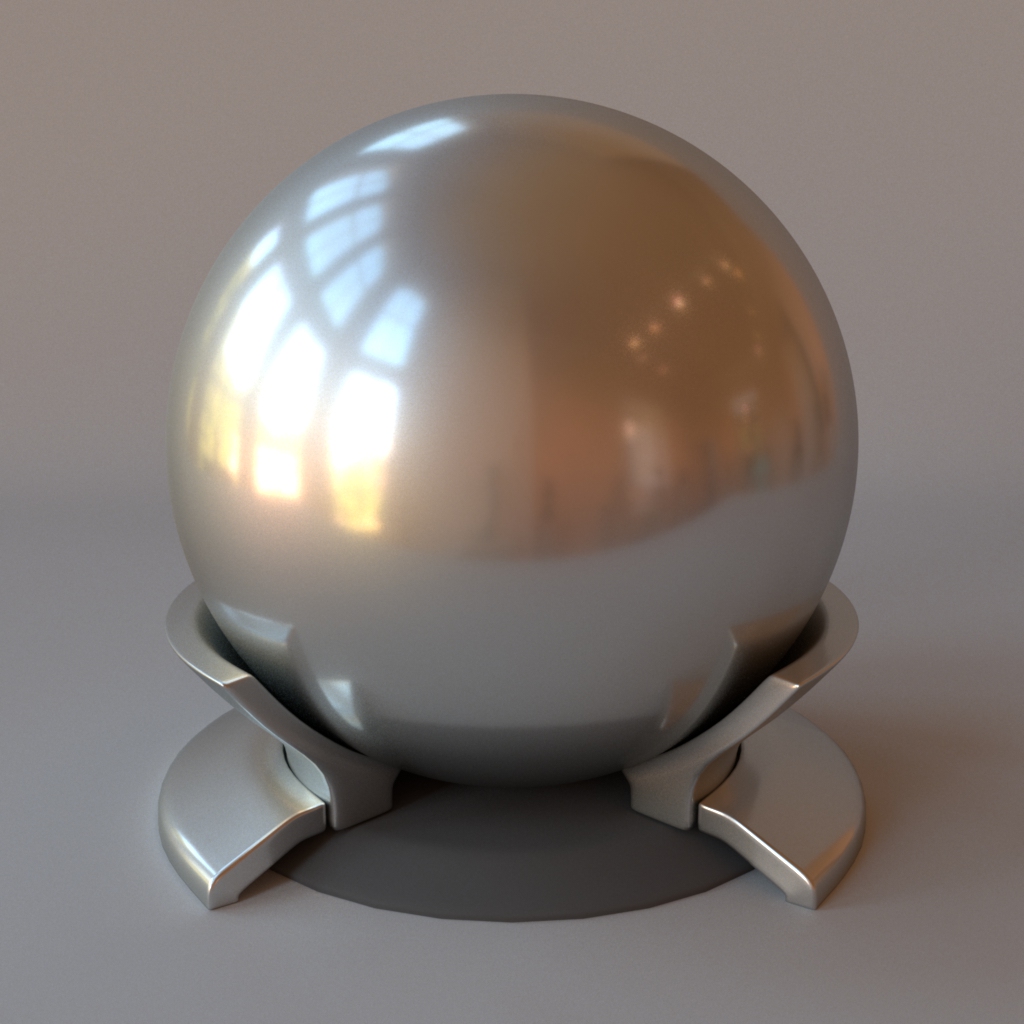

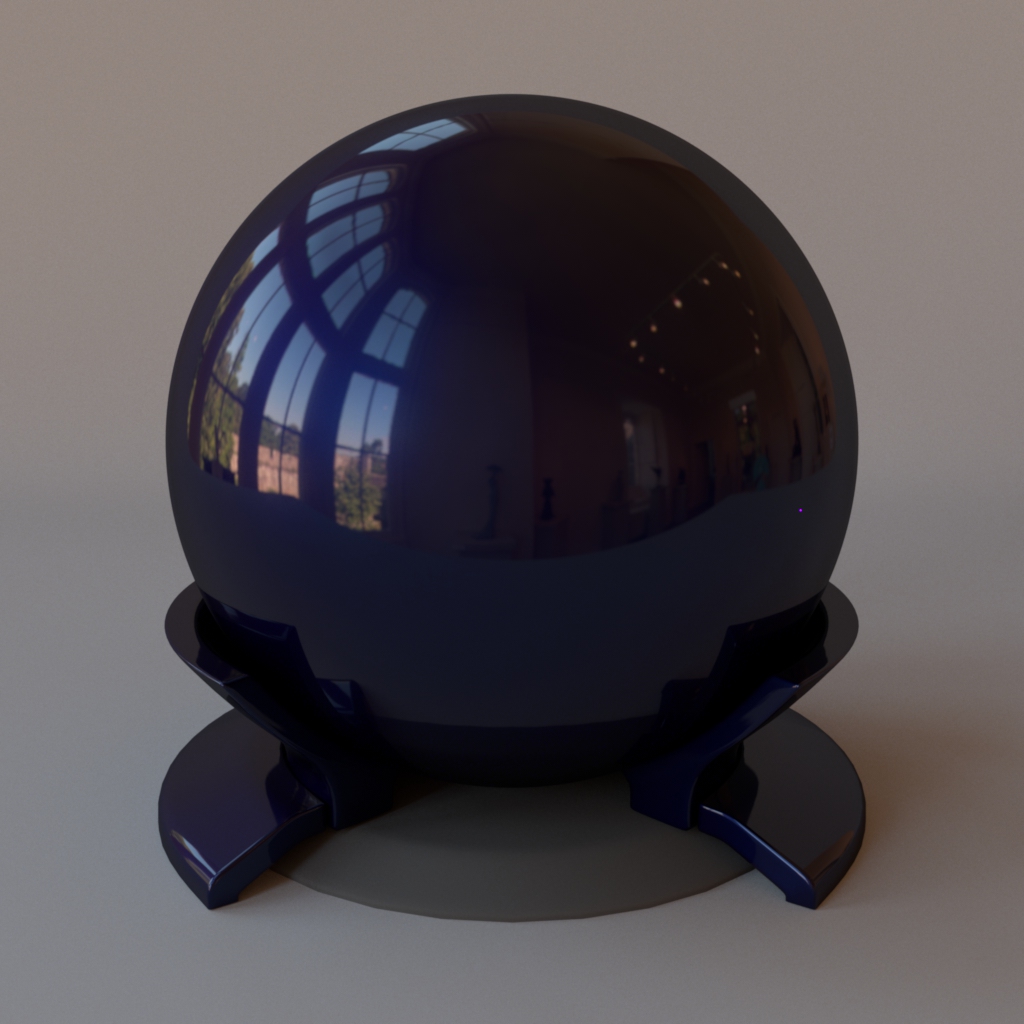

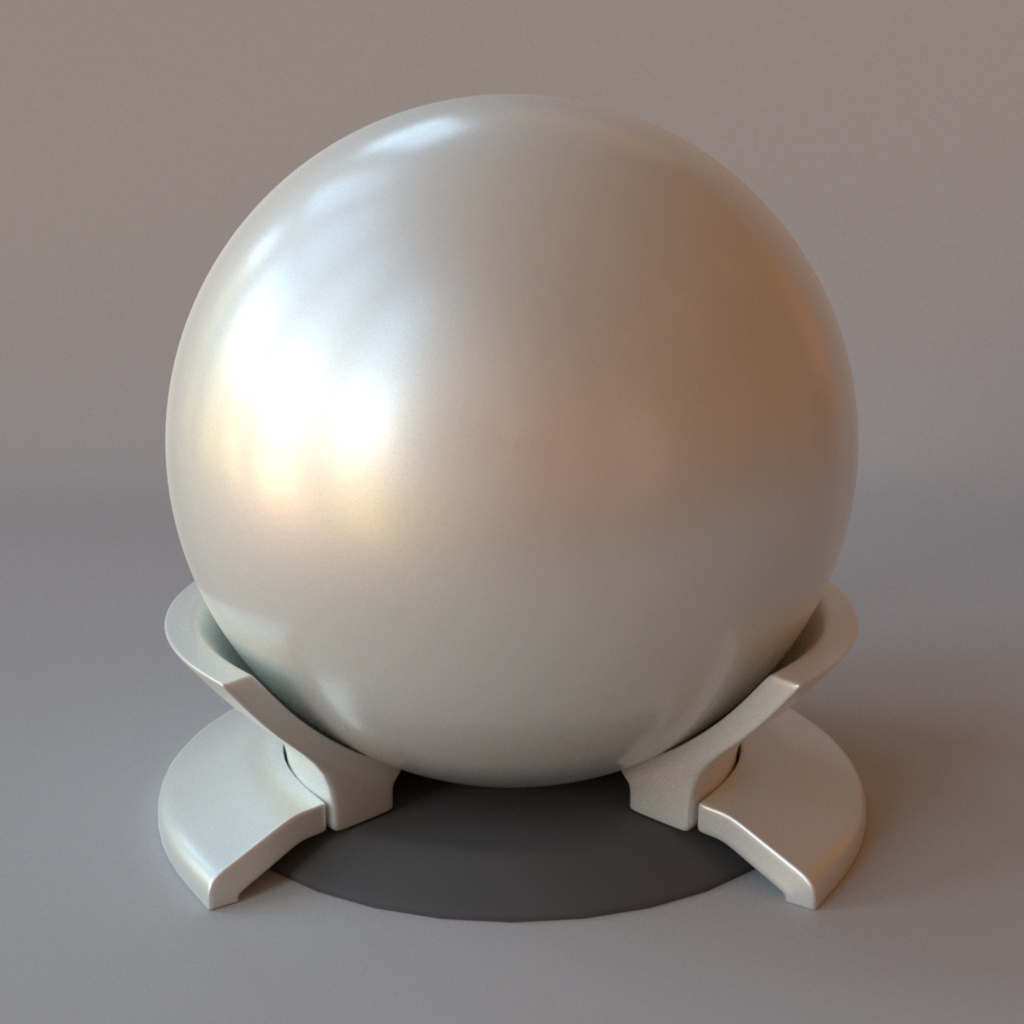

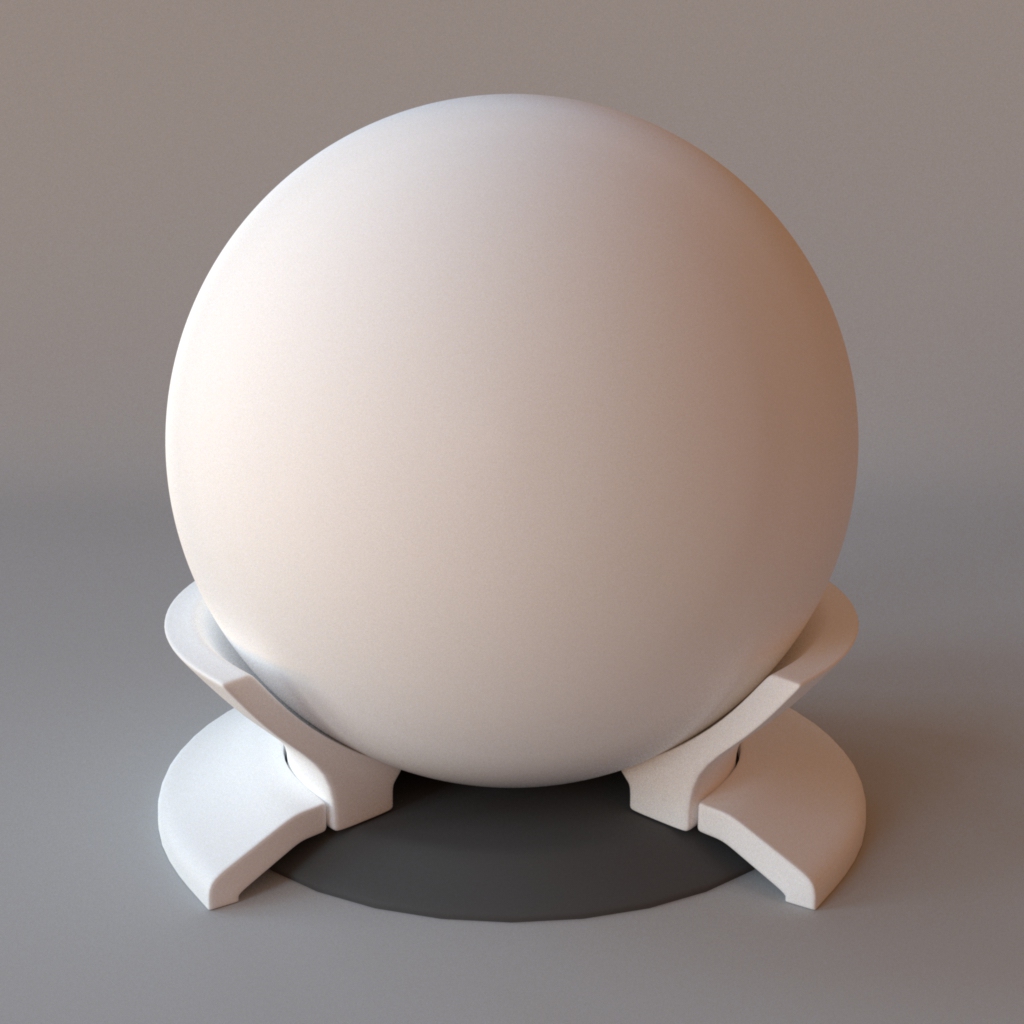

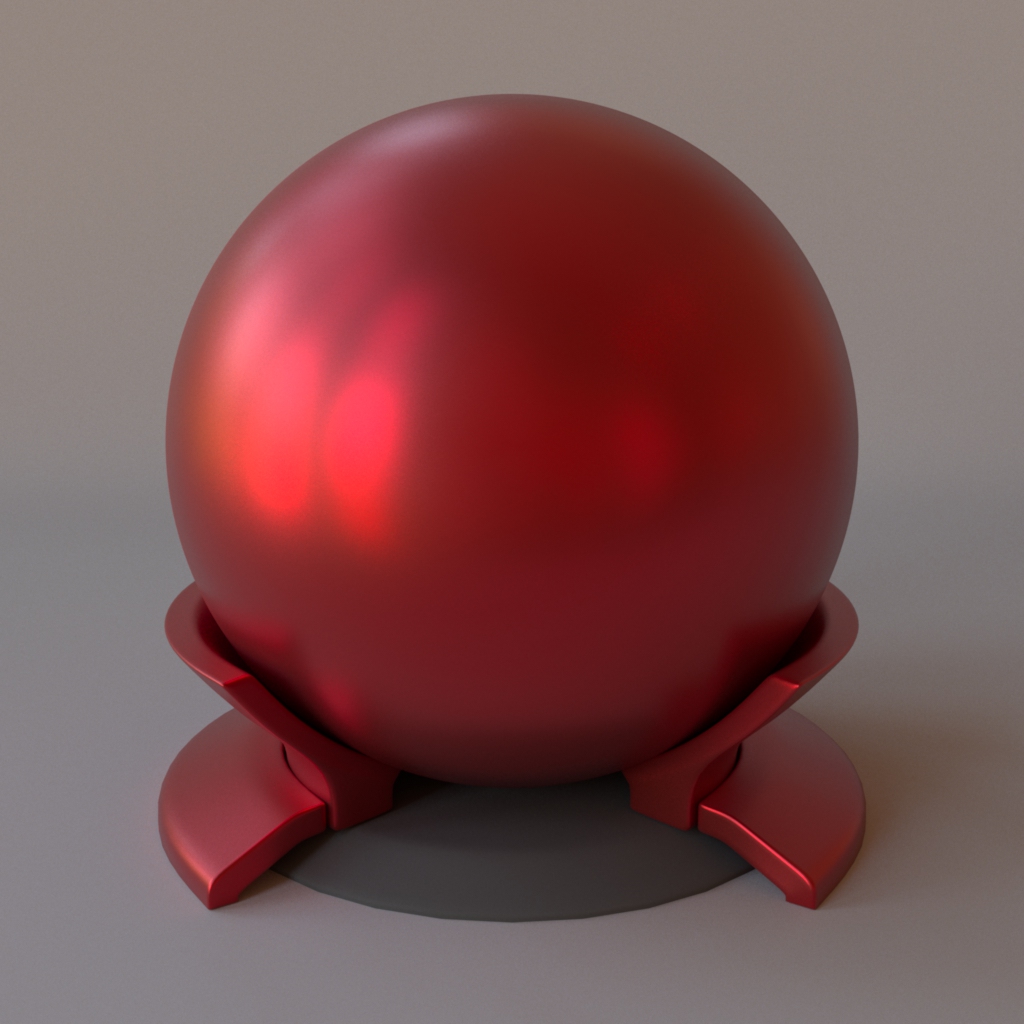

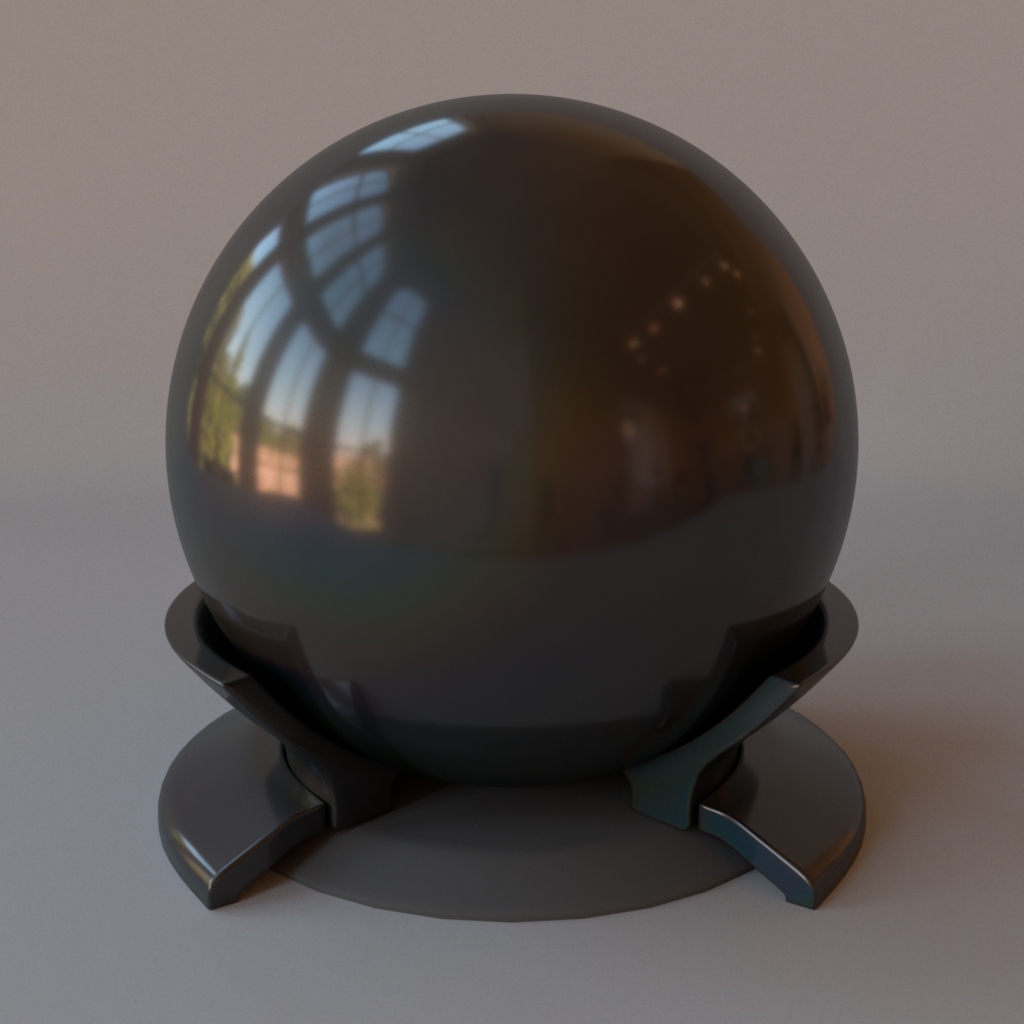

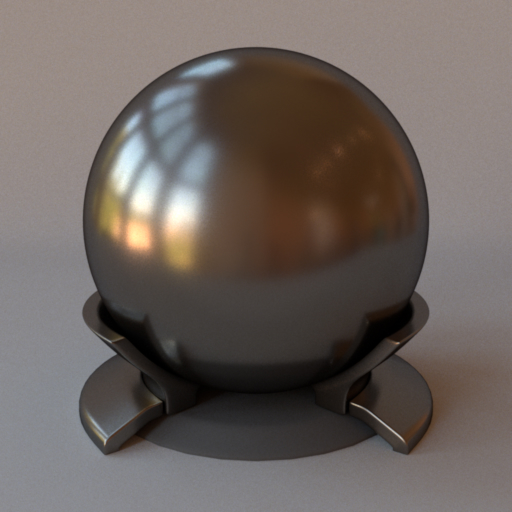

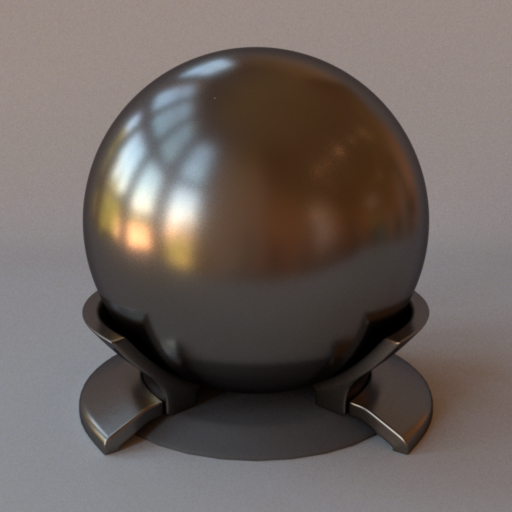

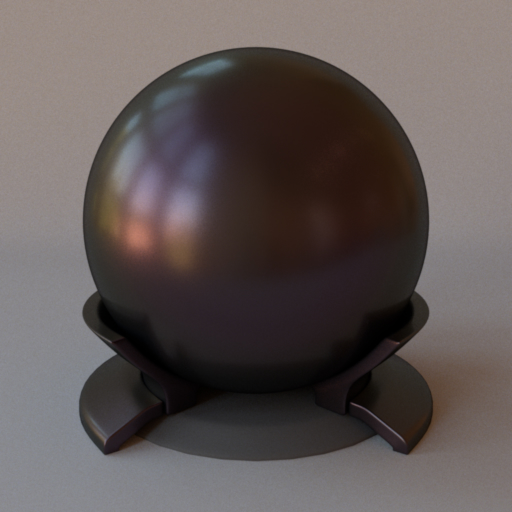

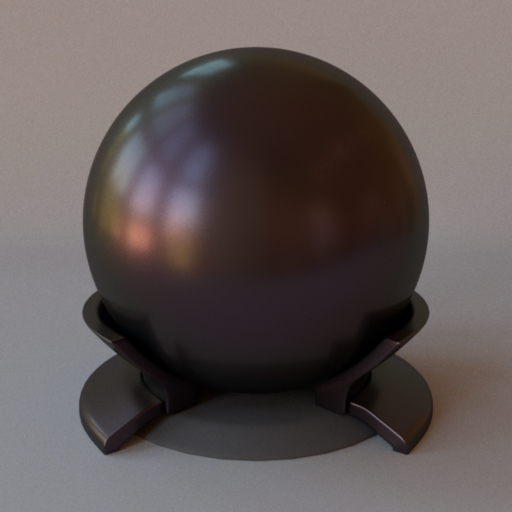

In this paper, we introduce a novel high quality BRDF measurement database.

We have acquired this data in such a way that it can be used it

straightforwardly and efficiently for photorealistic rendering.

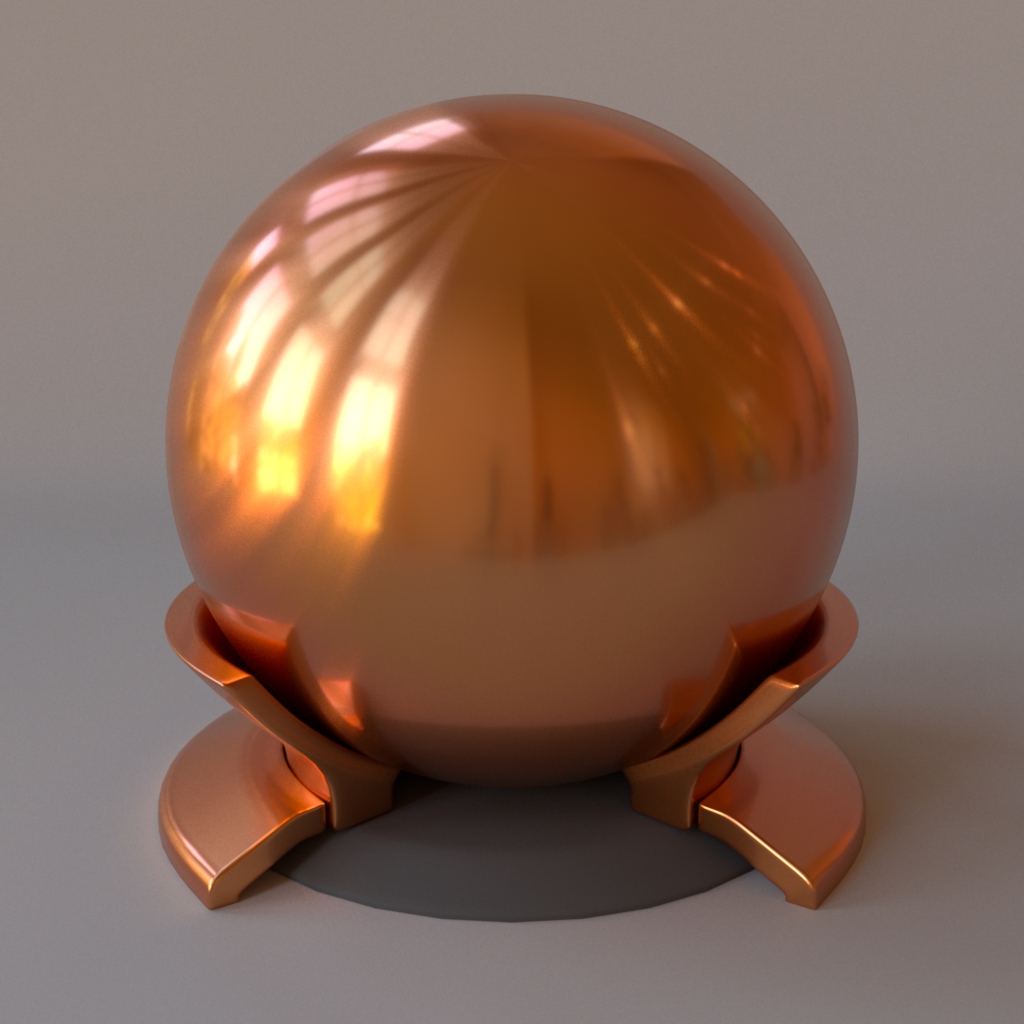

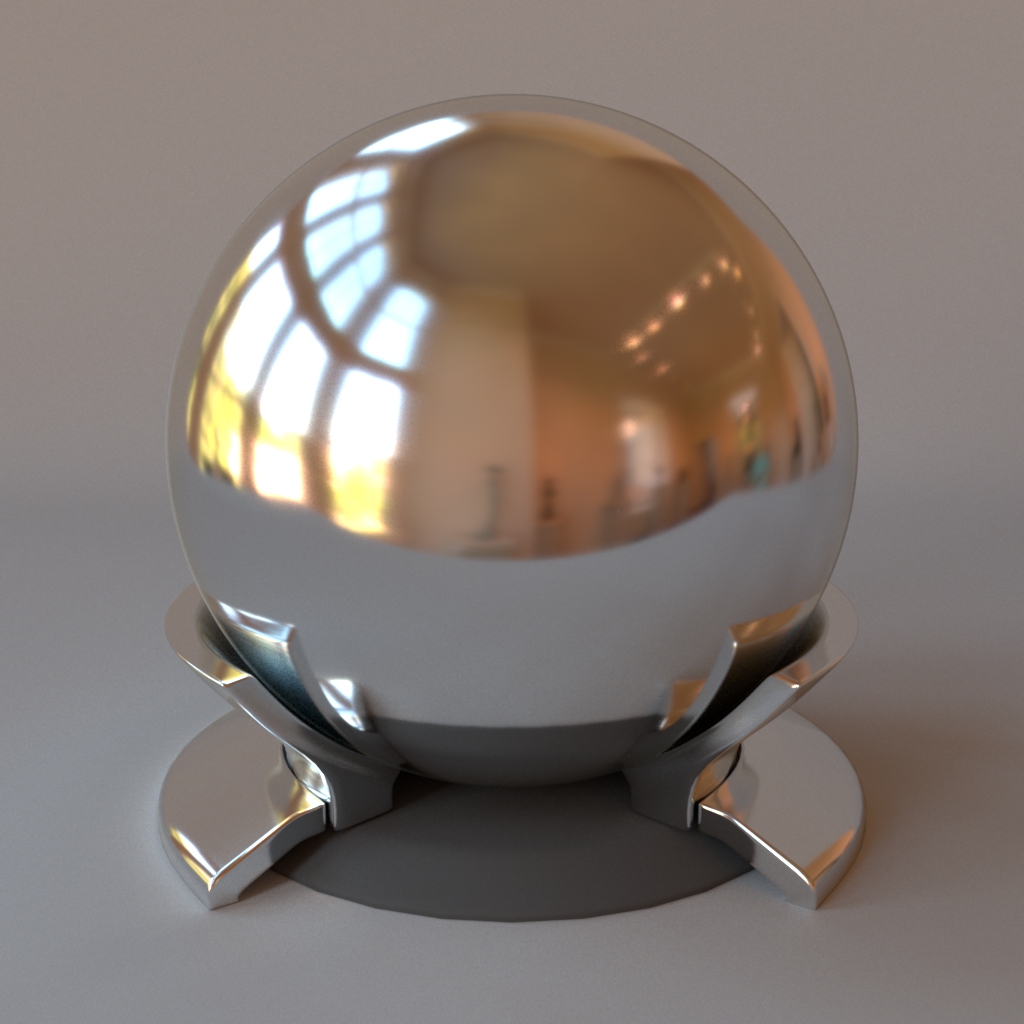

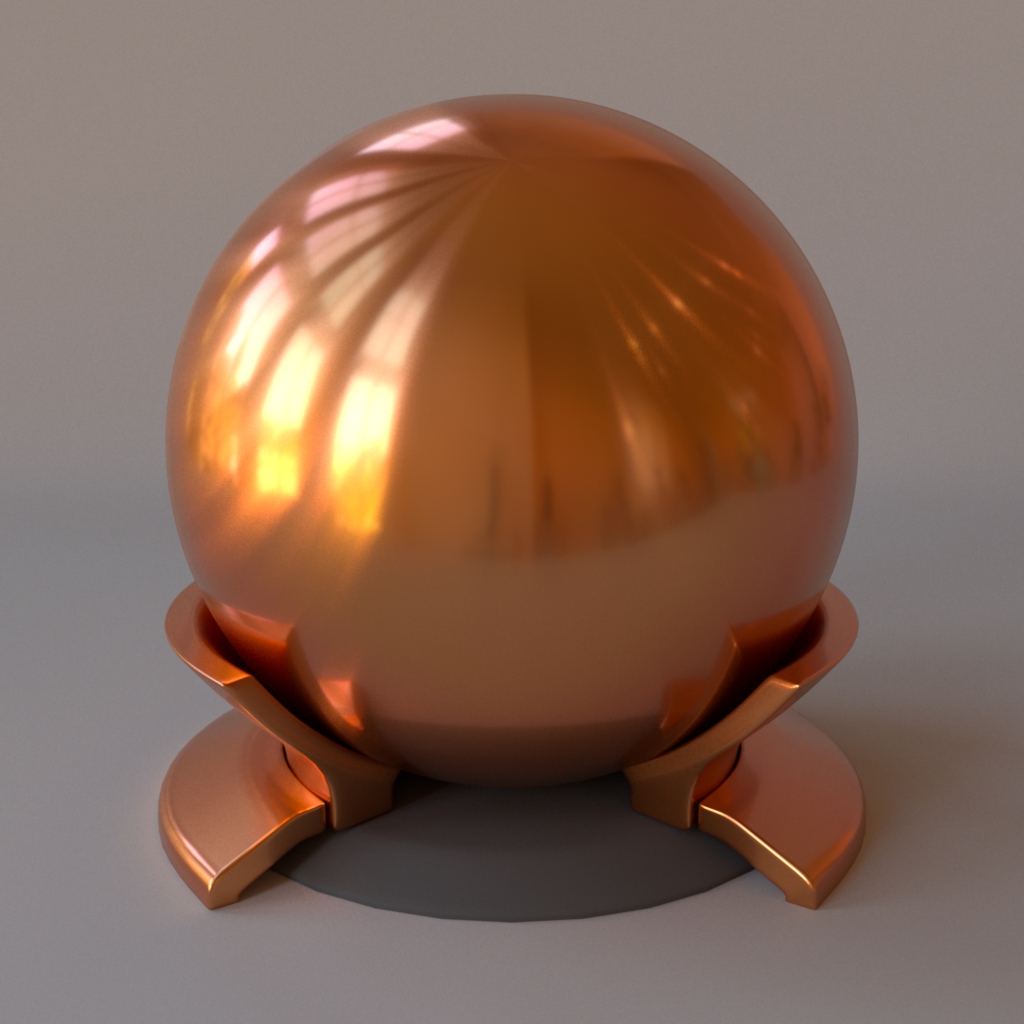

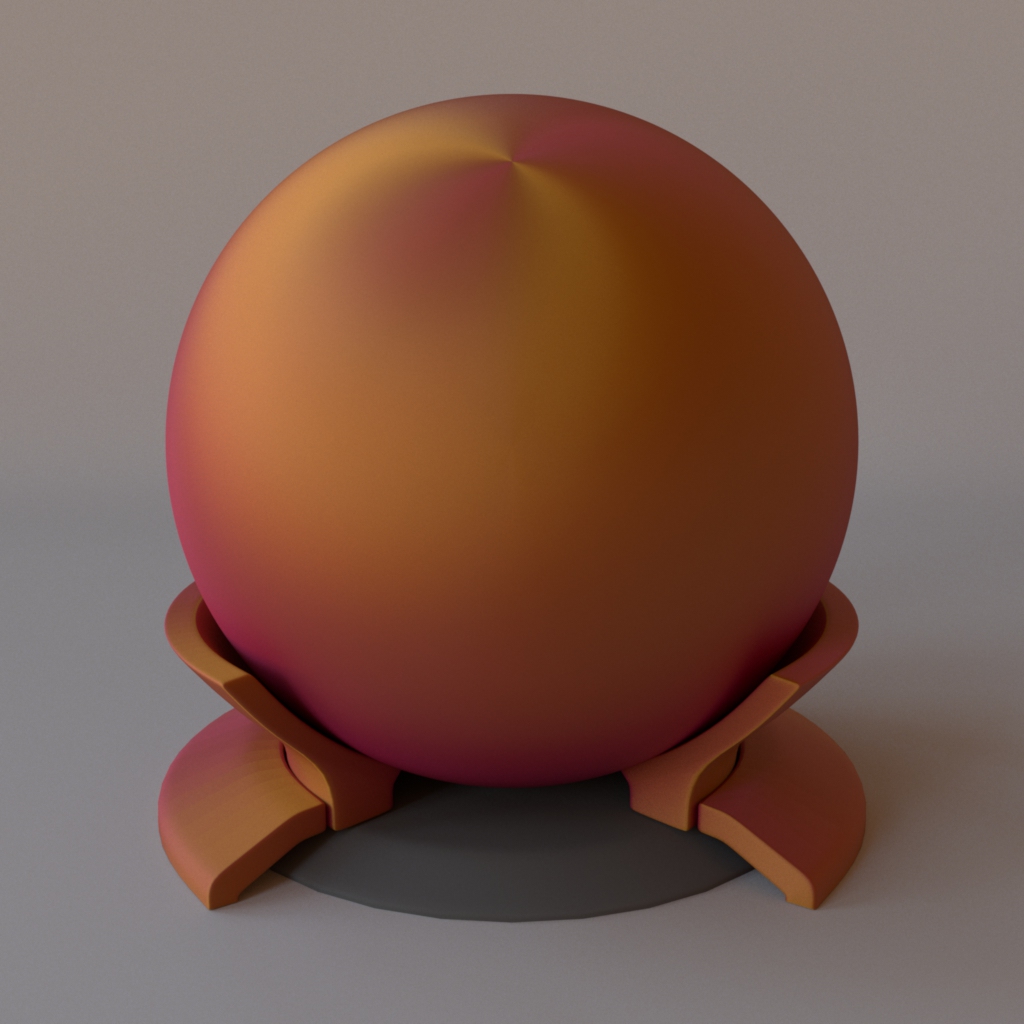

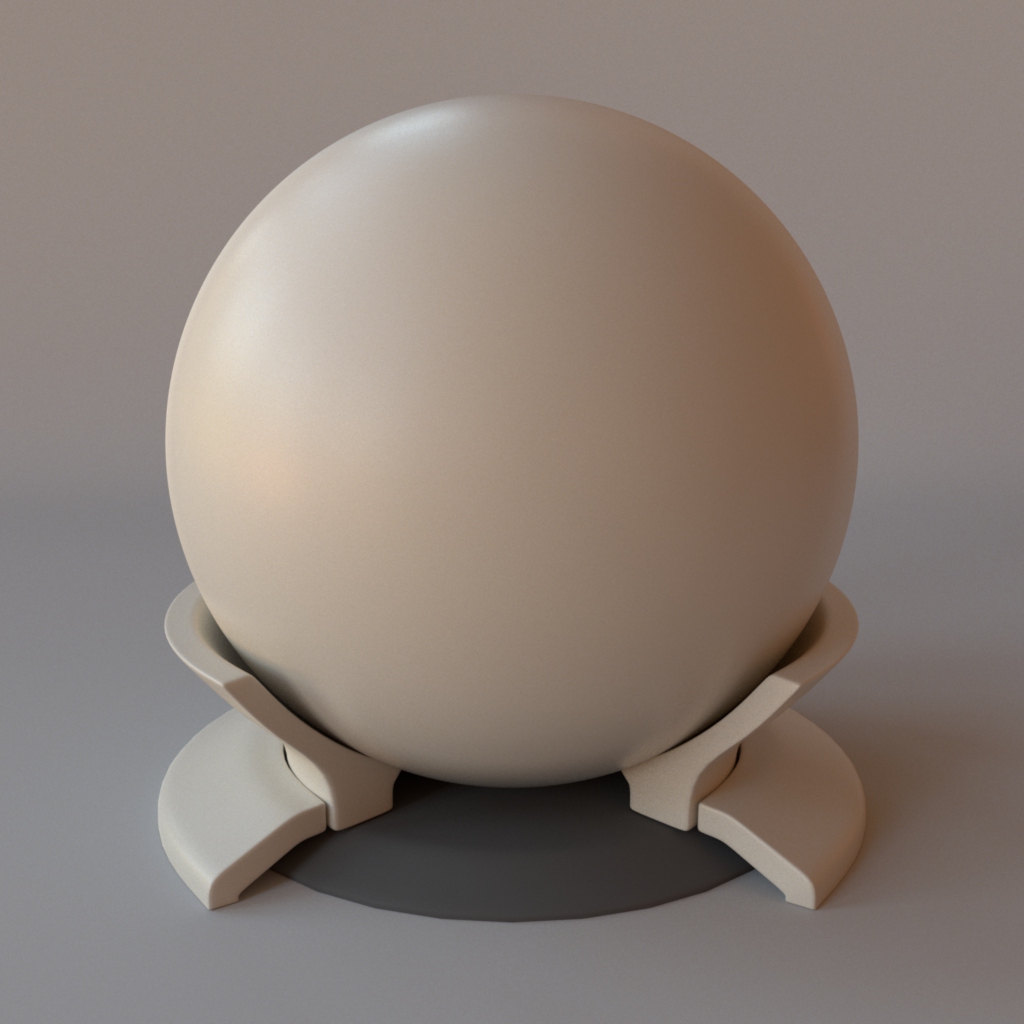

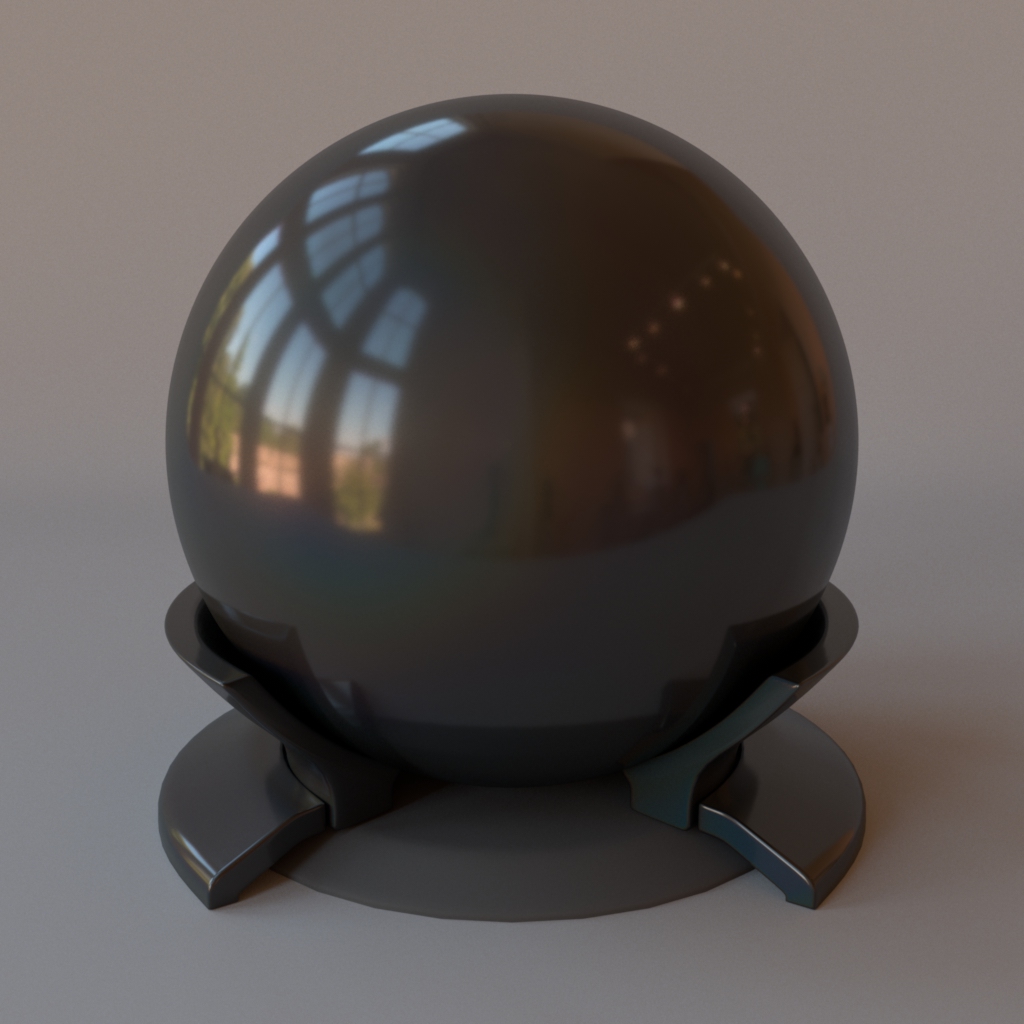

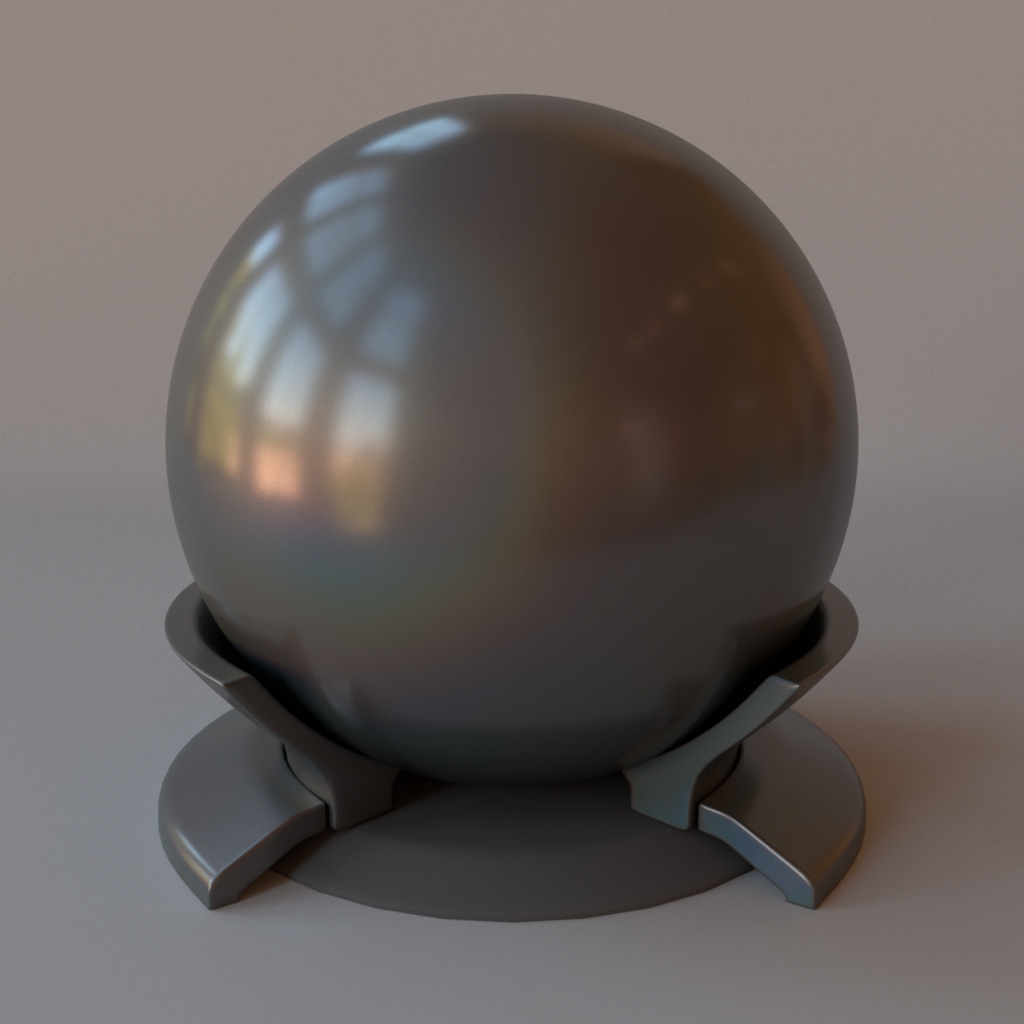

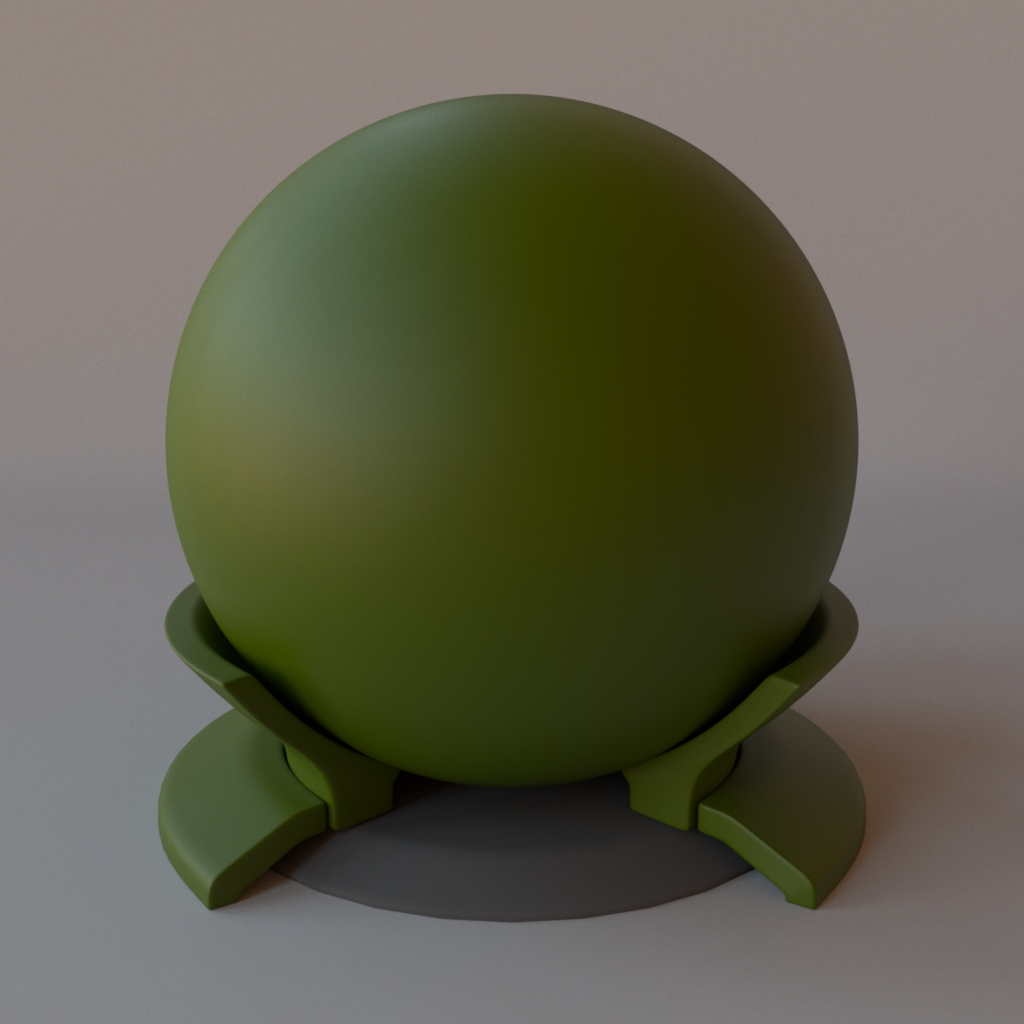

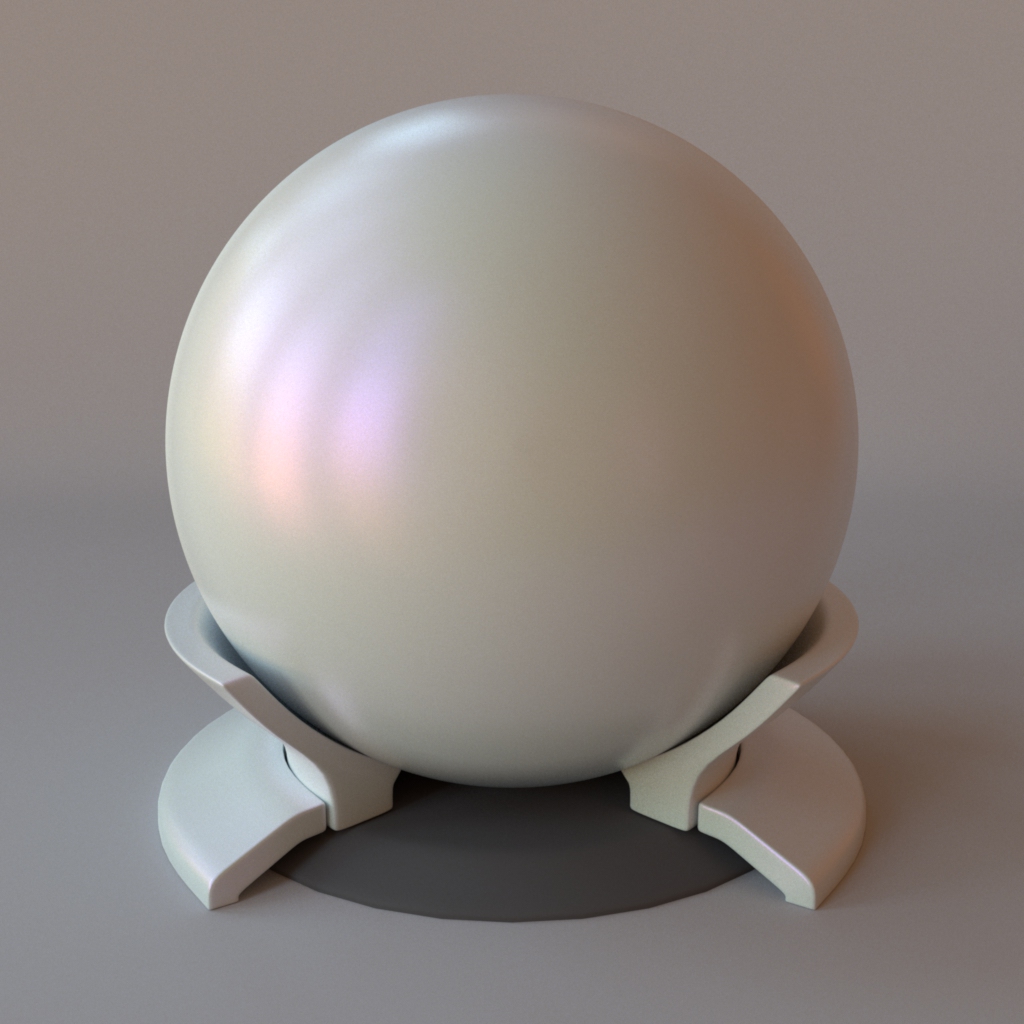

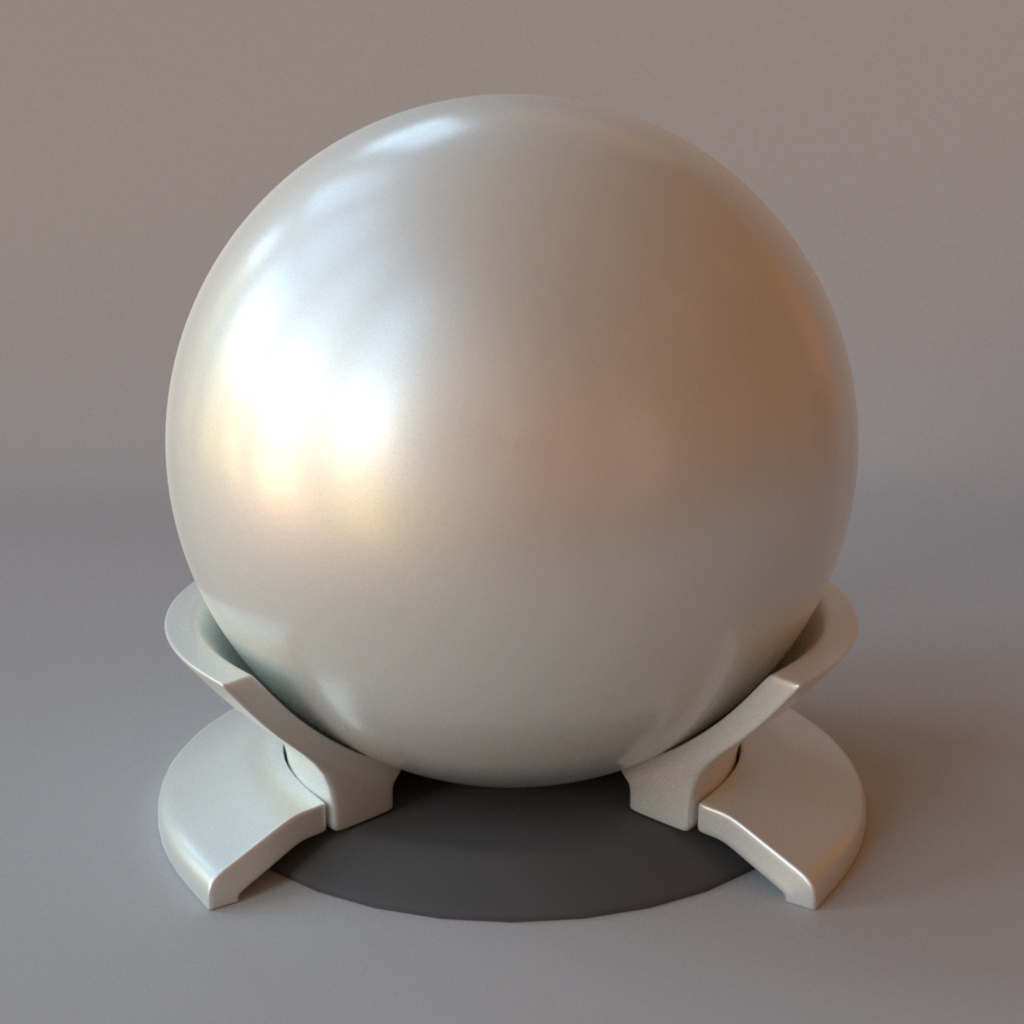

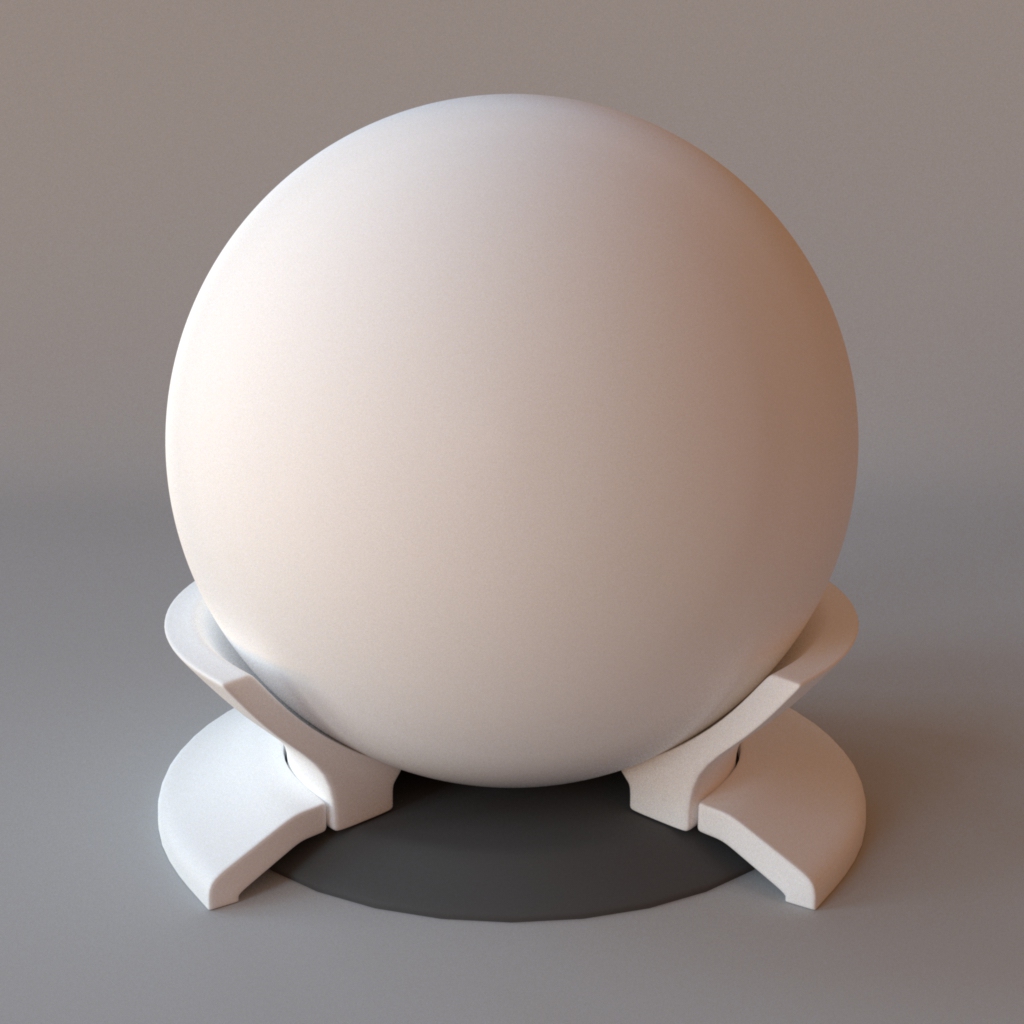

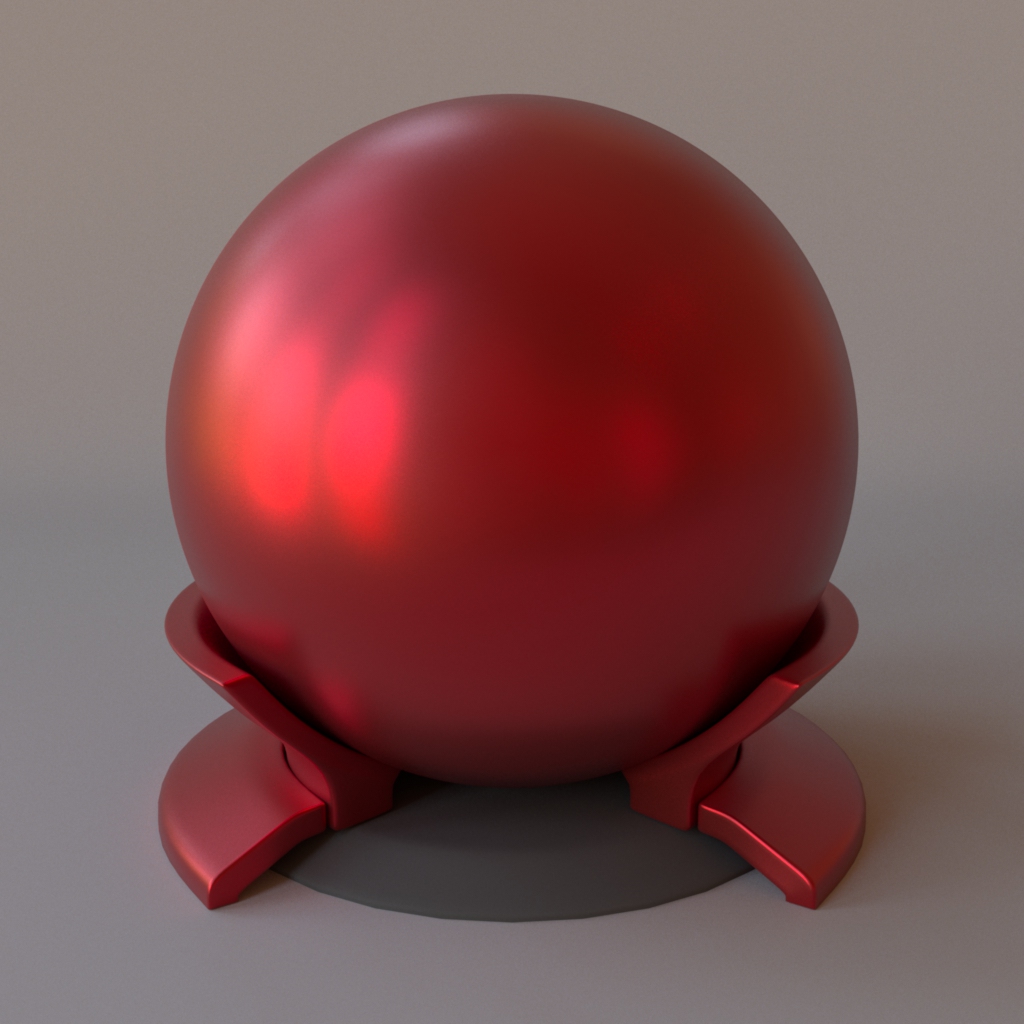

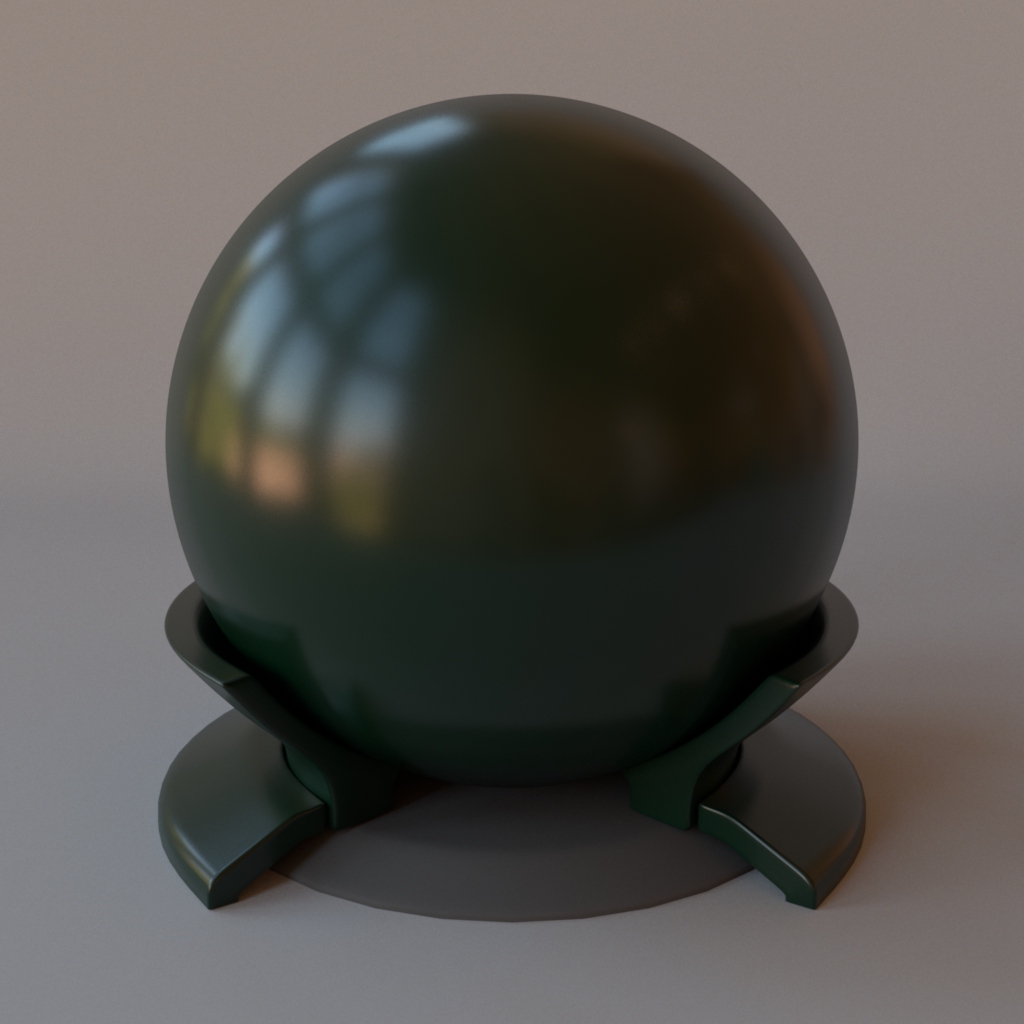

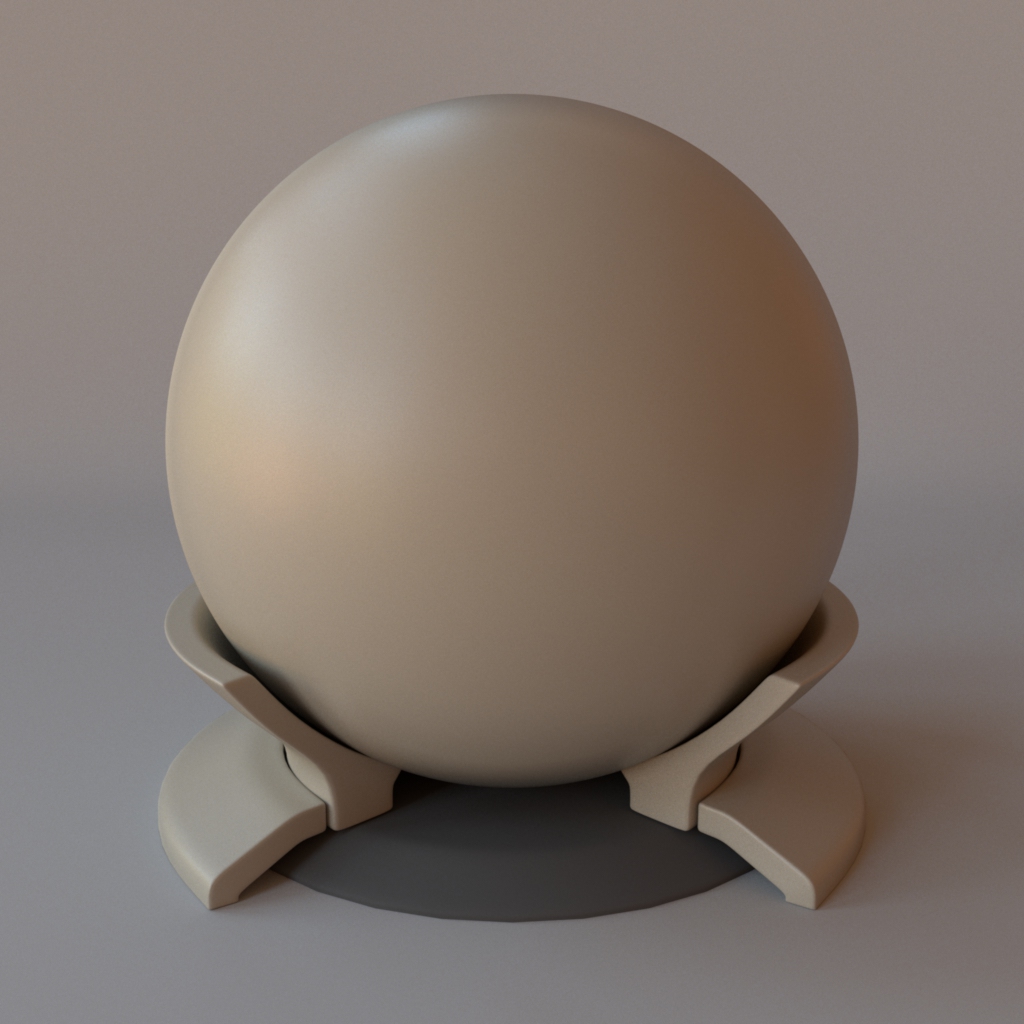

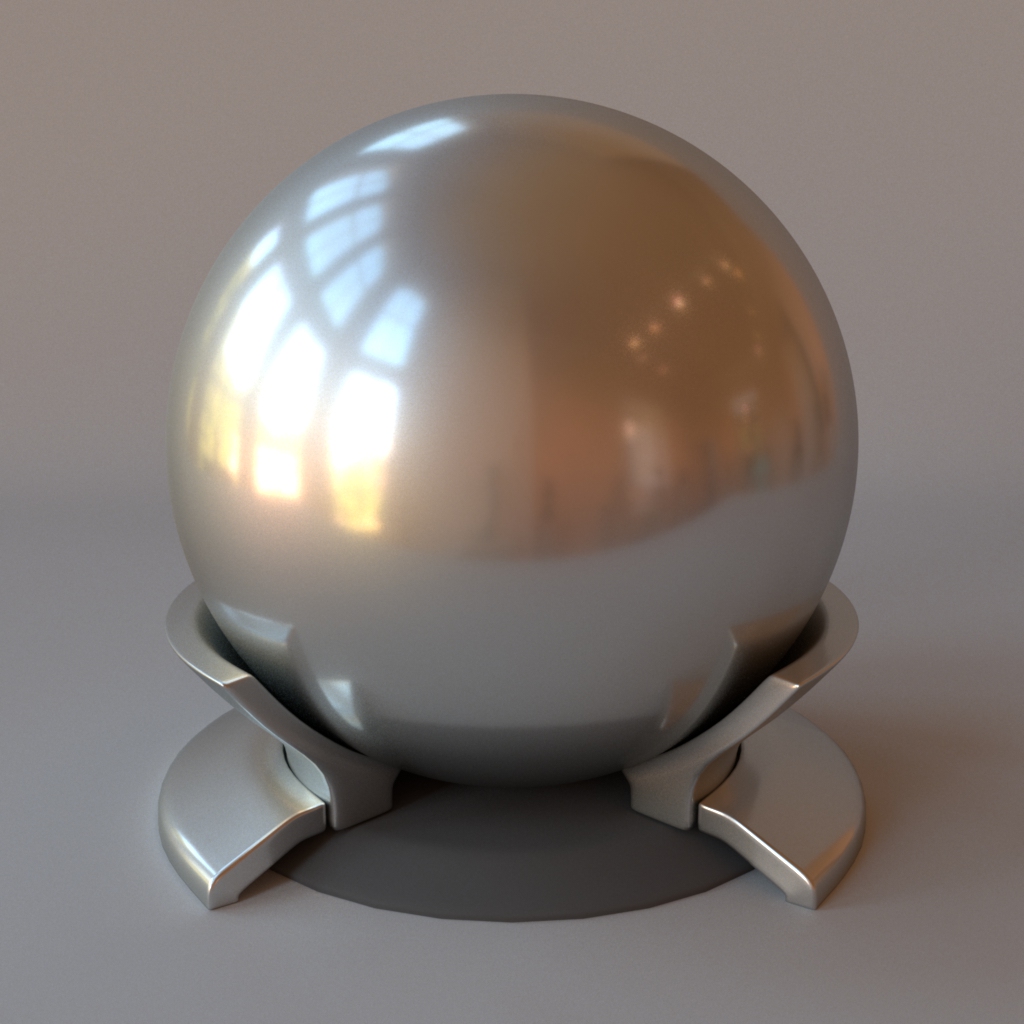

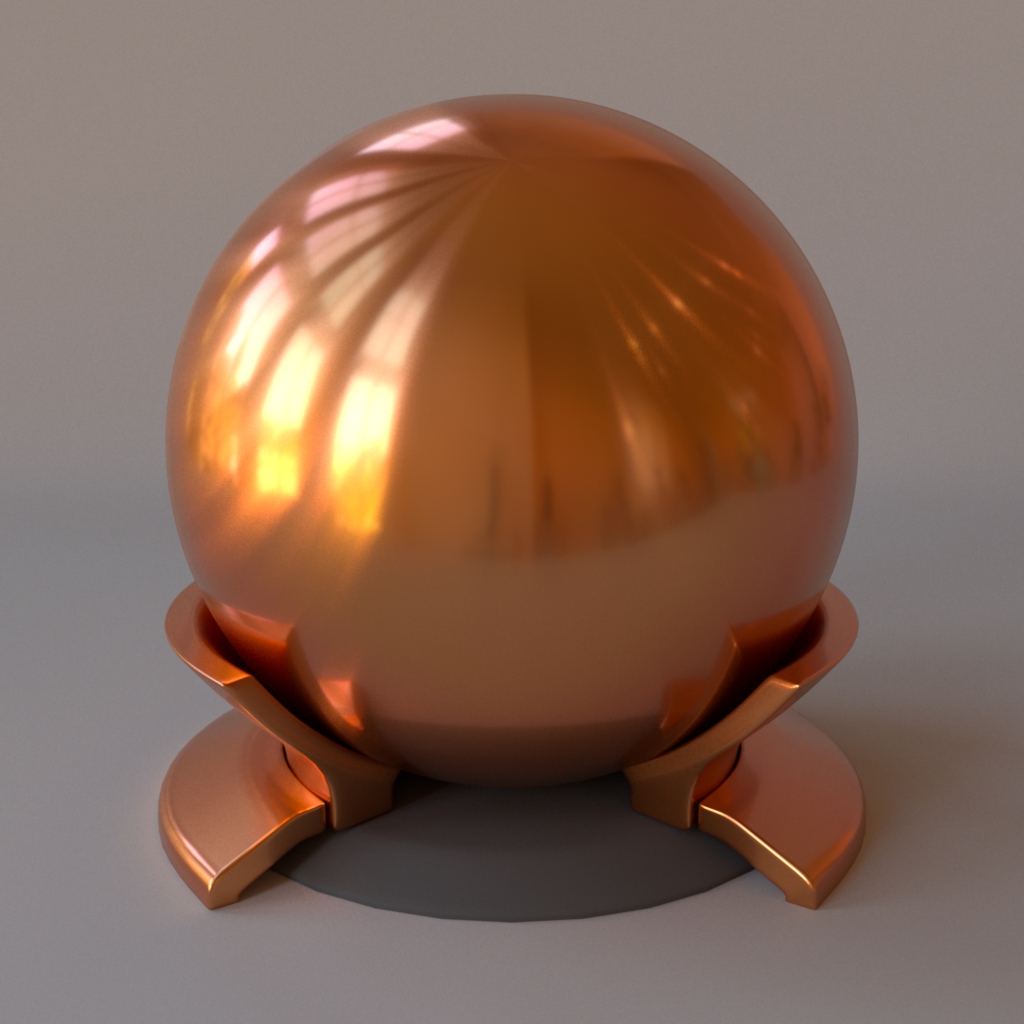

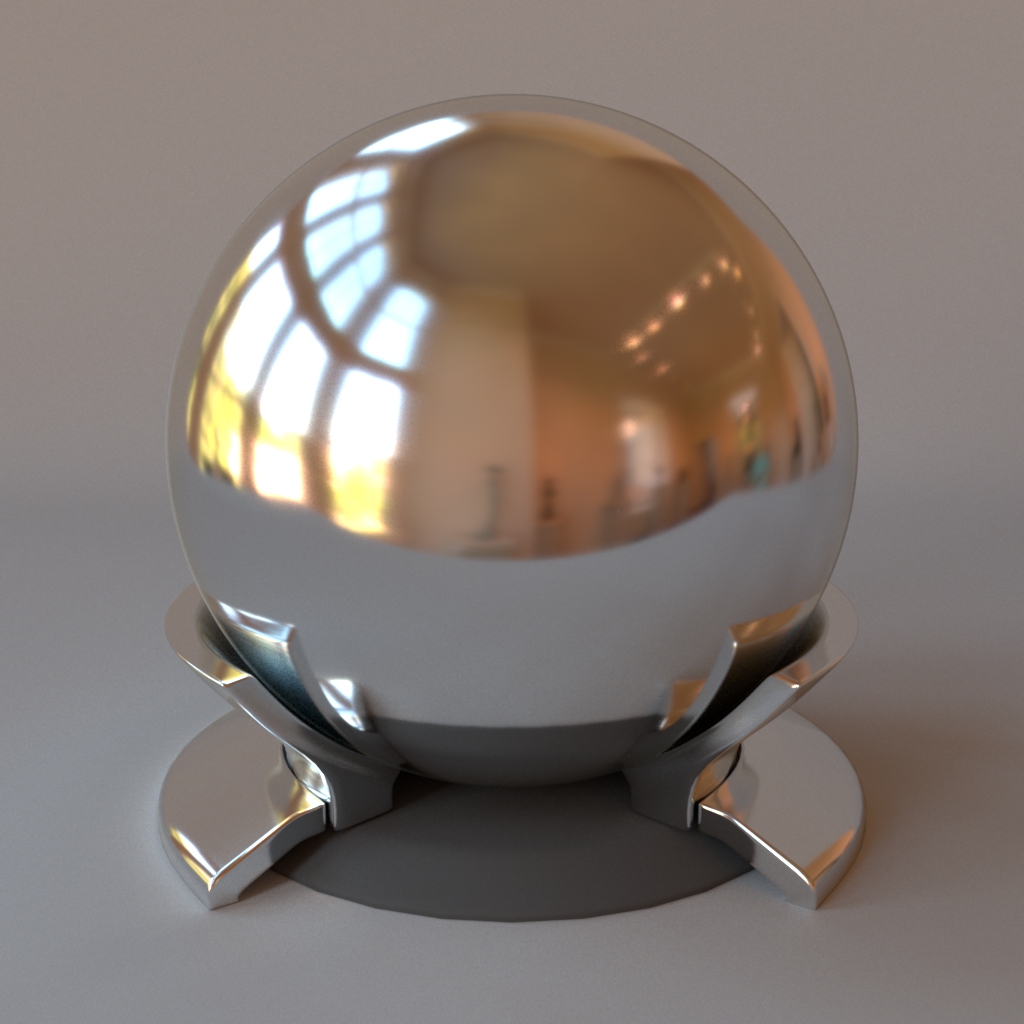

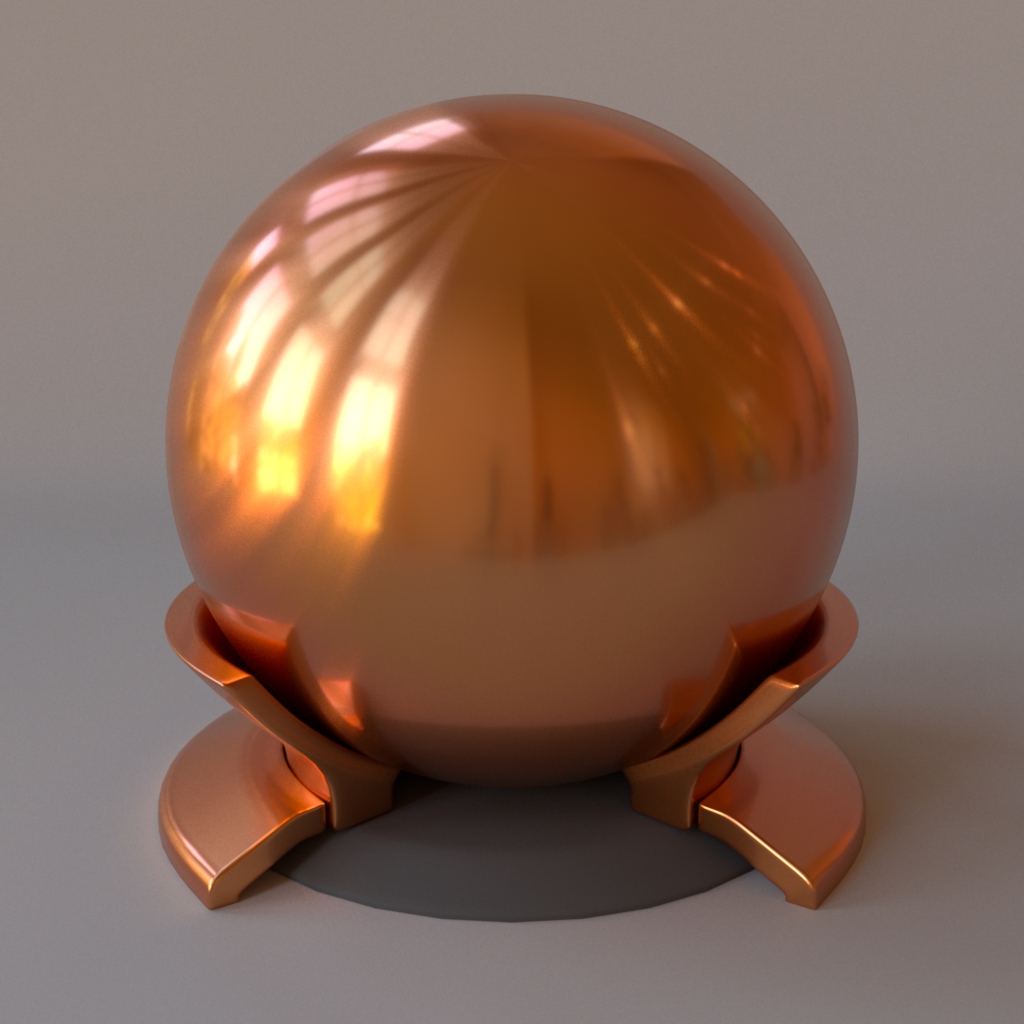

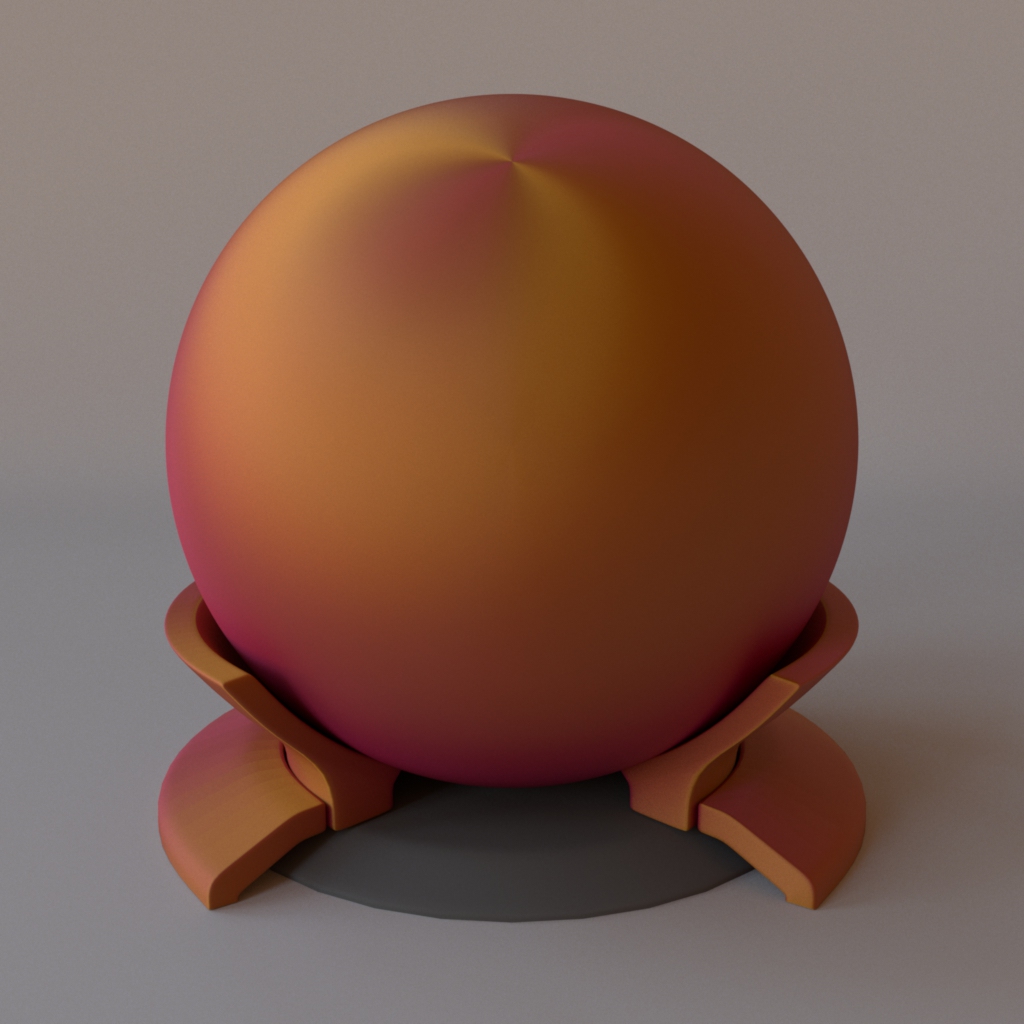

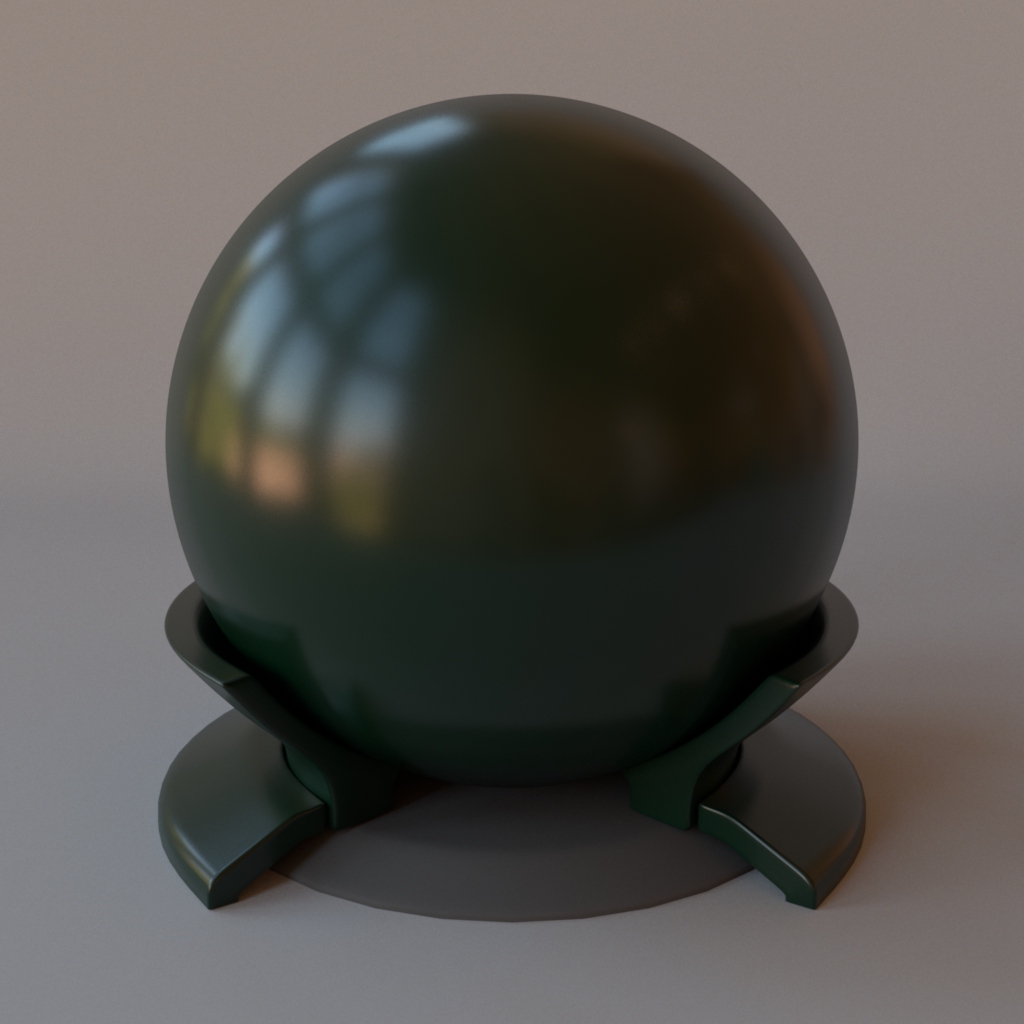

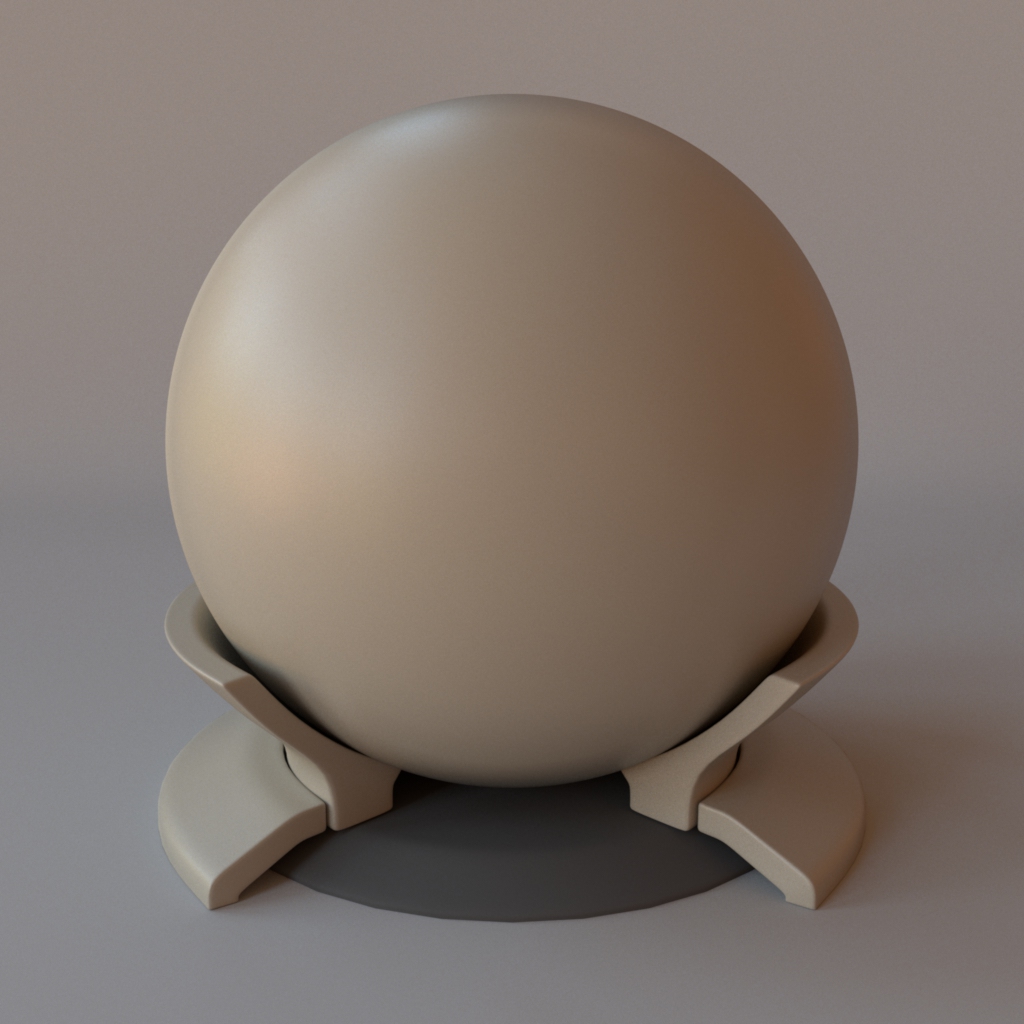

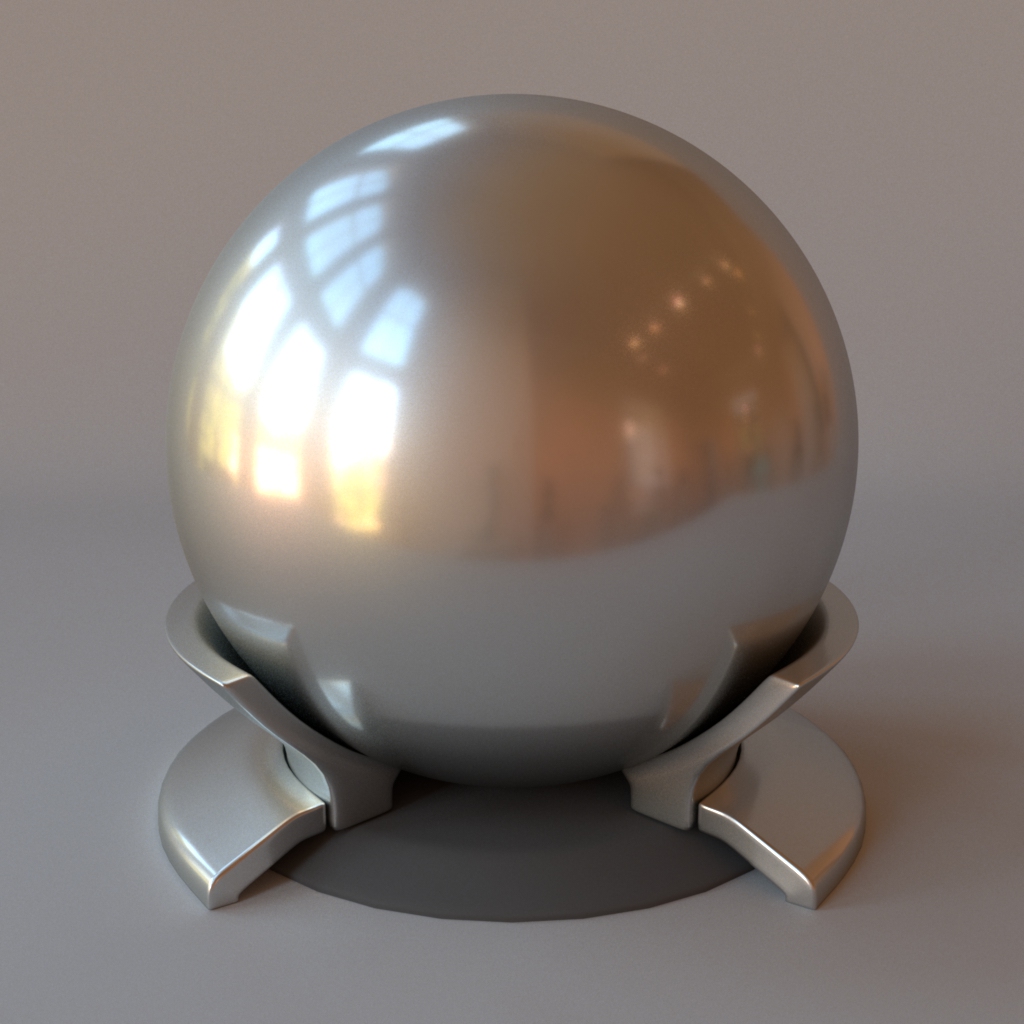

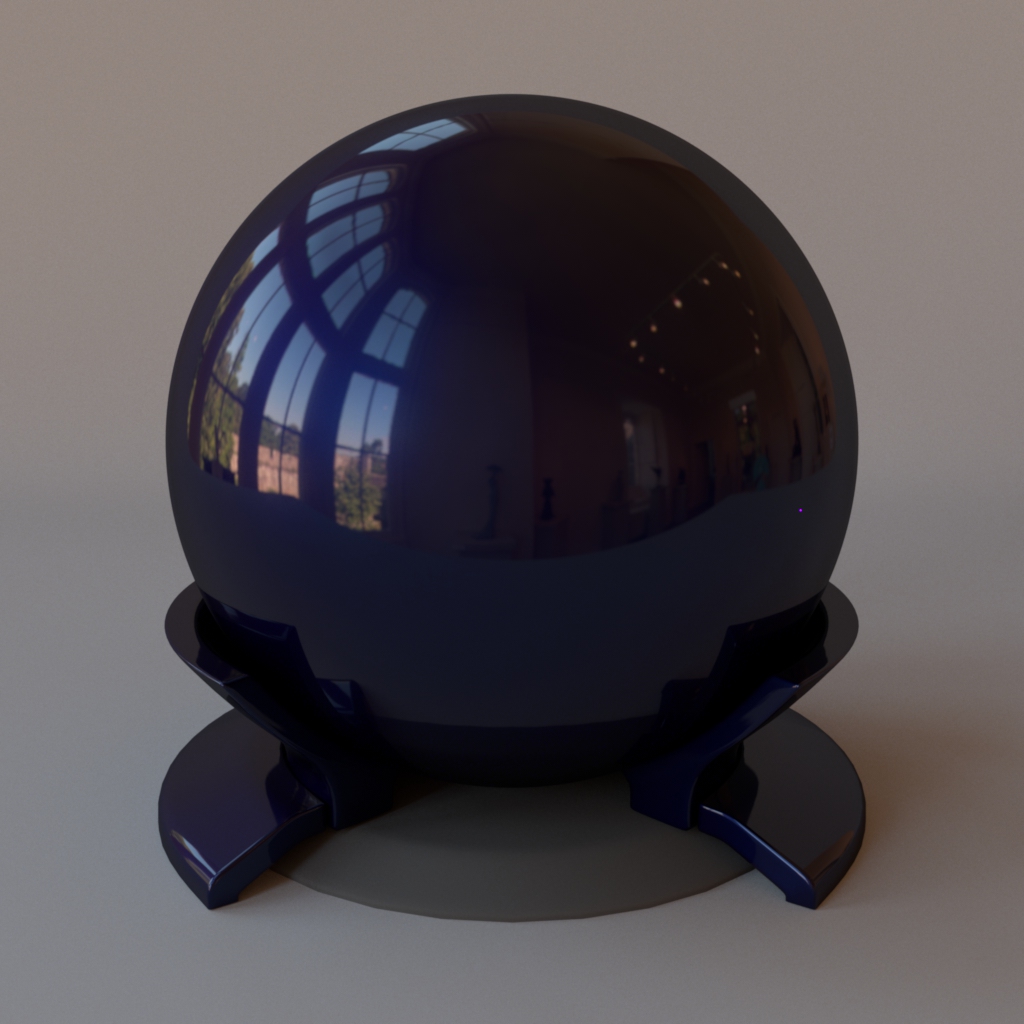

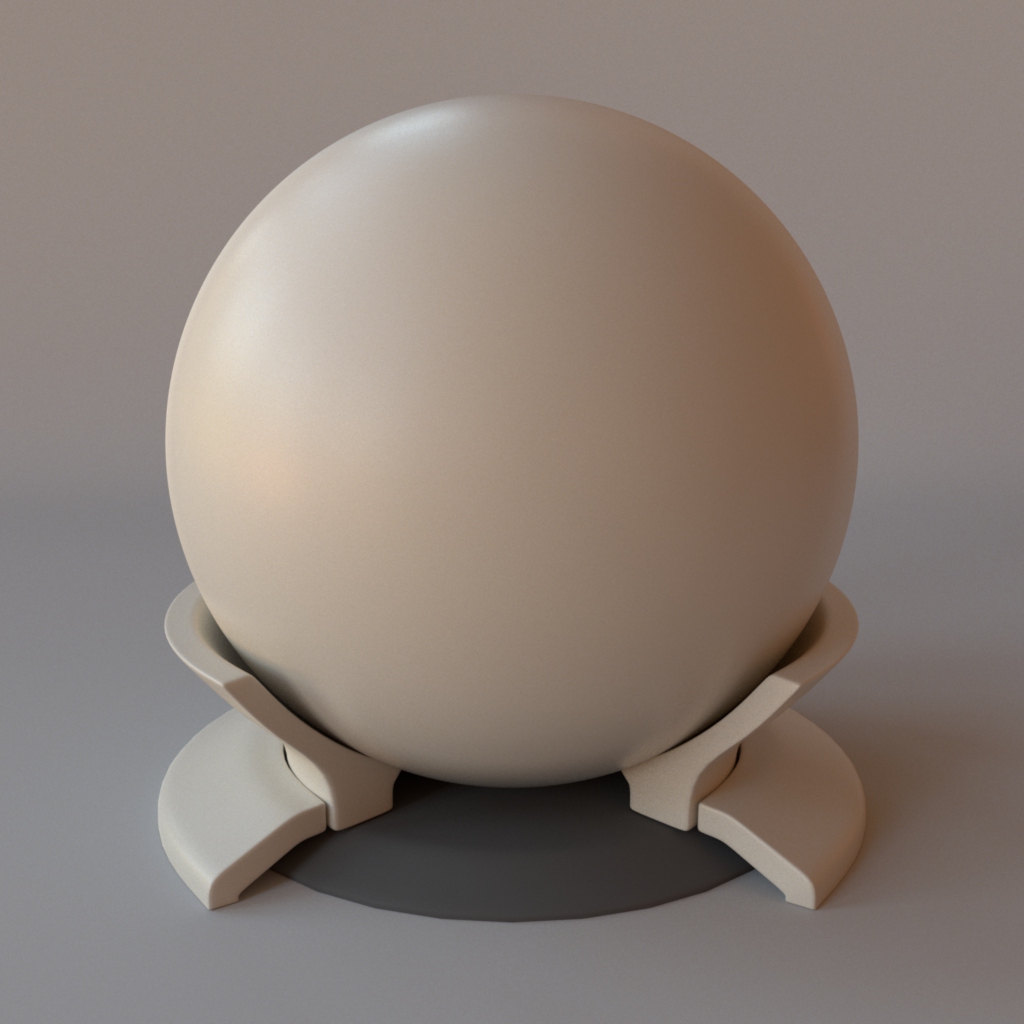

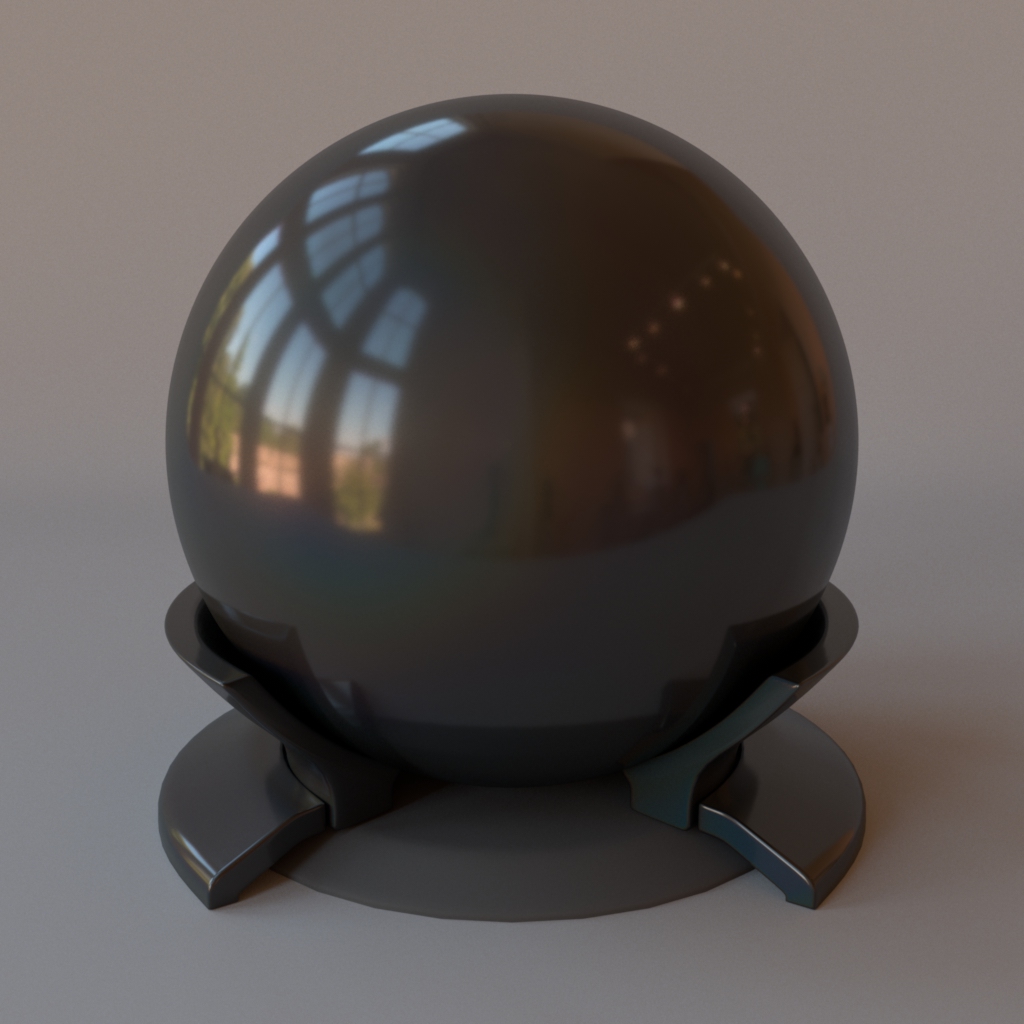

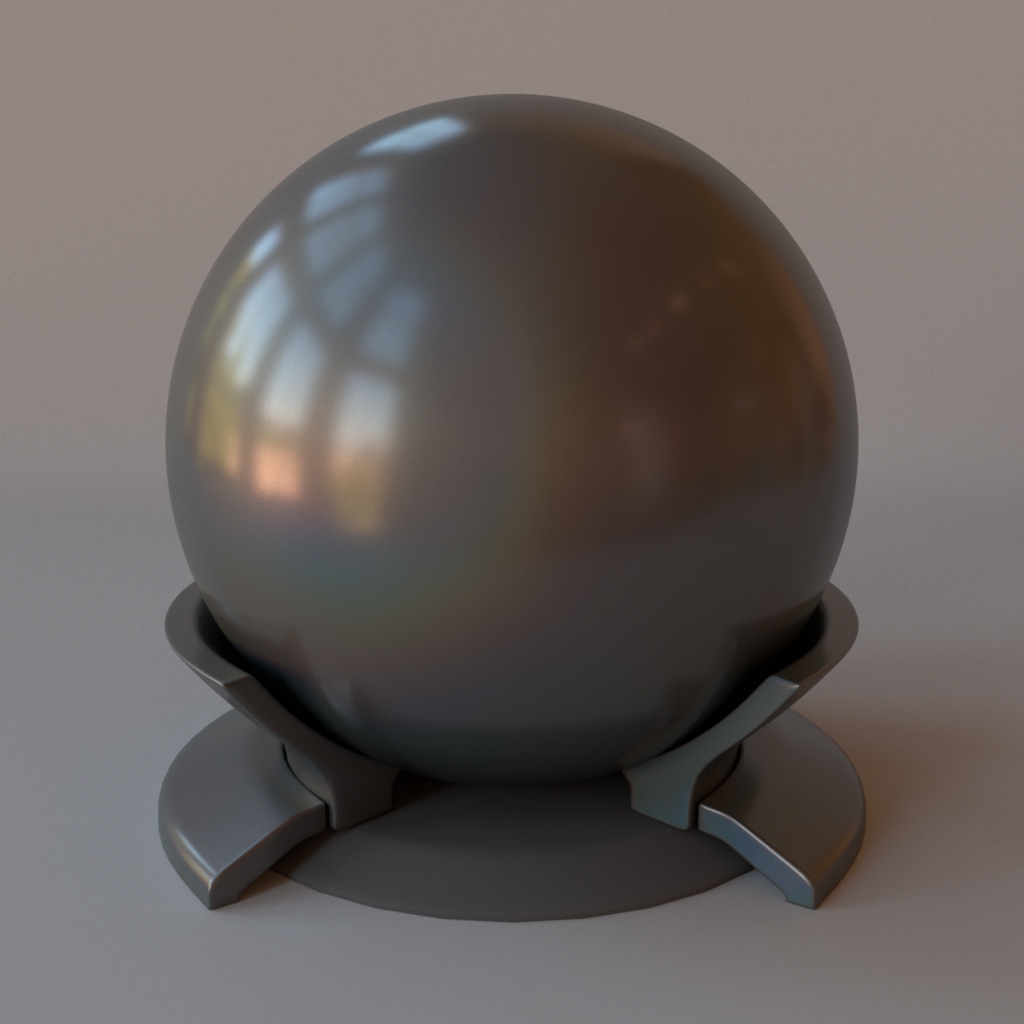

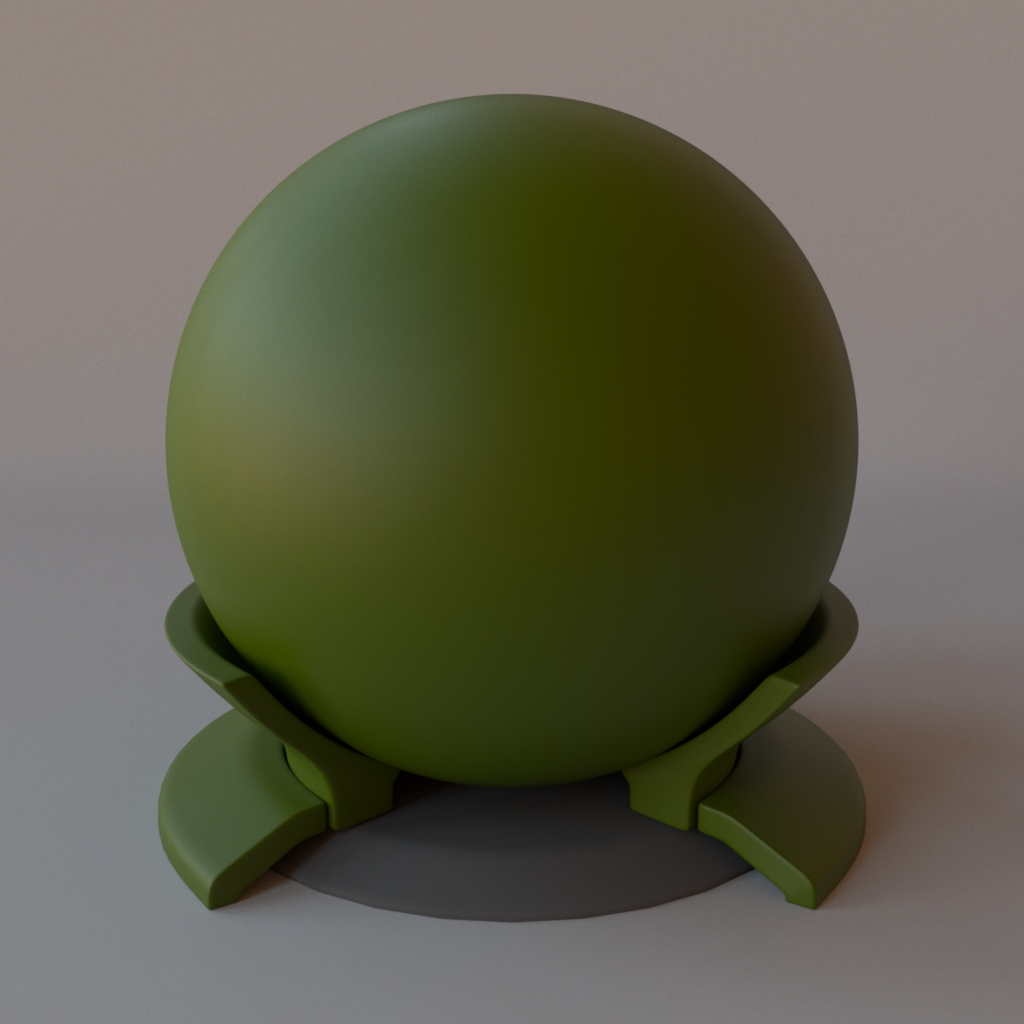

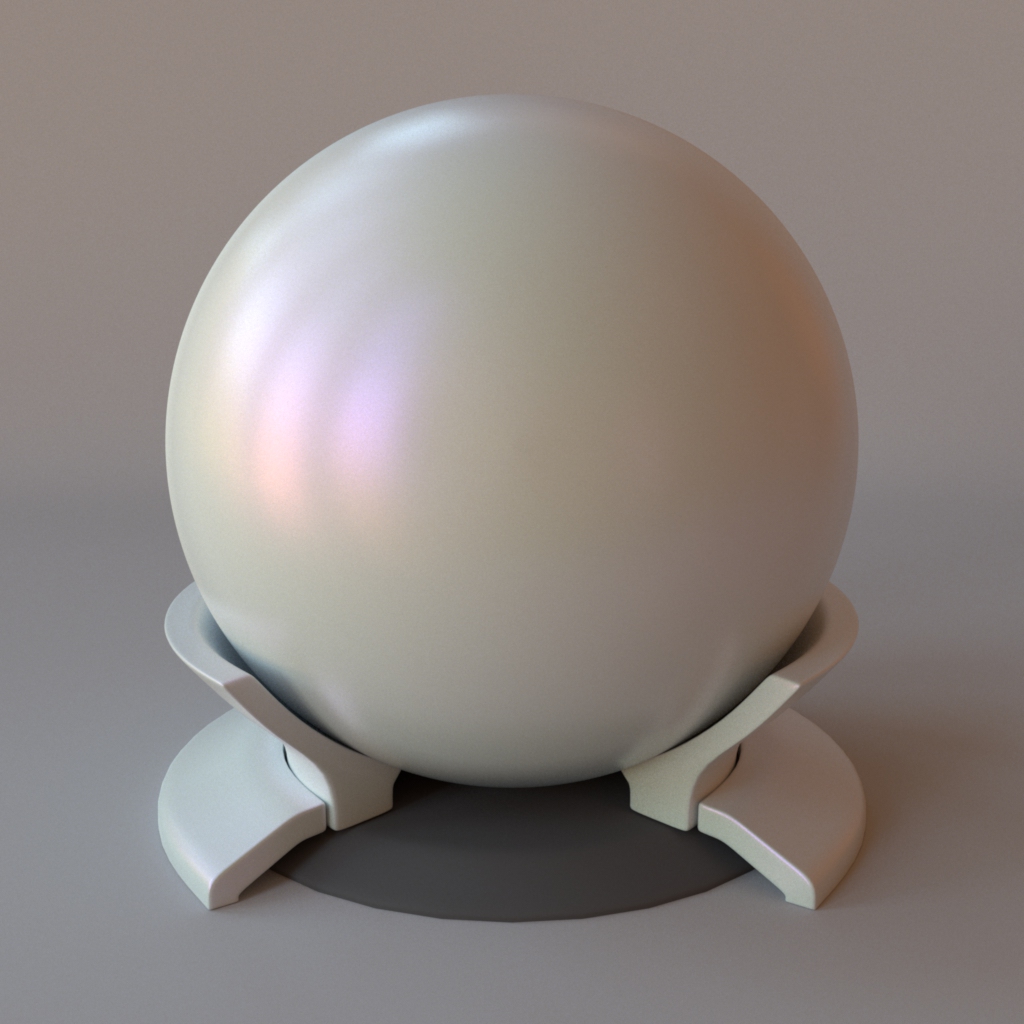

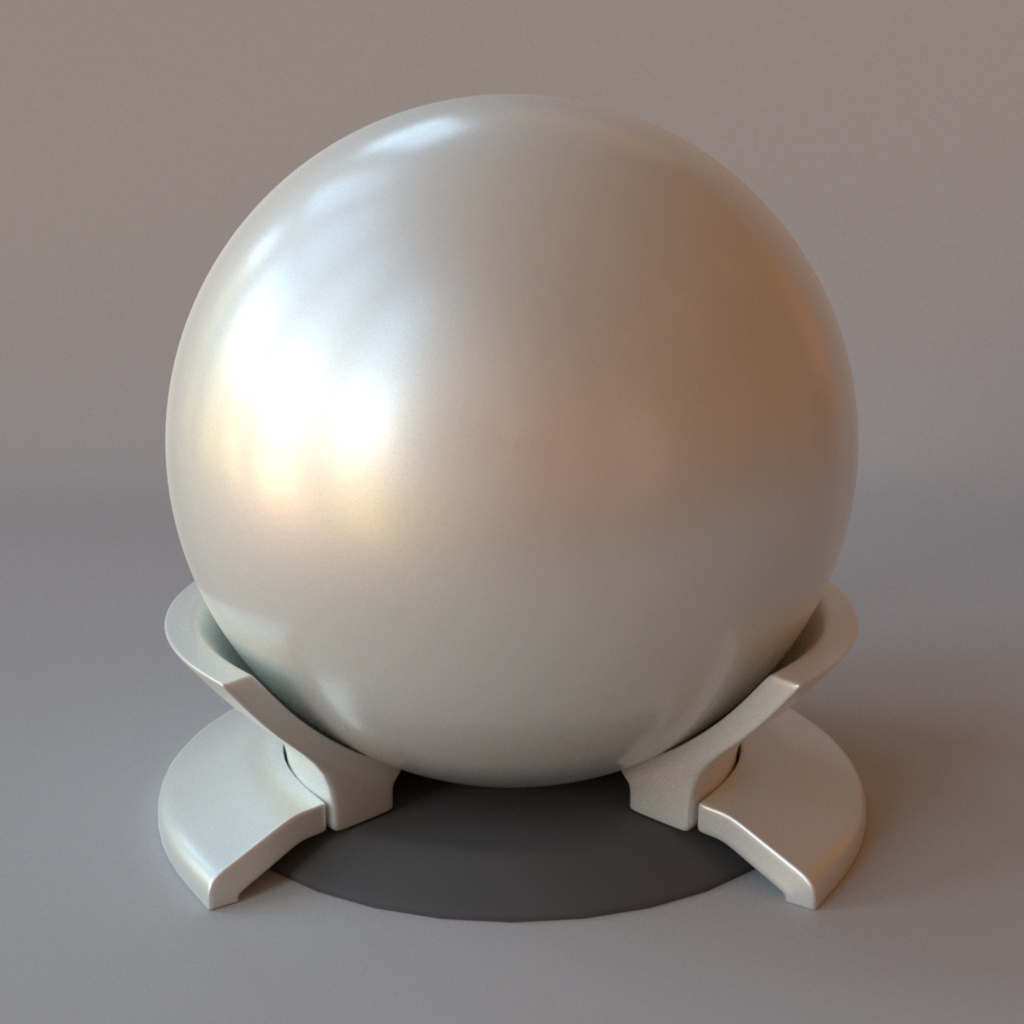

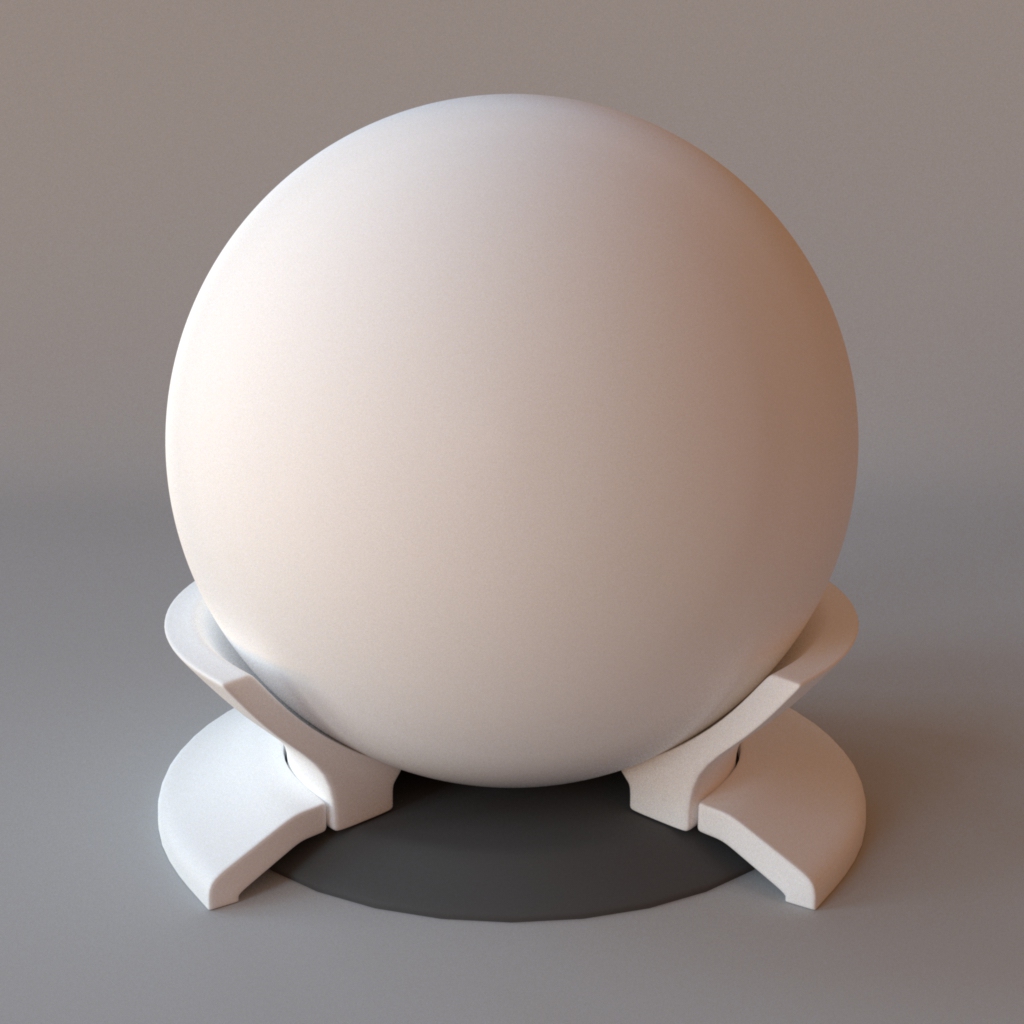

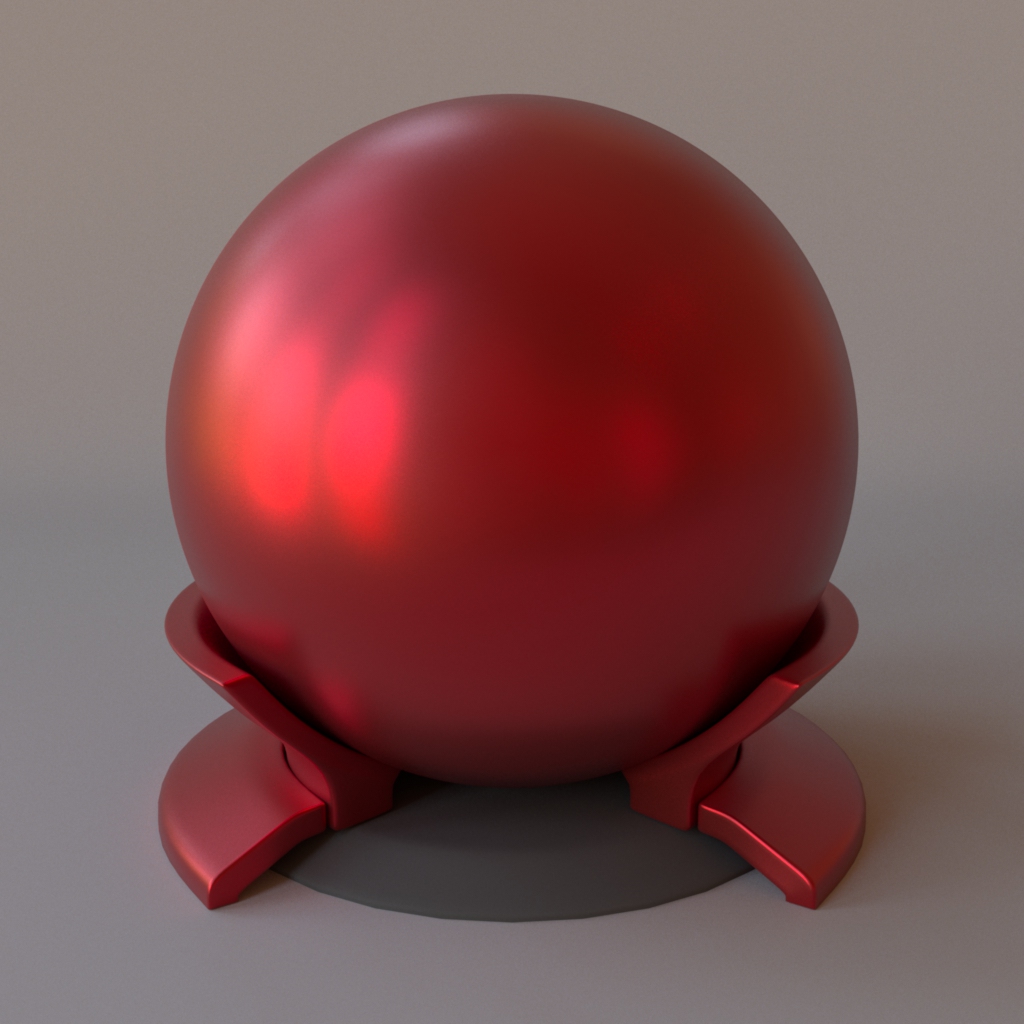

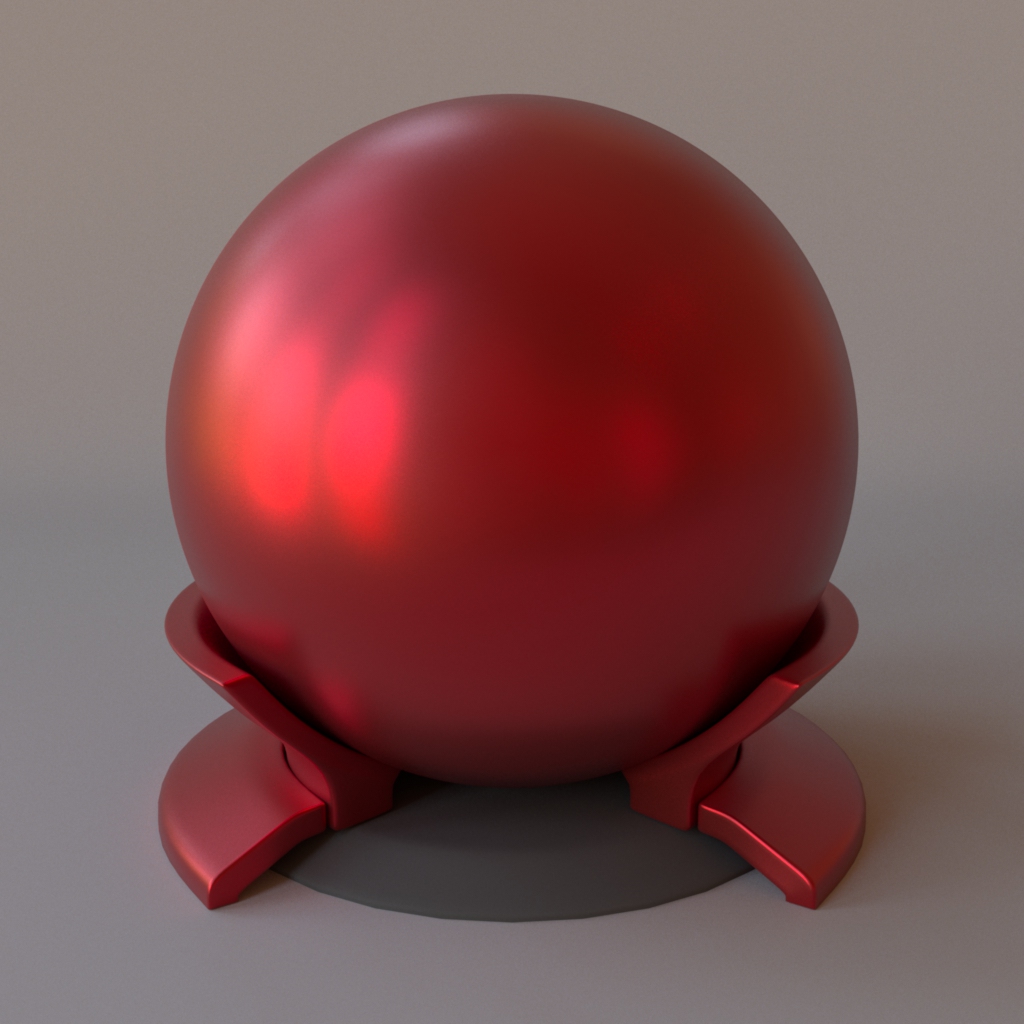

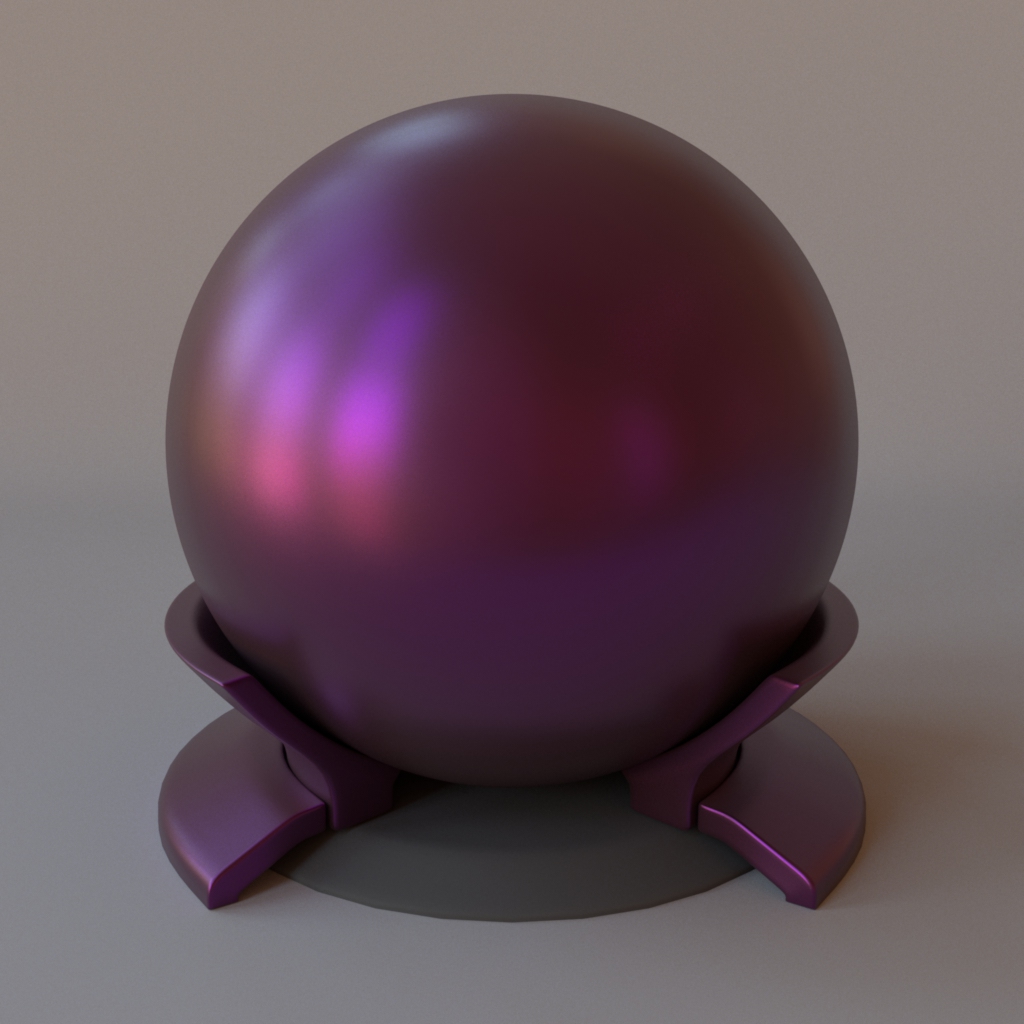

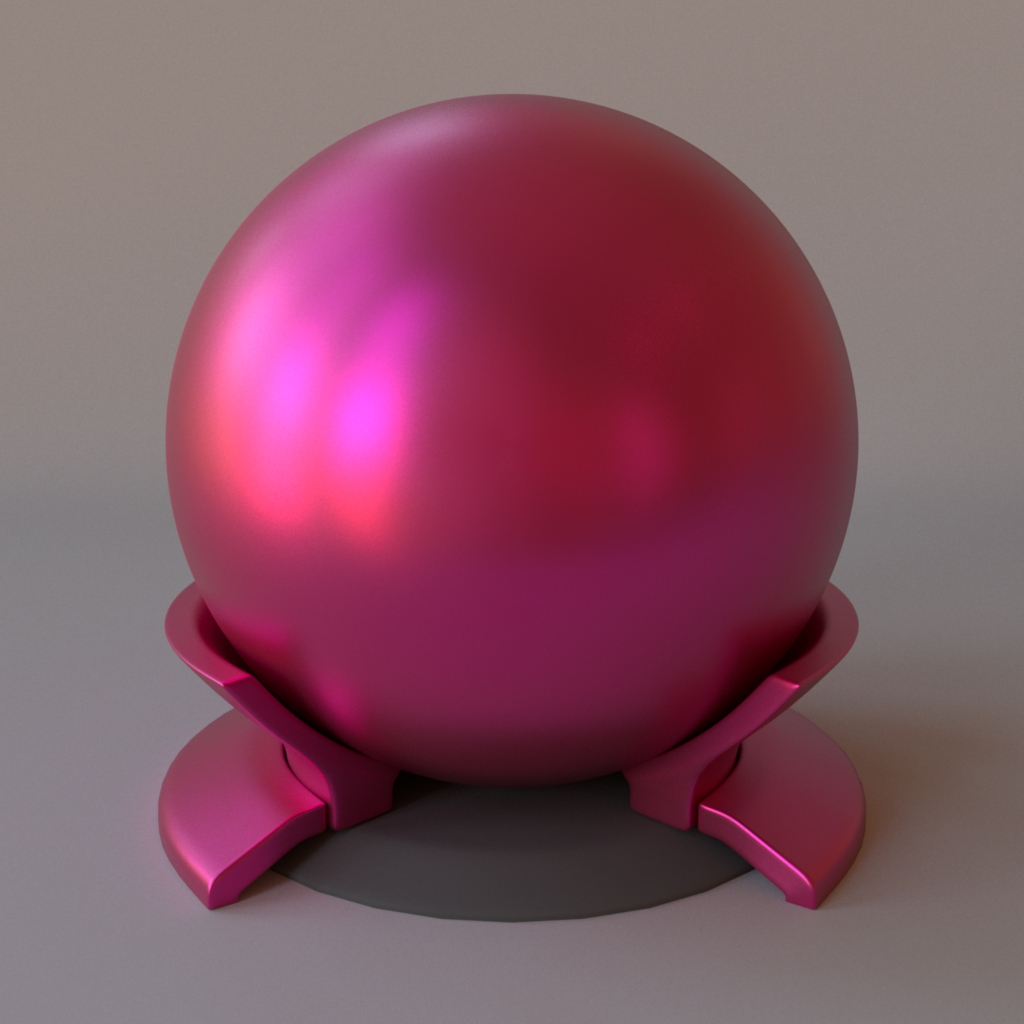

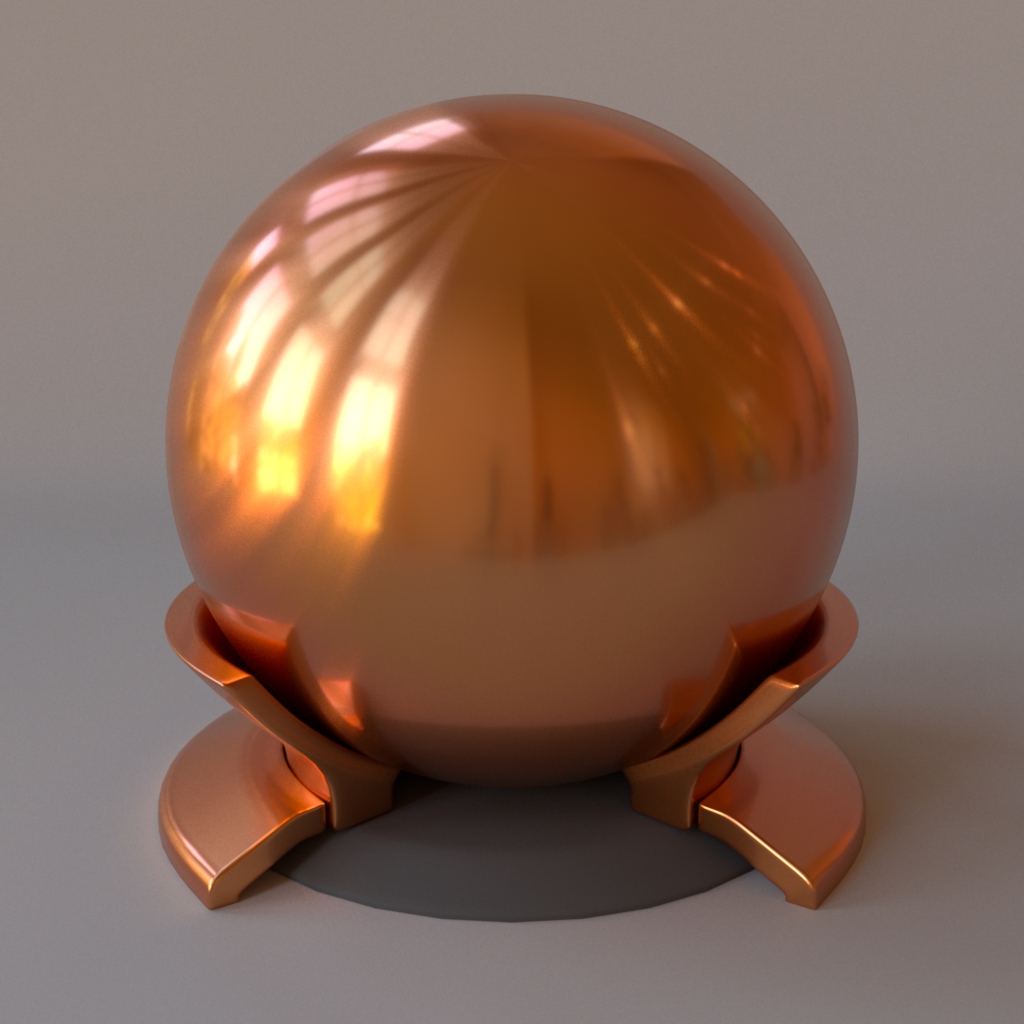

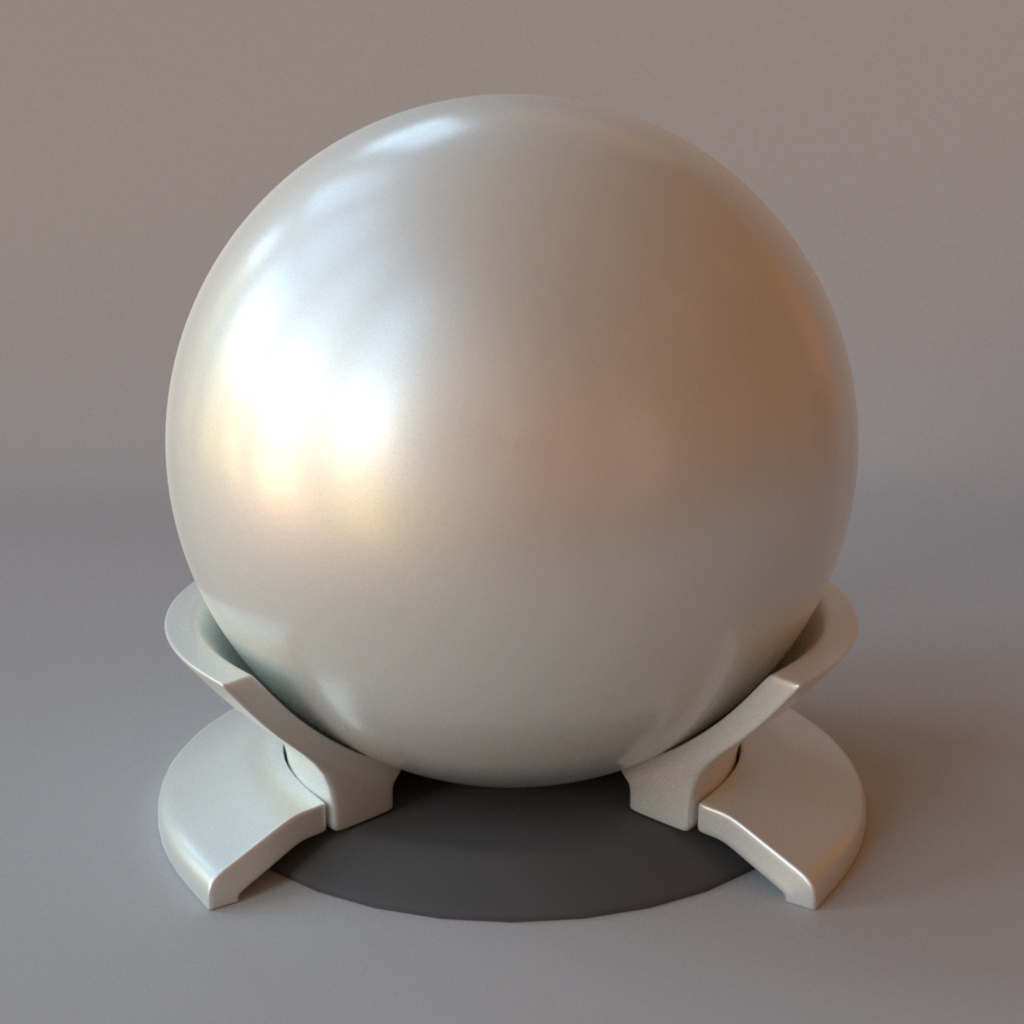

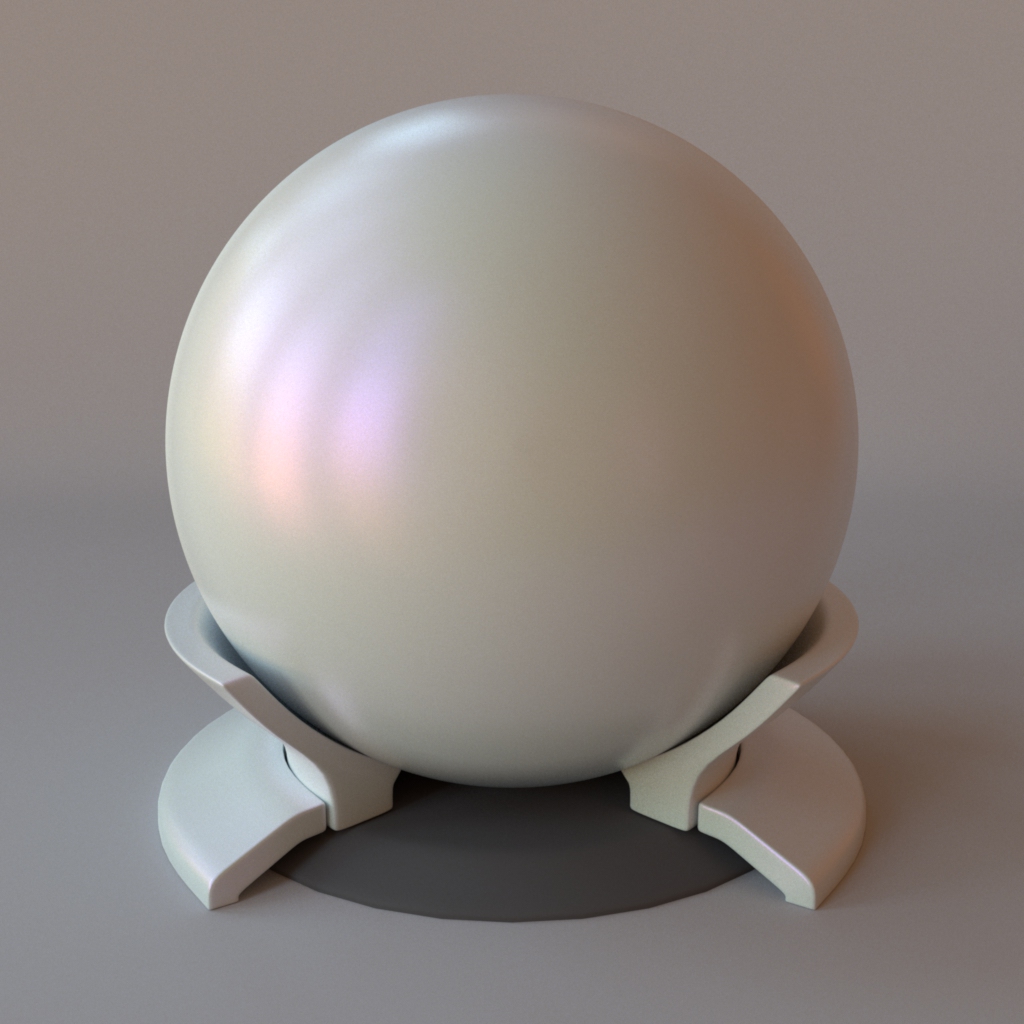

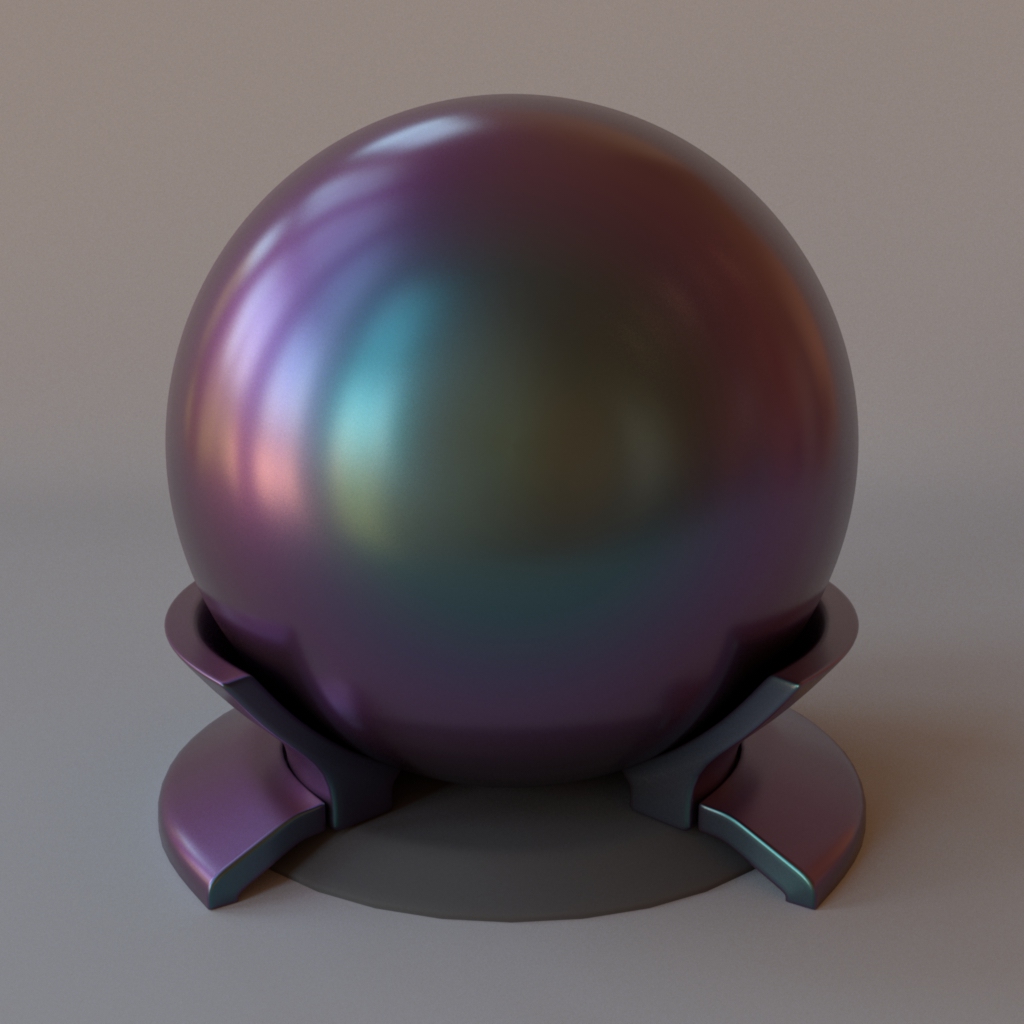

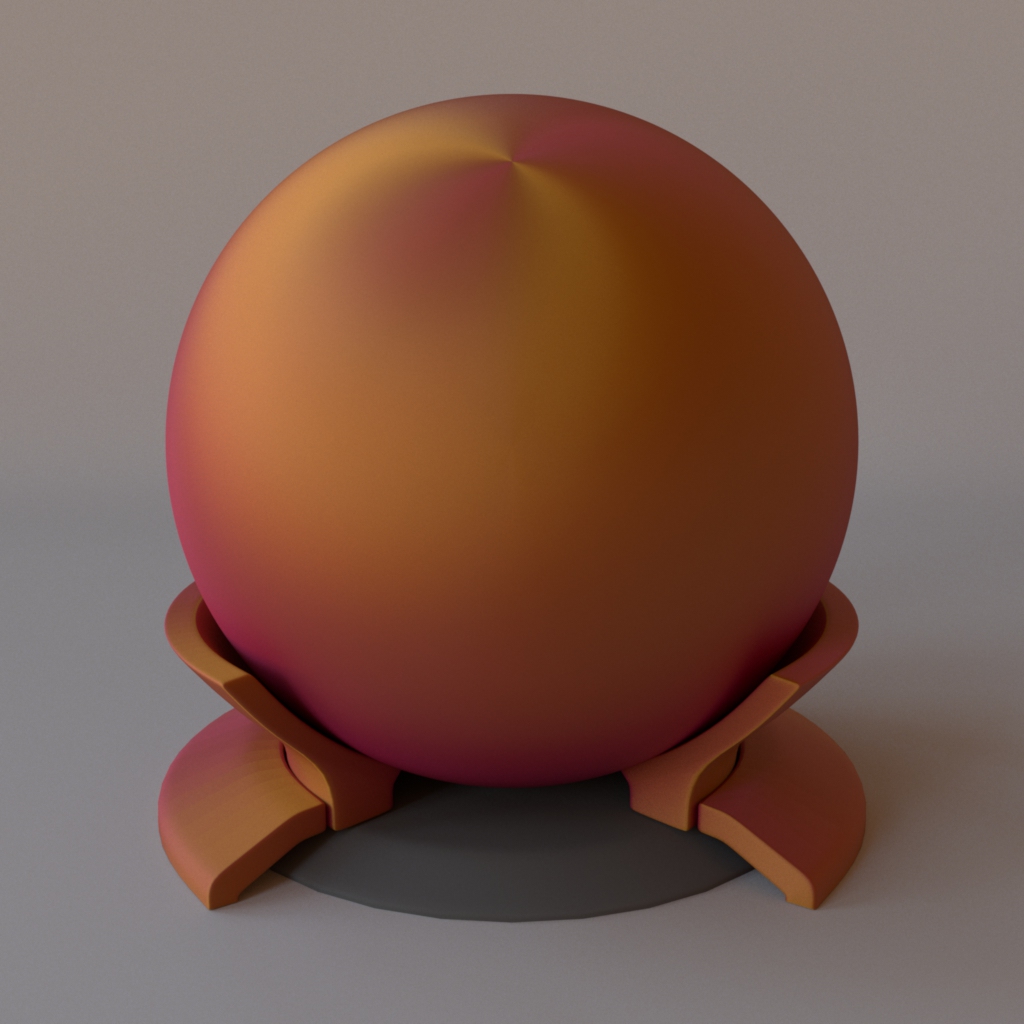

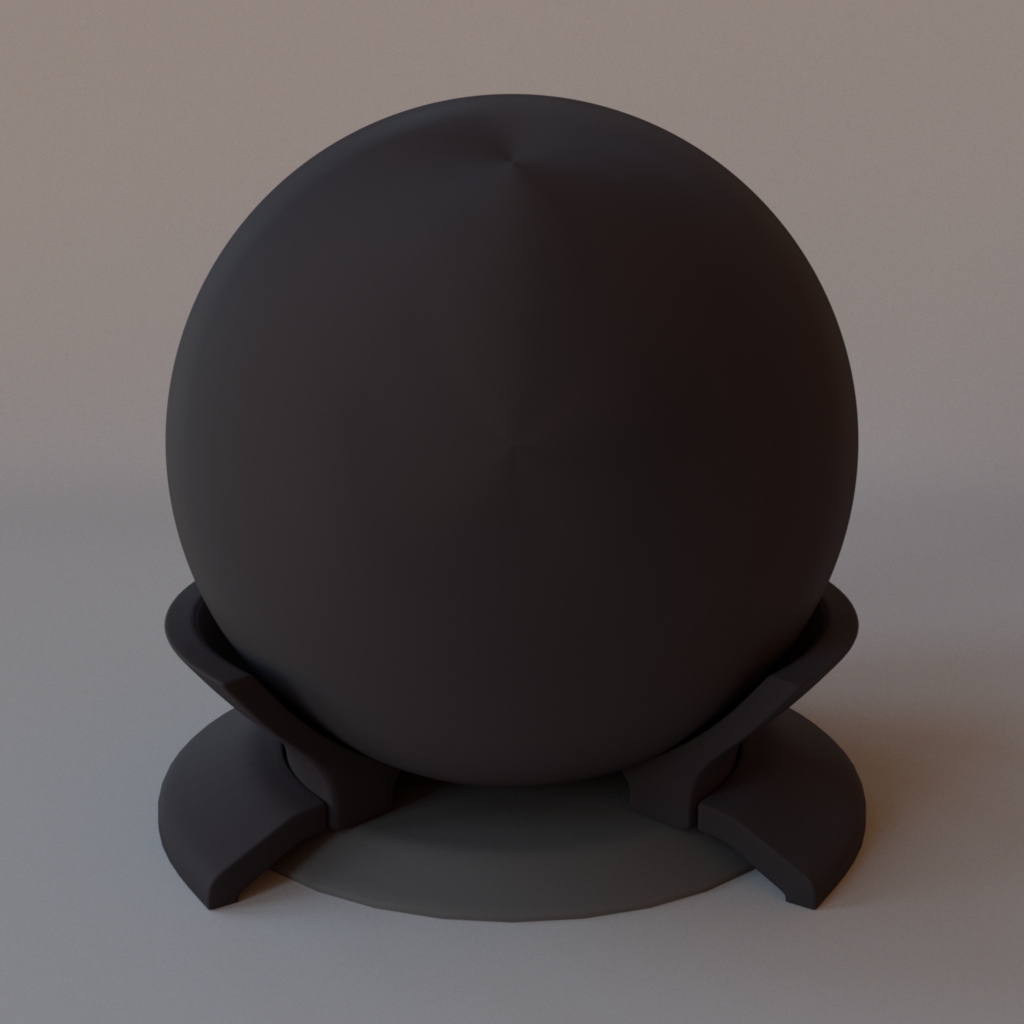

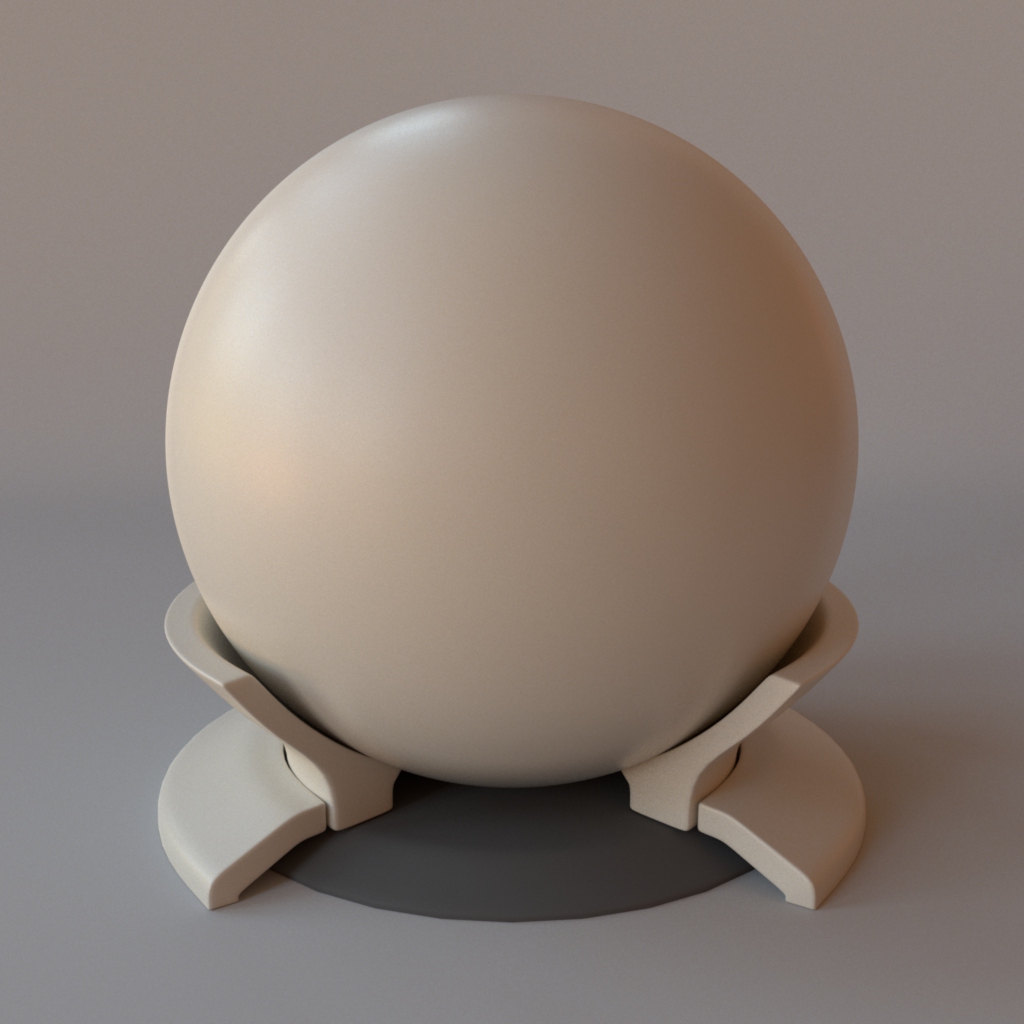

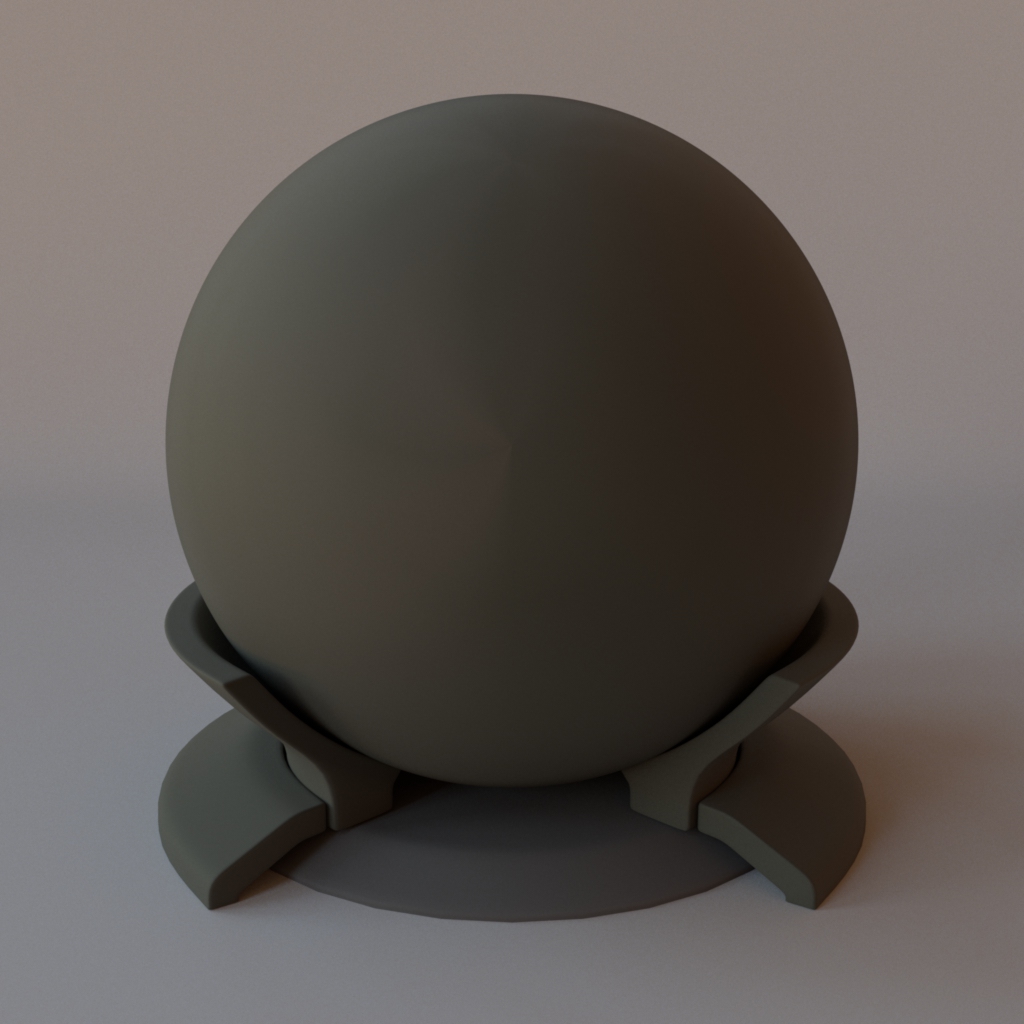

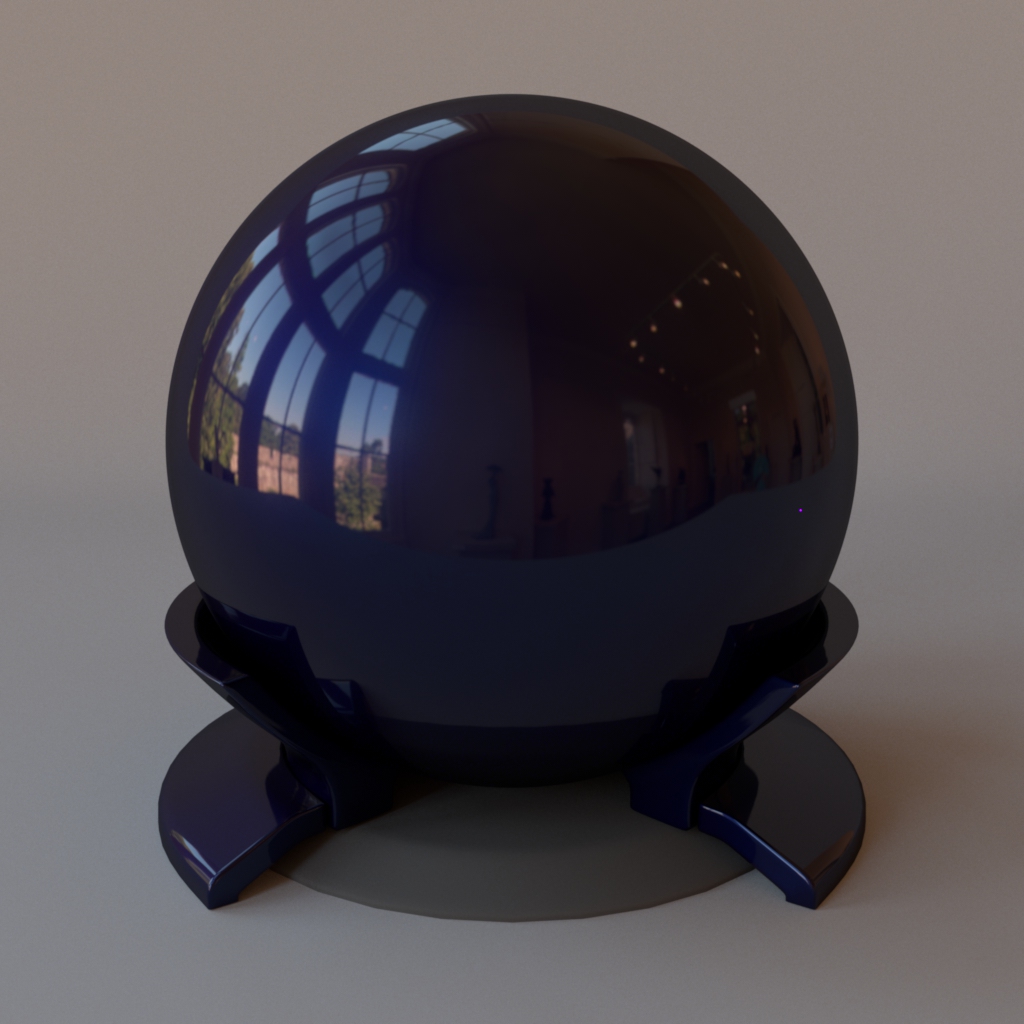

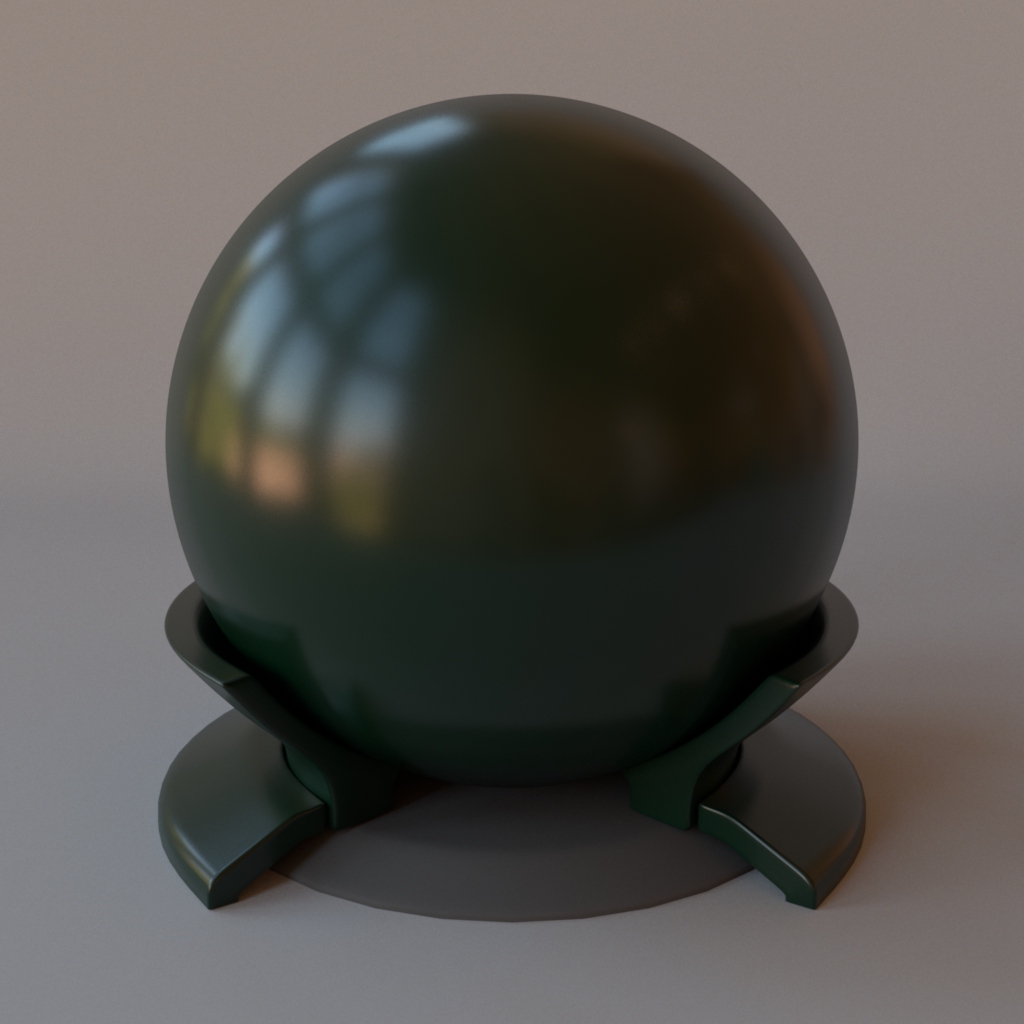

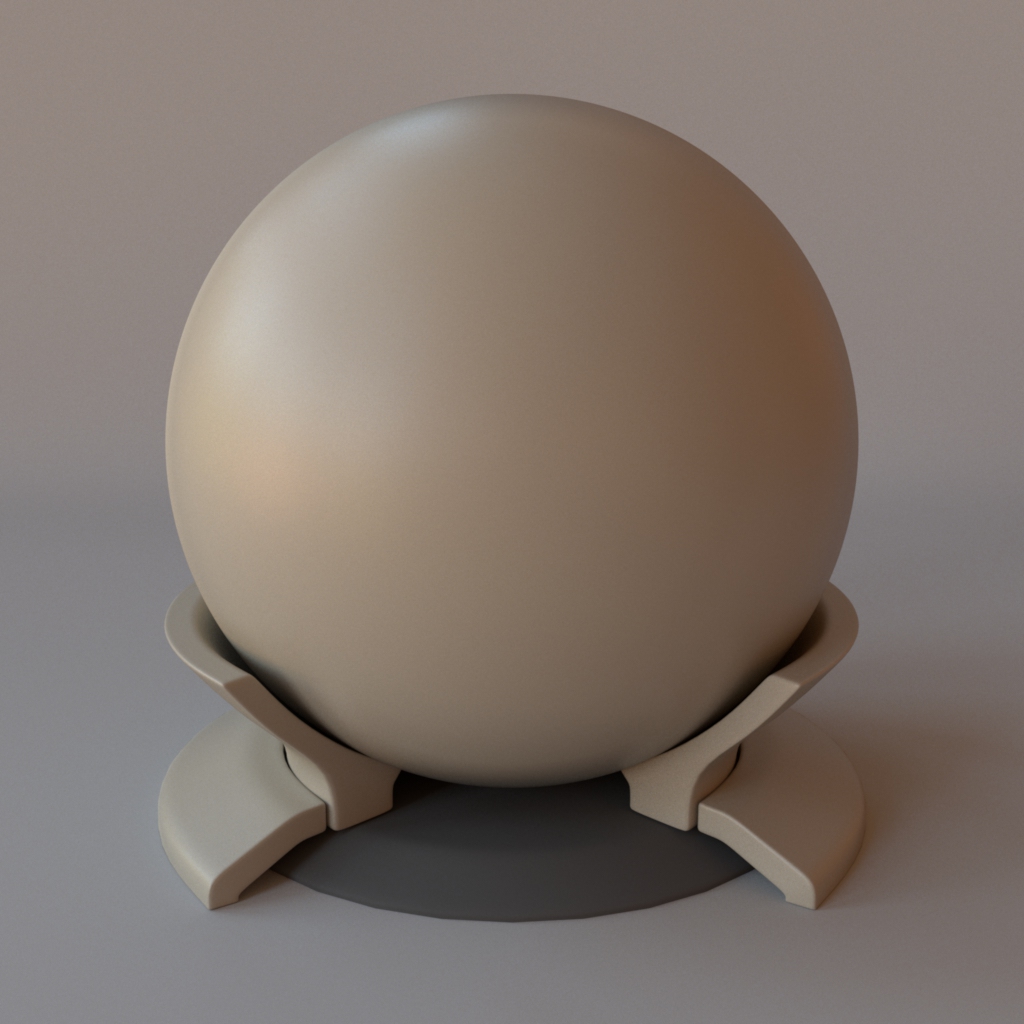

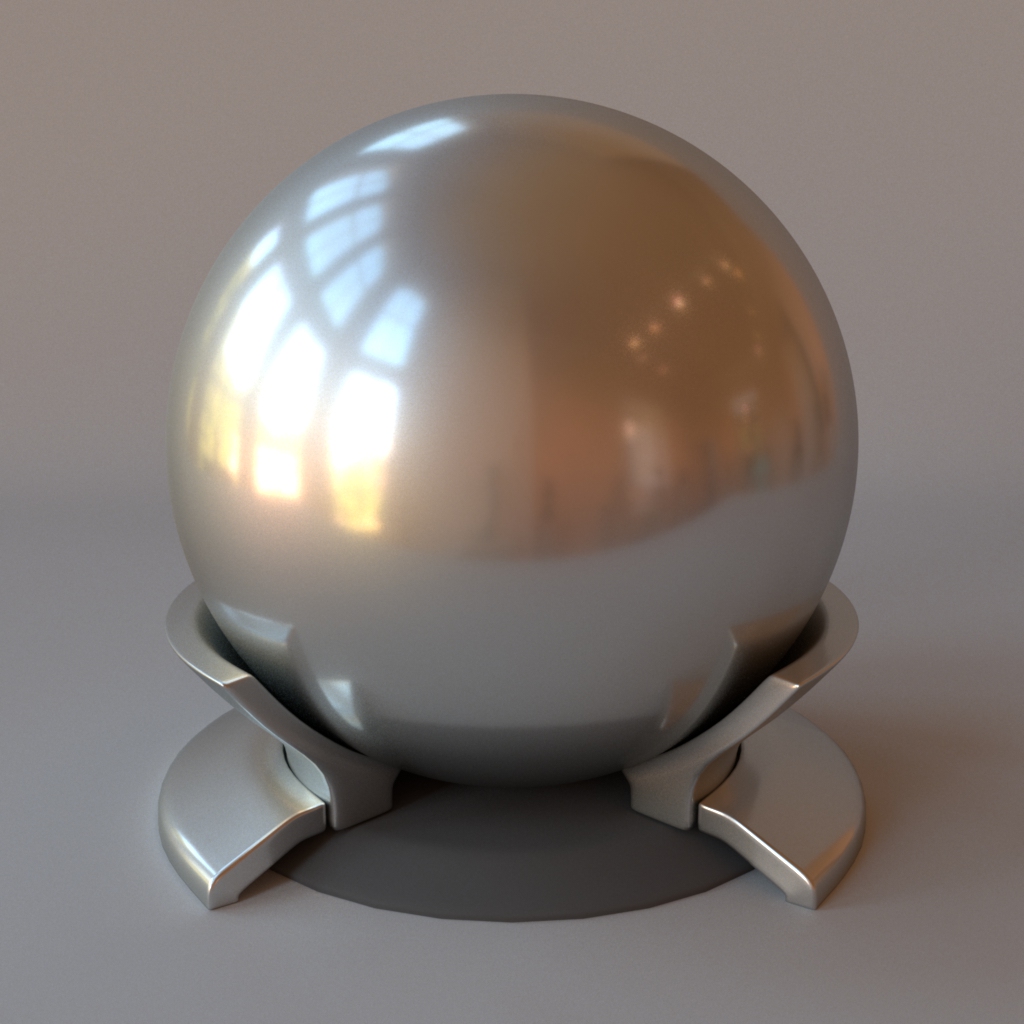

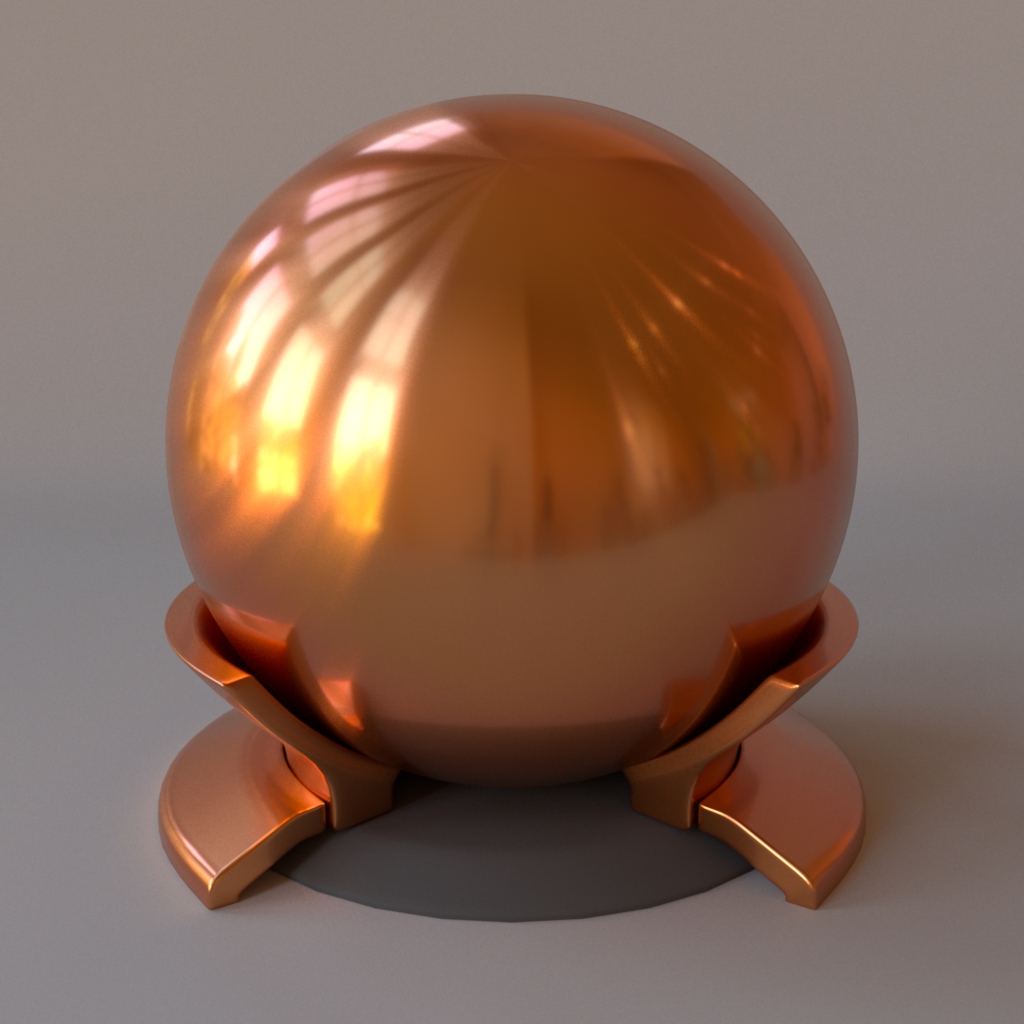

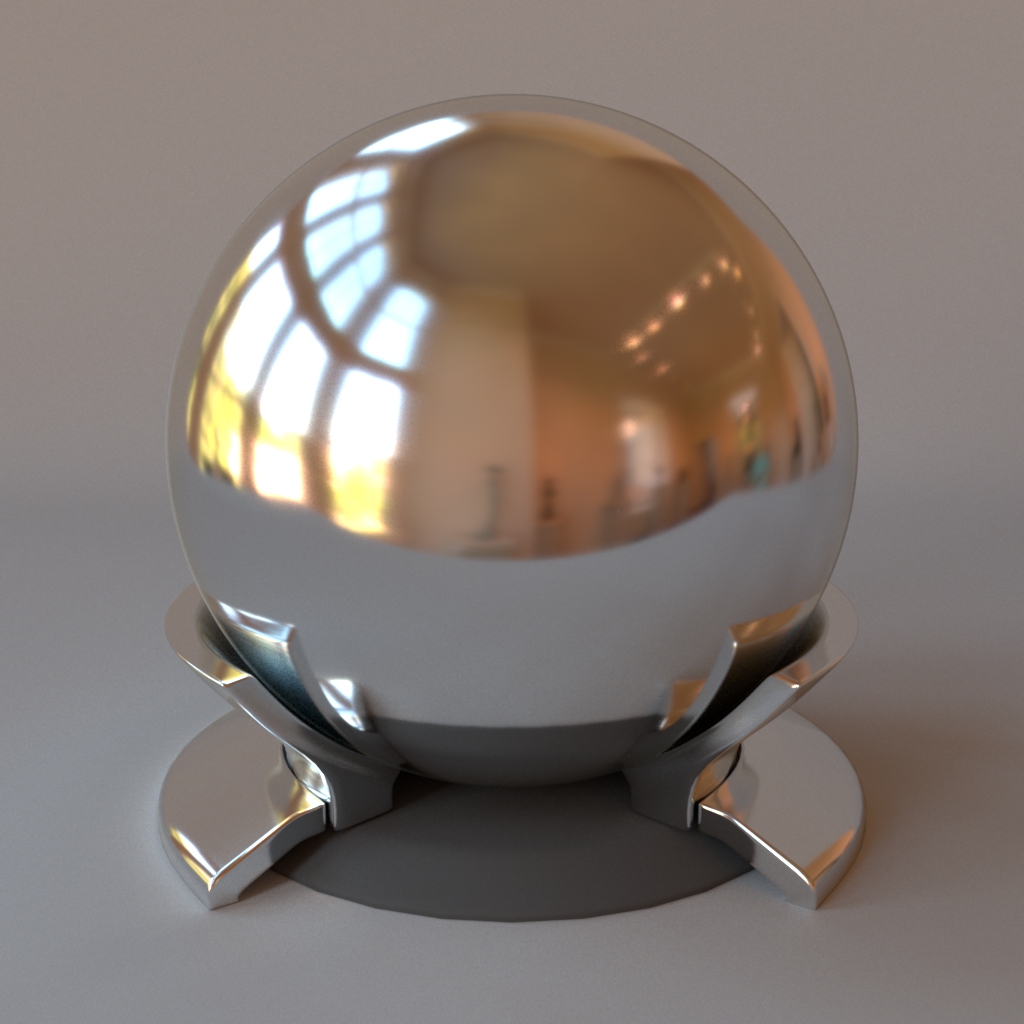

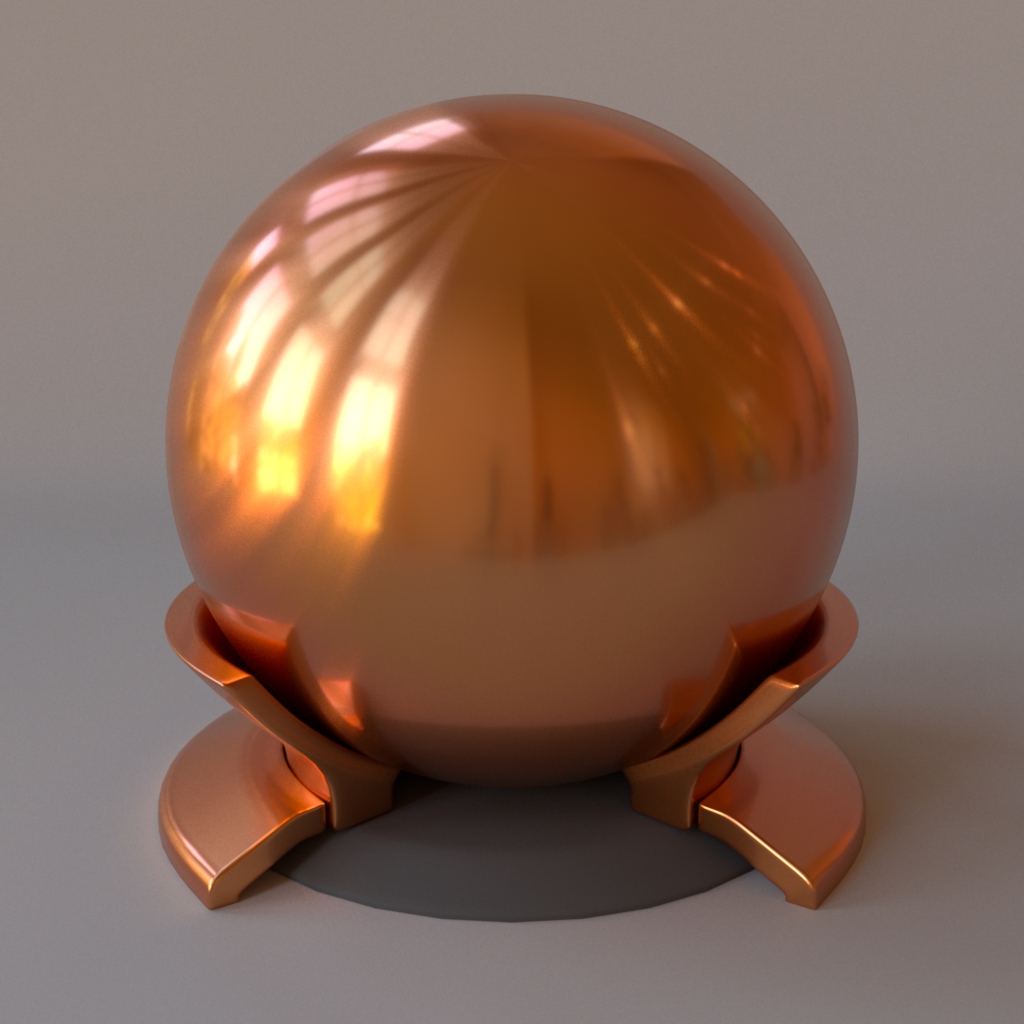

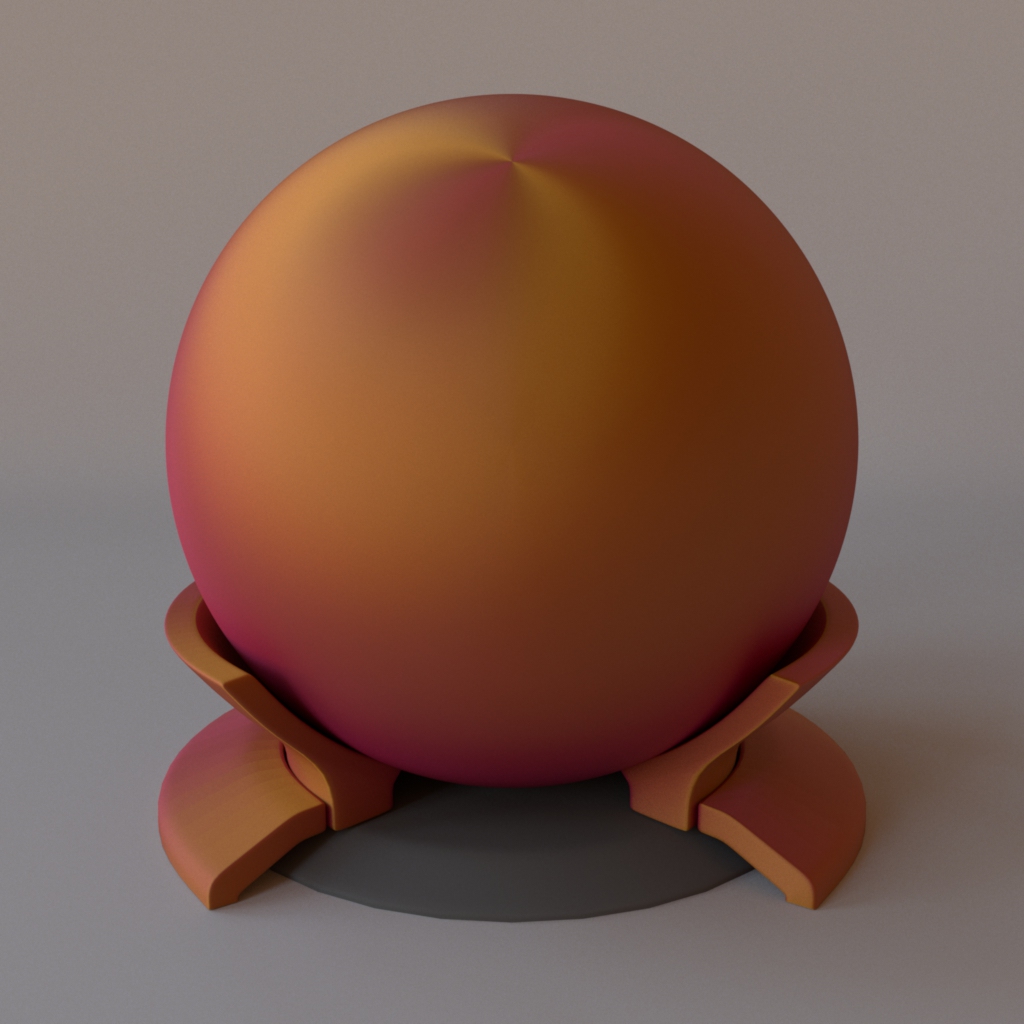

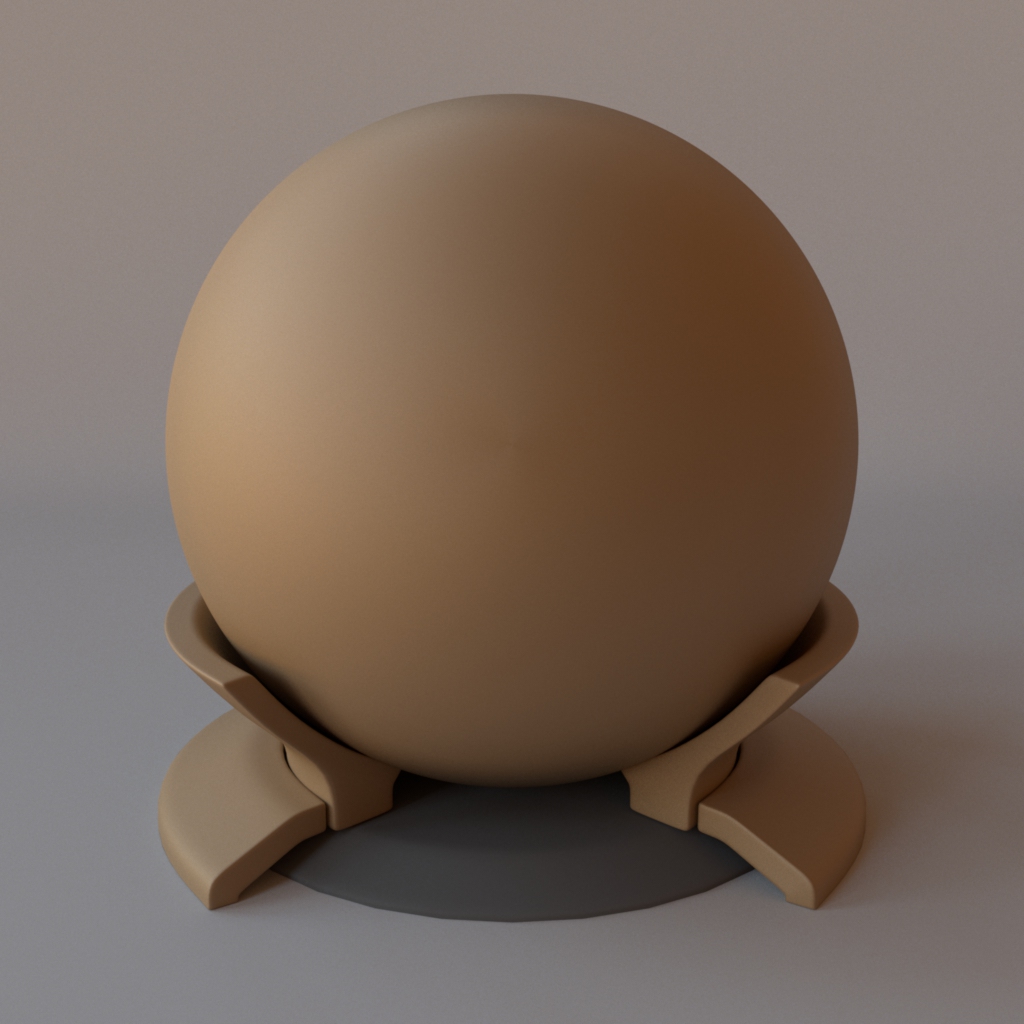

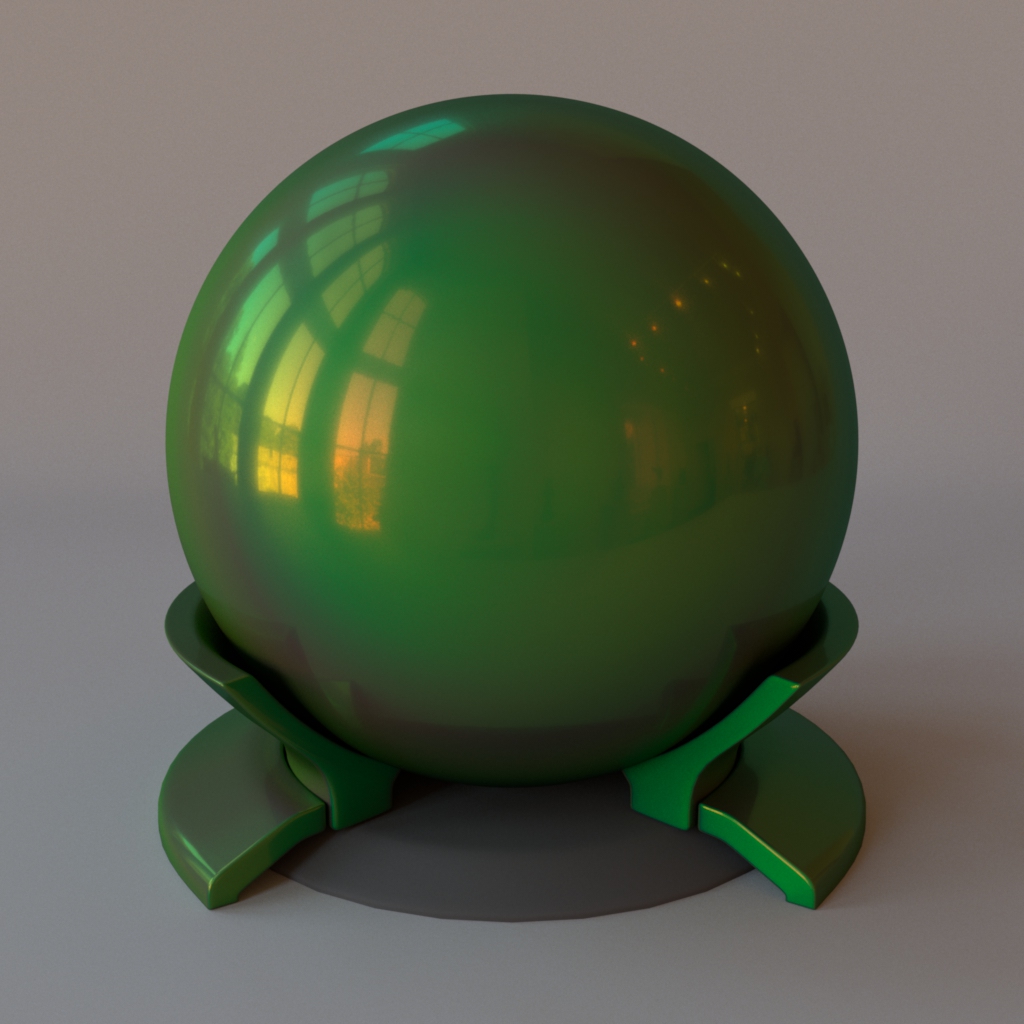

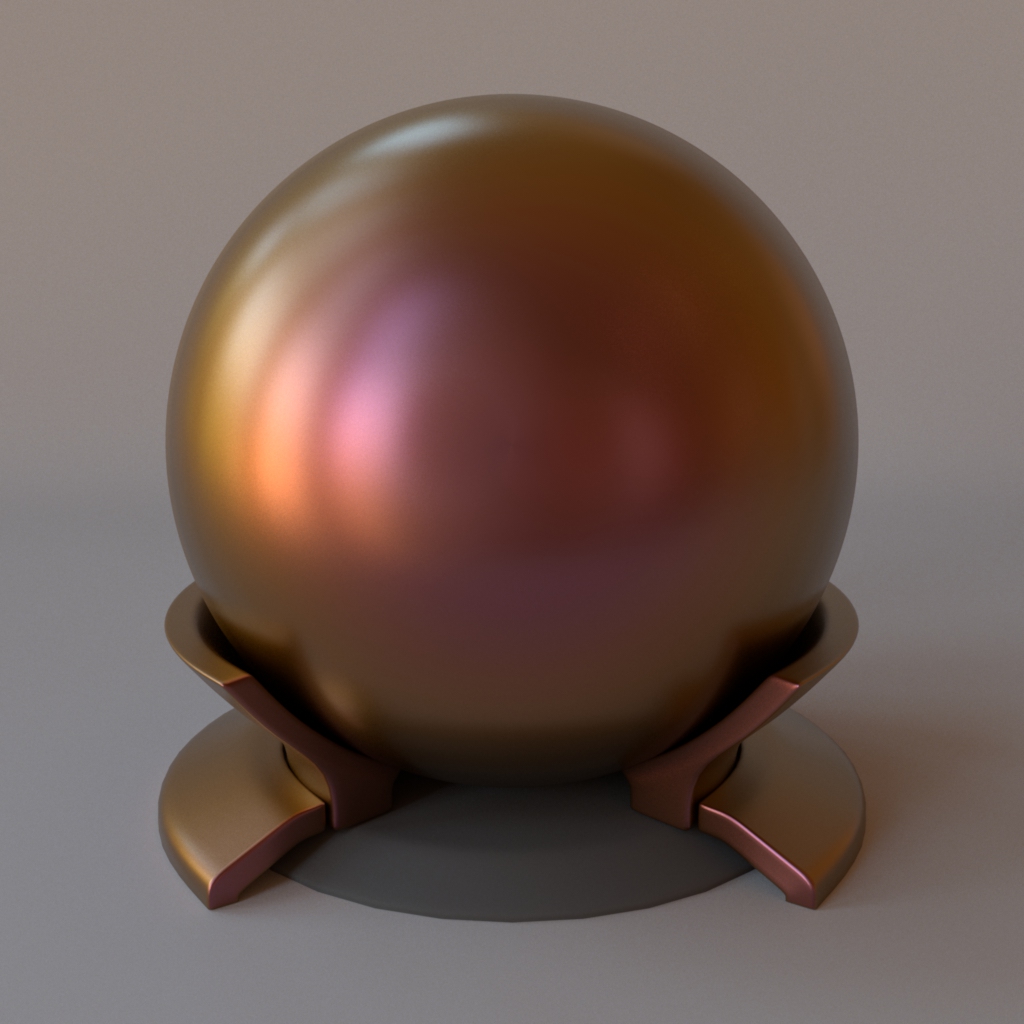

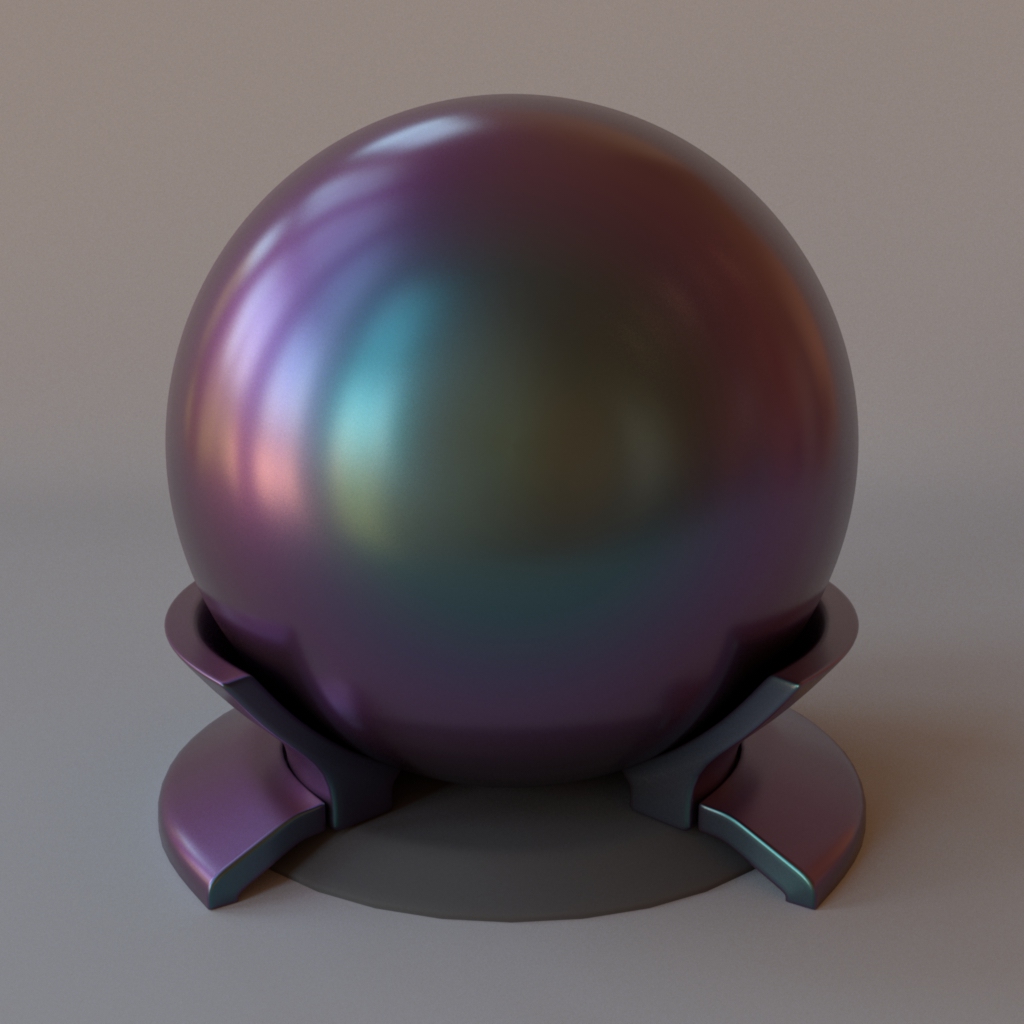

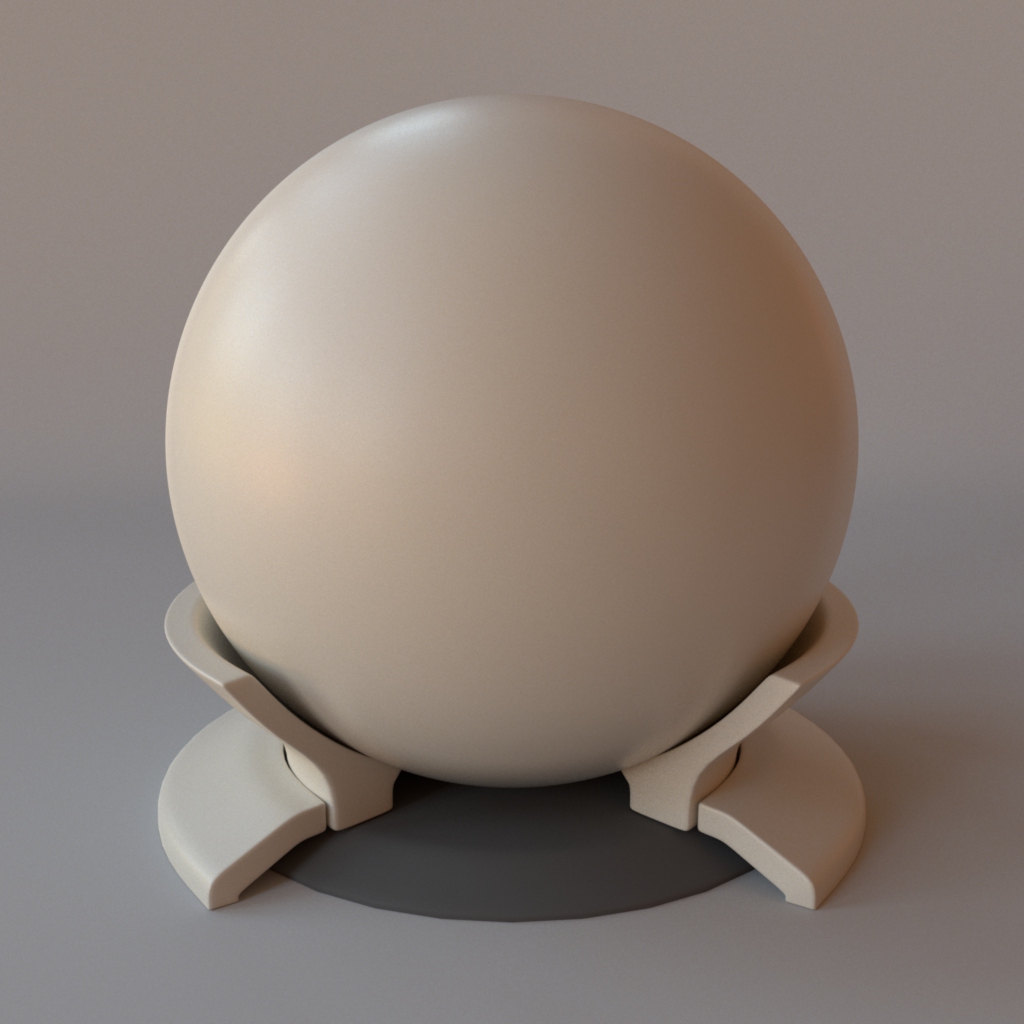

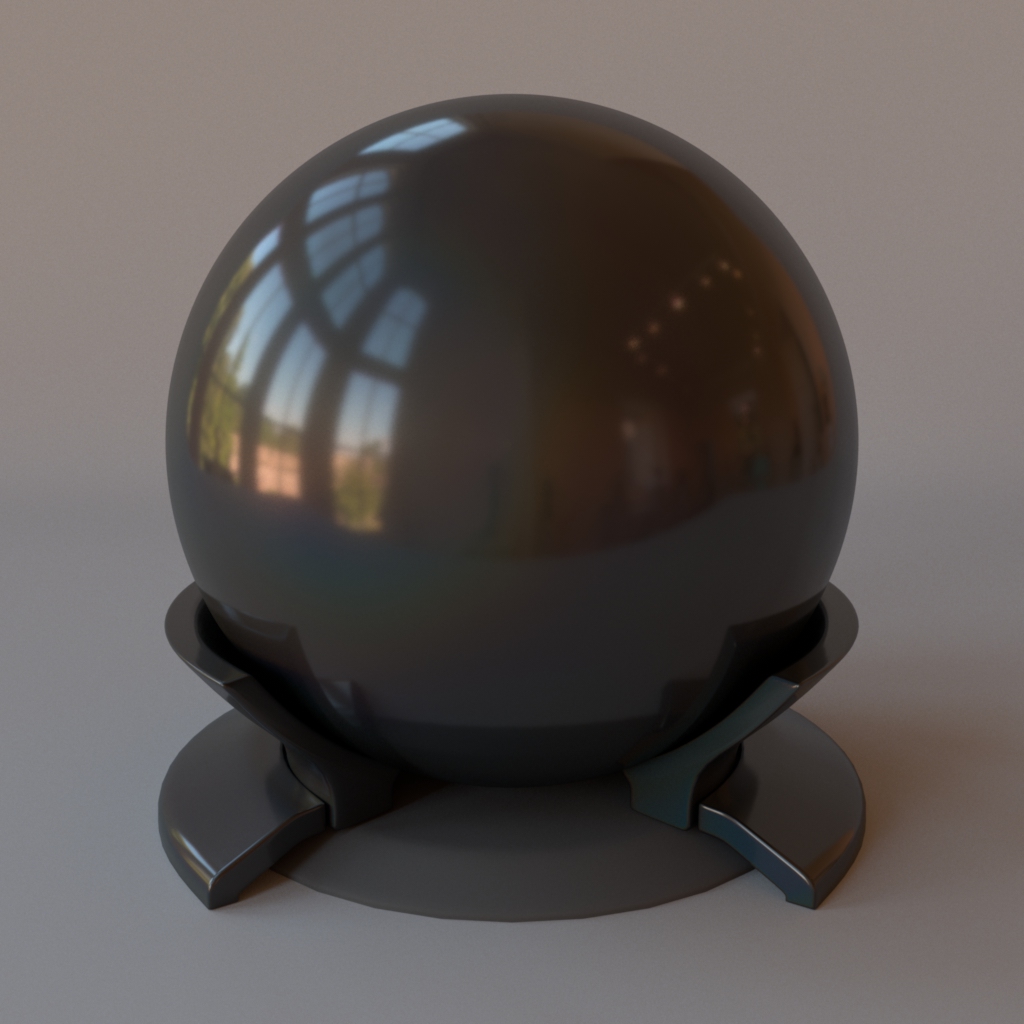

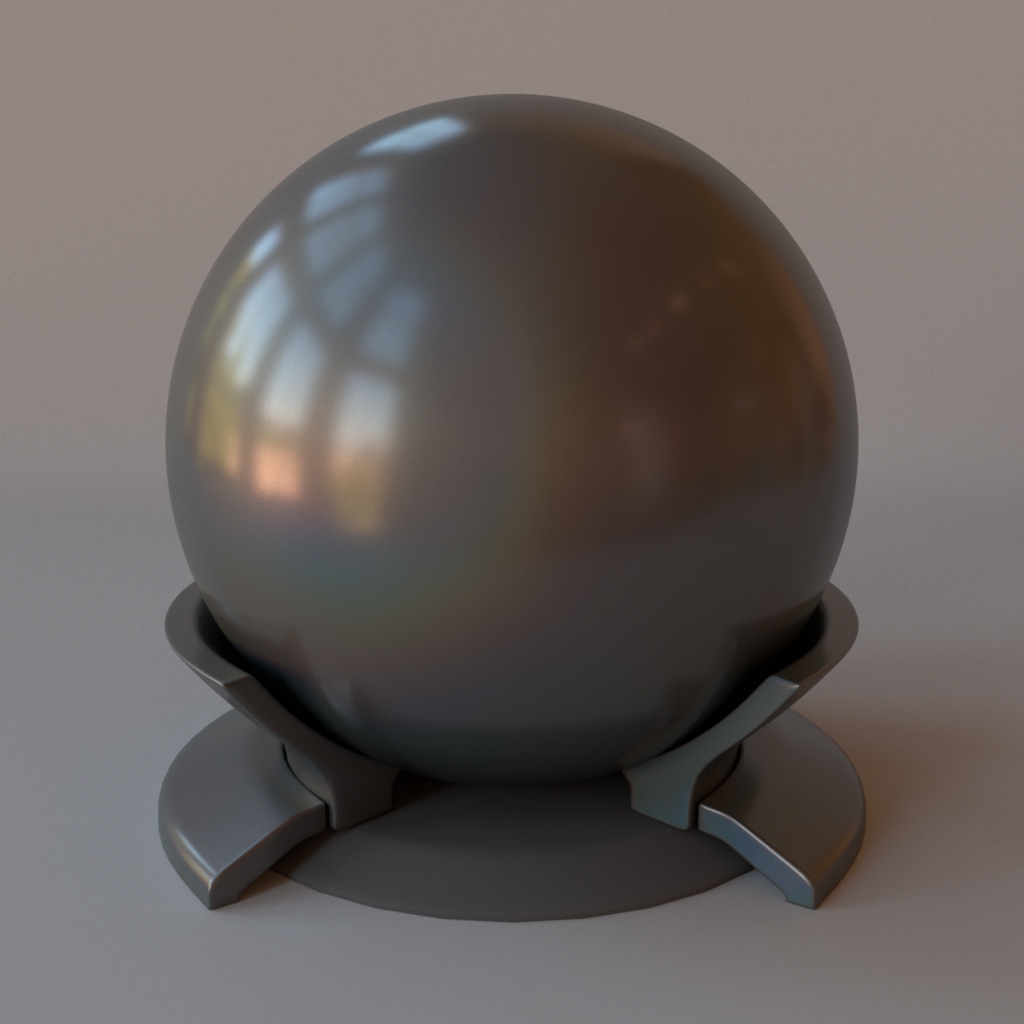

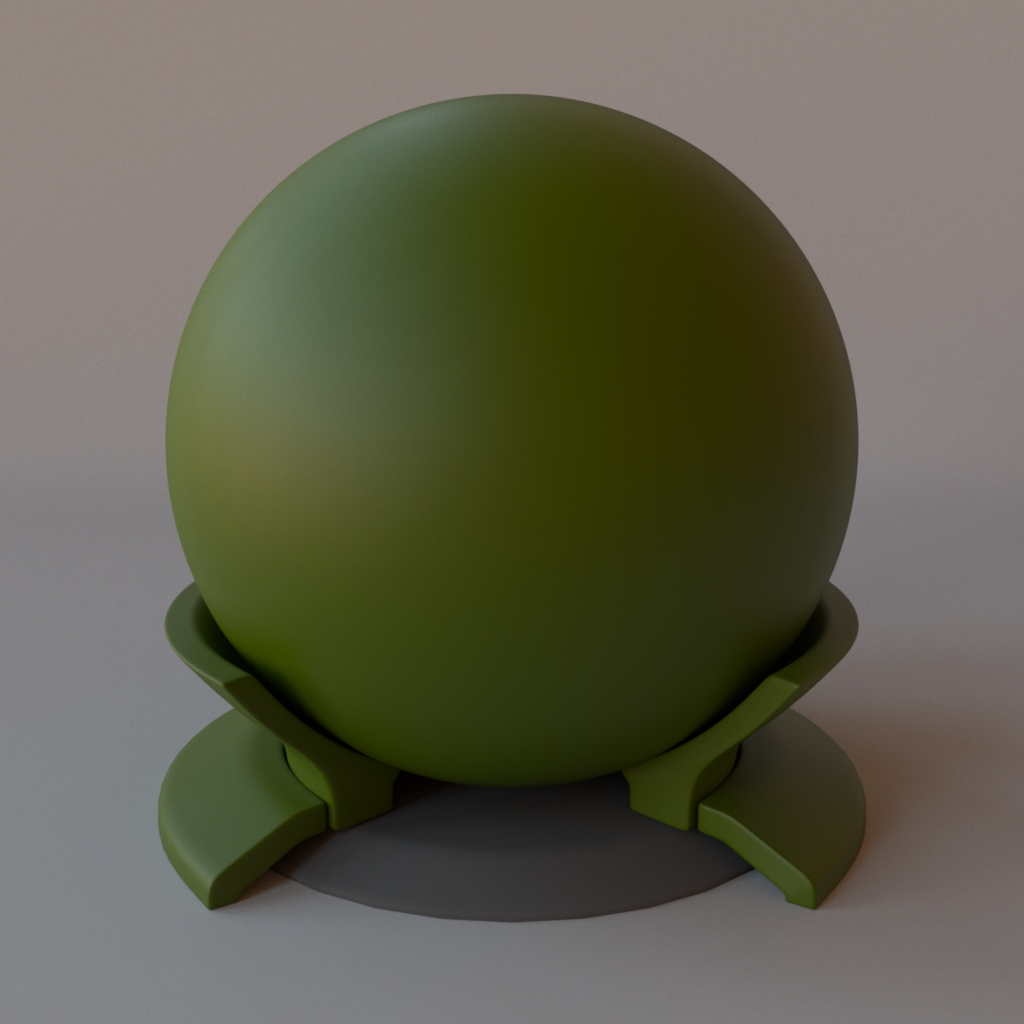

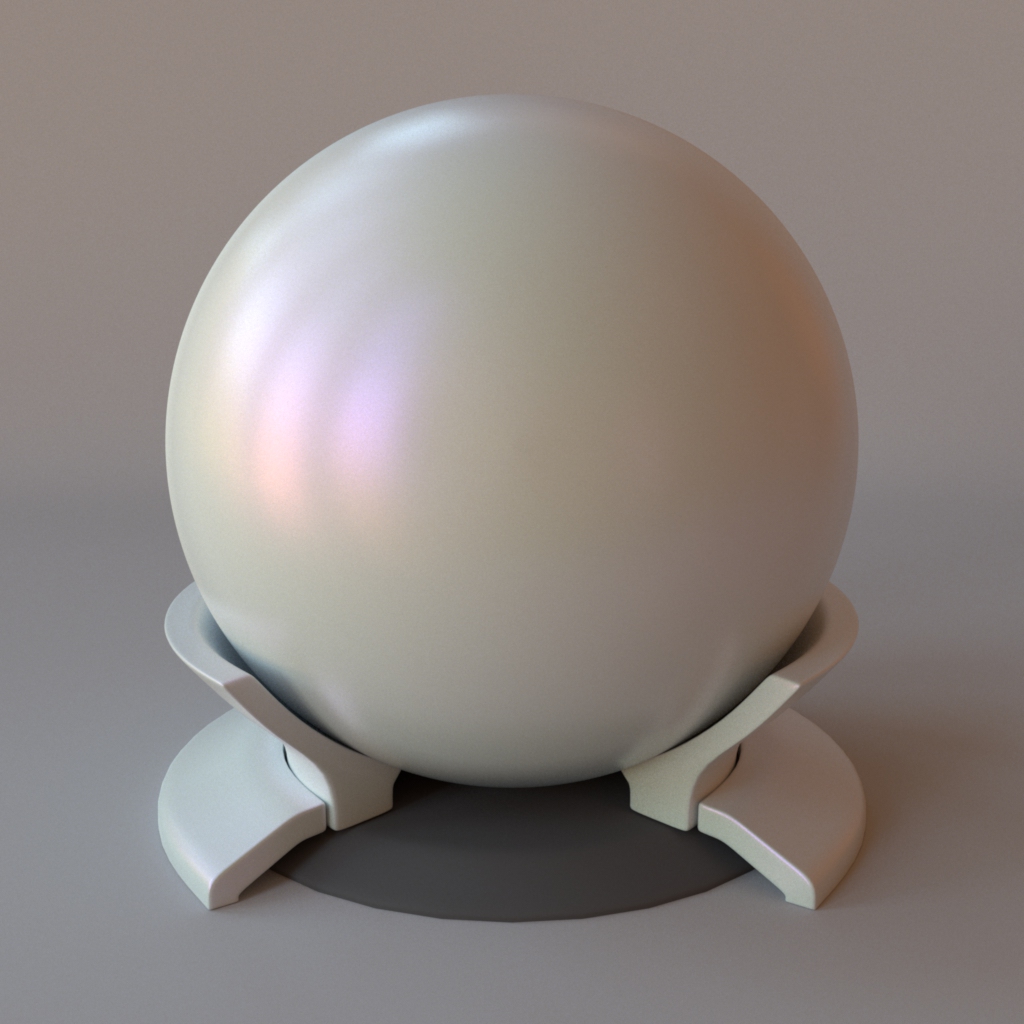

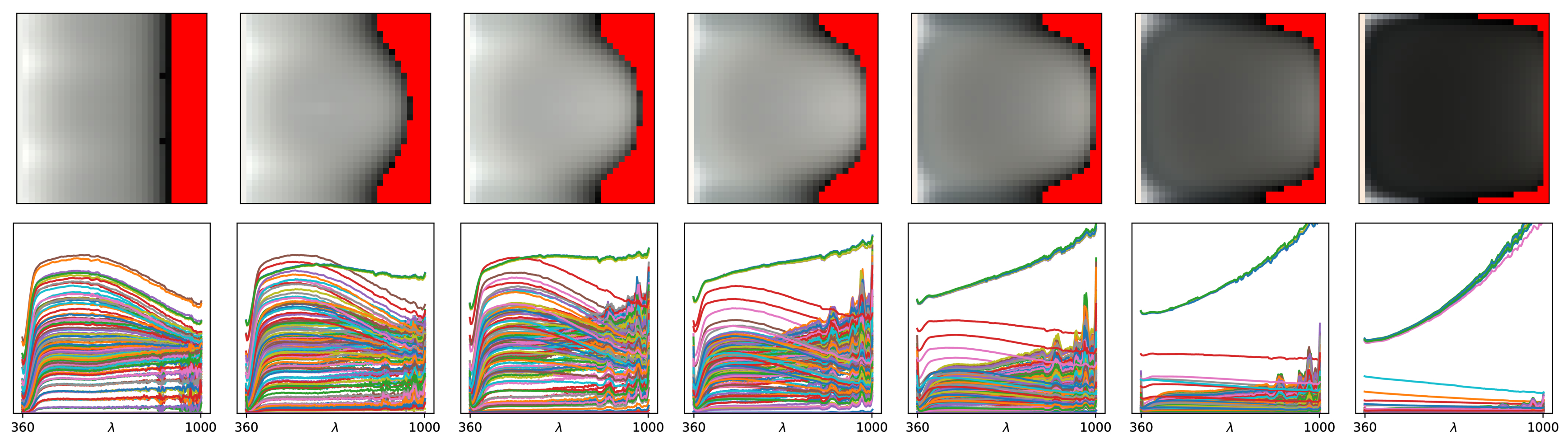

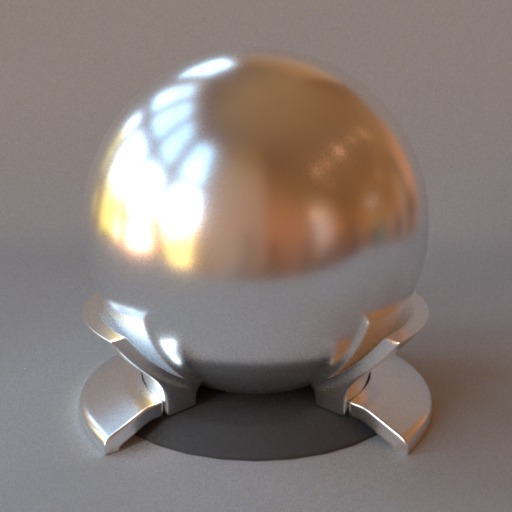

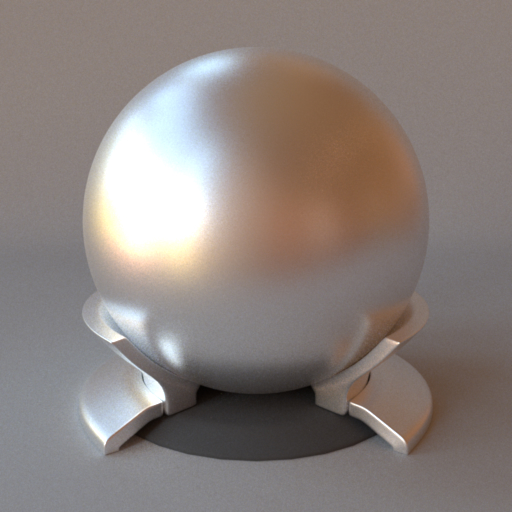

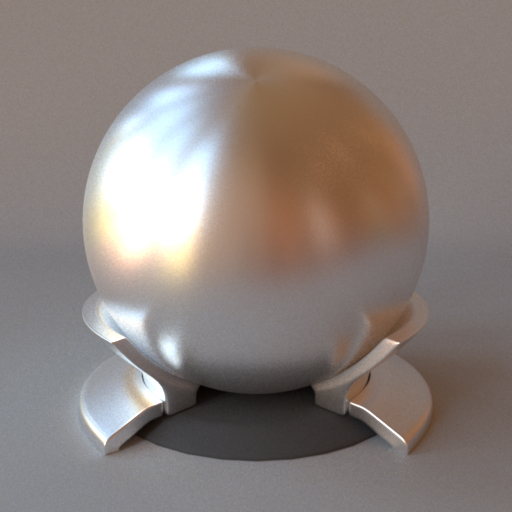

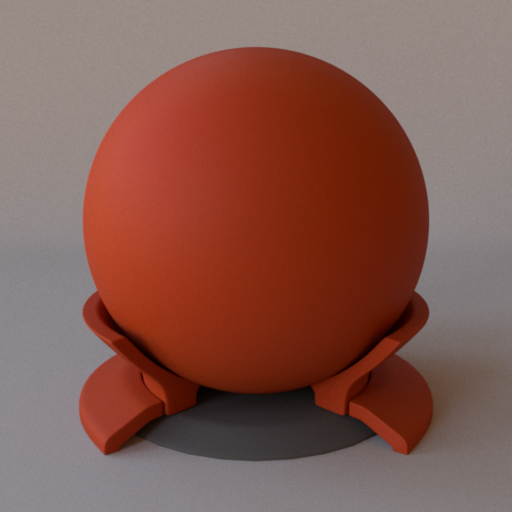

Here, we show a few such renderings, computed using 1024 samples per pixel.

Careful observers will notice

complex optical effects such as hazy gloss, opalescence, iridescence,

anisotropy, color-changing highlights, etc. Such effects are rarely seen

in computer graphics, so we're excited to have them :)

[click] 57

different materials, including 10 that exhibit highly anisotropic behaviours.

Note that this number is not fixed, as we are still growing the database with

new measurements at the present time.

Your browser does not support the video tag.

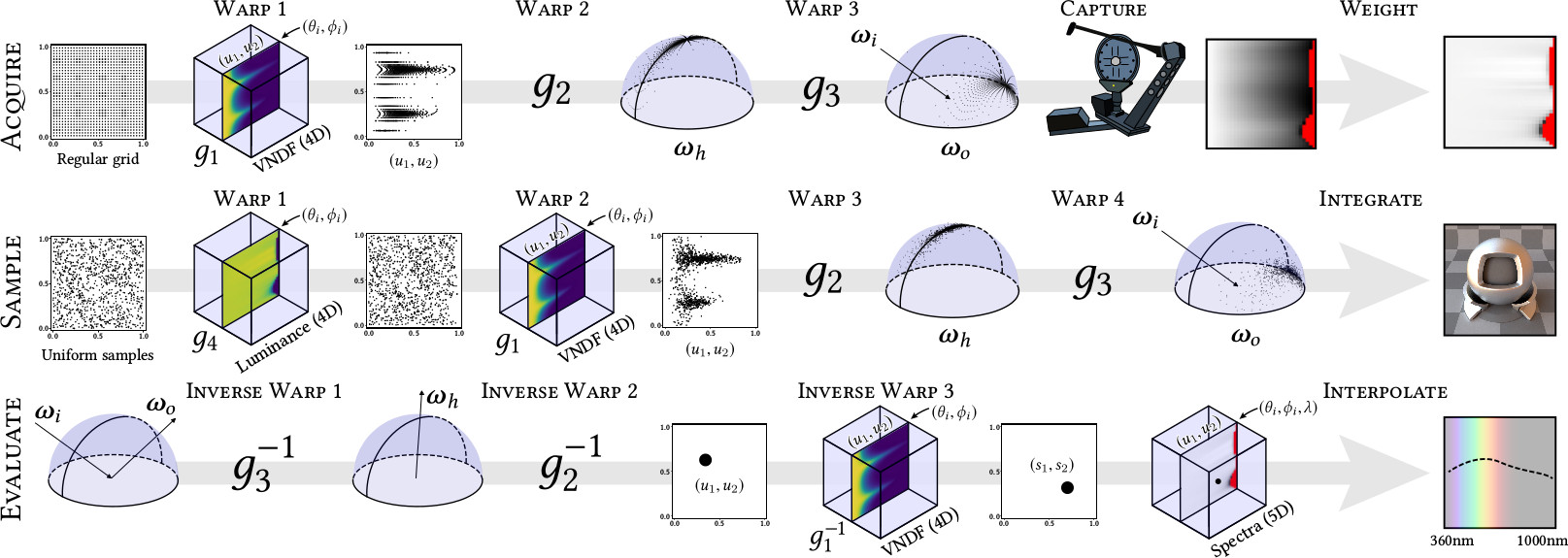

Our Pipeline

Acquisition Time:

(anisotropic) xx

2.5 days

(isotropic) xx

3 hours

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Our measurement pipeline relies on this new theoretical framework and runs

in two steps in practice.

[click]

With our pipeline, we acquire [click] anisotropic BRDFs in 2.5 days and

[click] isotropic ones in 3 hours. We believe that such

speeds is what will make BRDF measurement feasable for photorealistic

rendering.

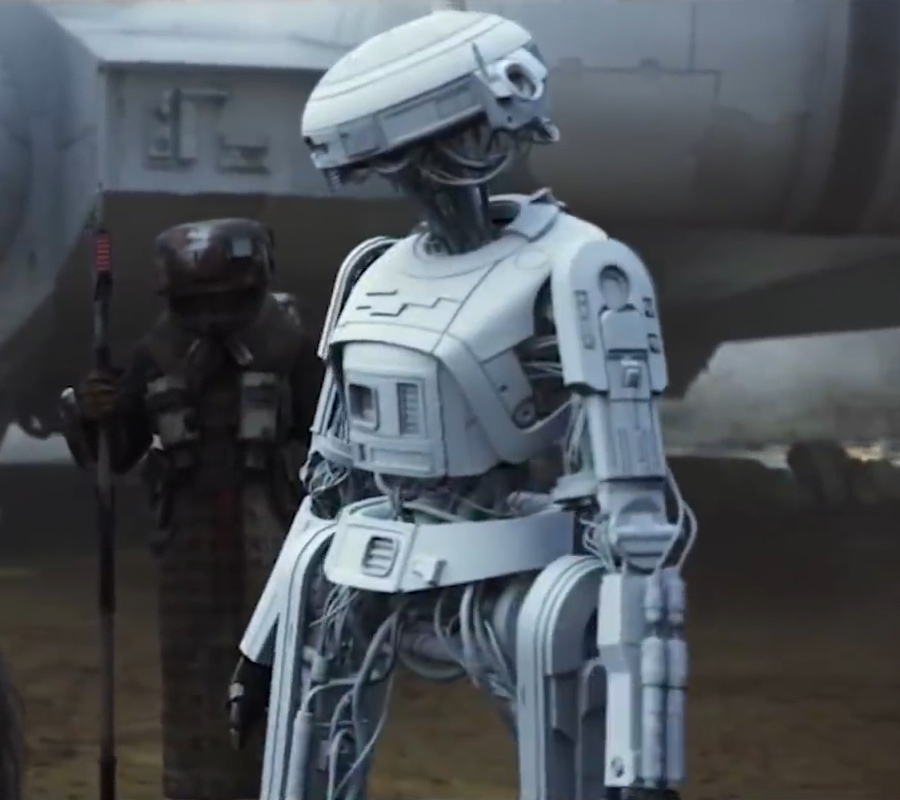

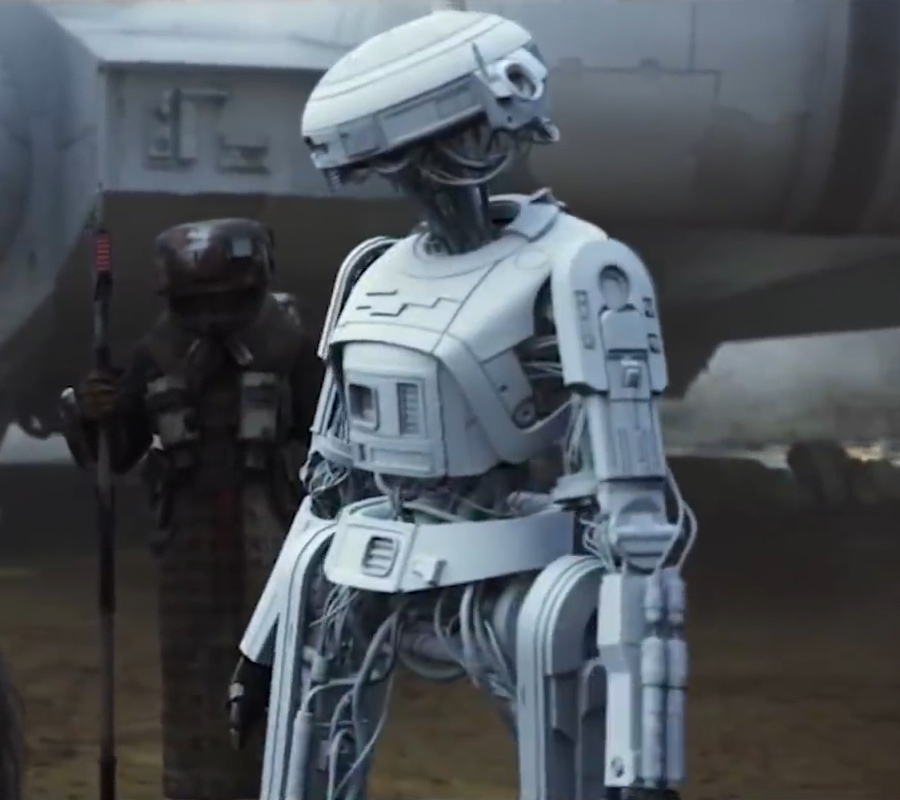

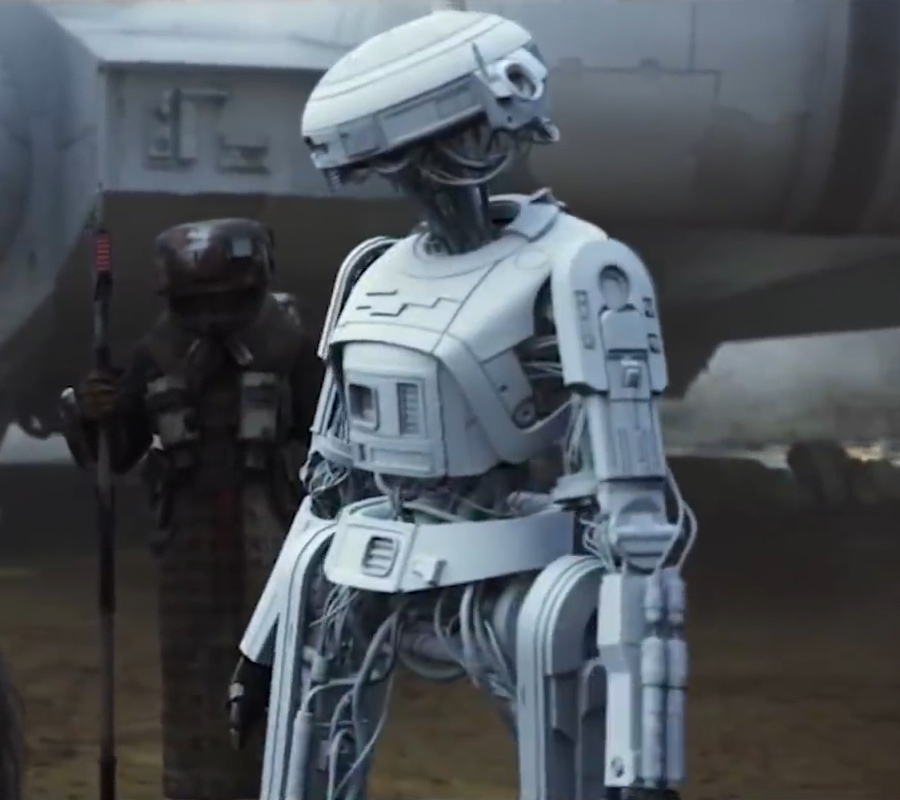

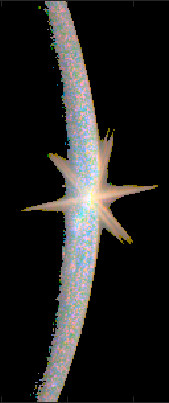

© Industrial Light & Magic

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Here is a cool fact to back up this claim: when we got our first

measurements, we were discussing with ILM (Industrial Light and Magic) to

see if they could send us some of the material samples they use for the

movies they work on. It turned out that, as they were very interested in

our project, they sent us some legit Star Wars samples :)

[click] some of the materials used to build some parts of

it, which are also available for free in our database.

Motivation

Real character

Digital double

The L3-37 droid is actually a digital double. It was created from the

performance of an actress

(Phoebe Waller-Bridge, shown on the left) who was wearing a costume built so

as to carry parts of the final droid character (shown on the right).

Motivation

Real character

Digital double

Solve $$L_o = \int_{\mathcal{S}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i $$

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Since ILM relies on photorealistic rendering for their special effects,

they create their digital doubles in two steps.

[click] the rendering equation, which is responsible

for giving the final photorealistic appearance to digital doubles.

Motivation

Real character

Digital double

Solve $$L_o = \int_{\mathcal{S}^2} L_i \cdot {\color{red}f_r^\perp} \cdot d\boldsymbol{\omega}_i $$

In the context of this Star Wars movie, the lighting is known beforehand.

Hence the only variable that drives the appearance of the digital double is

the term $f_r^\perp$, i.e., is the BRDF. The BRDF is responsible for

describing the way materials interact with light, and thus varies for

each material.

$$f_r^\perp = f_r(\boldsymbol{\omega}_i, \boldsymbol{\omega}_o, \lambda) \cos \theta_i$$

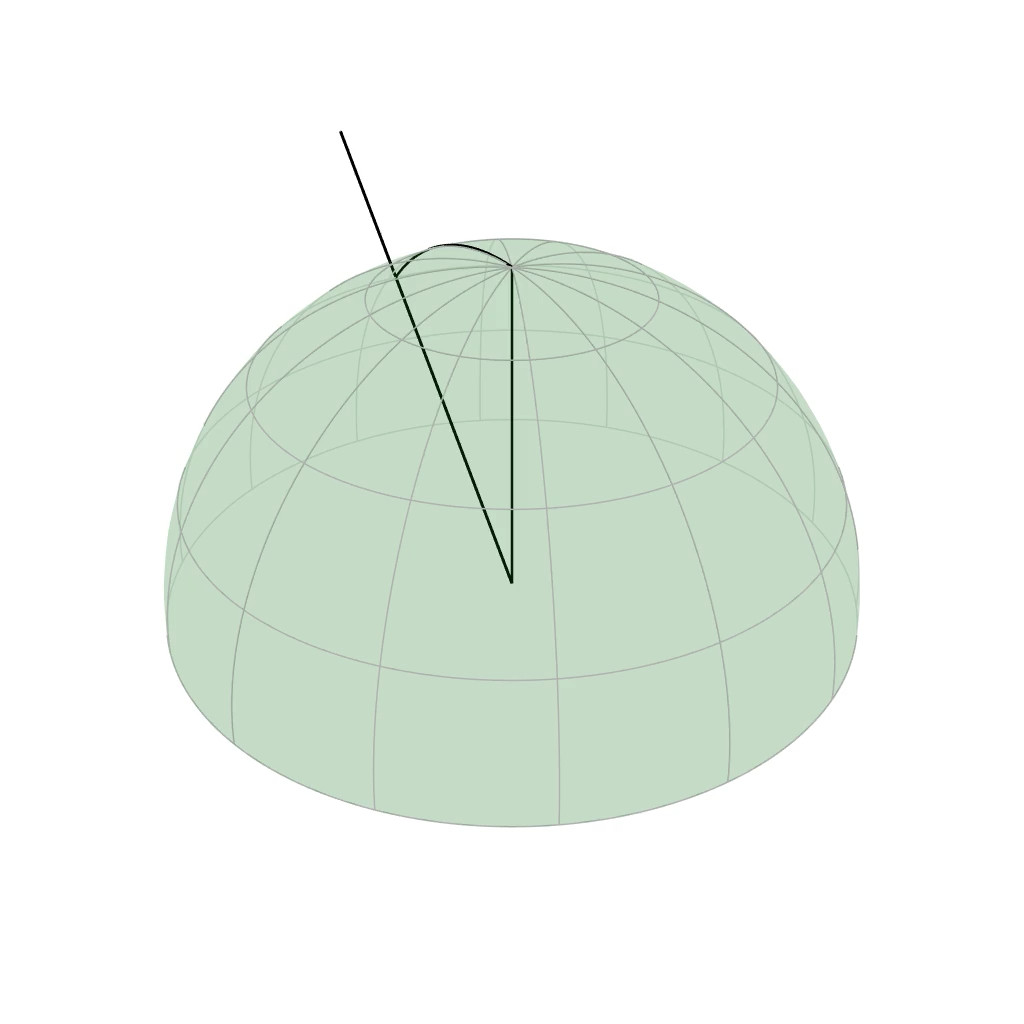

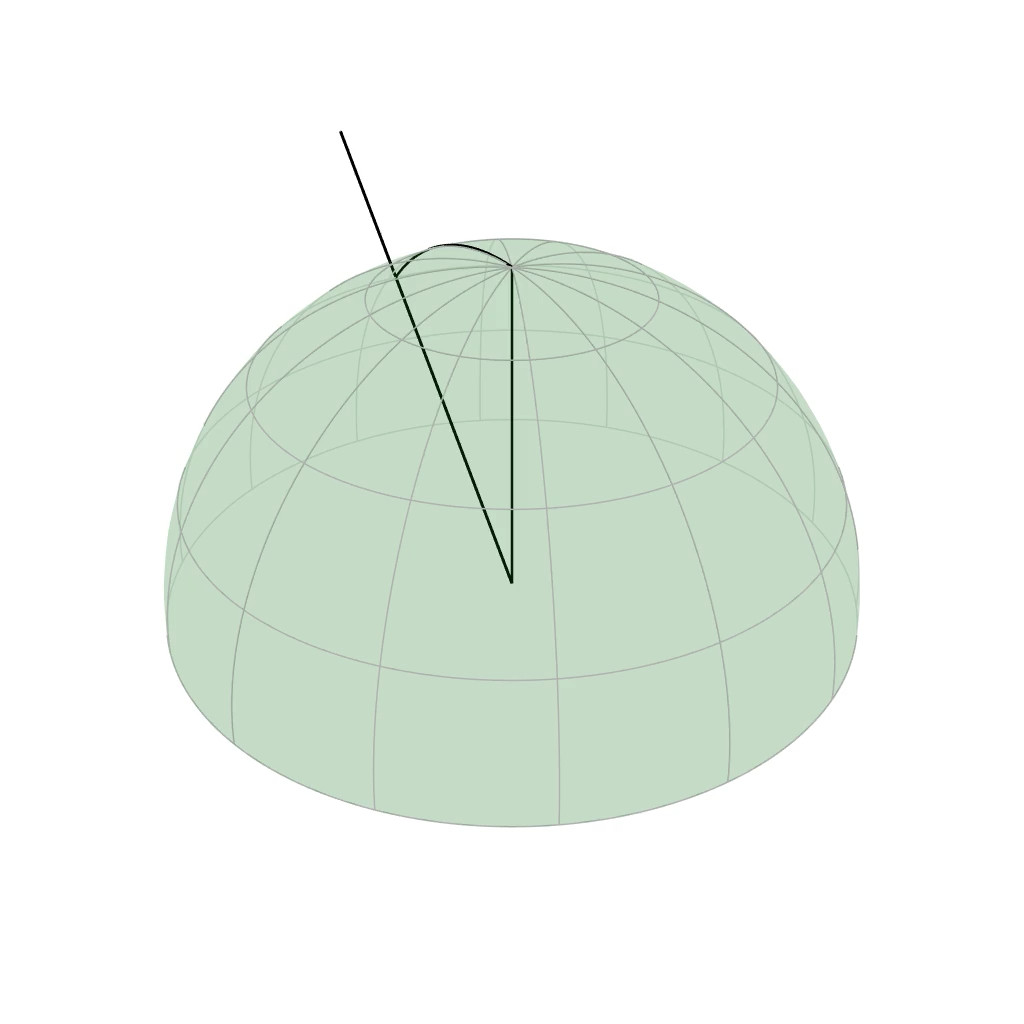

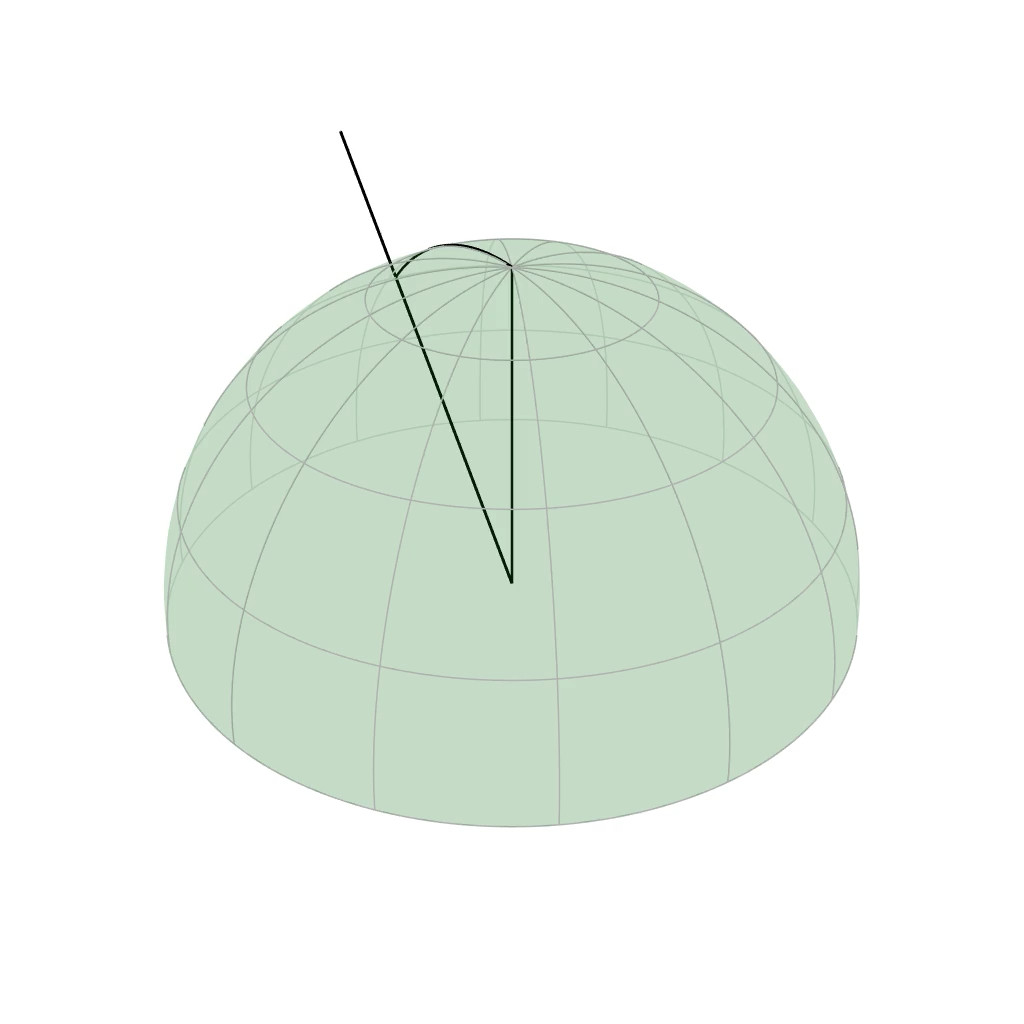

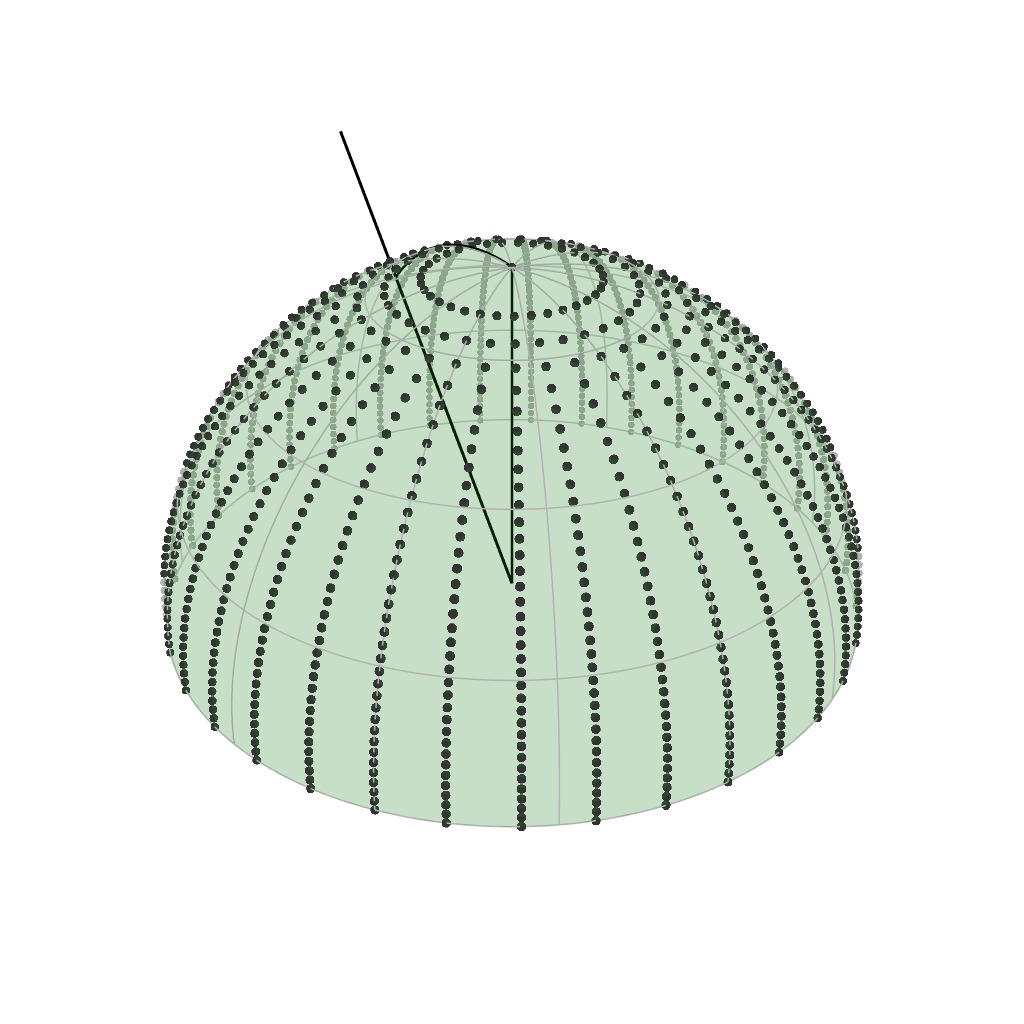

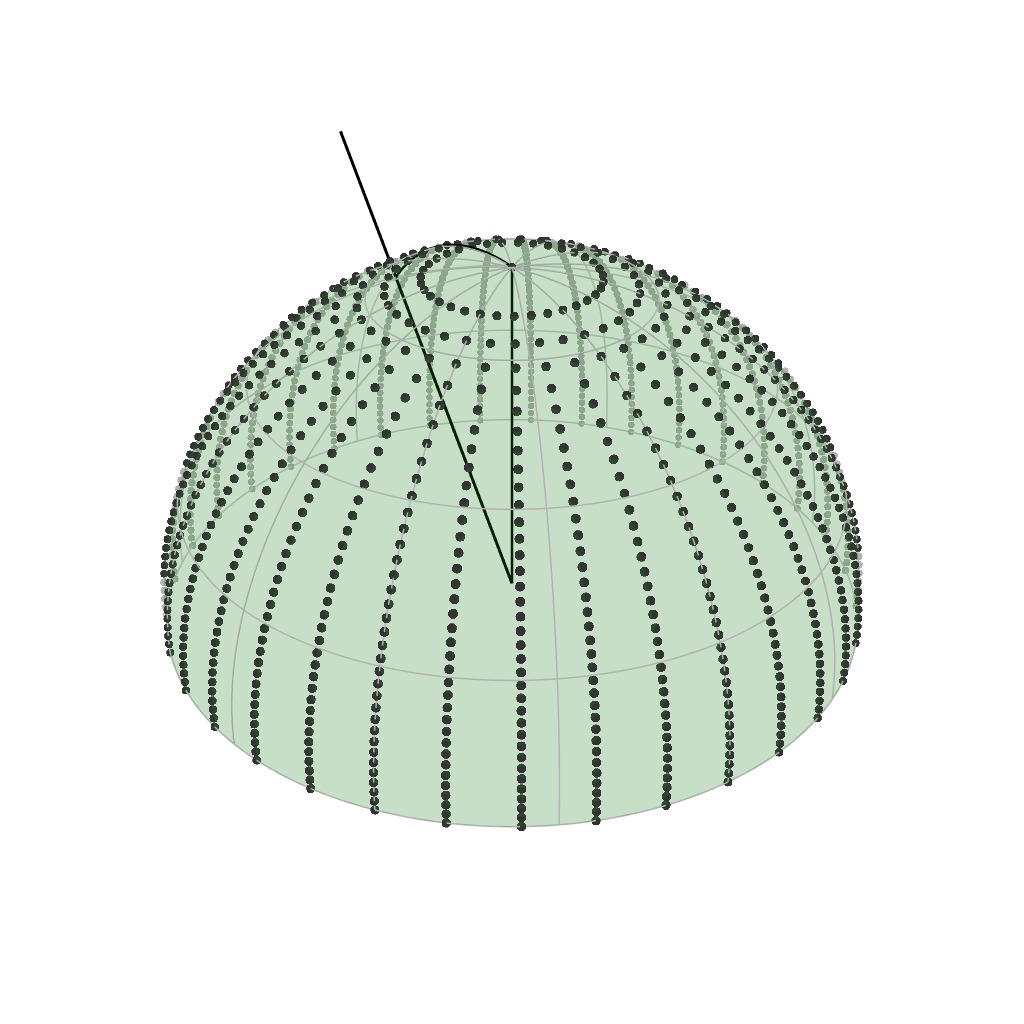

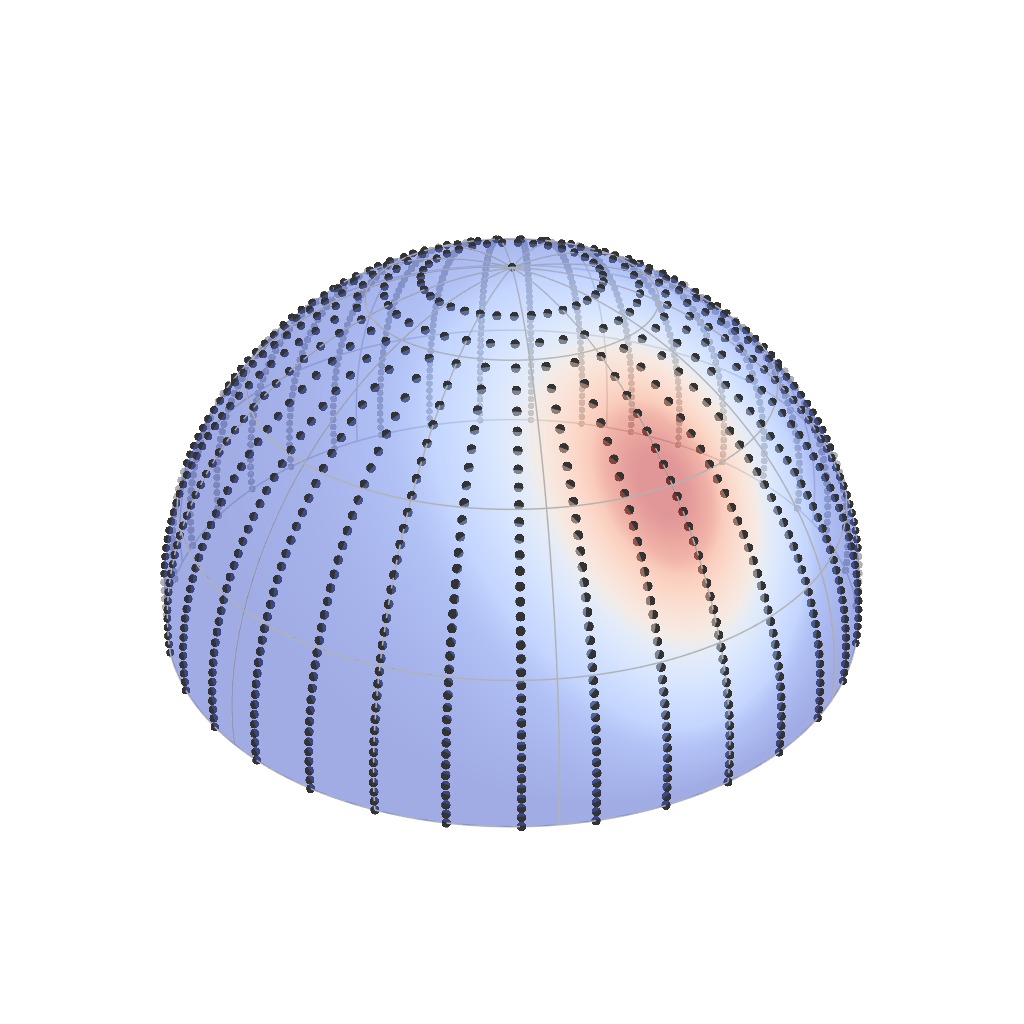

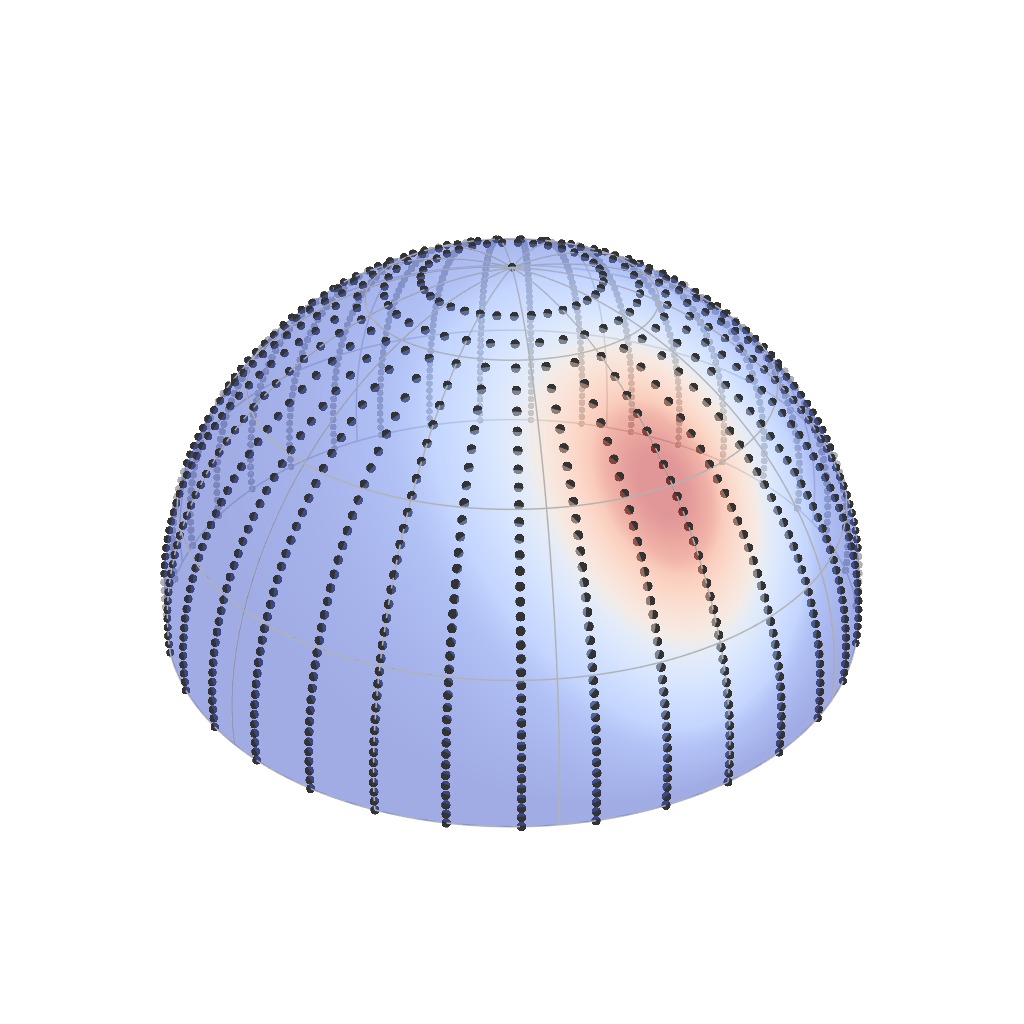

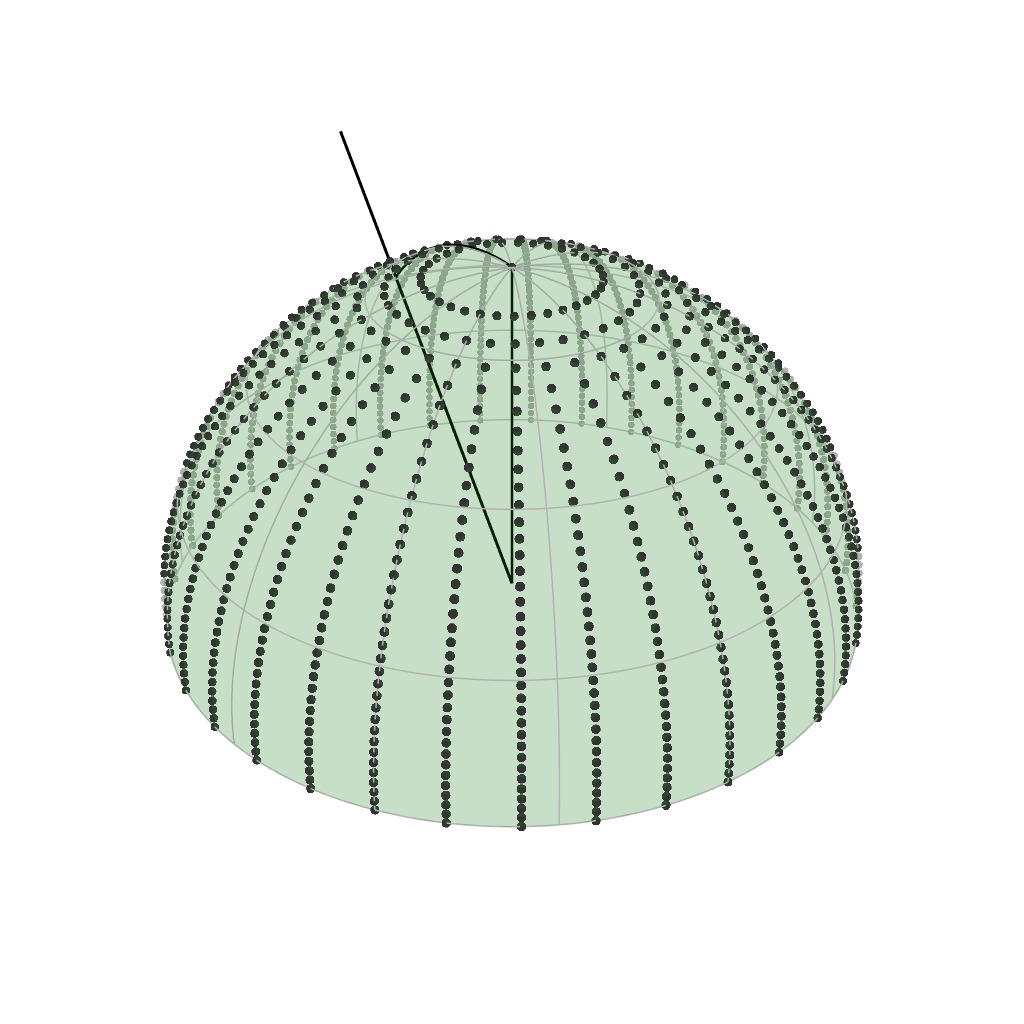

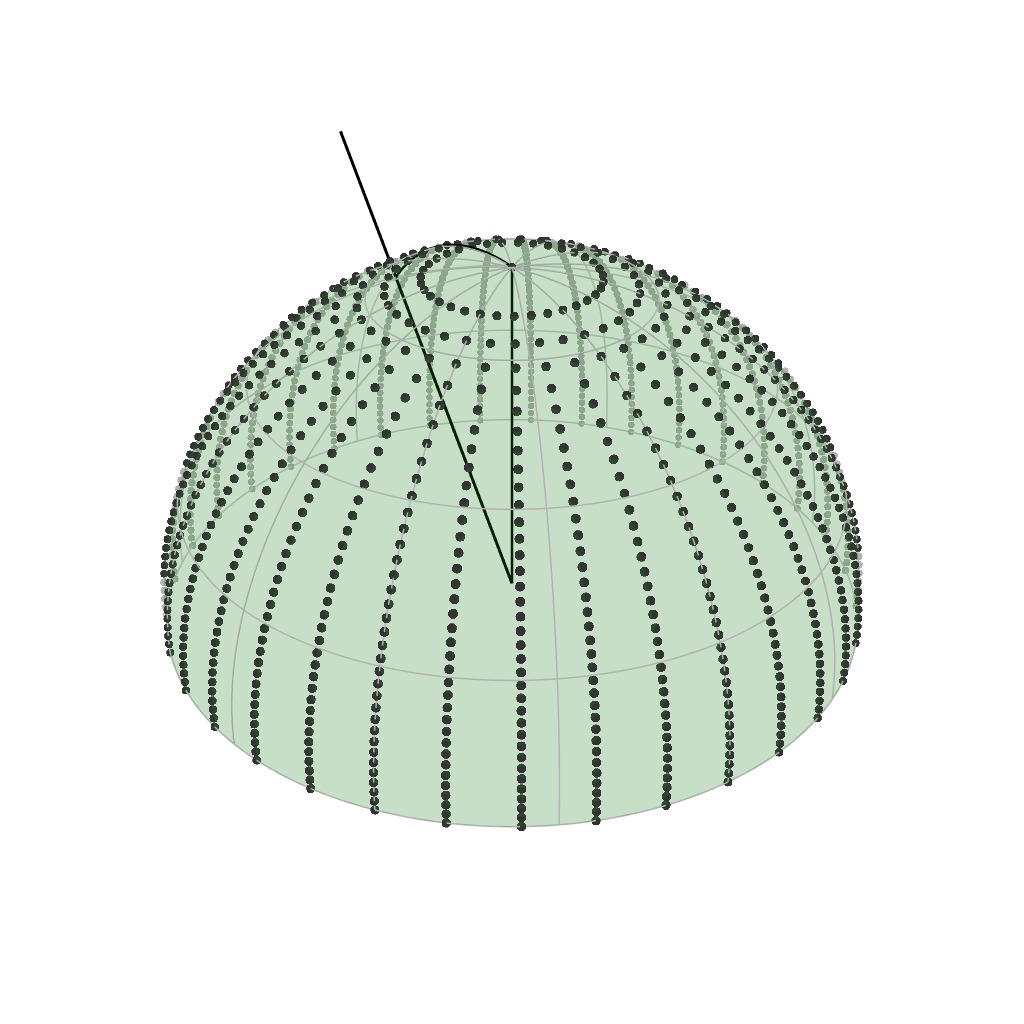

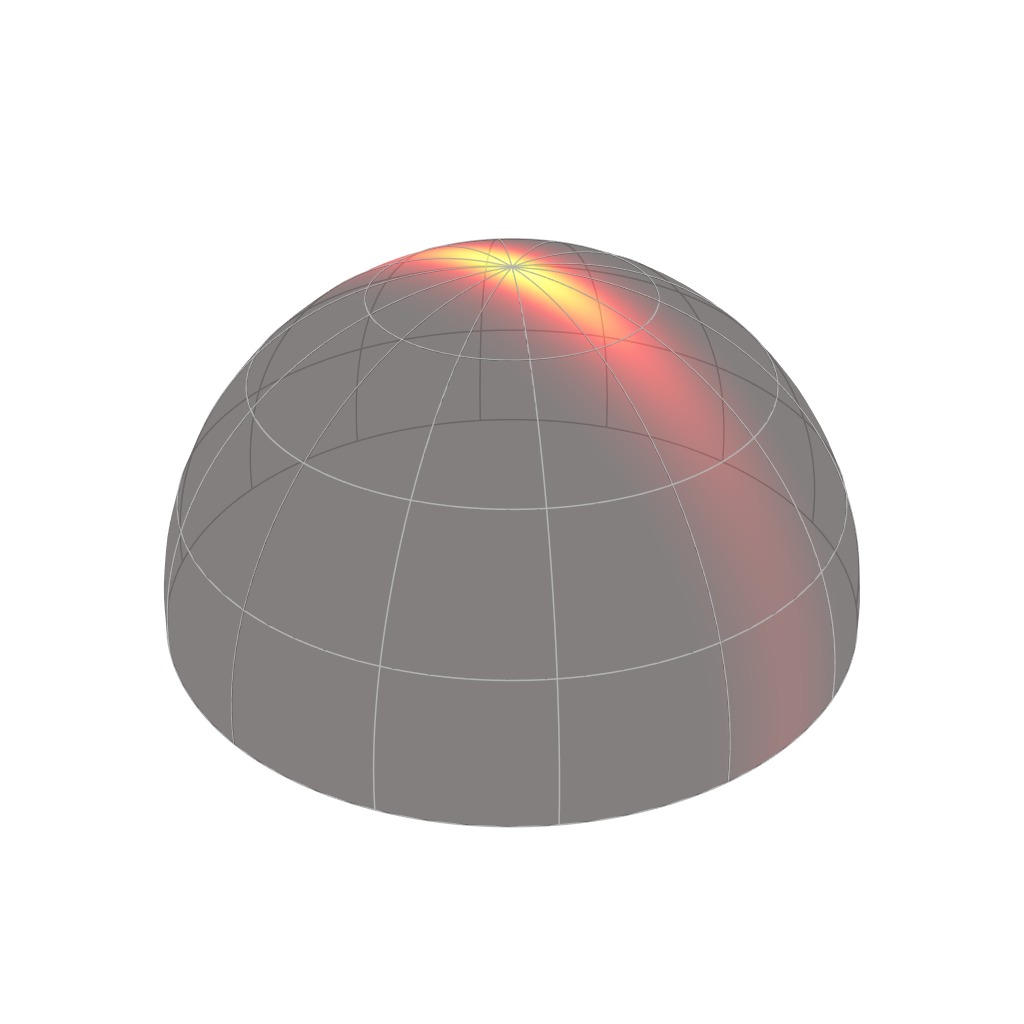

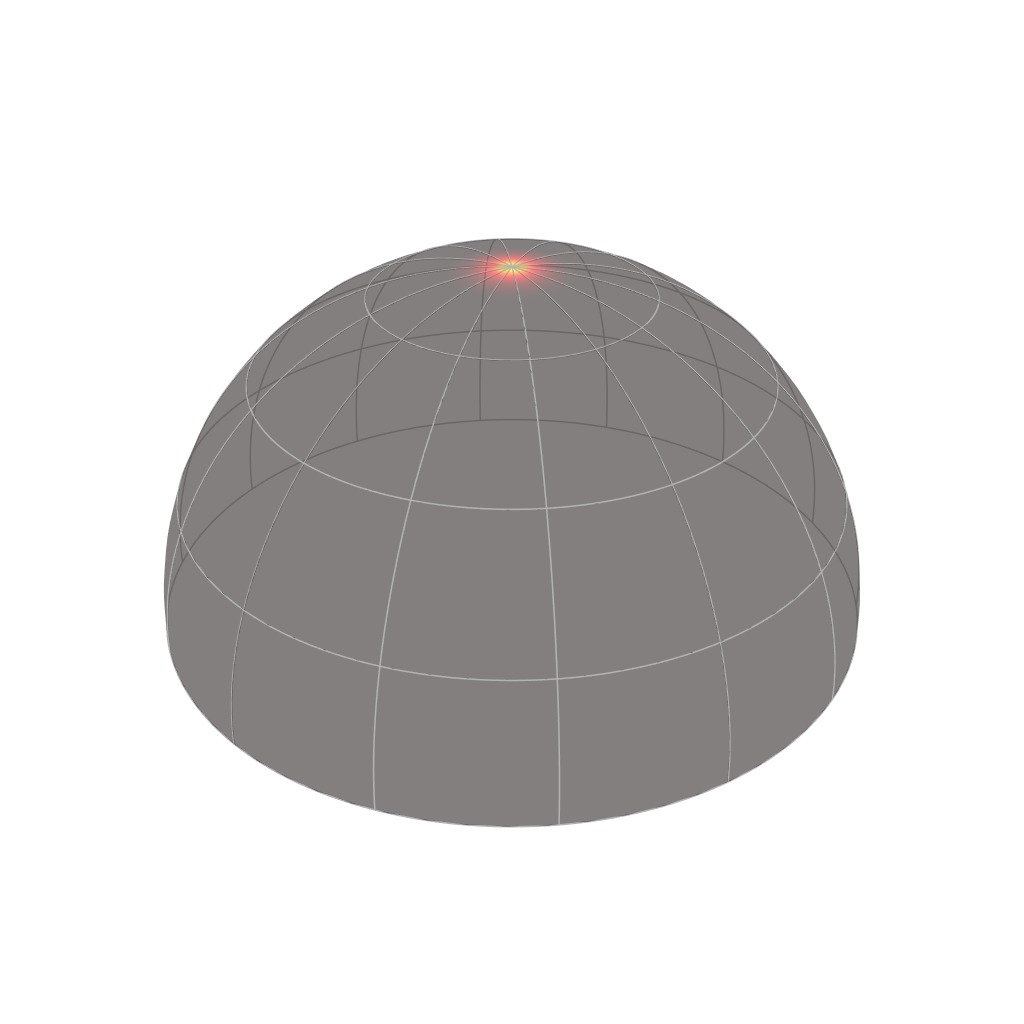

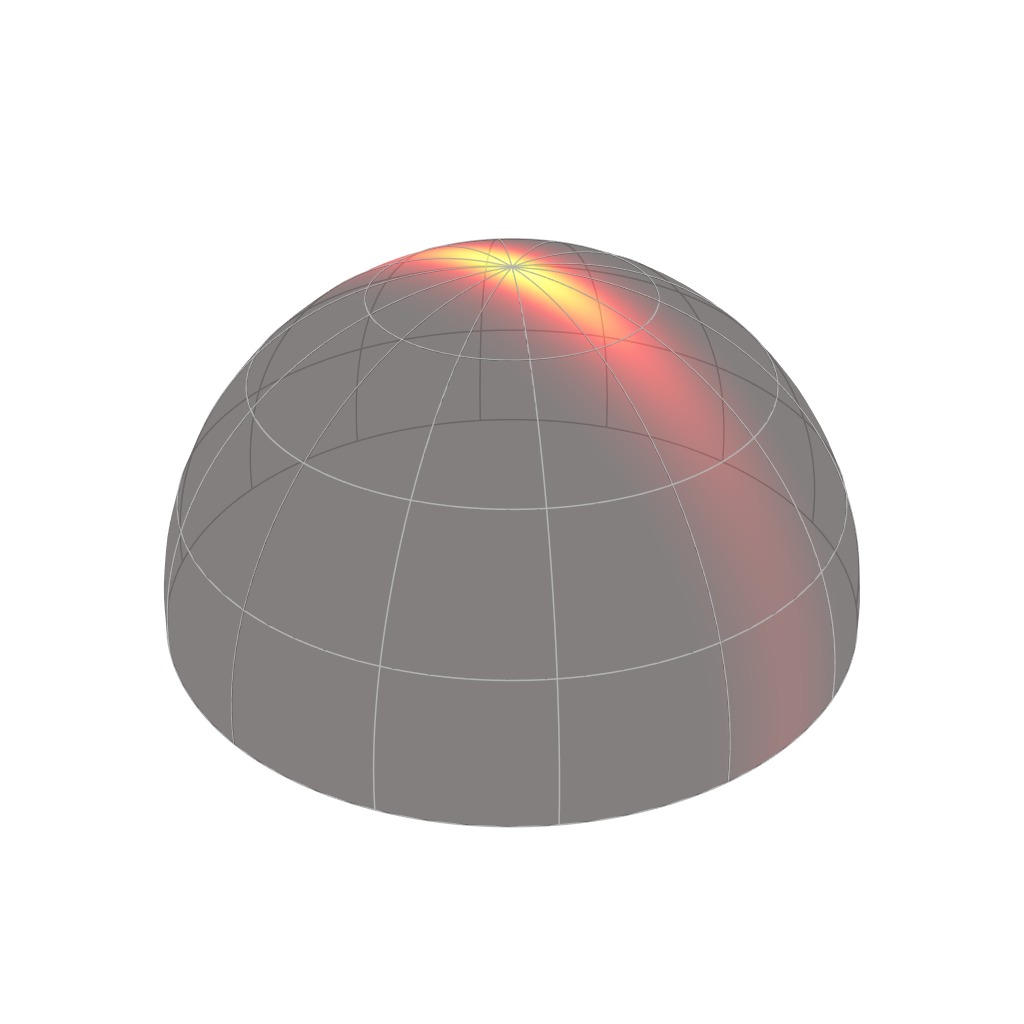

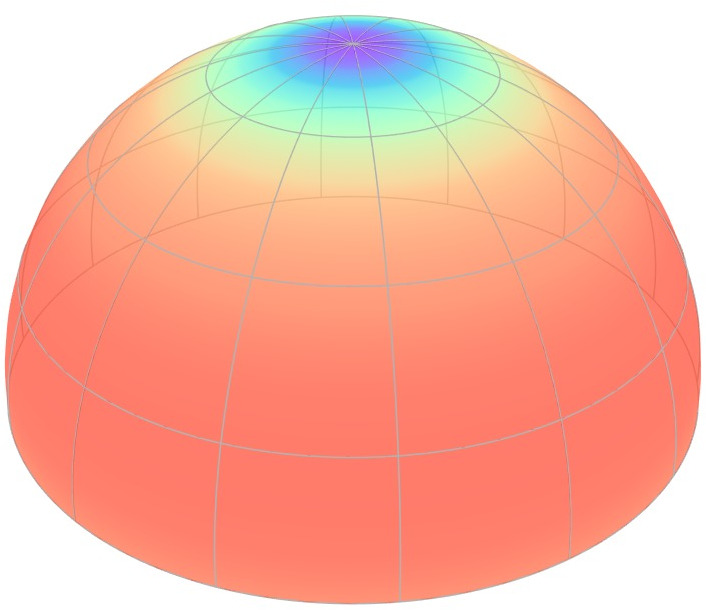

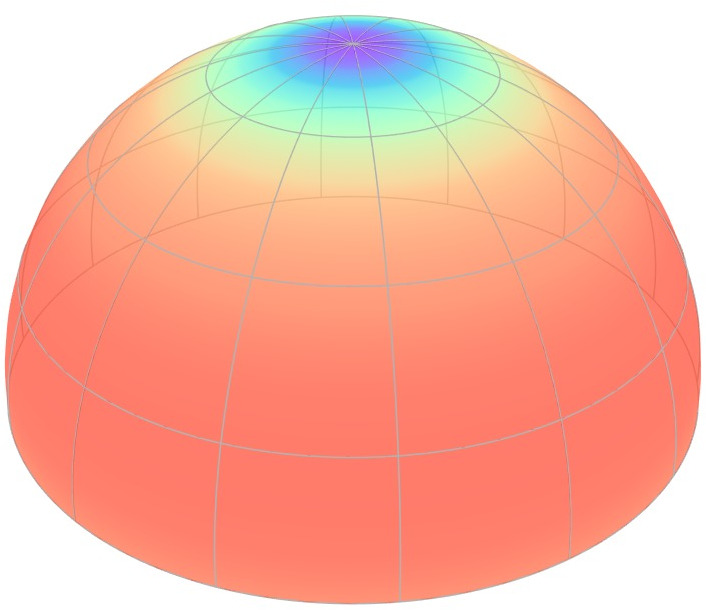

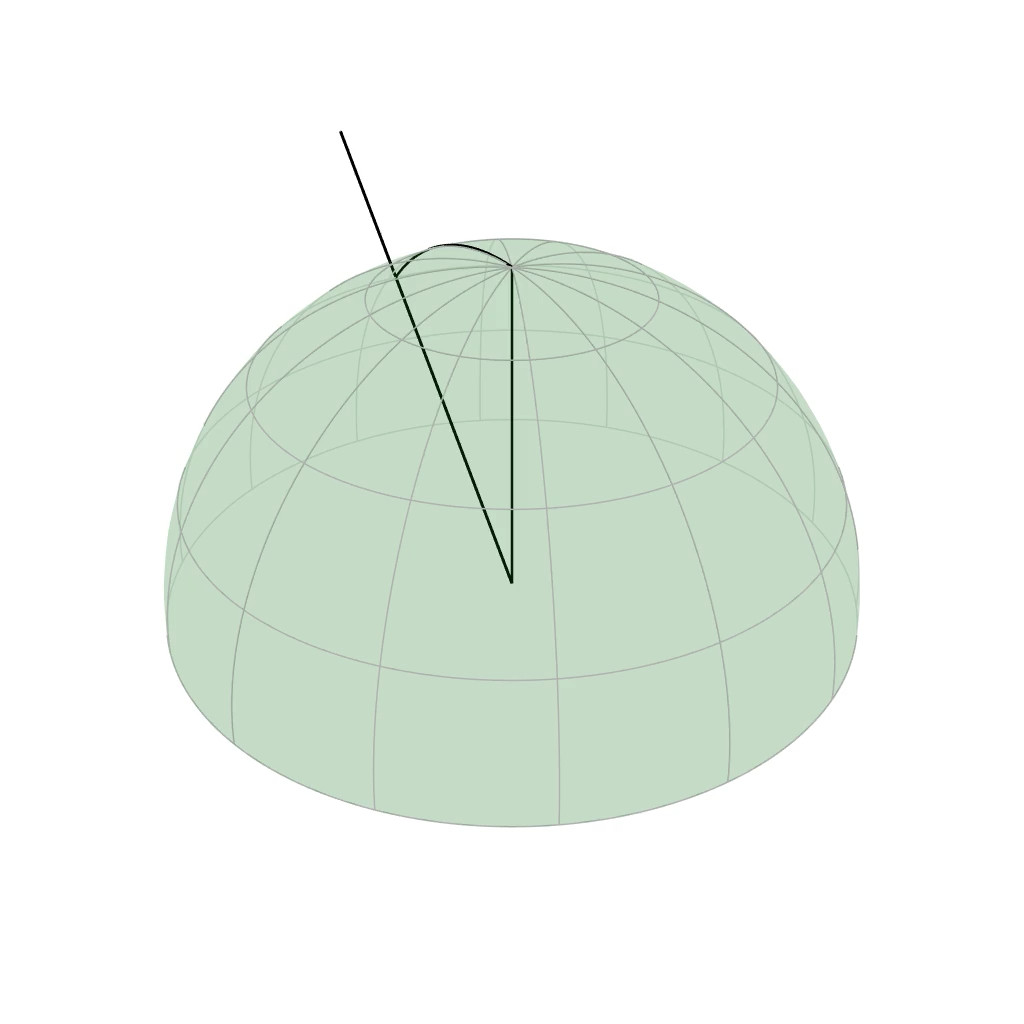

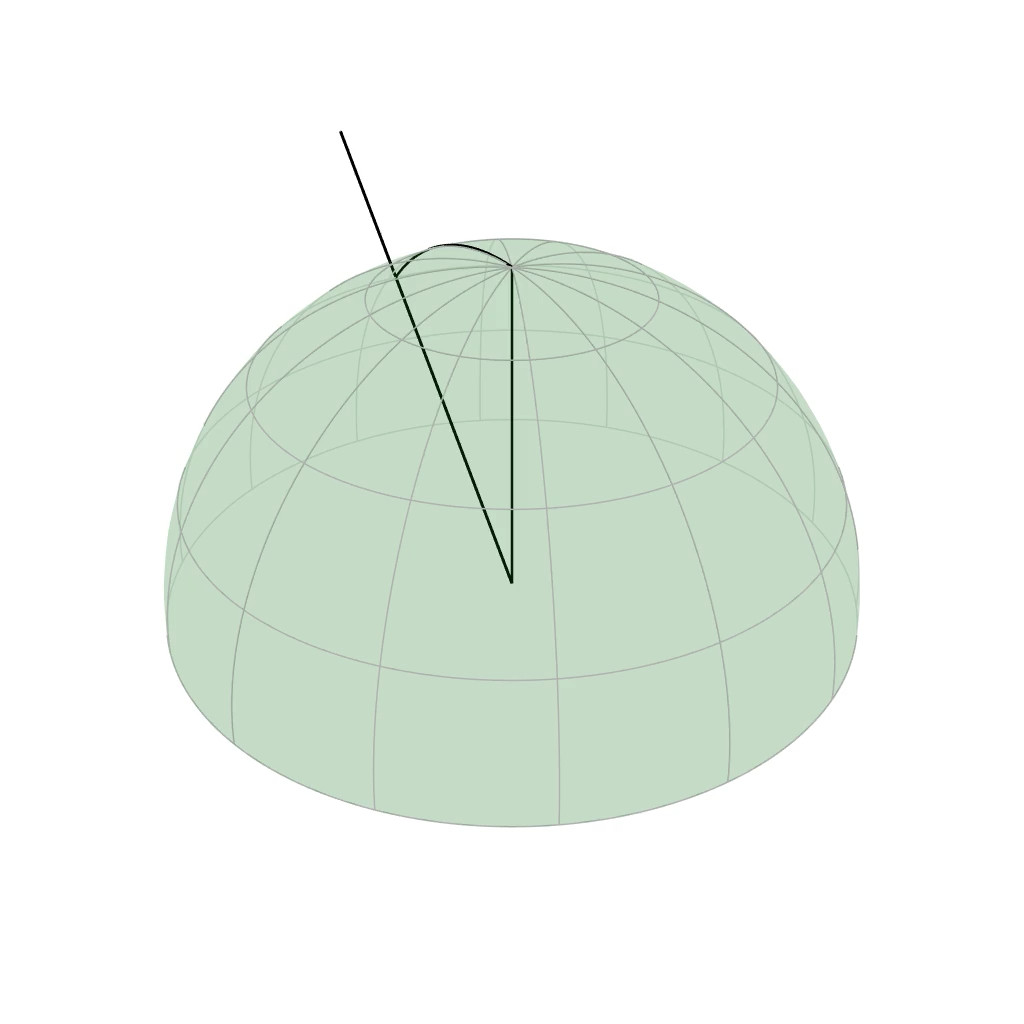

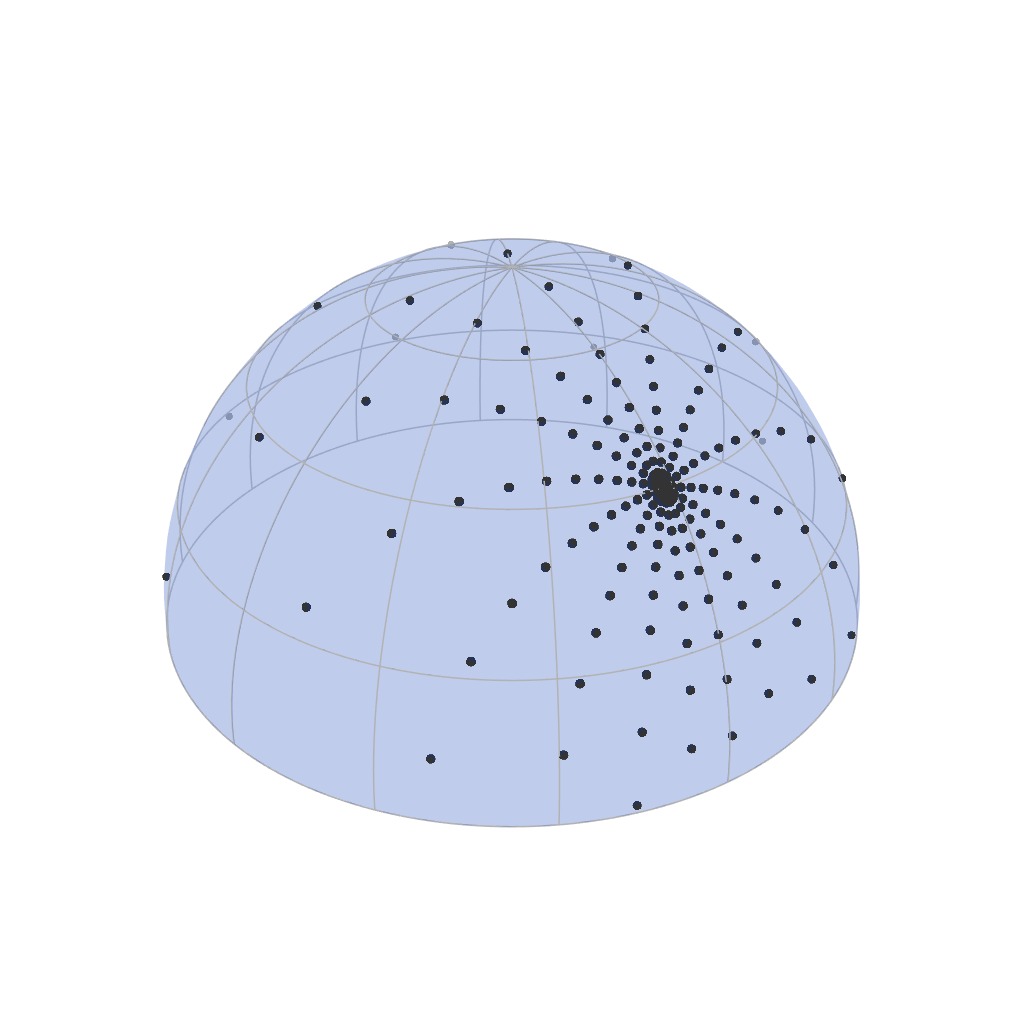

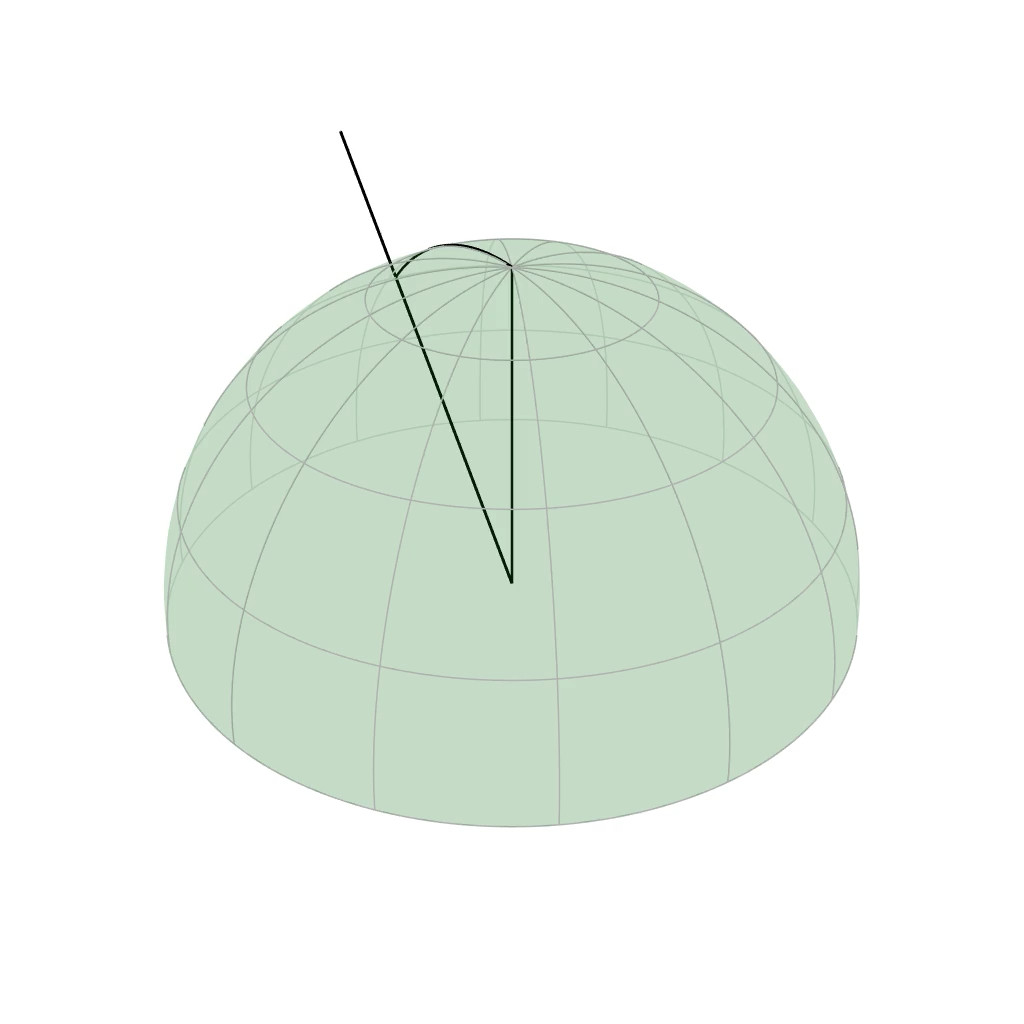

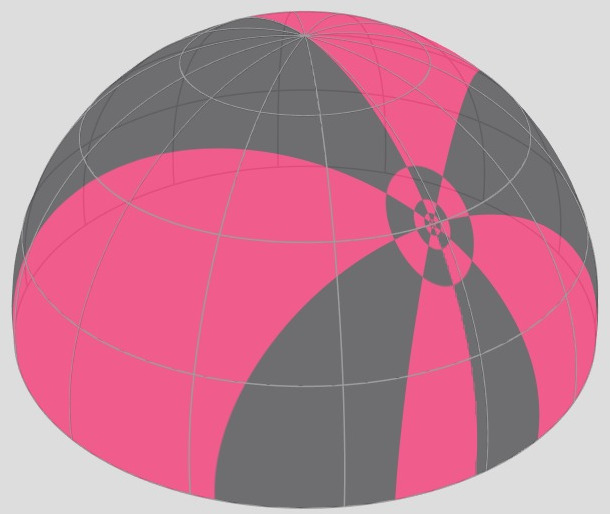

Incident domain

Outgoing domain

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

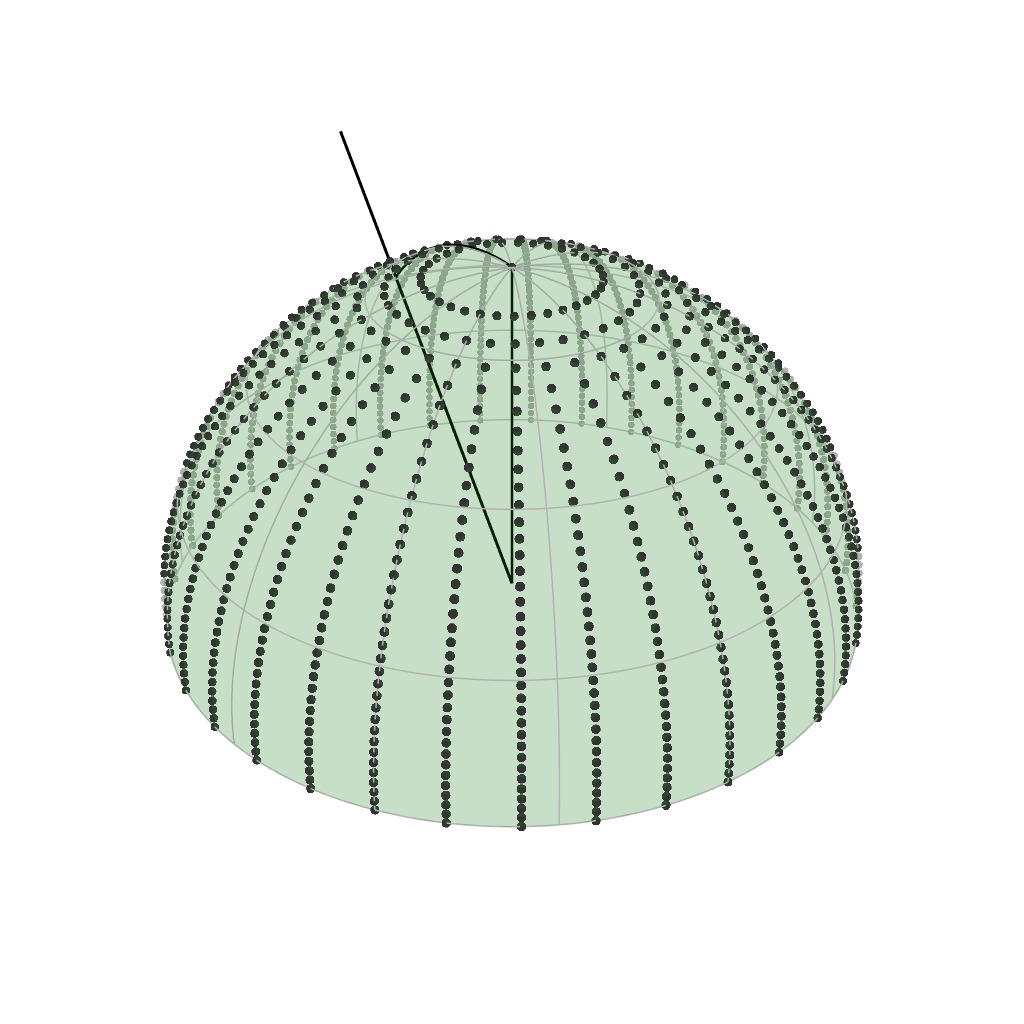

Here is an intuitive definition of the BRDF.

[click] a fixed incident direction, the BRDF describes how a

material scatters light for any [click] outgoing direction.

$$f_r^\perp = f_r(\boldsymbol{\omega}_i, \boldsymbol{\omega}_o, \lambda) \cos \theta_i$$

Your browser does not support the video tag.

Your browser does not support the video tag.

Incident domain

Outgoing domain

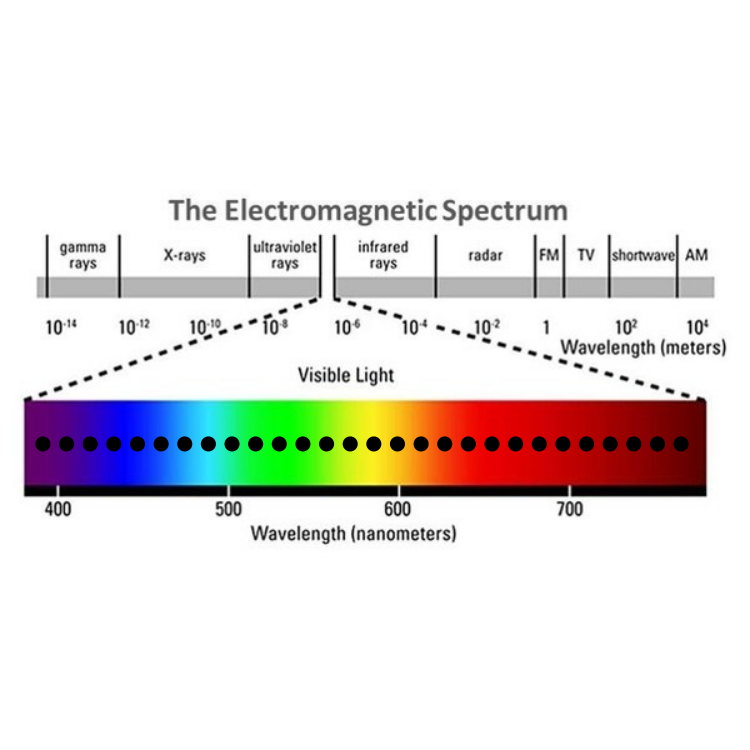

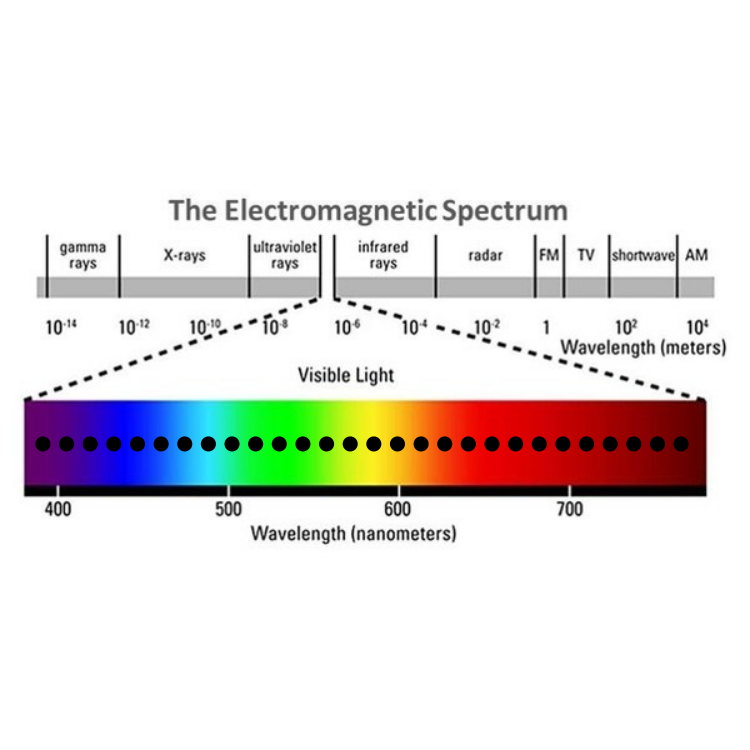

Wavelength

(varying)

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

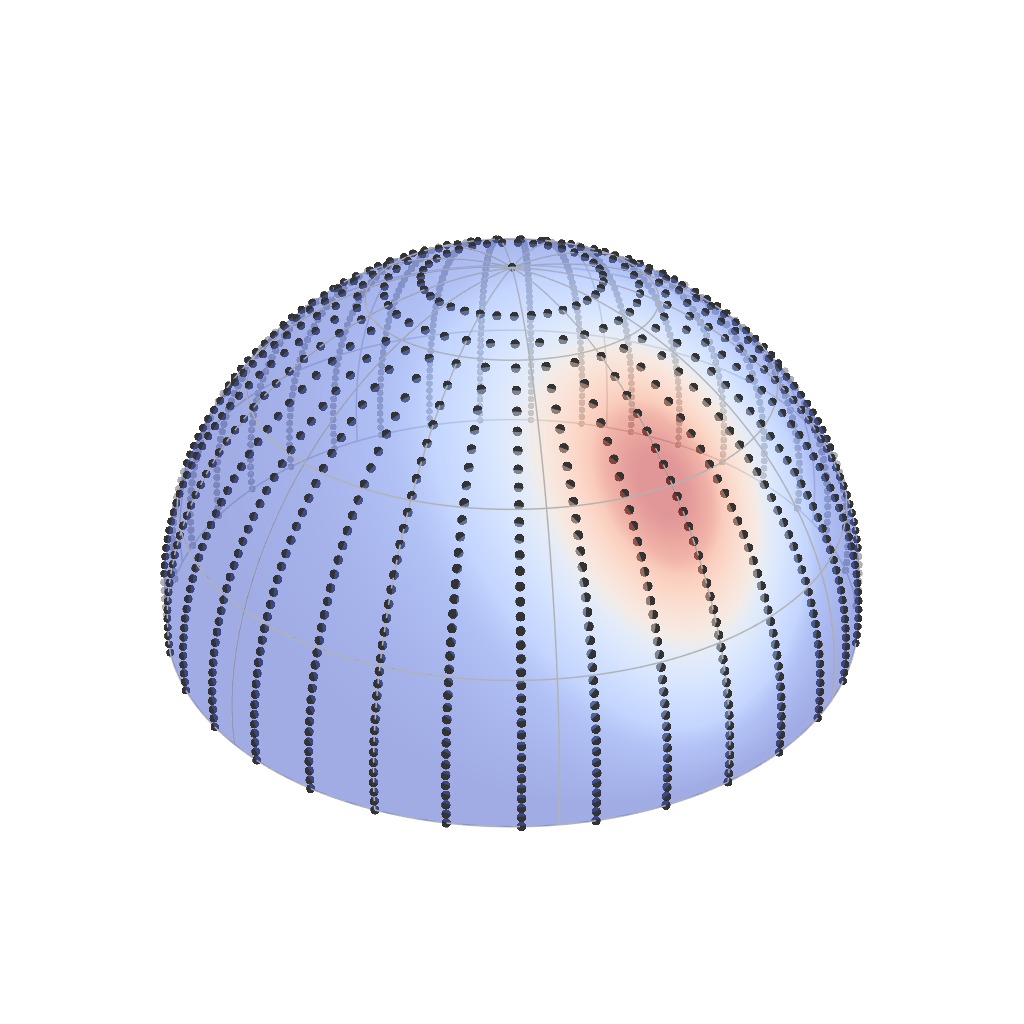

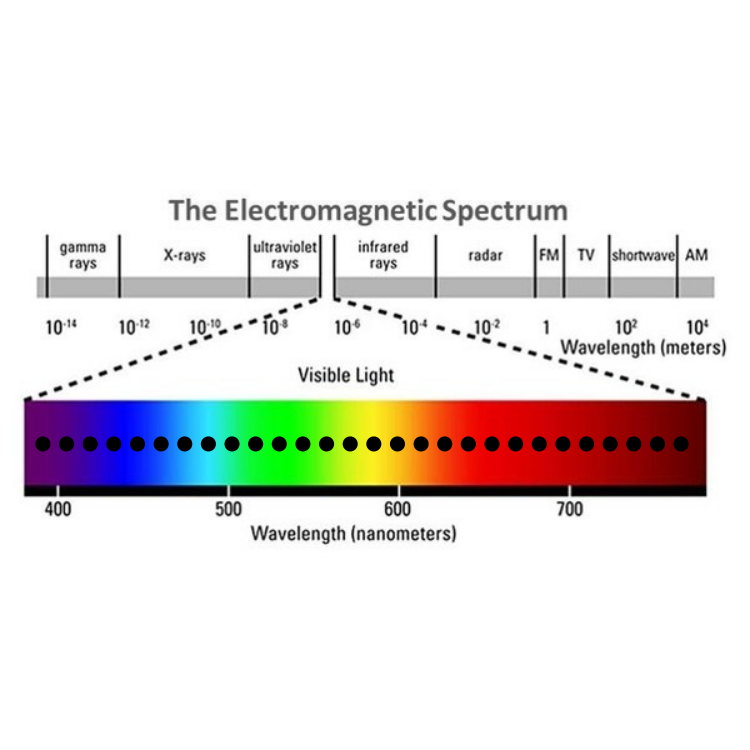

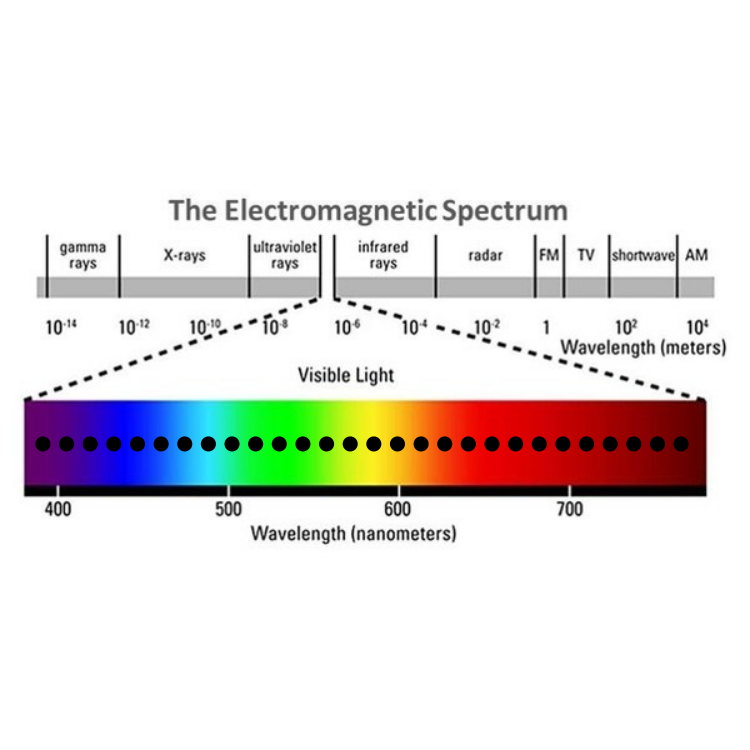

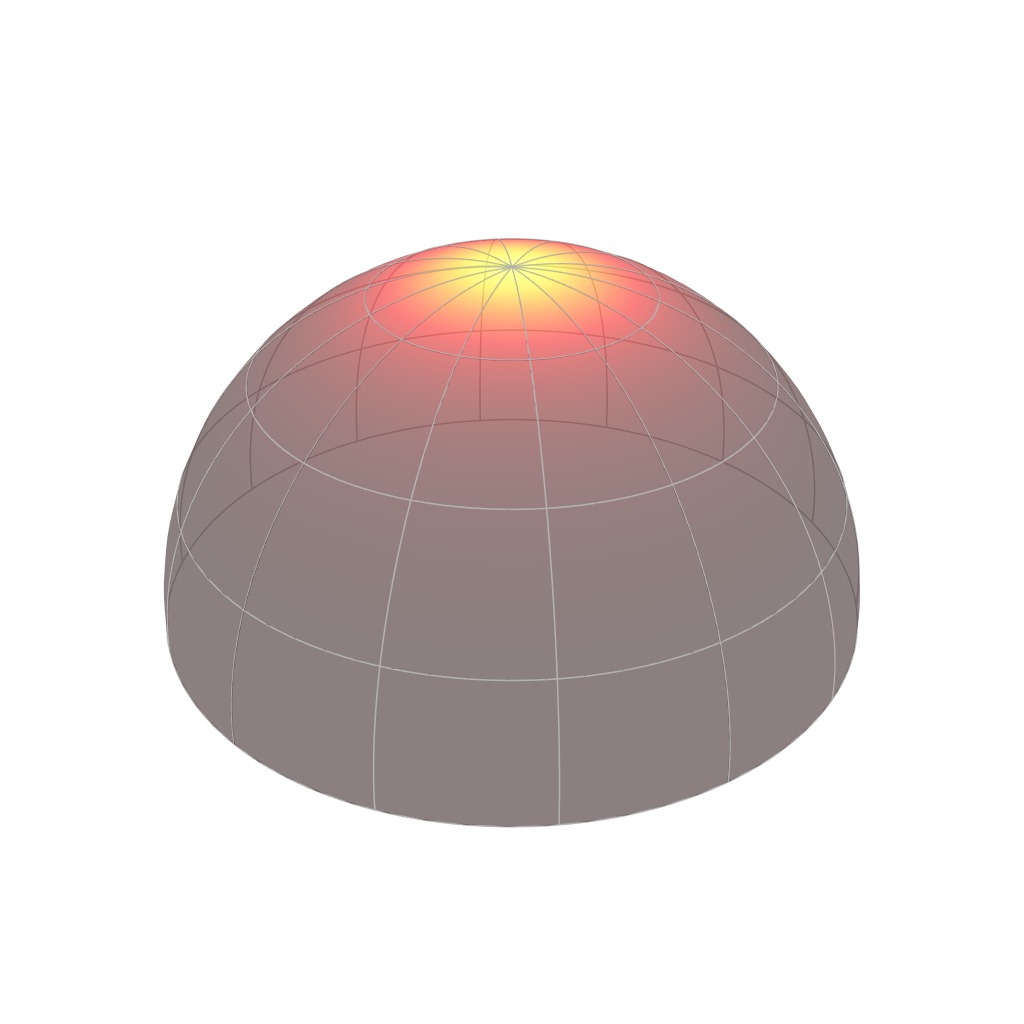

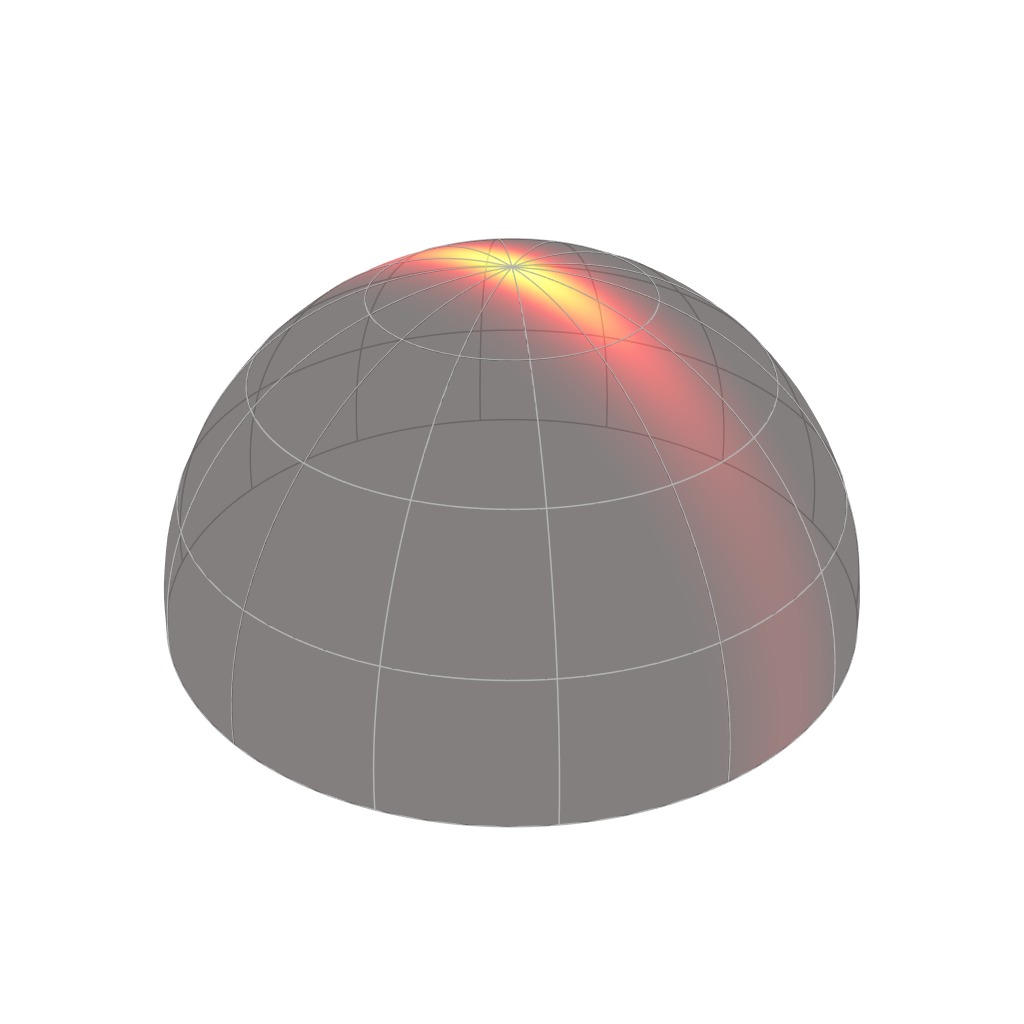

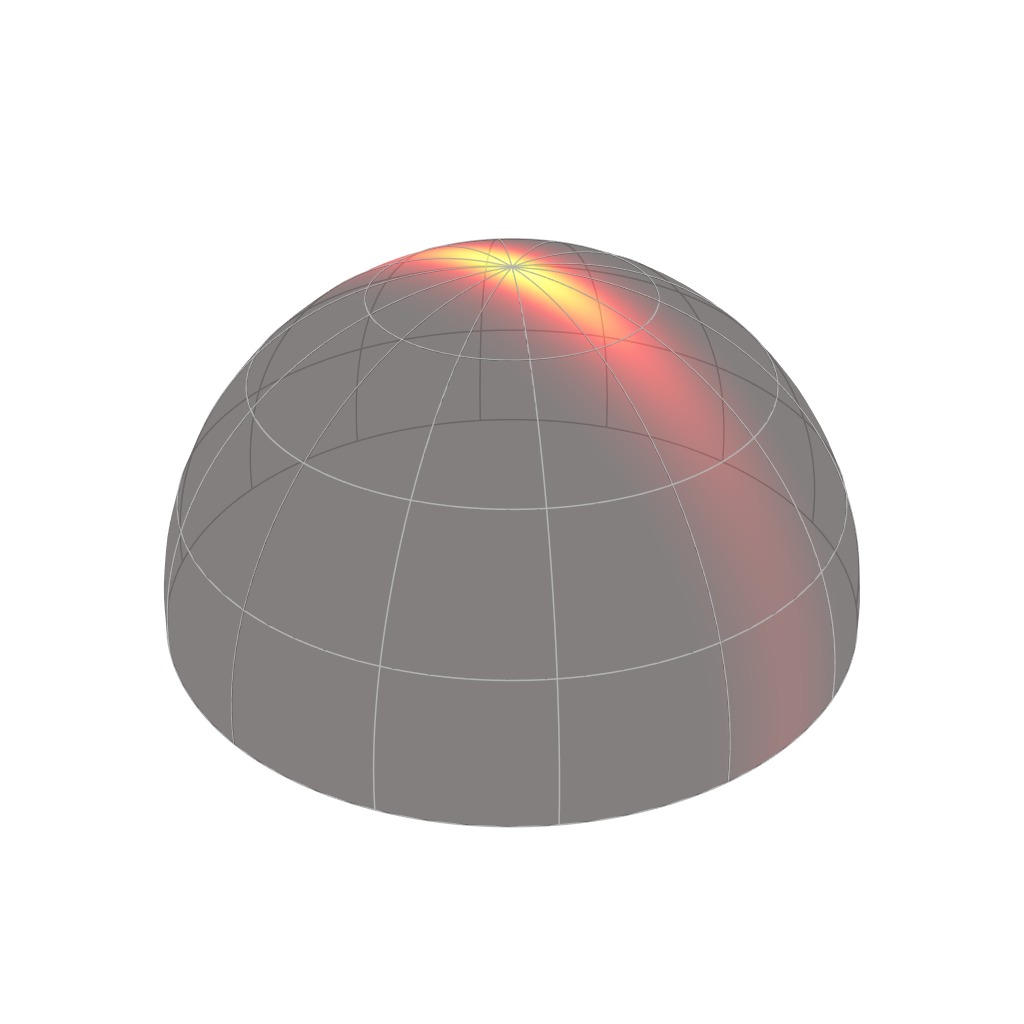

Note that the shape of these BRDF lobes also vary depending on the direction

of incident light, as well as [click] on the wavelength of this

particular incident light.

Motivation

Real character

Digital double

Solve $$L_o = \int_{\mathcal{S}^2} L_i \cdot {\color{red}f_r^\perp} \cdot d\boldsymbol{\omega}_i $$

Acquire ? $$f_r^\perp = f_r^\perp(\boldsymbol{\omega}_i, \boldsymbol{\omega}_o, \lambda) $$

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

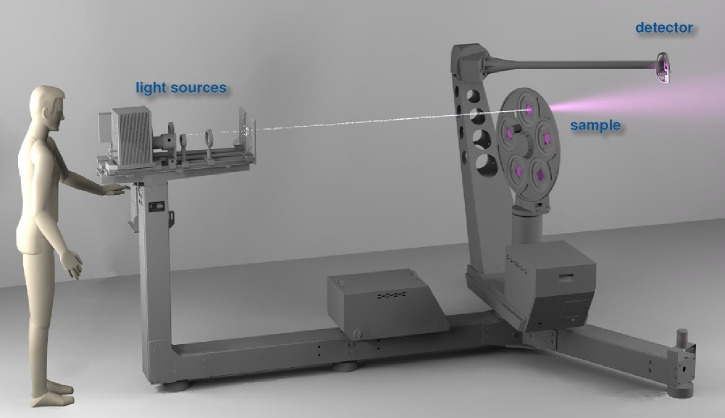

Given this definition, it is tempting to rely on [click] a

goniophotometer to actually measure how each material reacts to incident

lighting and simply use these measurements to solve the rendering equation.

Unfortunately, this was not possible until now, because such measurements

carried intractable difficulties that we will identify shortly.

Outline

What makes BRDF measurements difficult ?

A: Curse of dimensionality

How to lower the number of measurements ?

A: Image-based setup ? Use an adaptive parameterization

Is there a way to quickly characterize a material ?

A: We measure retro-reflection

Implementation details + results

Discussion

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

So why are such measurements so difficult ? In the remainder of this

presentation, we will see why and then [click] answer a series of

other questions that both describes the way we approached this problem,

and the ideas we introduce in the paper.

Problem

Incident domain

Outgoing domain

Wavelength

(2D)

(2D)

(1D)

The process of BRDF acquisition consists in exploring the high dimensional

manifold subtended by the definition of the BRDF...

Problem

Incident domain

Outgoing domain

Wavelength

(2D)

(2D)

(1D)

... and sampling each dimension so as to create a discrete version of it.

Problem

Incident domain

Outgoing domain

Wavelength

(2D)

(2D)

(1D)

✔

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

So really, this dimension is [click] not a problem in practice.

Outline

What makes BRDF measurements difficult ?

A: Curse of dimensionality

How to lower the number of measurements ?

A: Through BRDF Parameterization

Is there a way to quickly characterize a material ?

A: We look at retro-reflection

Implementation details + results

Results

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Now, having [click] identified this issue, our only hope in making

acquisition practical is to attenuate the effects of the curse of

dimensionality. How to do such a thing ?

[click] BRDF parameterization as a

means to drastically reduce the number of measurements.

BRDF Parameterization

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

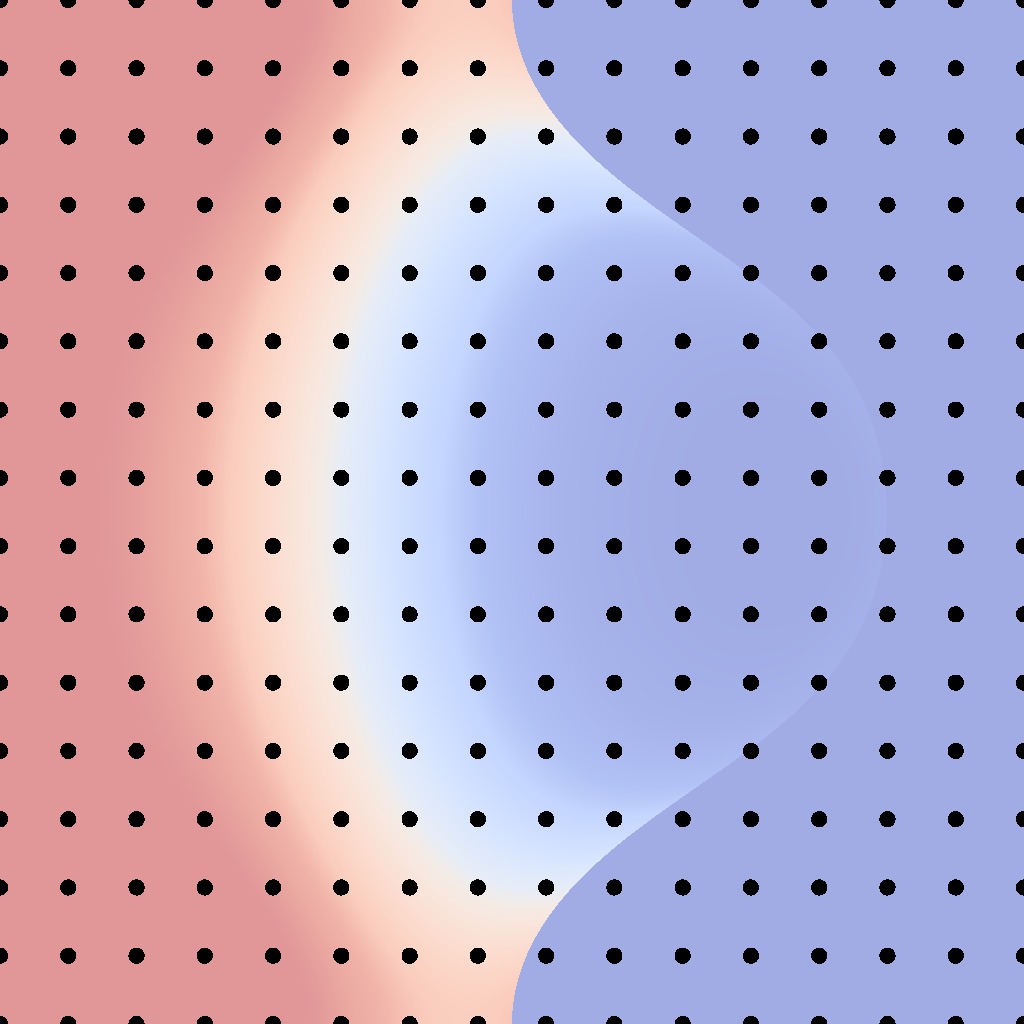

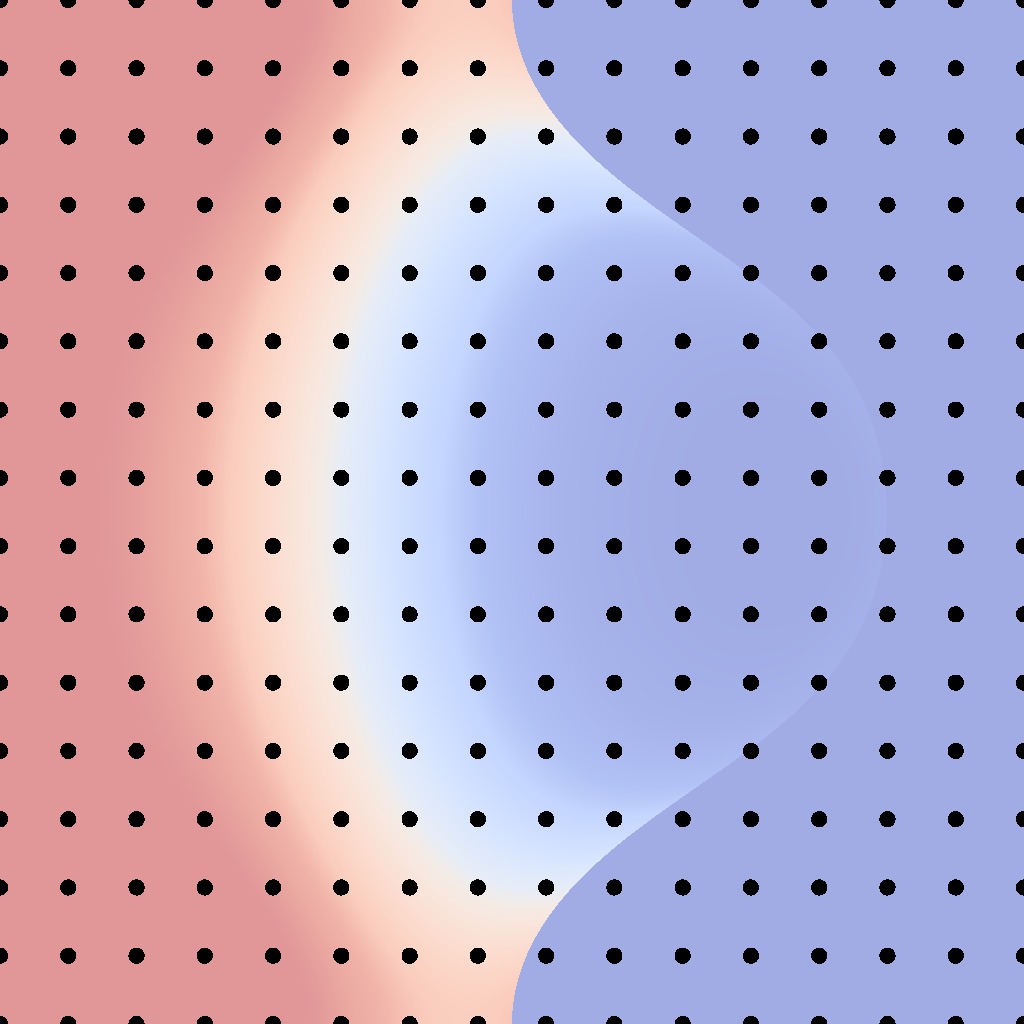

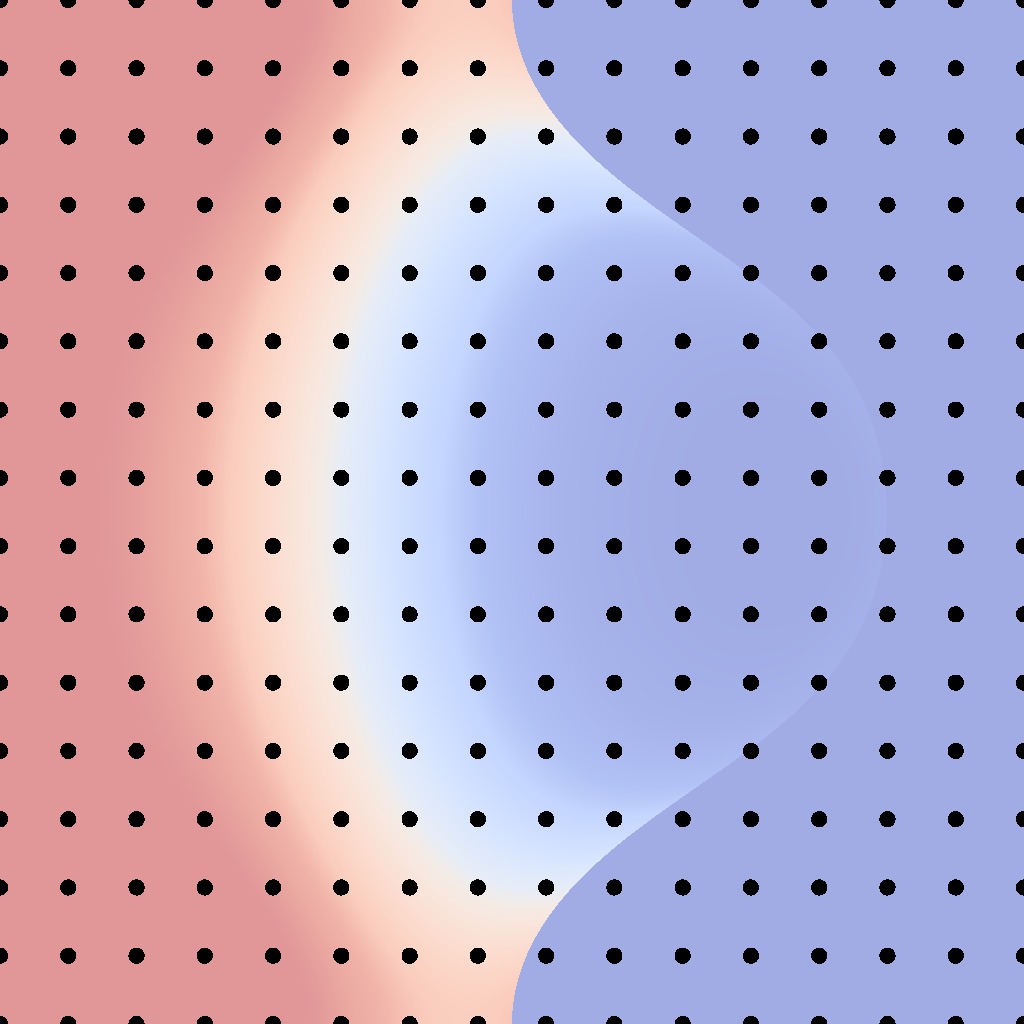

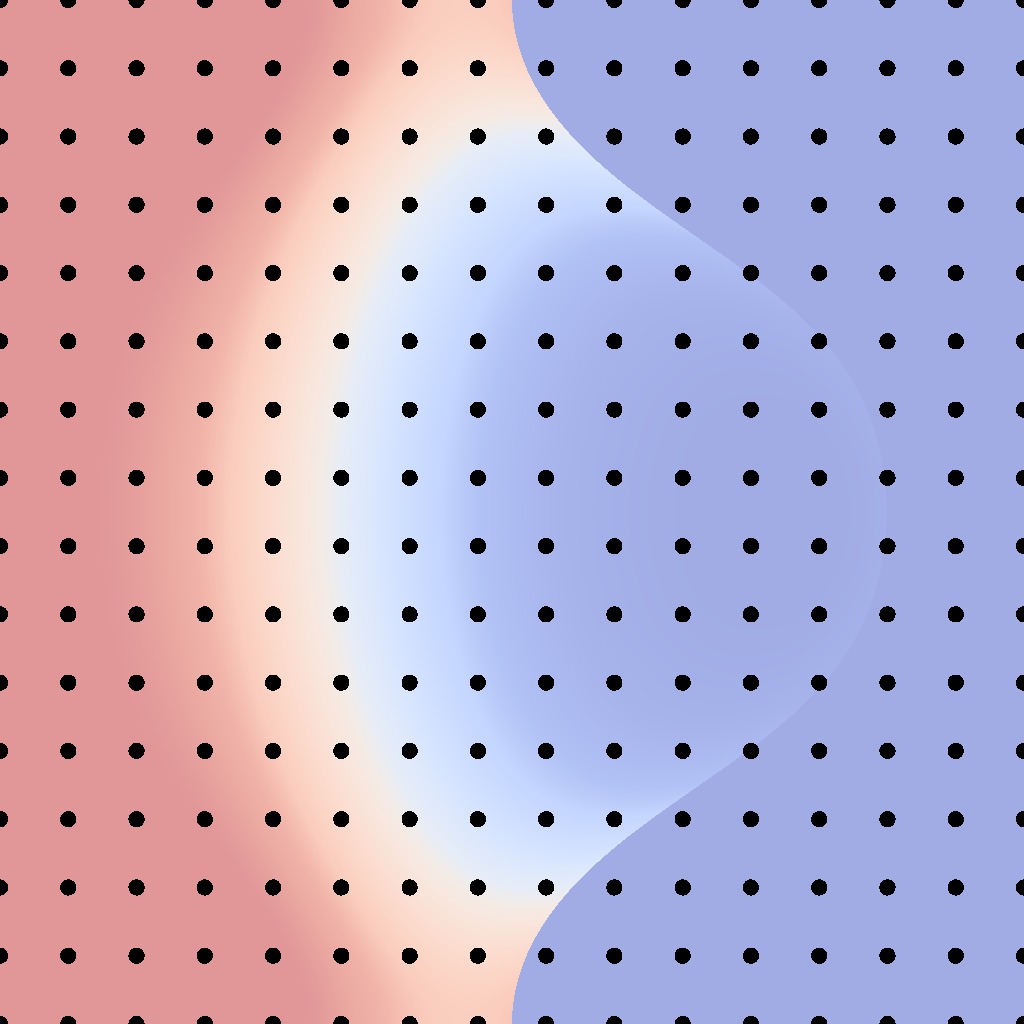

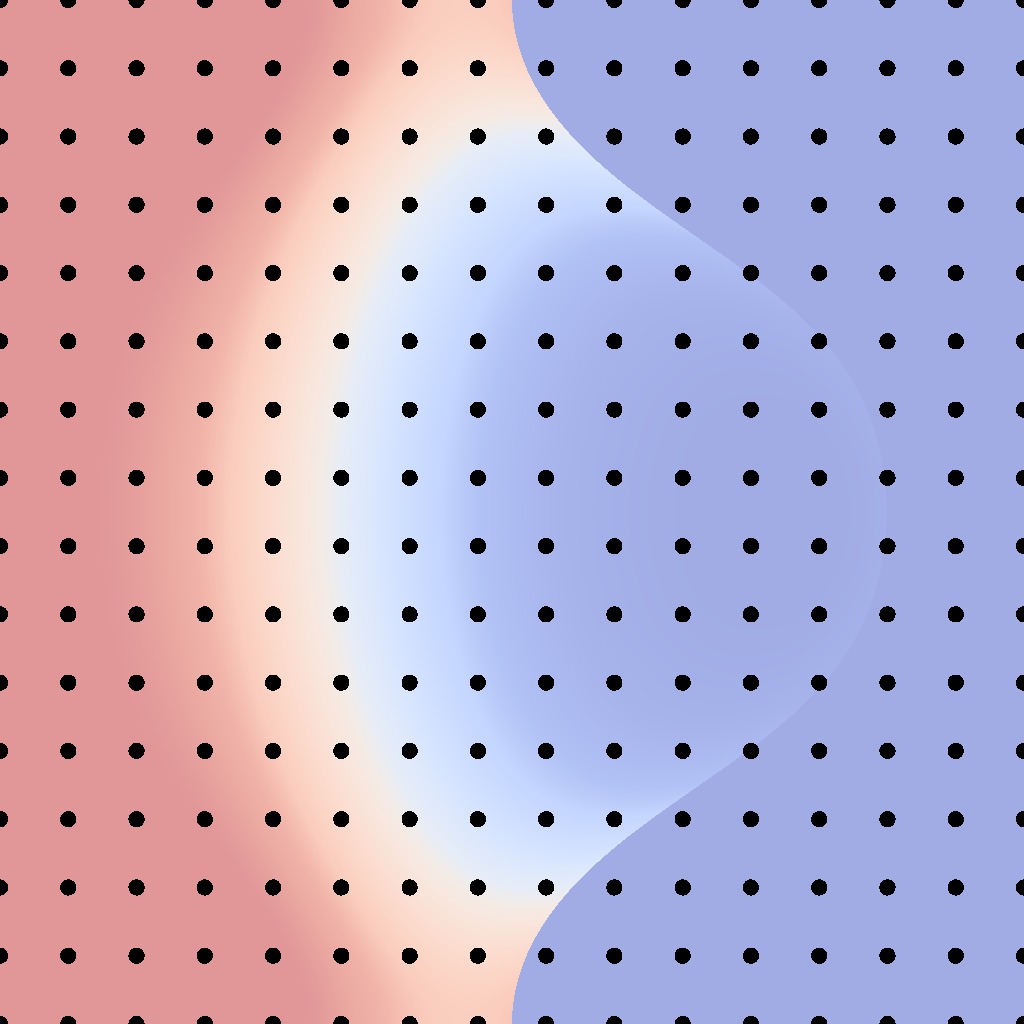

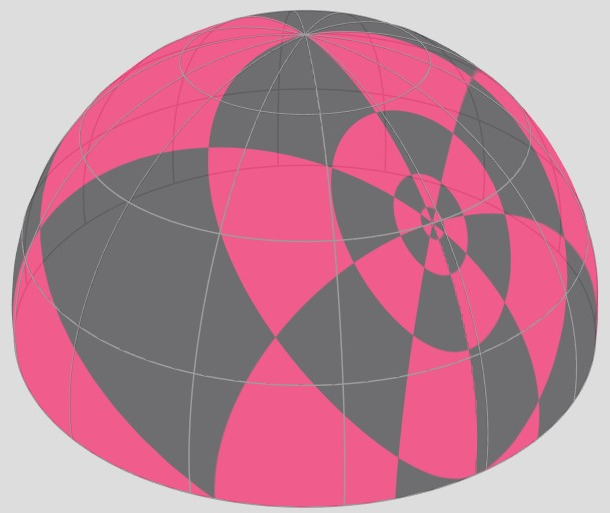

Intuitively, a parameterization is a way to look at a complex

object from a simpler one, typically a hypercube. For instance, a

parameterization of a BRDF's outgoing domain allows to visualize its

lobe inside [click] a square.

BRDF Parameterization

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

Sample count:

> 2x max frequency

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

The good thing about parametric space is that it gives us a bound for the

number of measurements we need to make. Specifically, the Nyquist limit tells

that we should sample parametric space at more than twice the highest frequency

of the lobe as seen from that space.

Rusinkiewicz [1998]

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

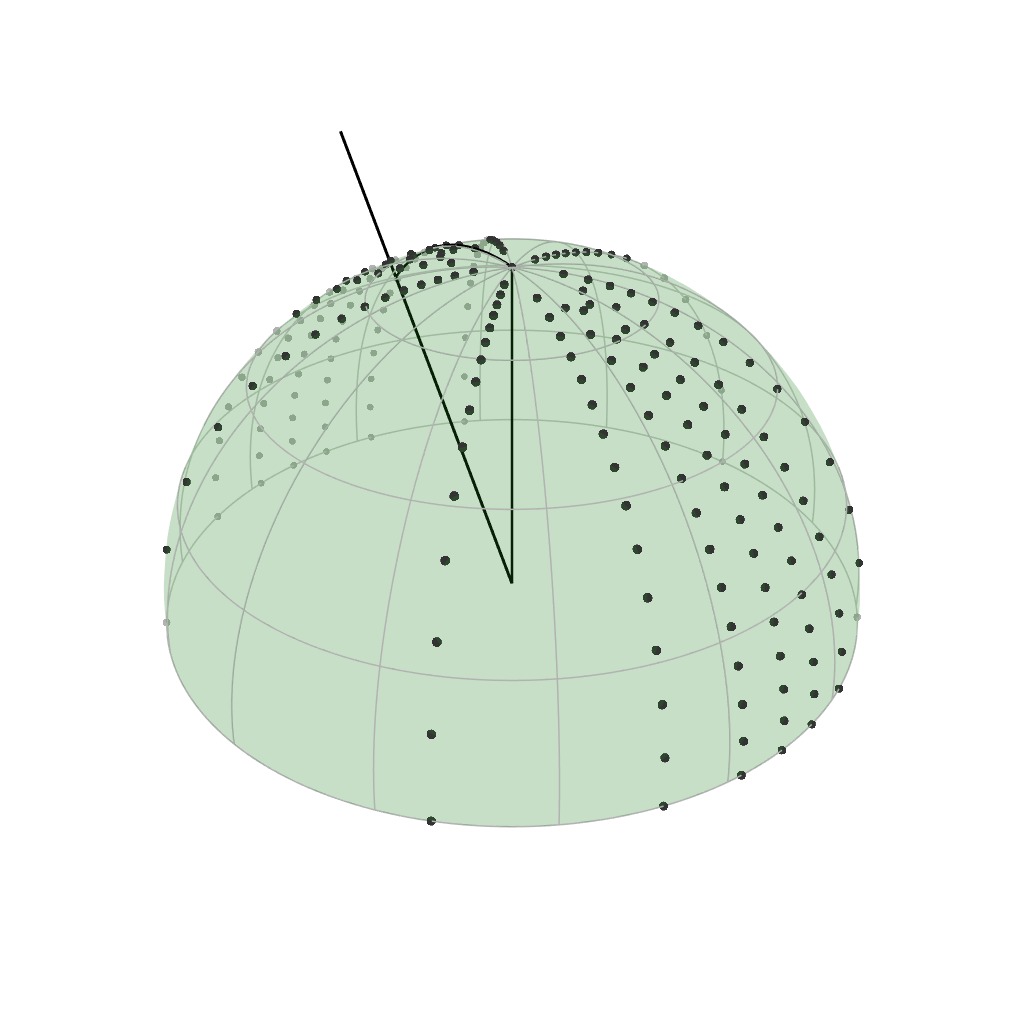

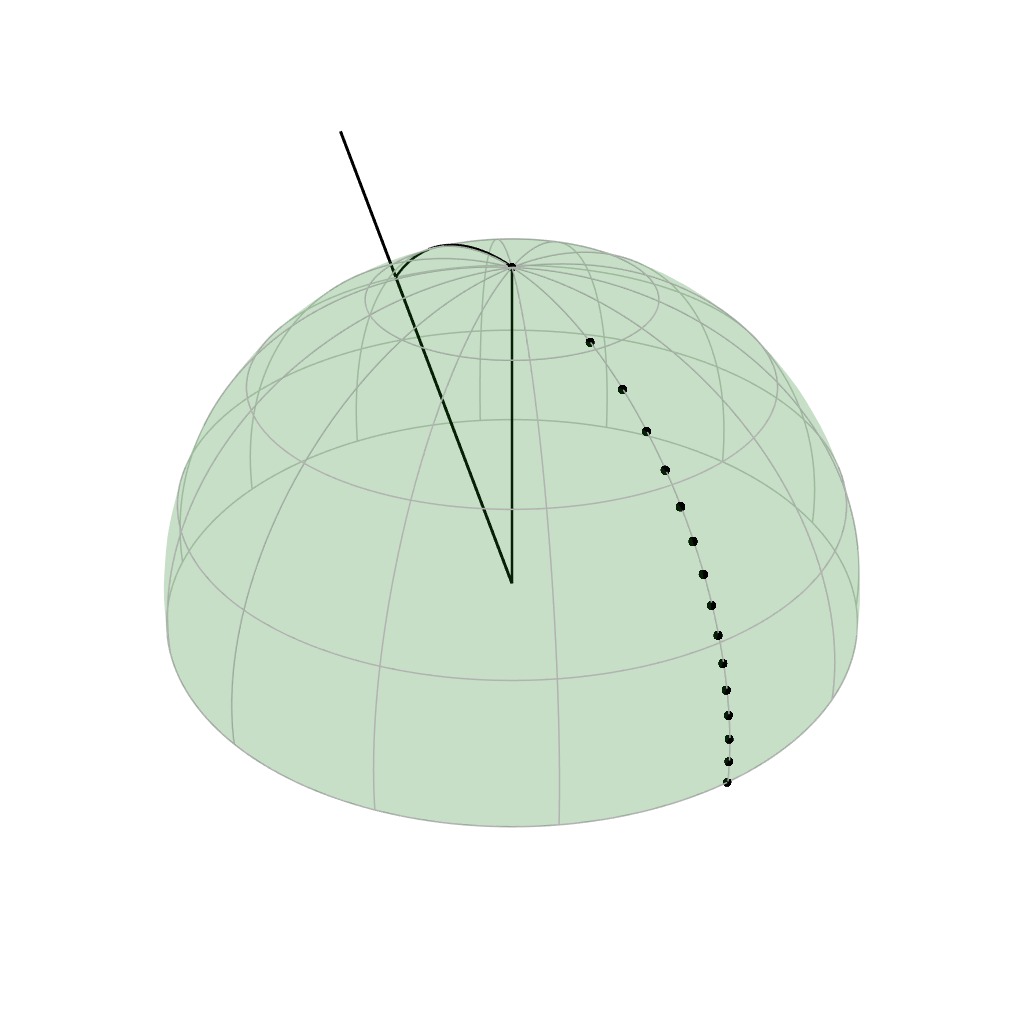

The Rusinkiewicz parameterization is a BRDF parameterization designed to do

just that. Based on the observation that BRDFs tend to peak around

the mirror reflection of the incident direction, the parameterization

places the samples around precisely this reflected direction.

Rusinkiewicz [1998]

Your browser does not support the video tag.

Your browser does not support the video tag.

Your browser does not support the video tag.

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

Here is an animation that shows how the samples vary as the incident

direction changes. Notice how the samples are always concentrated around

the mirror reflection of the incident direction.

MERL [Matusik et al. 2003]

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

Despite these limitations, the Rusinkiewicz parameterization was

used to create the MERL database, which, up until now, was the only

all-frequency BRDF database publicly available.

MERL [Matusik et al. 2003]

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

Because the Rusinkiewicz parameterization is far from perfect, it still

incurs quite a lot of measurements. To further lower this constraint,

the azimuthal dimension of incident directions was dropped. This is

acceptable if the materials under measurement are isotropic, i.e.,

they carry a radial symmetry.

Isotropic BRDFs

Your browser does not support the video tag.

Your browser does not support the video tag.

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

(azimuthal symmetry)

Such a symmetry is illustrated in this animation. Notice how the shape of the

BRDF lobe is invariant to azimuthal rotation of the incident direction.

MERL [Matusik et al. 2003]

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

90x90x180 resolution:

xx

16 days

x

[1 meas/s]

12 MiB

per wavelength

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Under these assumptions, each material of the MERL database was acquired

at [click] 90x90x180 resolution, which corresponds to 1,458,000

measurements.

[click] 16 days,

which is already much better than 3+ years, but still too much to

be really practical (hence the orange color).

MERL [Matusik et al. 2003]

Spherical samples

Image-based setup

90x90x180 resolution:

xx

3 hours

x

[135 meas/s]

12 MiB

per wavelength

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Because 16 days was still too much, Matusik et al. had a very clever idea

to further reduce these acquisition times.

[click] spherical samples, and then

built a custom [click] acquisition device based on a camera that would

take pictures of the spheres under different lighting conditions. By taking

pictures of spheres, they cover a large portion of the directional domain at

once, which strongly reduces acquisition times.

[click] 3

hours for one material, which is a huge improvement!

Outline

What makes BRDF measurements difficult ?

A: Curse of dimensionality

How to lower the number of measurements ?

Is there a way to quickly characterize a material ?

A: We look at retro-reflection

Implementation details + results

Results

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Given such speed-ups, one may be tempted to actually follow such a setup.

Could such [click] image-based setups be the solution to BRDF acquisition ?

It turns out that this is not the case.

MERL [Matusik et al. 2003]

Spherical samples

Image-based setup

Fundamental limitations

Isotropic BRDFs only

Recquires spherical samples

Artifacts due to camera

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

The reason is because the MERL setup, while extremely fast, carries a

number of fundamental limitations.

[click]

isotropic materials. While such materials cover a wide range of real-world

materials, anisotropy is also important for e.g., fabrics or brushed metals.

[click] samples, which

are actually quite hard to manufacture and hence procure.

[click] artifacts, such as lens flare effects.

MERL [Matusik et al. 2003]

Spherical samples

Image-based setup

Fundamental limitations

Isotropic BRDFs only

Recquires spherical samples

Artifacts due to camera

source: [Lucat et al. 2017]

Here is an example of such an artifact. Note that this image is taken from a

recent work by Lucat et al. aiming at reproducing the setup of

Matusik et al. who were also directly confronted to these difficulties.

MERL [Matusik et al. 2003]

$\,$

$\,$

$\,$

$\,$

$\,$

$\,$

The MERL database is known to carry artifacts that can manifest in renderings

such those shown here. Notice the color-oscillations or the silver-lining

effects at grazing angles present on these MERL materials.

Outline

What makes BRDF measurements difficult ?

A: Curse of dimensionality

How to lower the number of measurements ?

Is there a way to quickly characterize a material ?

A: We look at retro-reflection

Implementation details + results

Results

So rather than relying on an image-based setup ...

Outline

What makes BRDF measurements difficult ?

A: Curse of dimensionality

How to lower the number of measurements ?

Is there a way to quickly characterize a material ?

A: We look at retro-reflection

Implementation details + results

Results

..., we decided to revisit the

parameterization. We took a step back and had a deeper analysis of the Rusinkiewicz

parameterization.

Rusinkiewicz [1998]

Your browser does not support the video tag.

Your browser does not support the video tag.

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

Limitation: frequency 🔗 shininess

It turns out that the Rusinkiewicz parameterization works fairly well for

rough materials, but its efficiency decreases along with shininess.

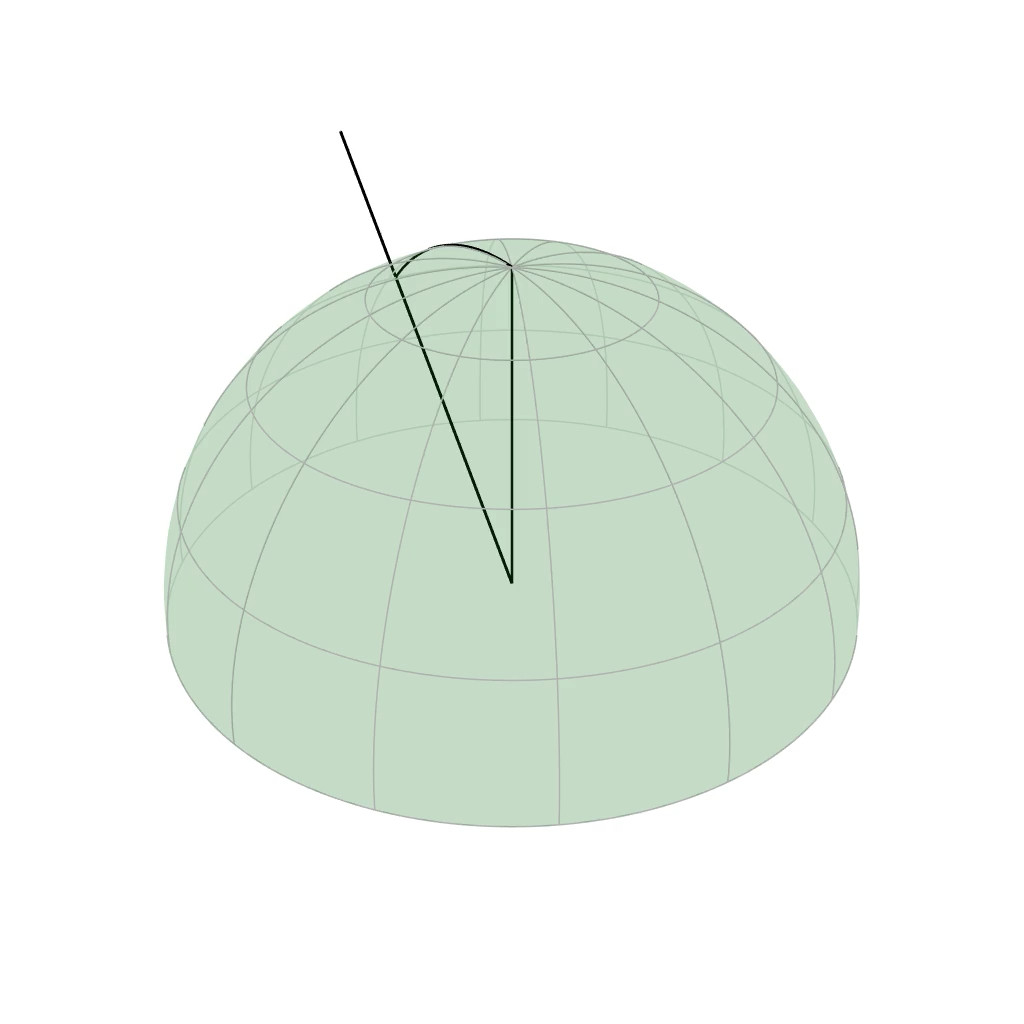

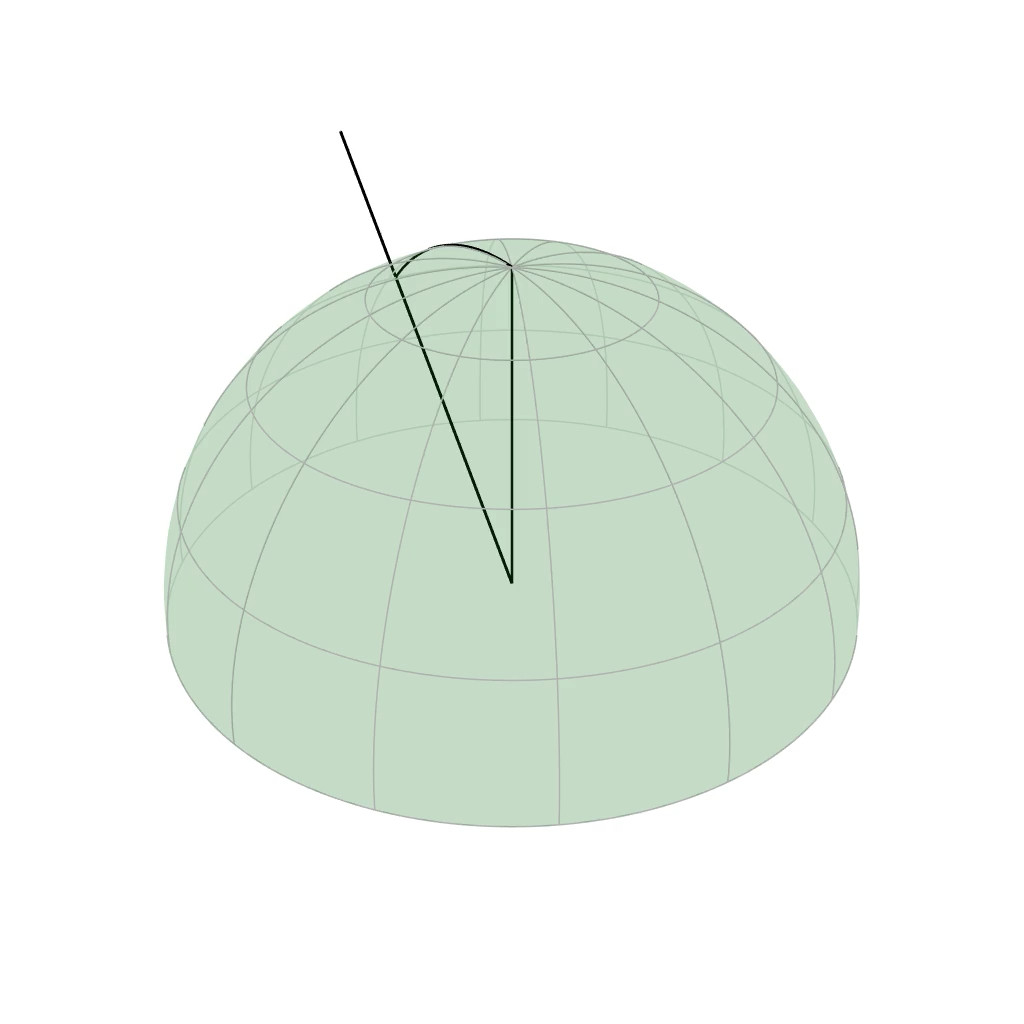

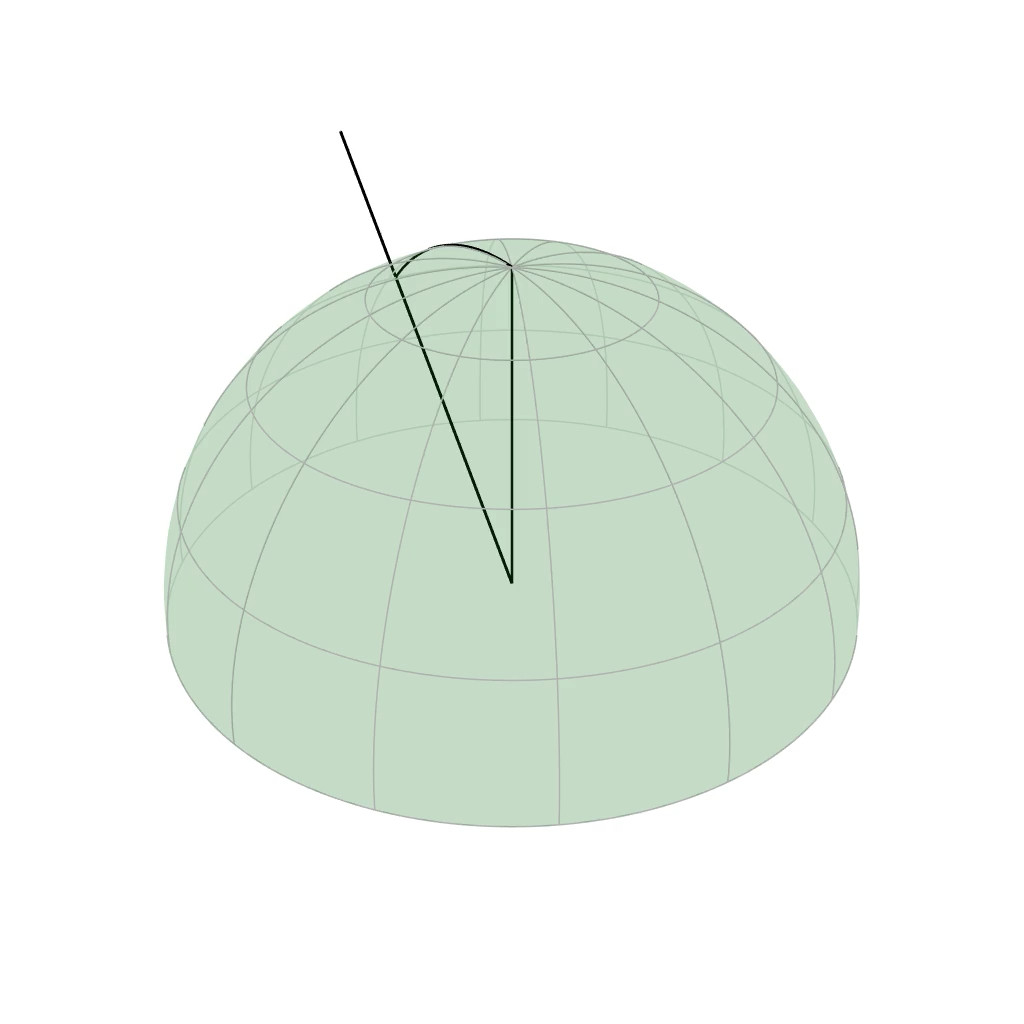

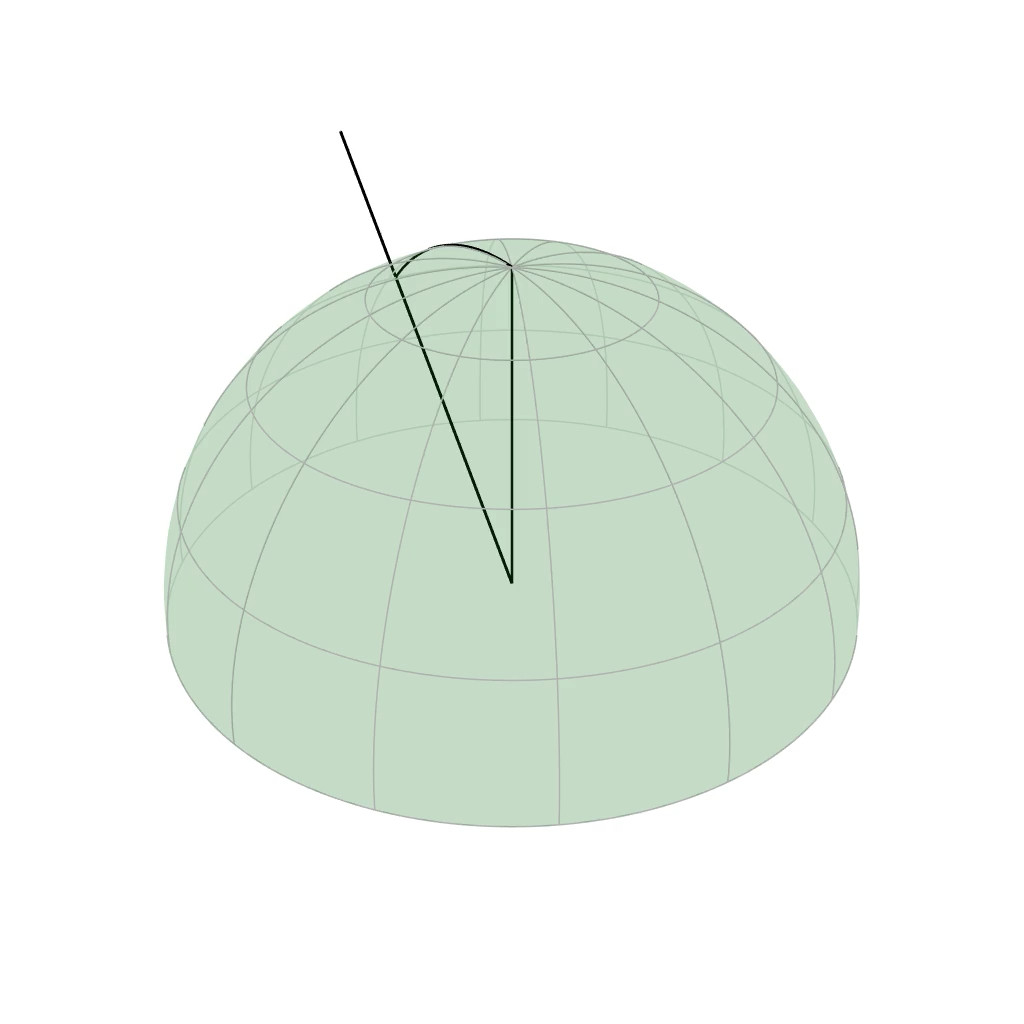

Our Approach

Your browser does not support the video tag.

Your browser does not support the video tag.

Incident domain

Outgoing domain

Outgoing domain

(parametric space)

Now, since shiny materials tend to concentrate around the specular direction,

a simple way to resolve this limitation is to concentrate the parameterization

near the mirror-reflection direction. This animation shows just that.

Outline

What makes BRDF measurements difficult ?

A: Curse of dimensionality

How to lower the number of measurements ?

A: Image-based setup ? Use an adaptive parameterization

Is there a way to quickly characterize a material ?

A: We measure retro-reflection

Implementation details + results

Results

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

This is the fundamental idea behind our paper: develop an [click]

adaptive parameterization based on the shininess of the material we want to

measure.

[click] the retro-reflection domain of the BRDF.

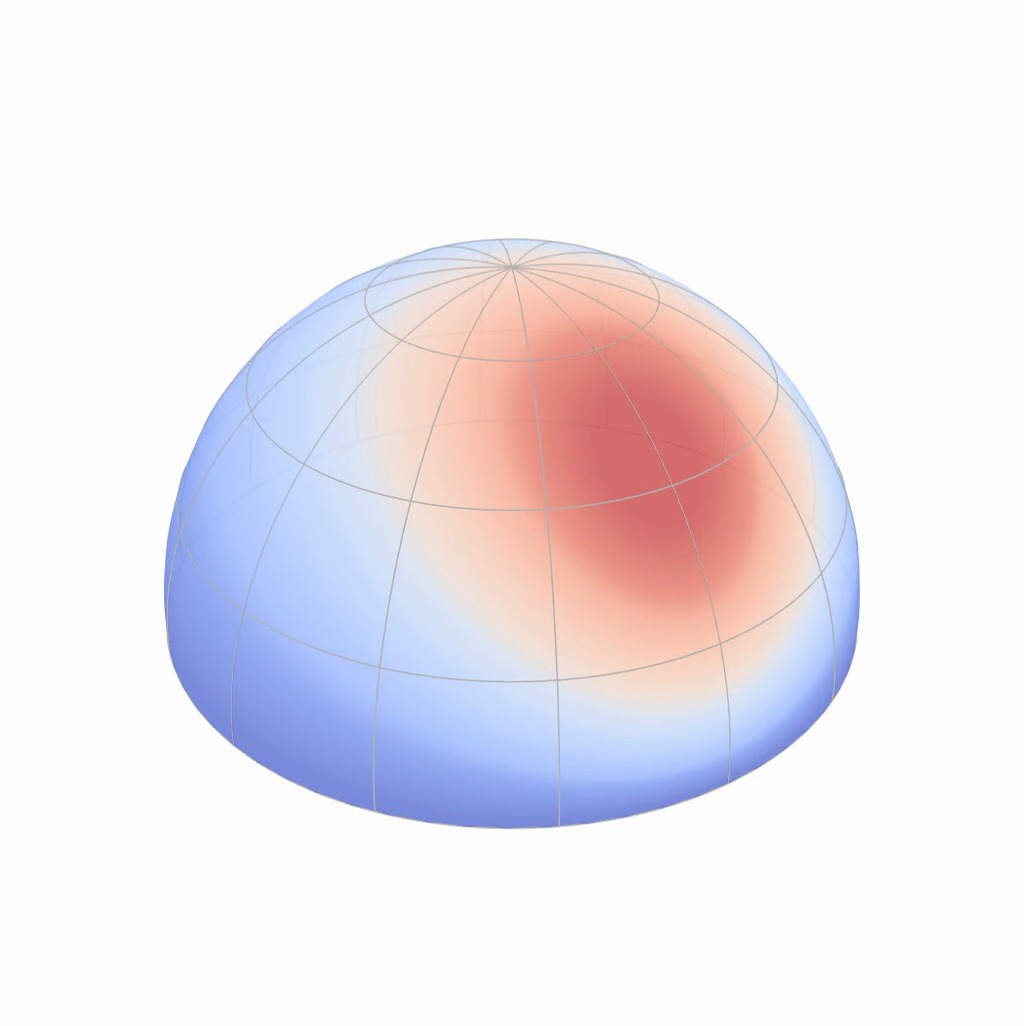

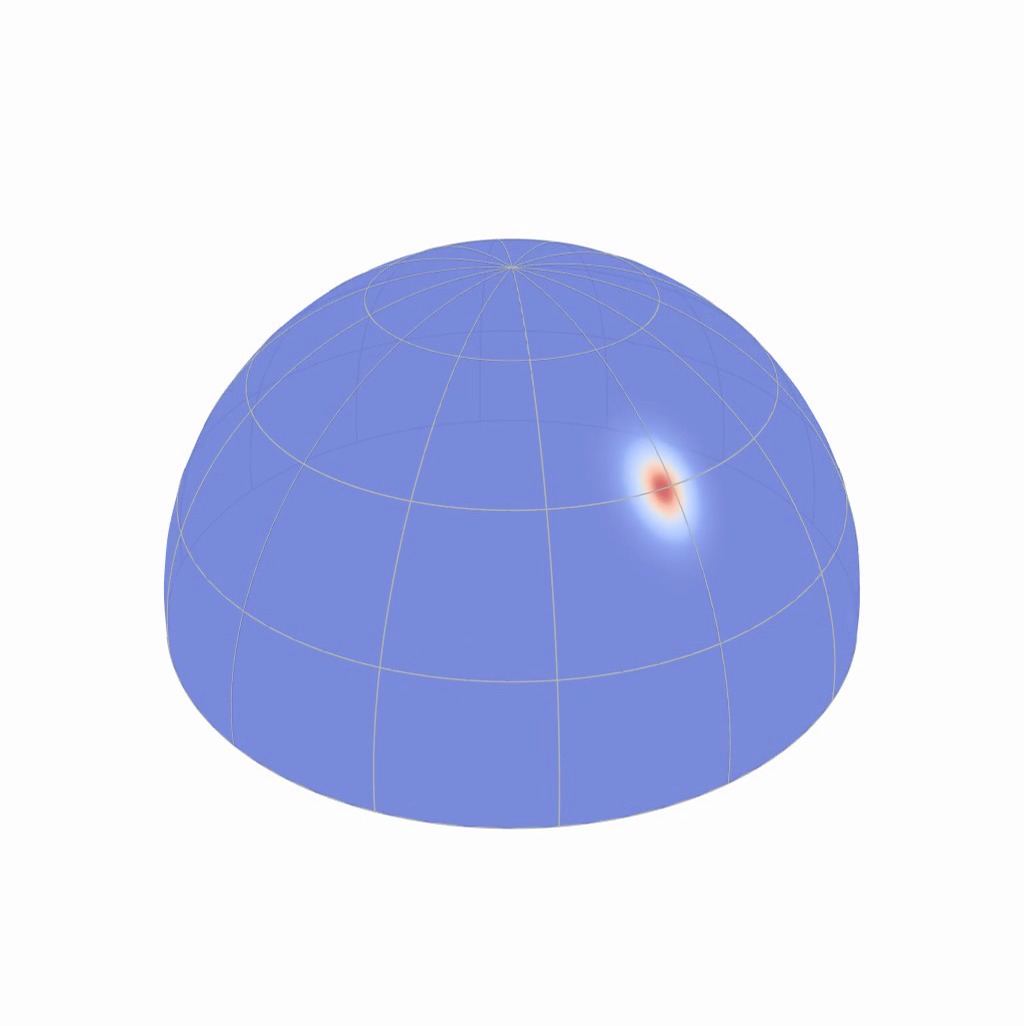

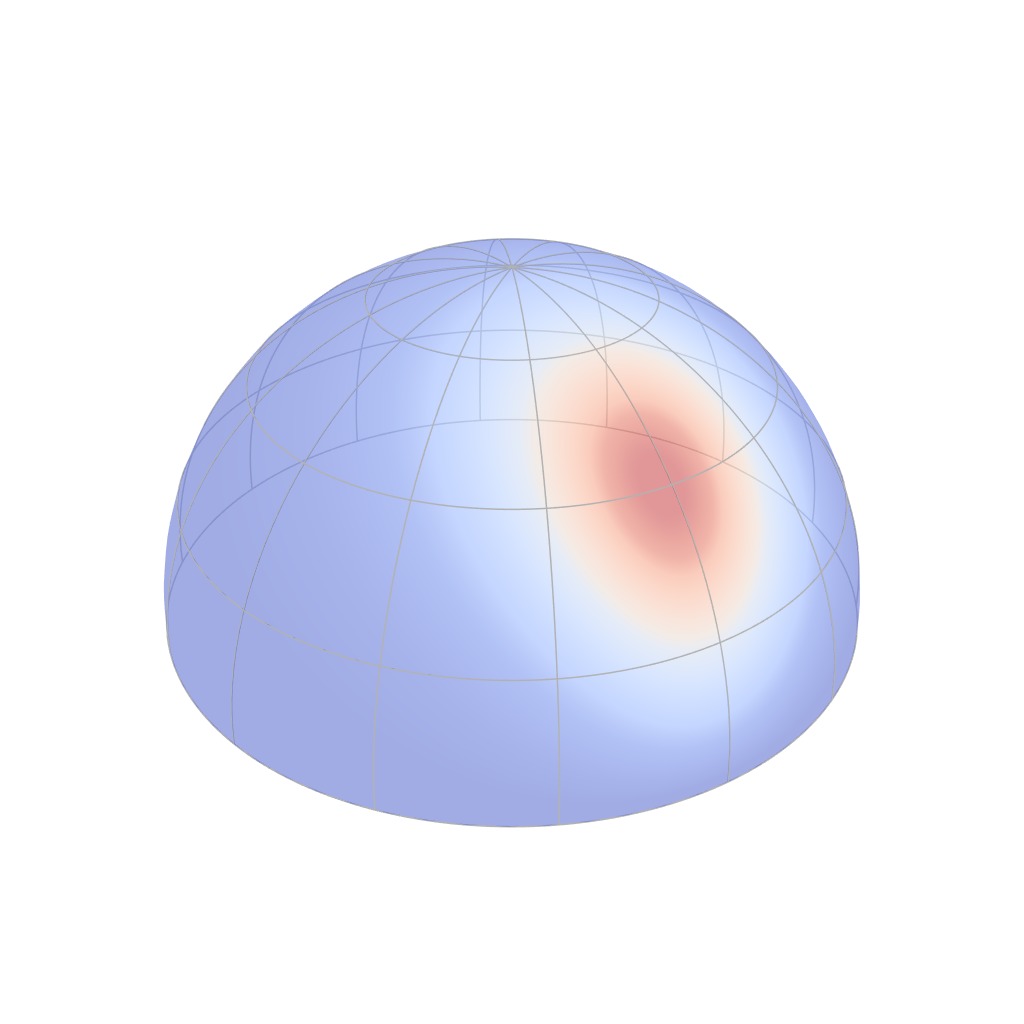

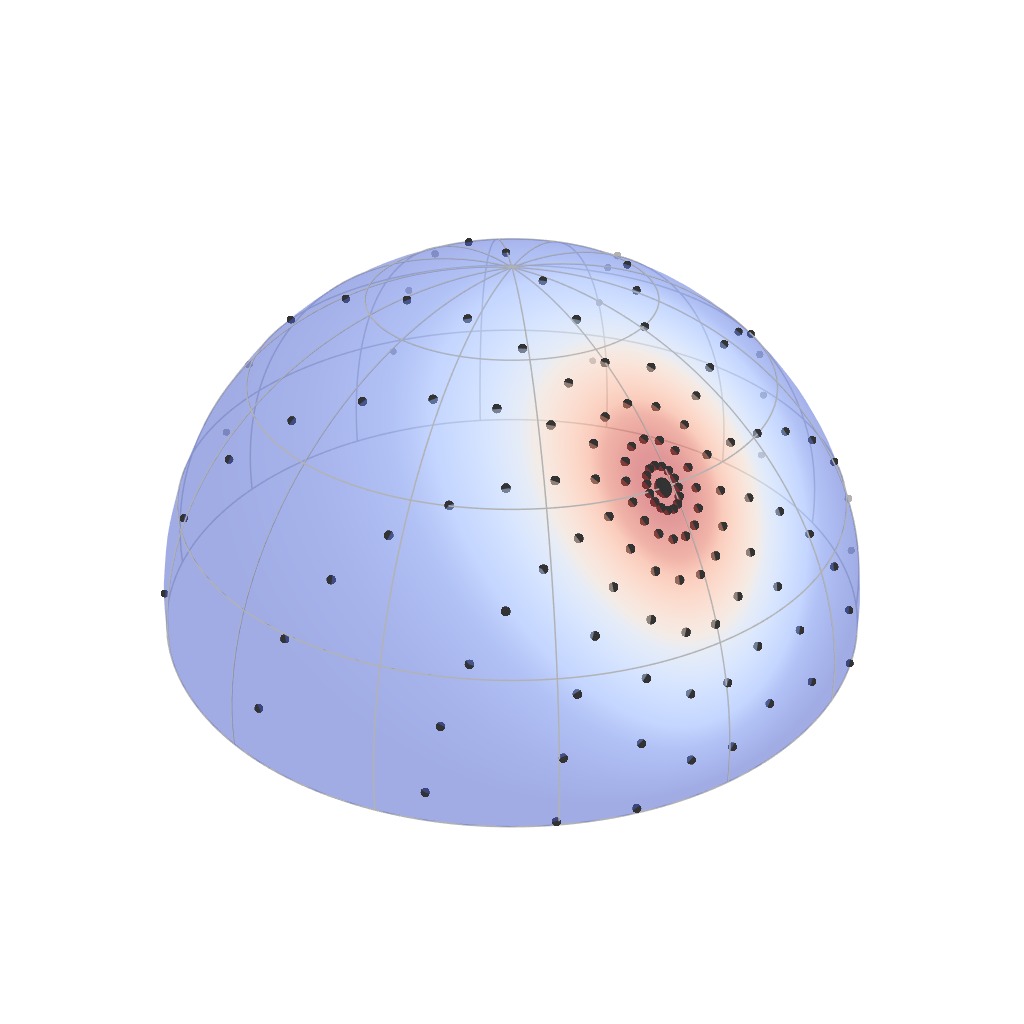

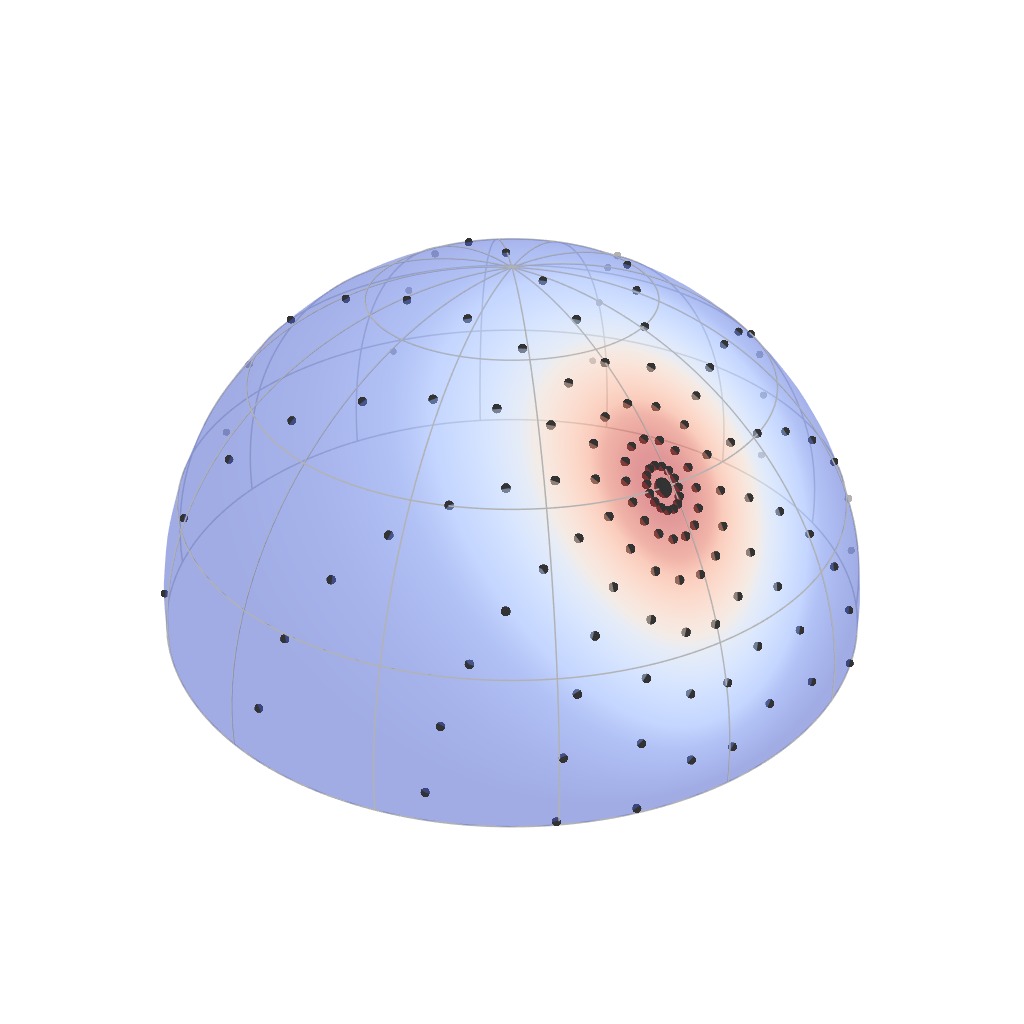

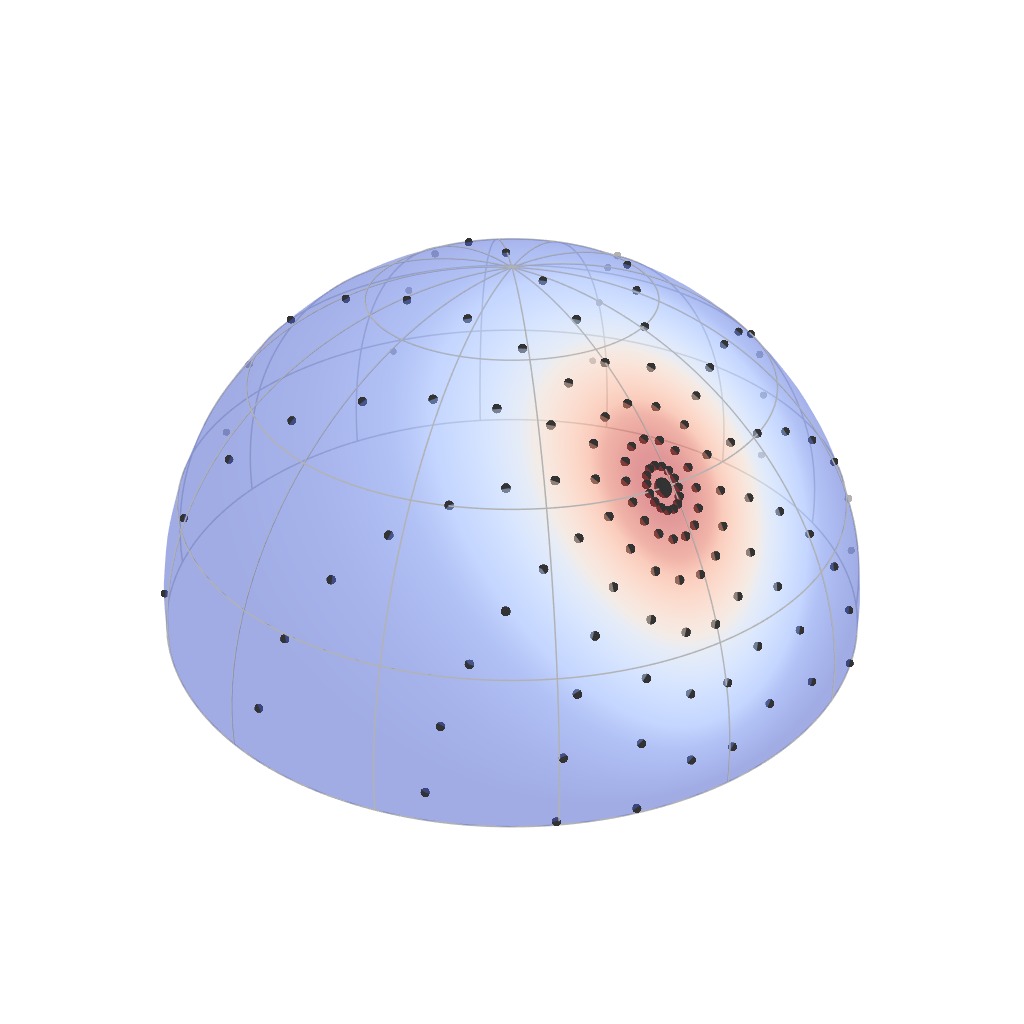

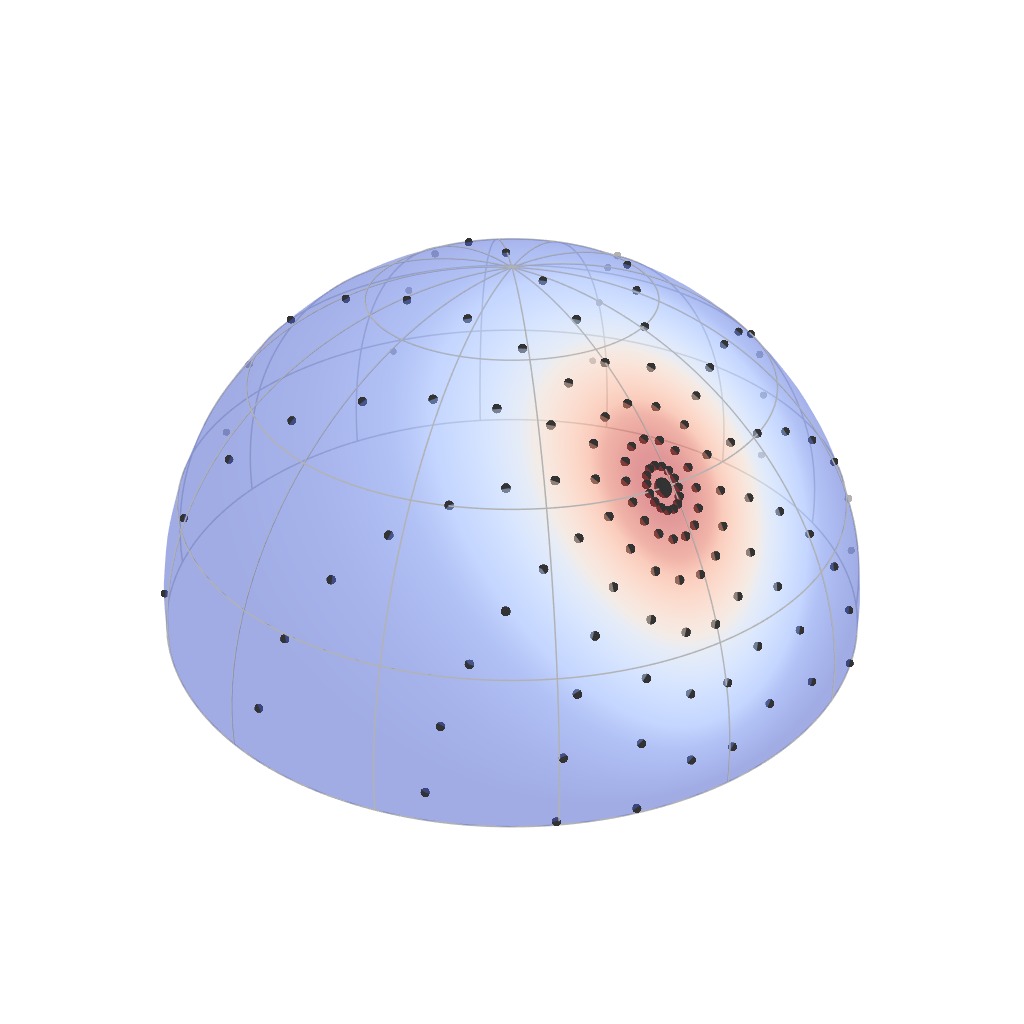

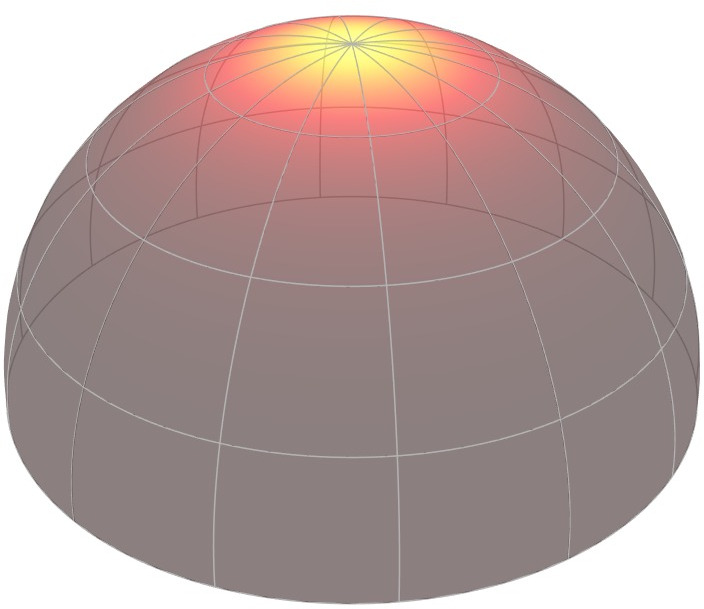

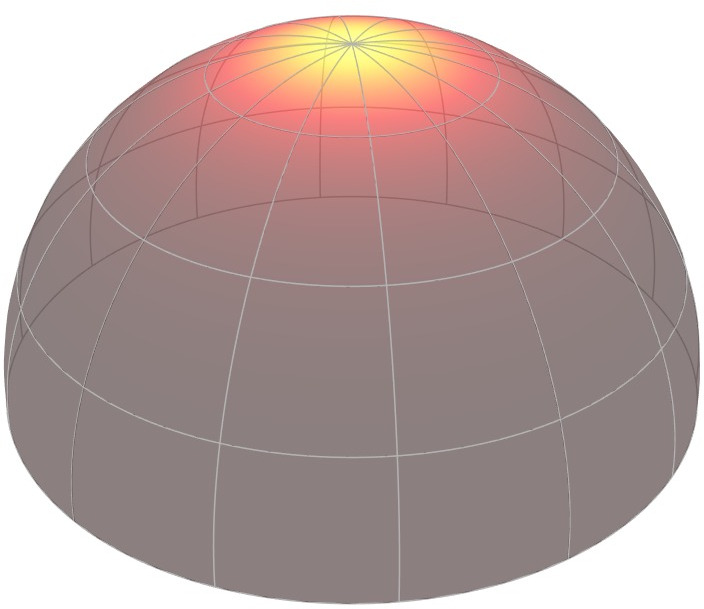

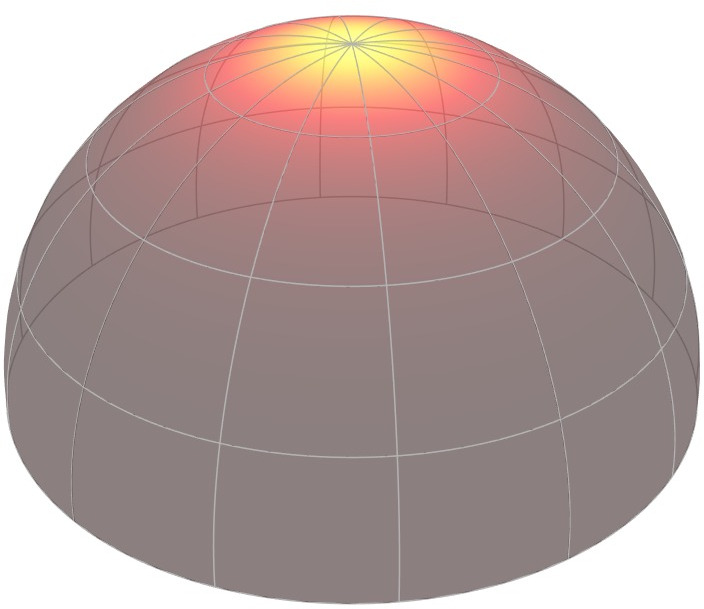

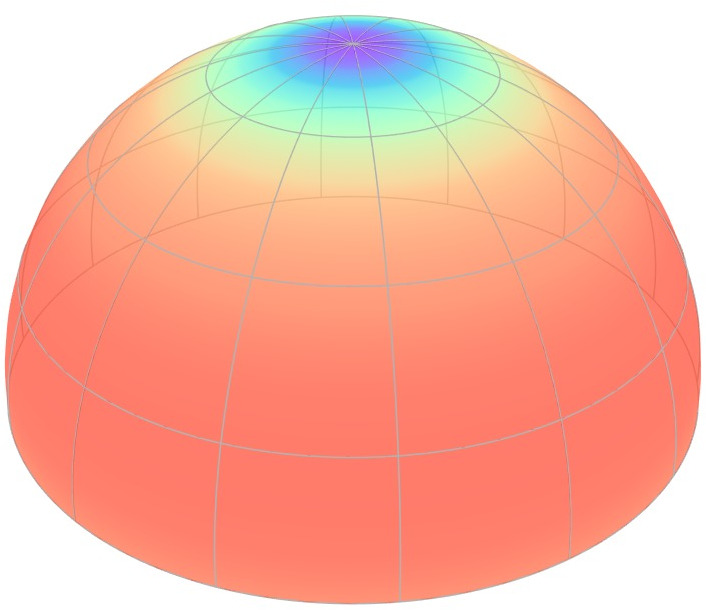

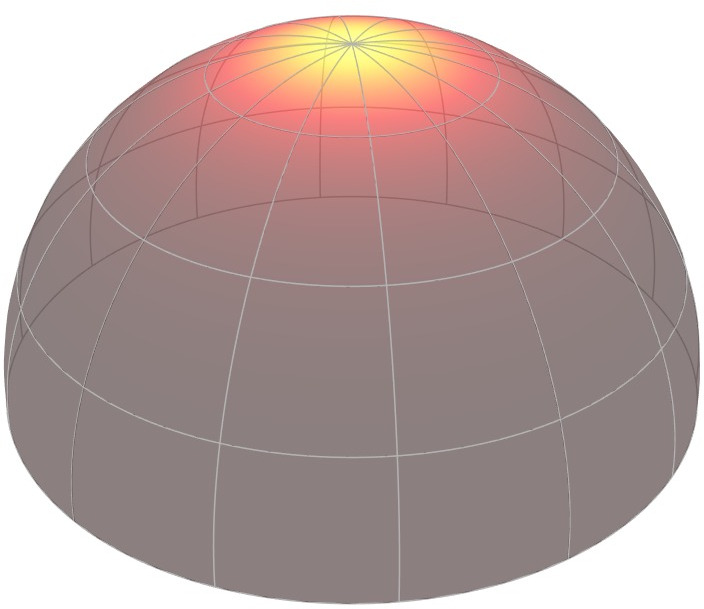

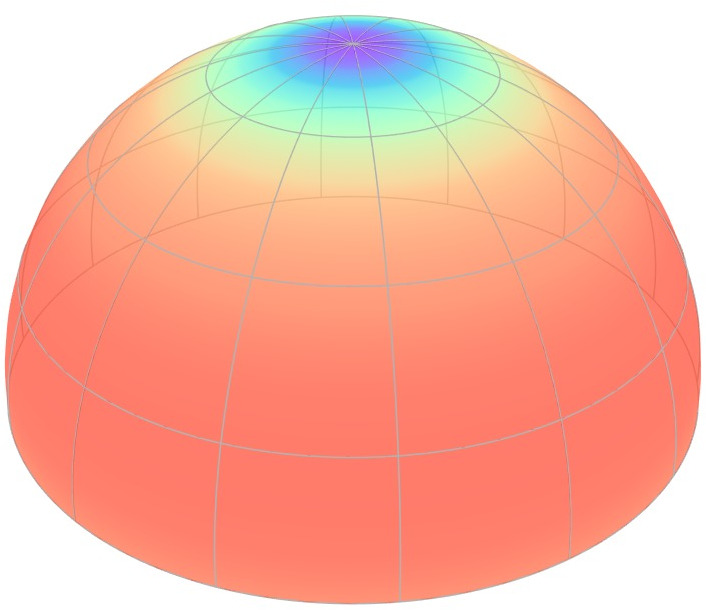

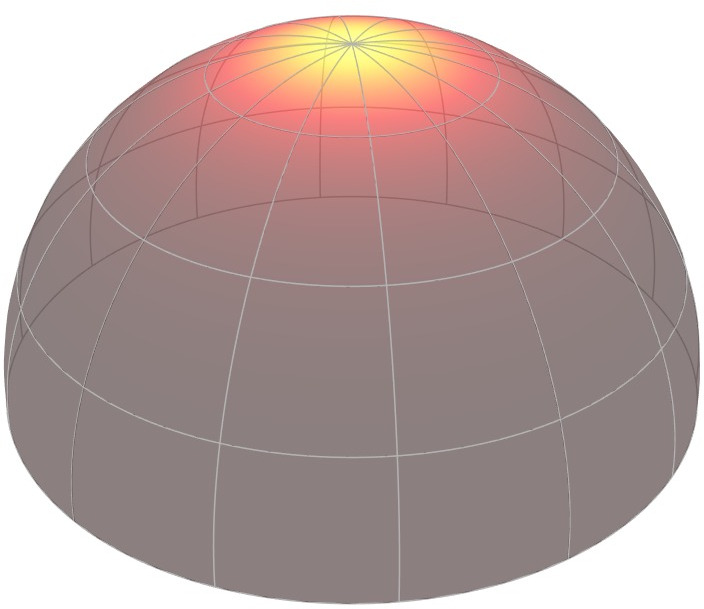

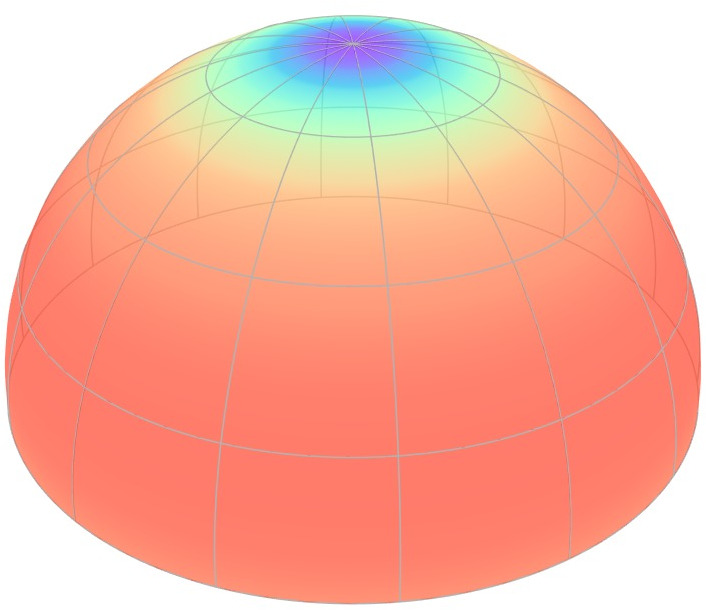

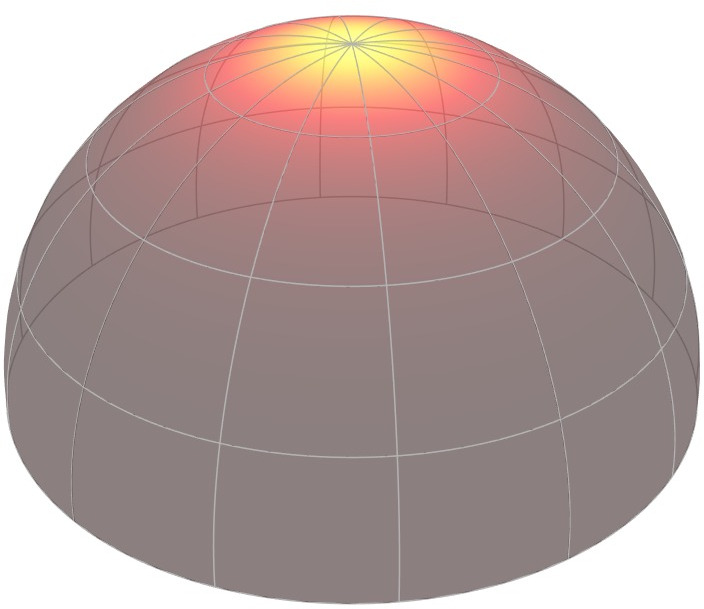

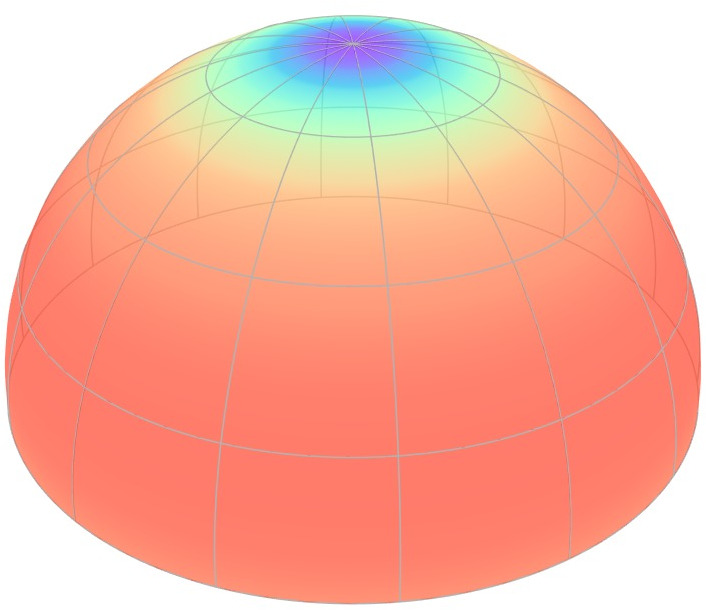

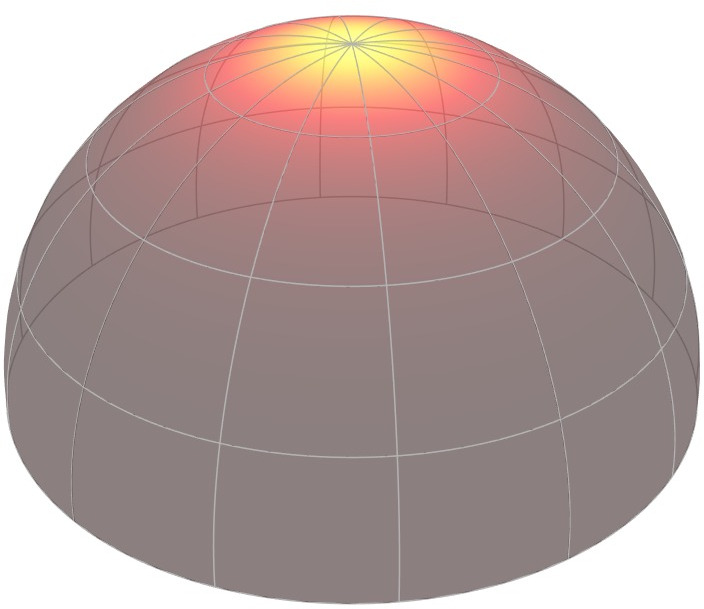

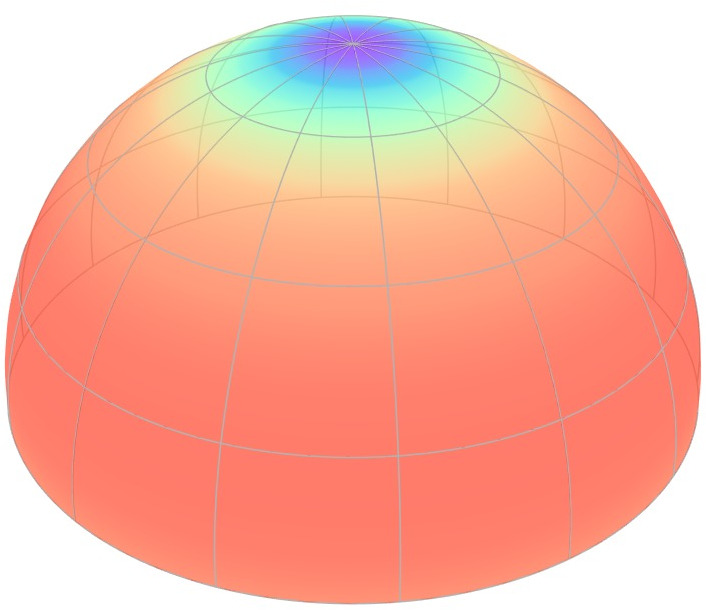

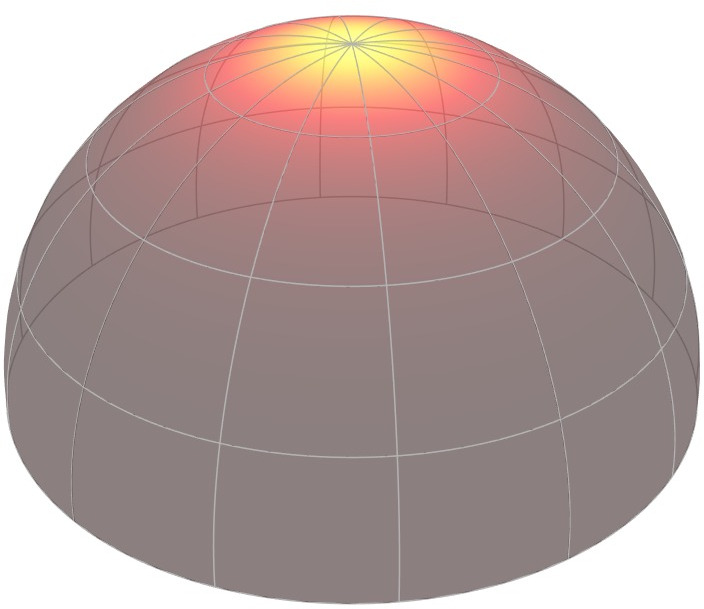

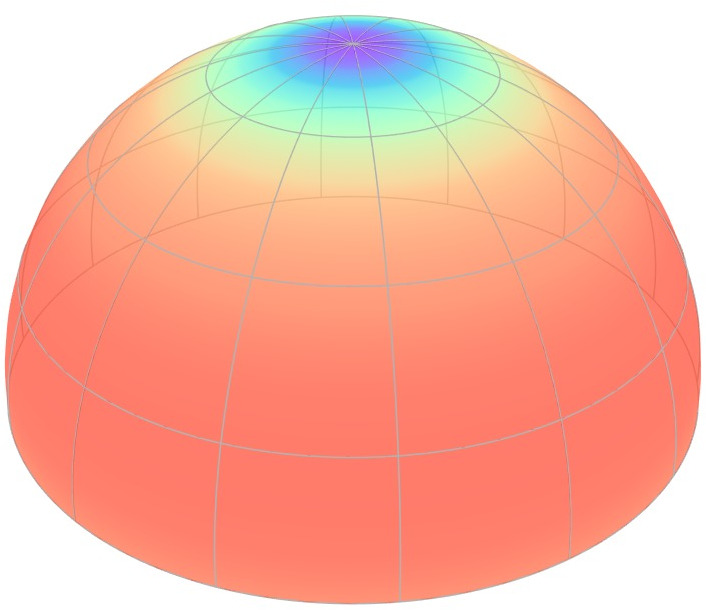

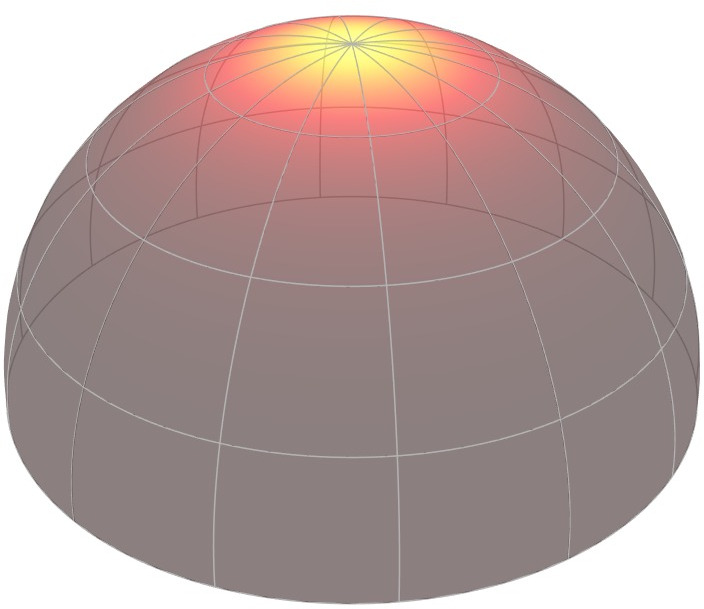

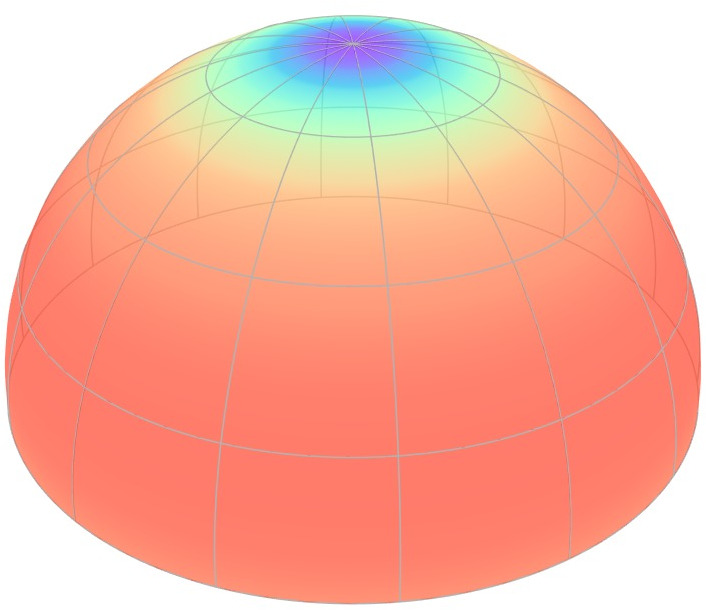

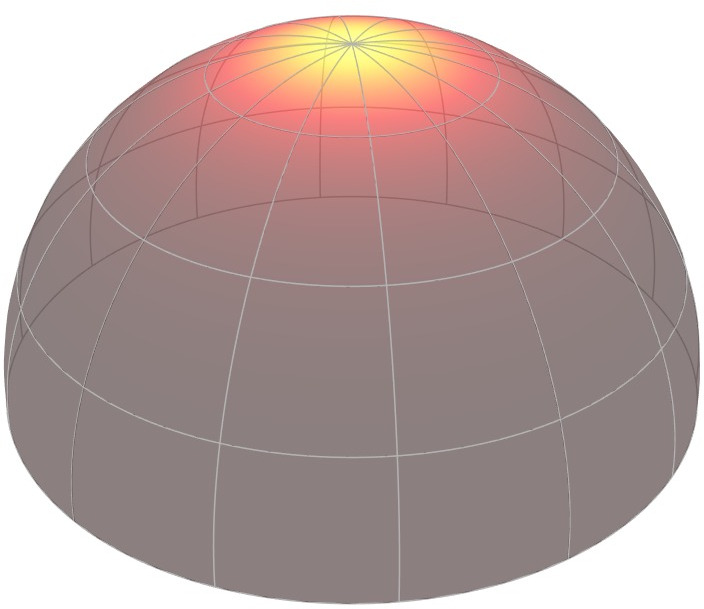

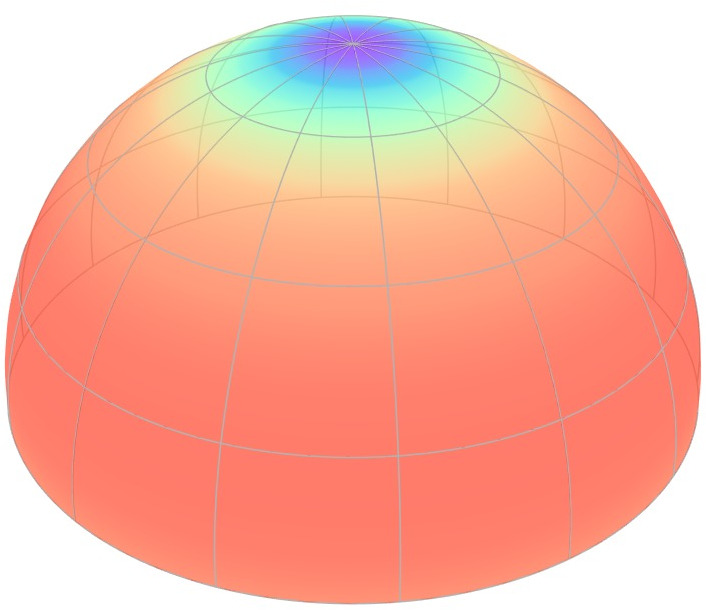

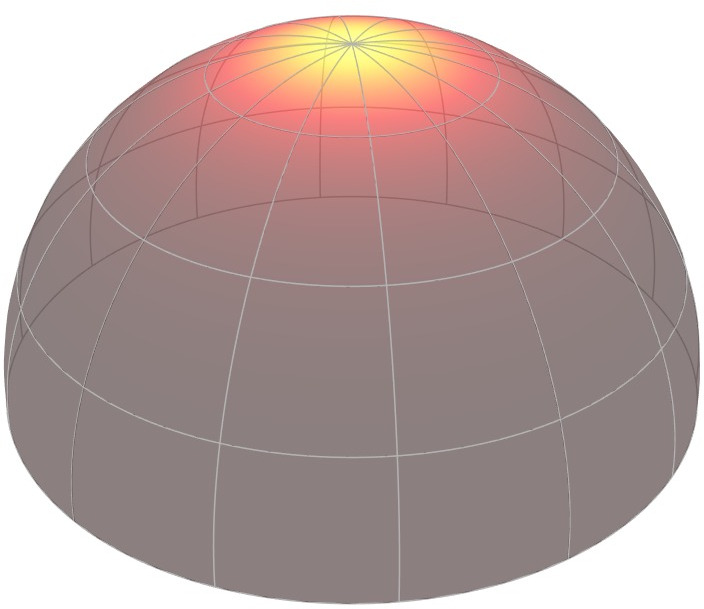

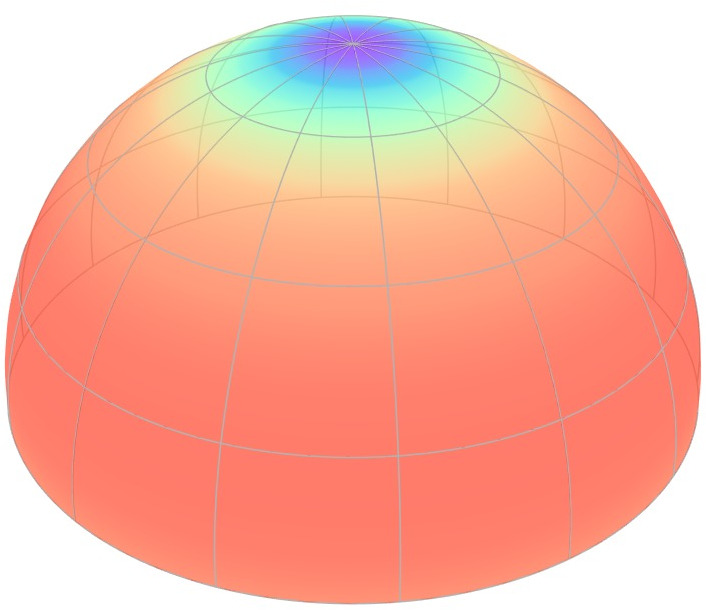

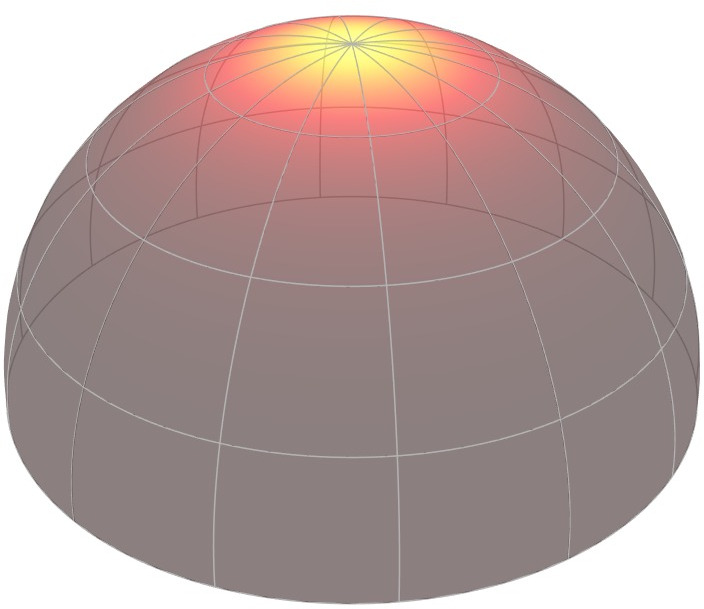

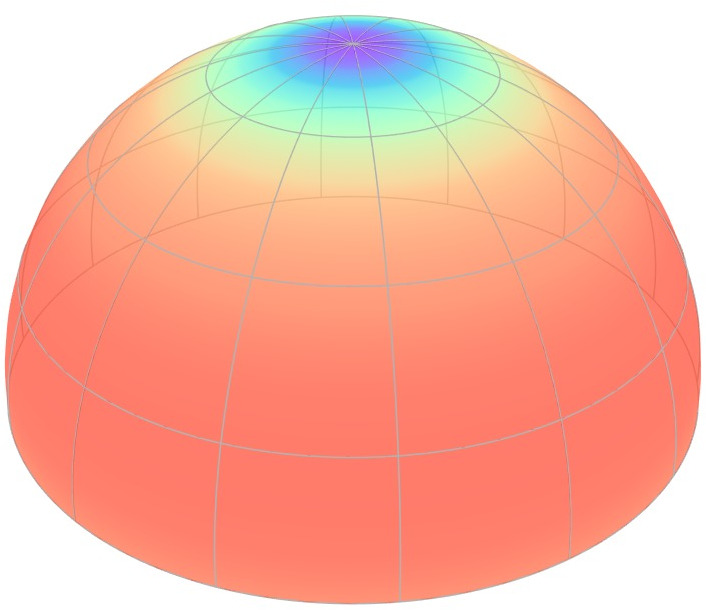

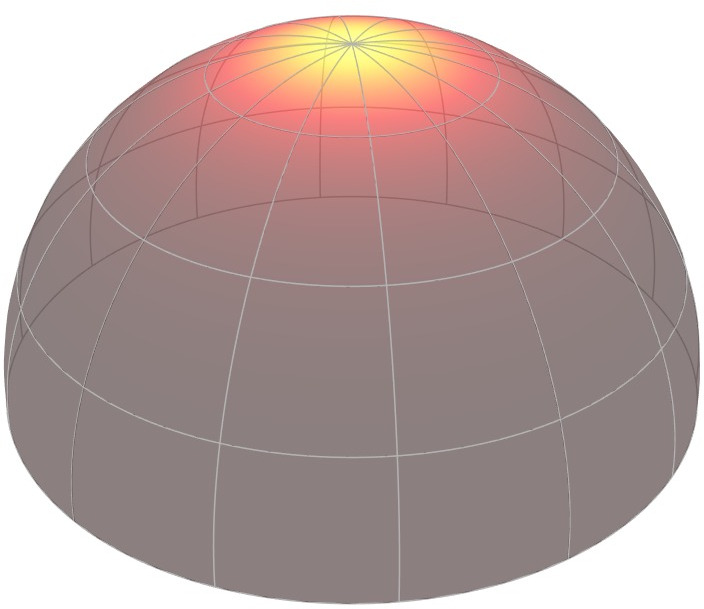

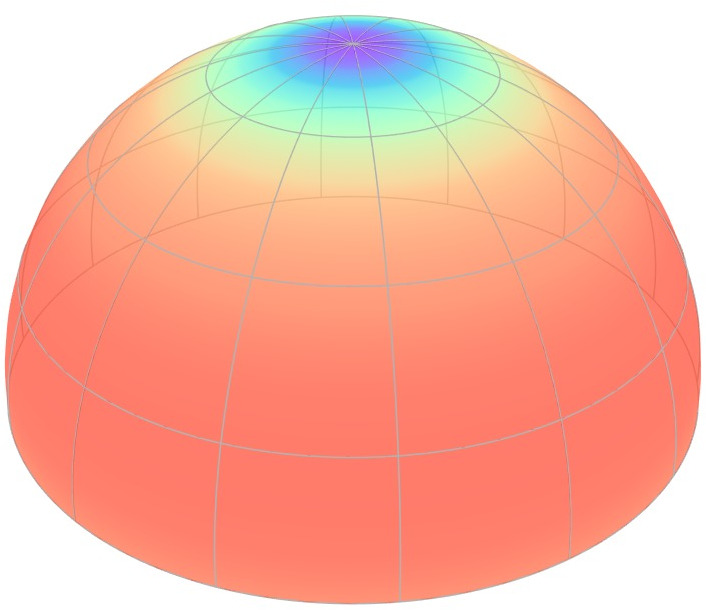

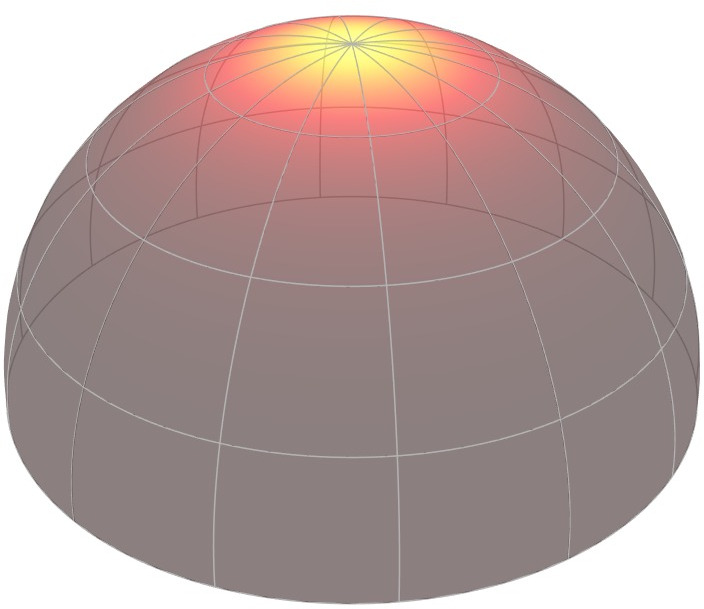

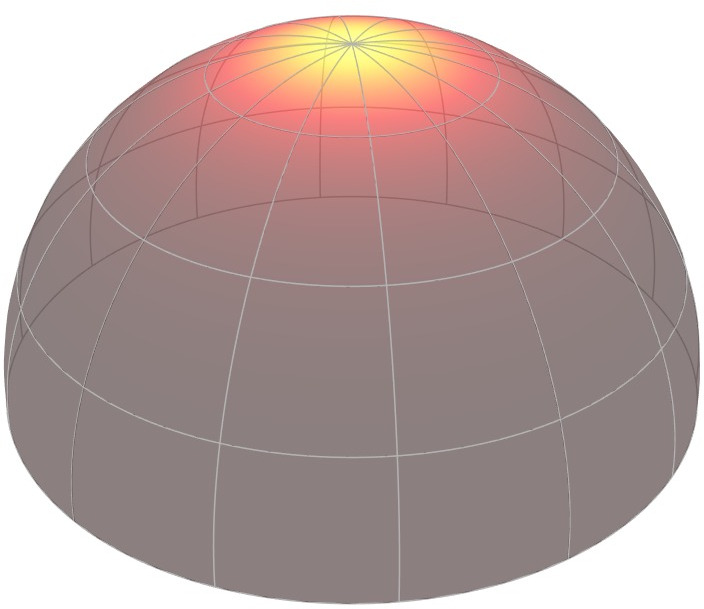

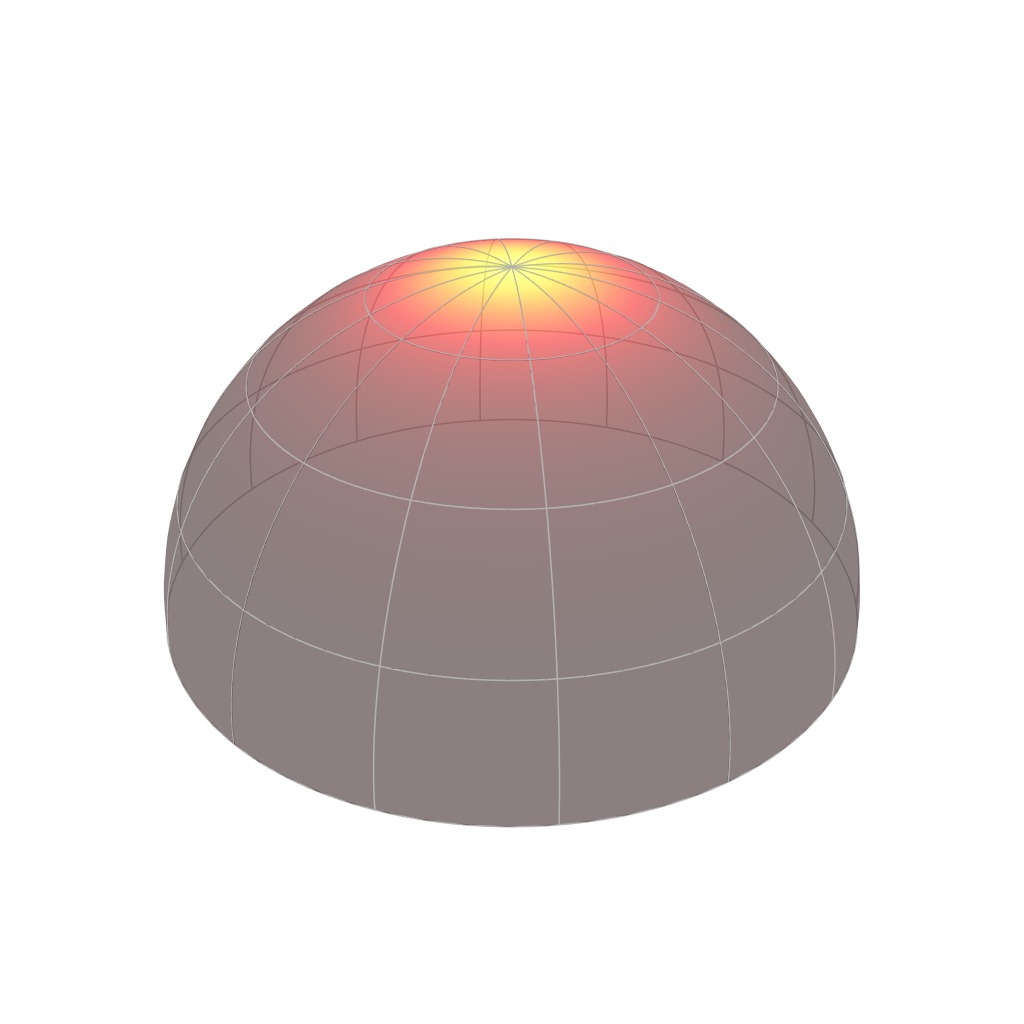

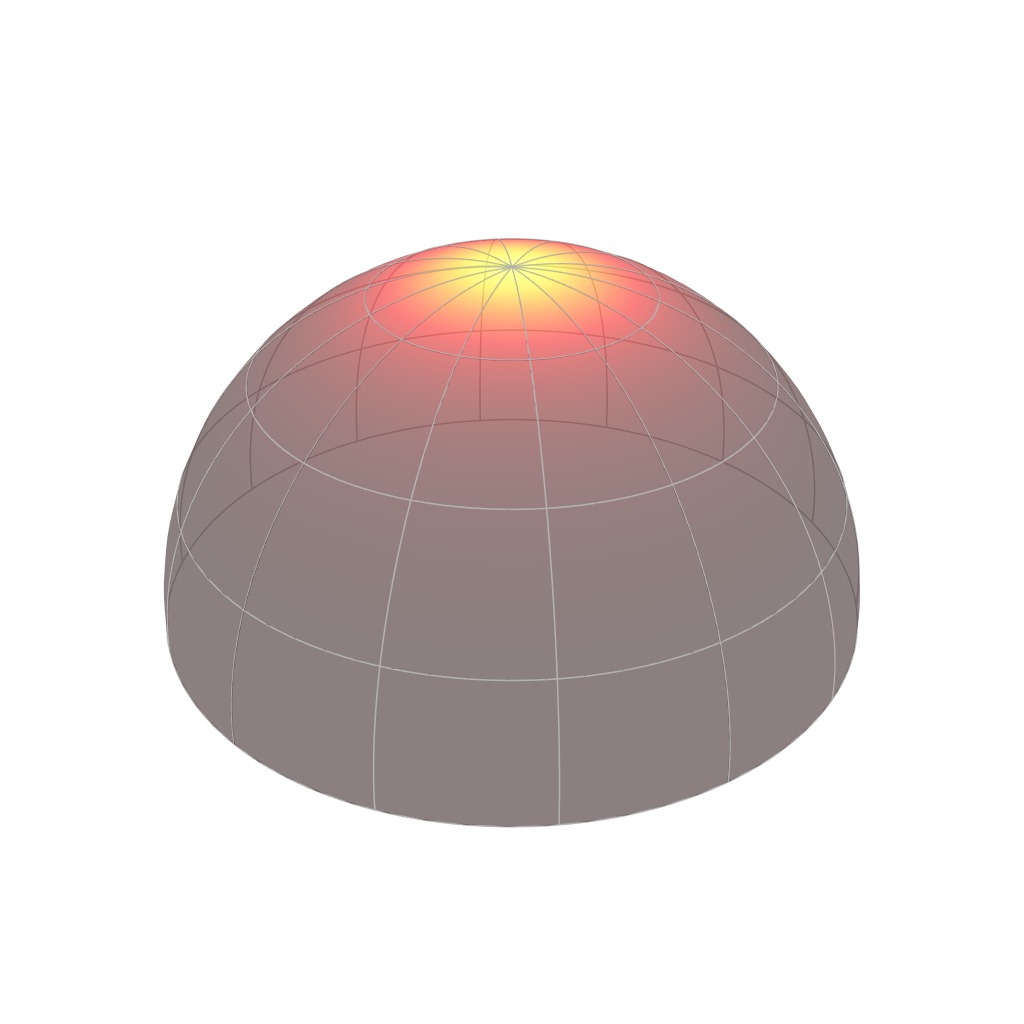

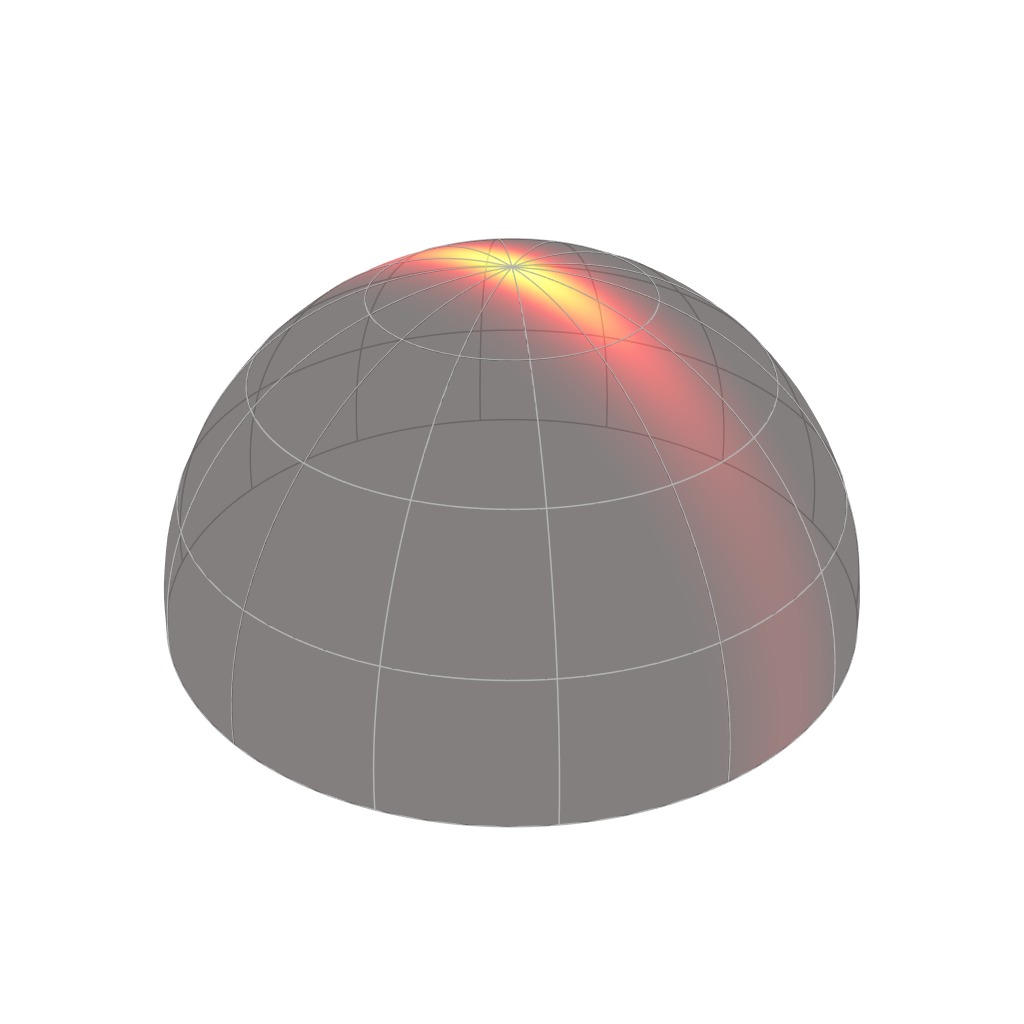

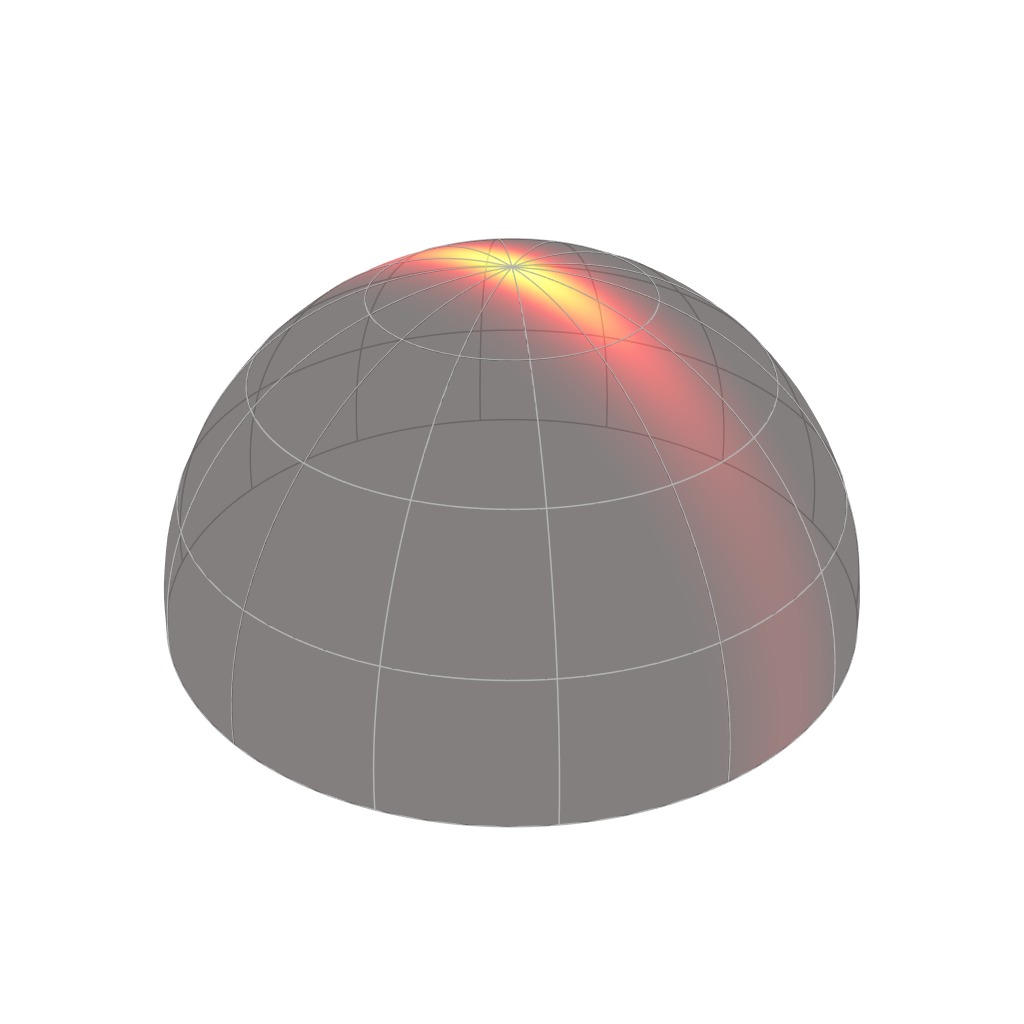

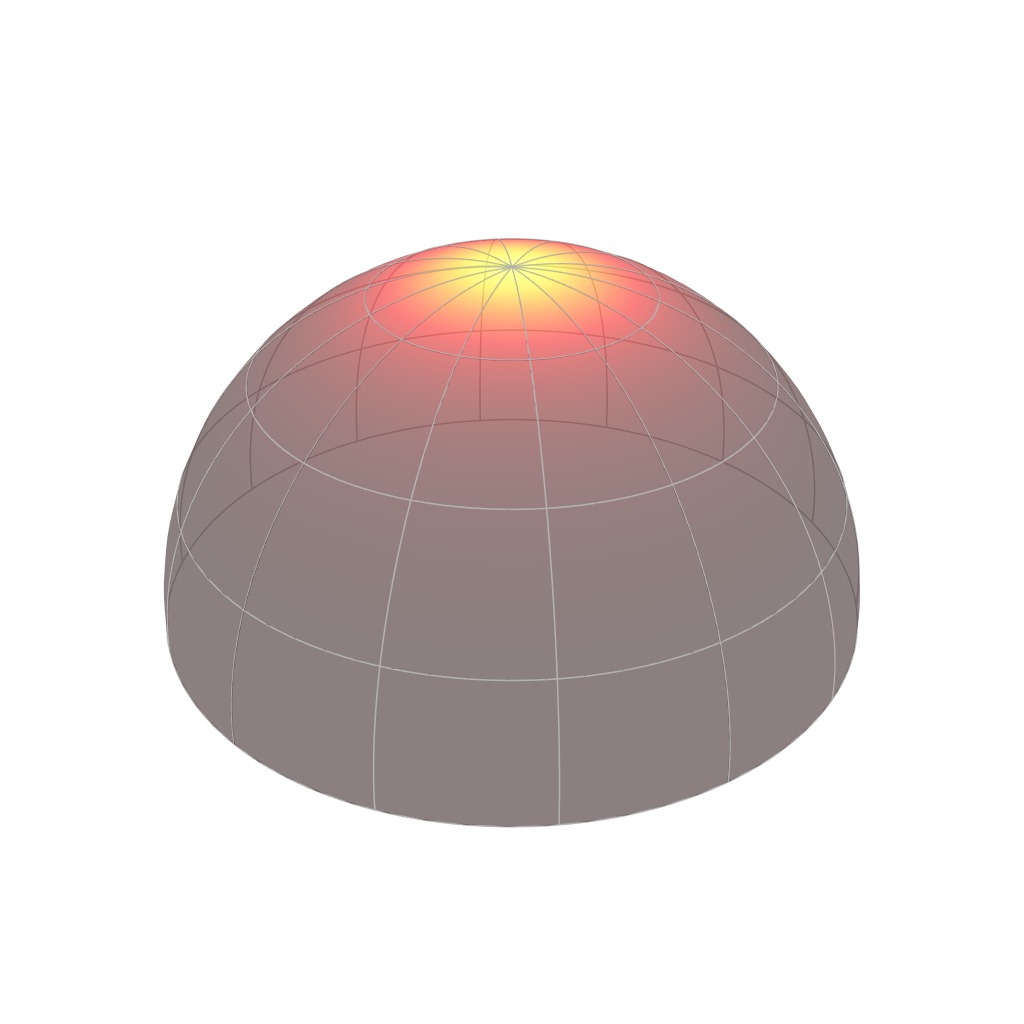

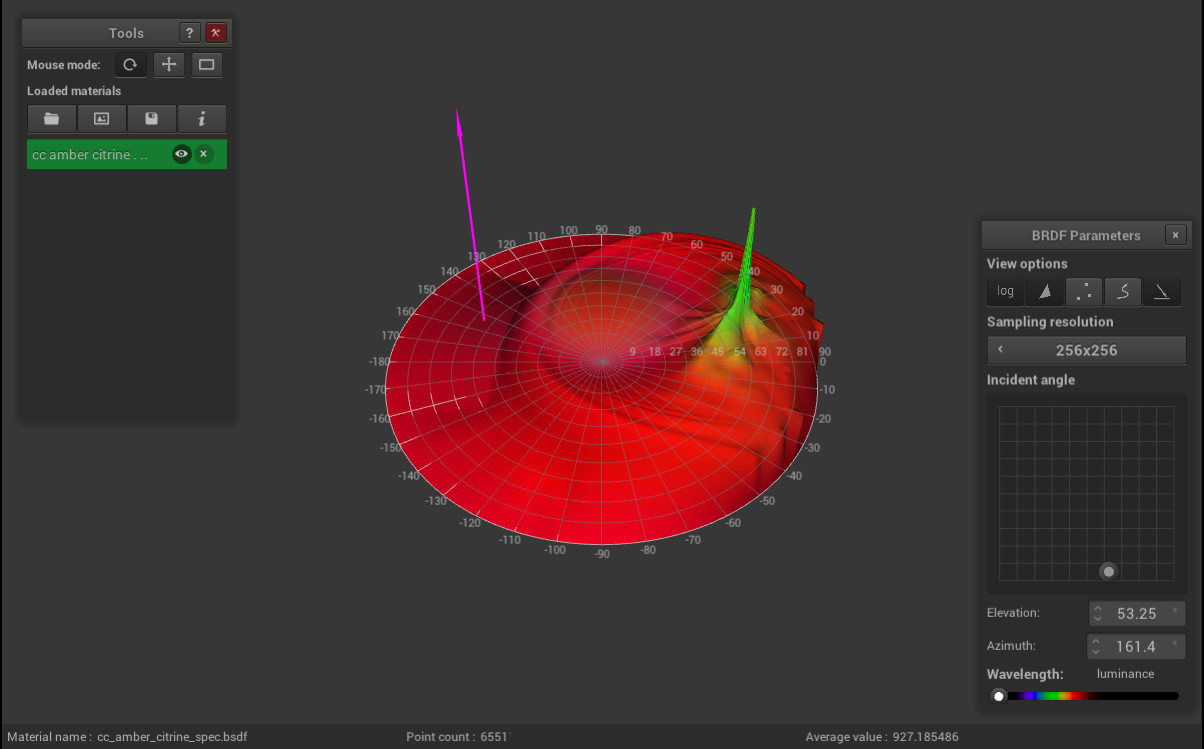

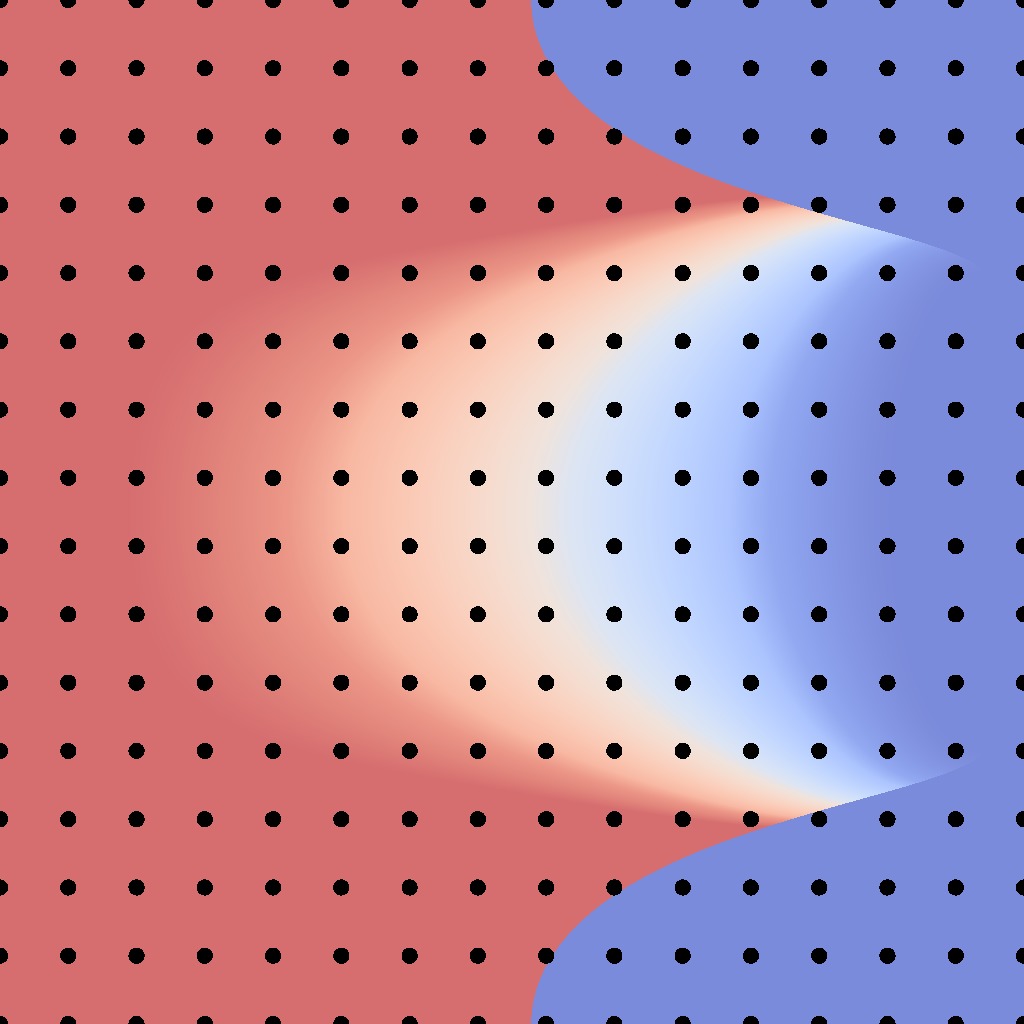

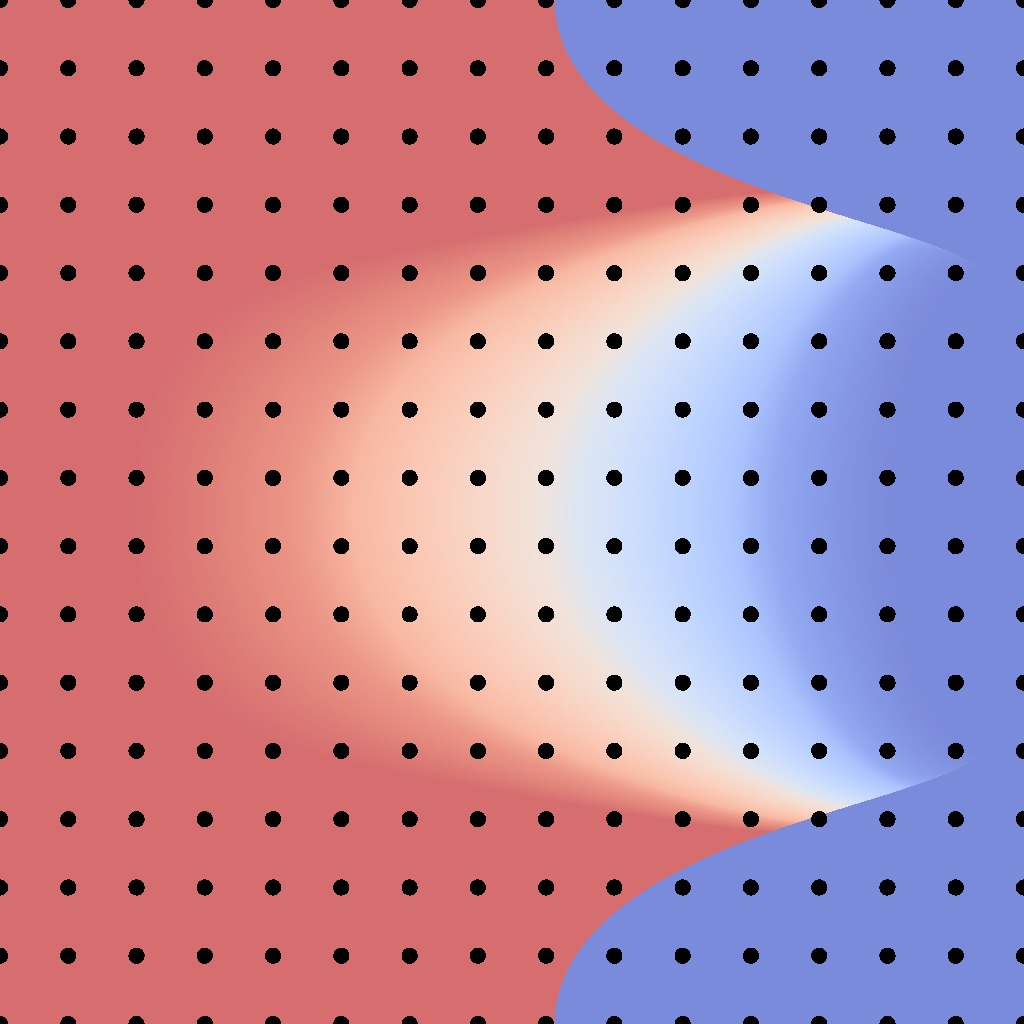

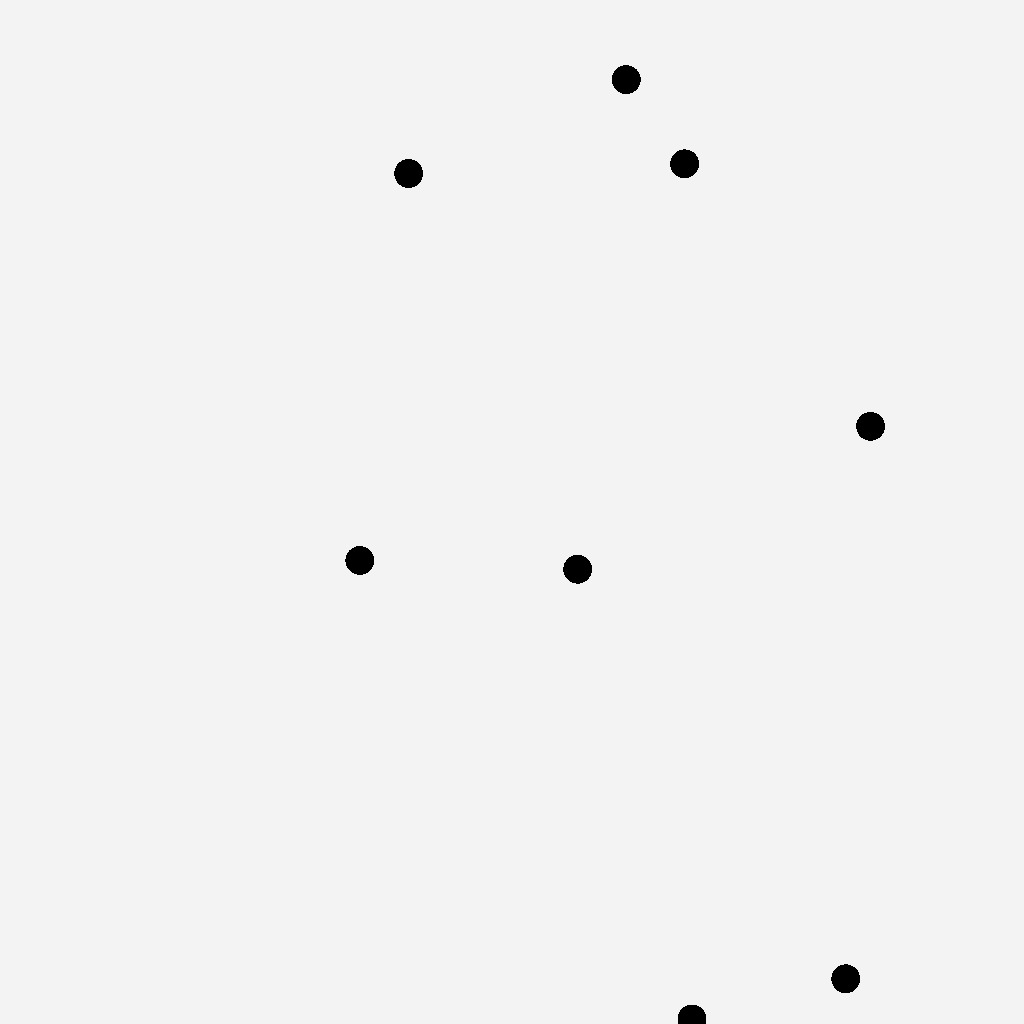

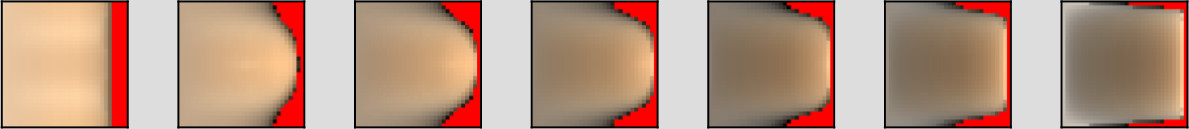

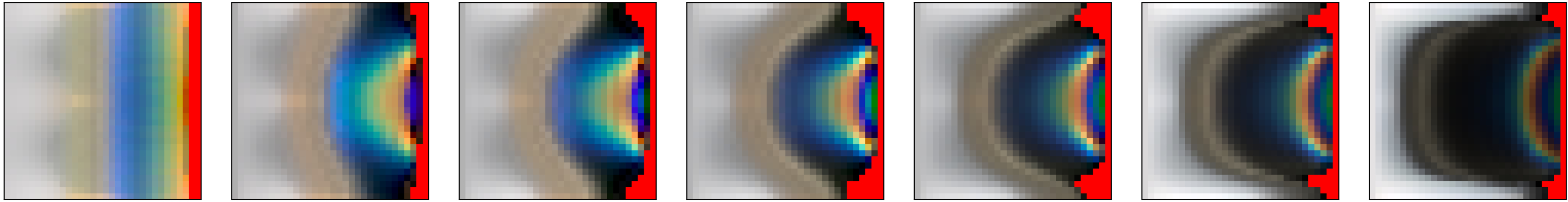

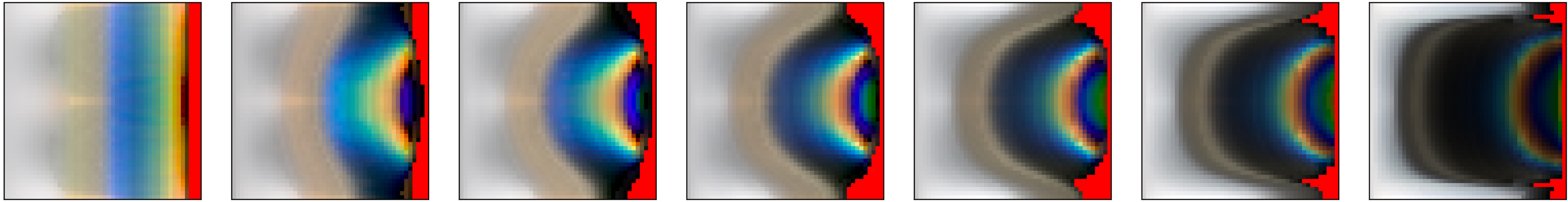

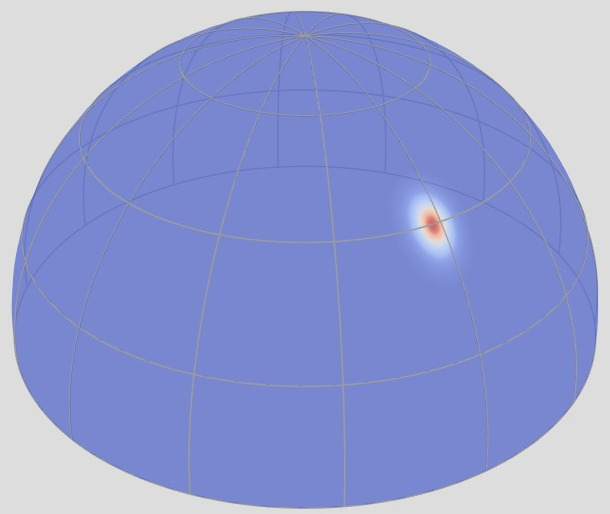

Retro-reflective Domain (2D)

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Rough

Shiny

Anisotropic

45x180 resolution:

xx

2 hours

x

[1 meas/s]

31 KiB

per wavelength

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

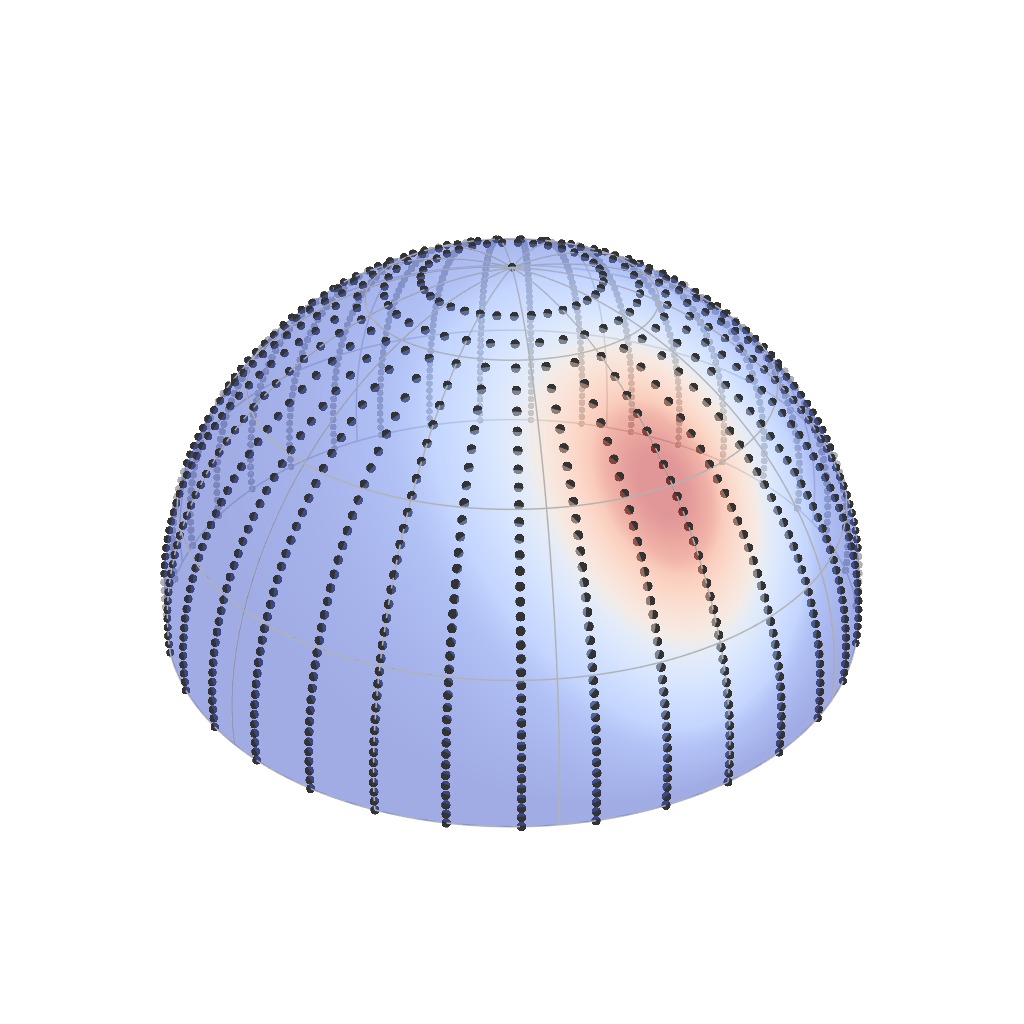

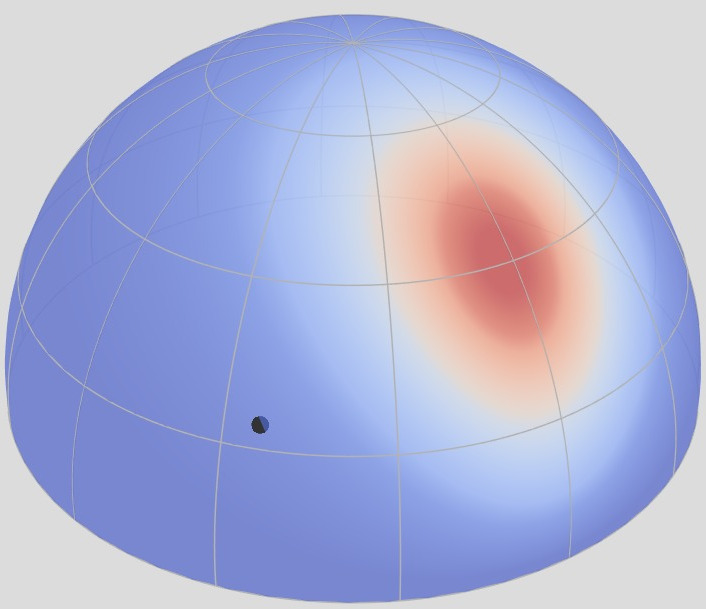

The retro-reflective domain is the directional sub-domain of the BRDF that

corresponds to the configurations where [click] the incident and

outgoing directions are aligned, i.e., $\boldsymbol{\omega}_i = \boldsymbol{\omega}_o$.

[click] shiny materials

have a narrow retro-reflective lobes, [click] rough materials have wide

ones, and finally [click] anistropic materials exhibit a radial

asymmetry.

[click] it is both fast to acquire,

and easy to store.

Retro-reflective Domain (2D)

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Rough

Shiny

Anisotropic

Now, these properties are quite straightforward in retrospect, but

of course we did not find them by chance ;)

Why Retro-reflection ?

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Actually, there is a theoretical justification to why we build our

parameterization using retro-reflection. This justification is microfacet

theory.

Microfacet Theory

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

Microfacet theory is a theoretical framework that justifies the behaviours

of BRDFs by modelling them as [click] the global response of a

collection of microscropic mirrors.

Microfacet Theory

NDF

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

This particular description is provided by the microfacet normal

distribution unction (NDF), which tells how much mirror (micro)area is

oriented towards a specific direction.

Microfacet Theory

NDF

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

intuition:

$

{\color{red}f_r^\perp}(\boldsymbol{\omega}_i, \boldsymbol{\omega}_o)

\propto

{\color{blue}D}(\boldsymbol{\omega}_h)

$

The reason why the NDF plays an important role in microfacet theory is

this.

Retro-reflection

NDF

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

intuition:

$

{\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)

\propto

{\color{blue}D}(\boldsymbol{\omega}_h)

$

Under this assumption, it follows that under retro-reflective configurations,

the amount of energy should be directly proportional to the value of the NDF.

Retro-reflection

NDF

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

intuition:

$

{\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)

\propto

{\color{blue}D}(\boldsymbol{\omega}_h)

$

This suggests that we can retrieve a microfacet NDF from an arbitrary material

solely from its retro-reflection responses.

NDF Extraction

NDF

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

Solve Fredholm equation of the second kind

with Kernel

$$

K(\boldsymbol{\omega}, \boldsymbol{\omega}_m)

=

{\color{red}f_r^\perp}(\boldsymbol{\omega}, \boldsymbol{\omega})

\langle

\boldsymbol{\omega}

\cdot

\boldsymbol{\omega}_m

\rangle

$$

intuition:

$

{\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)

\propto

{\color{blue}D}(\boldsymbol{\omega}_h)

$

Actually in the paper, we show that this relation writes down to a simple equation

that relates the NDF (written in blue) to [click] the retro-reflection

response of the material (written in red).

[click] a Fredholm equation of

the second kind and we explain how to solve it in an efficient and robust

way using power iterations over an eigenvector problem. More details are in

the paper.

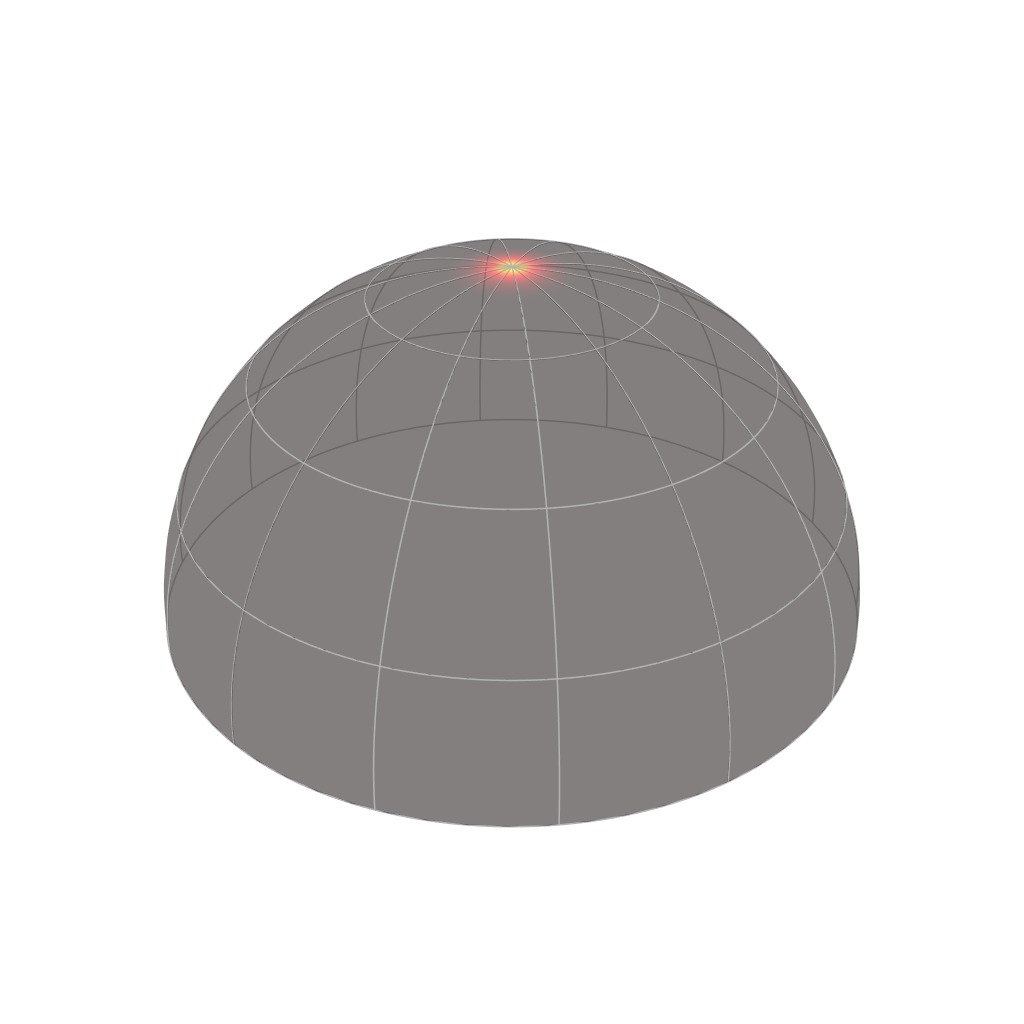

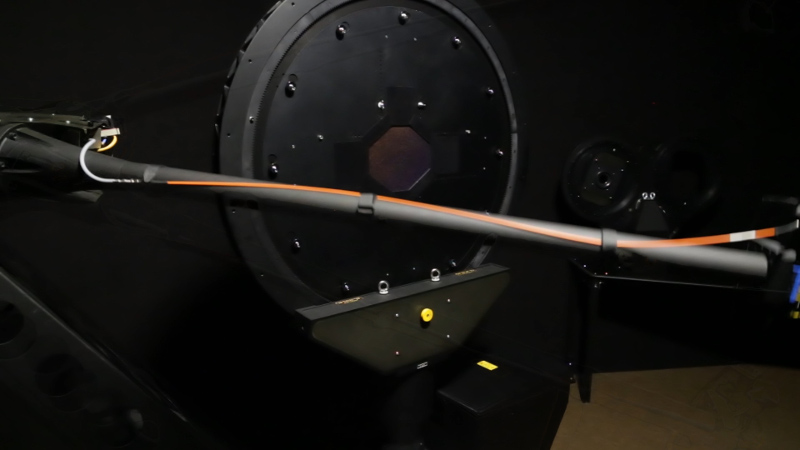

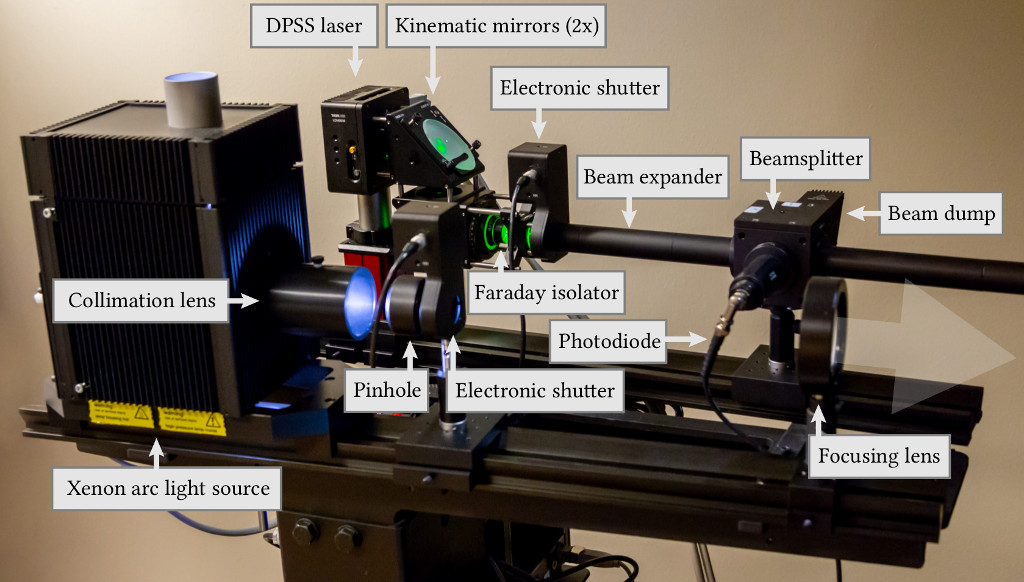

Retro-reflection Acquisition

NDF

${\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

intuition:

$

{\color{red}f_r^\perp}(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)

\propto

{\color{blue}D}(\boldsymbol{\omega}_h)

$

laser

beam dump

photodiode

beamsplitter

sample

isolator

Note that acquiring retro-reflection can be quite tricky in practice and we

have a specific setup solely dedicated to that purpose. The setup is based on

a laser and a beam splitter that partially lets the light through to

illuminate the sample and reflects some of the scattered light into a

photodiode. More details are in the paper.

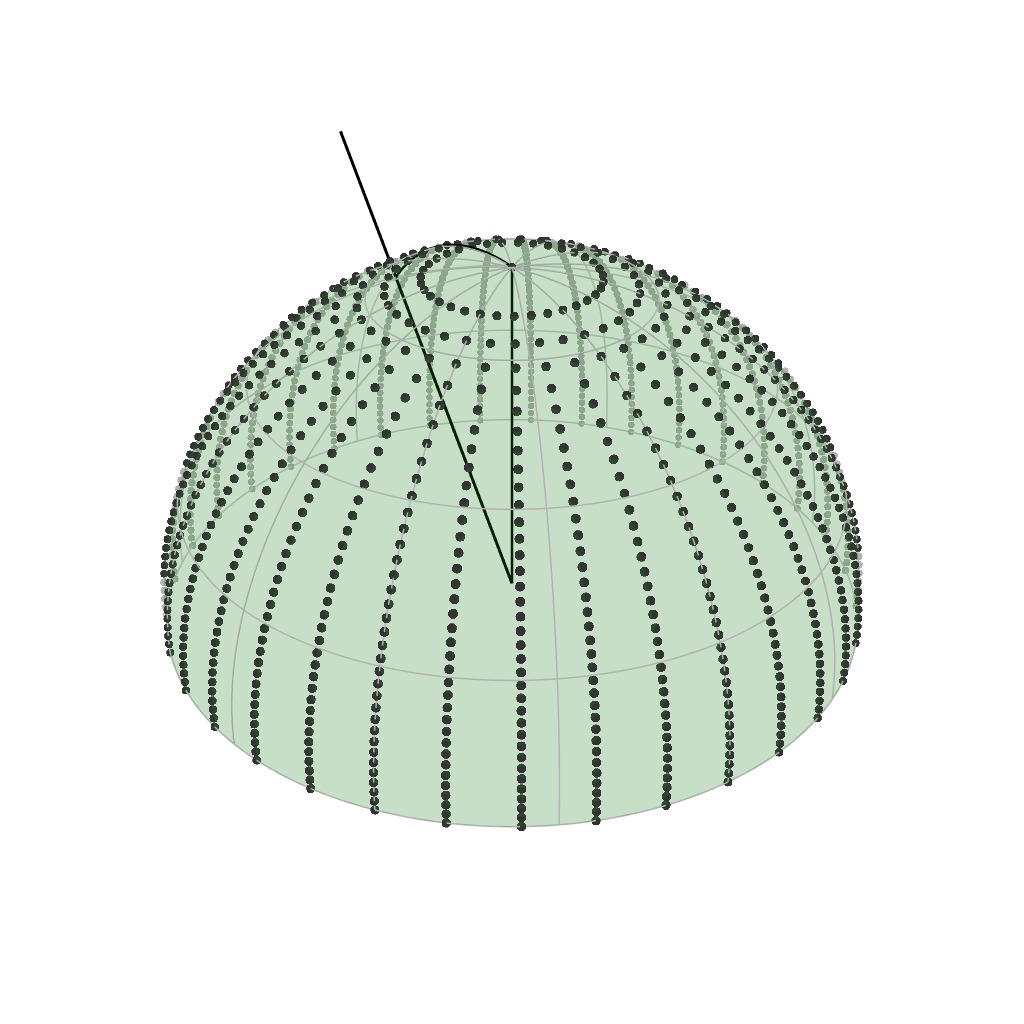

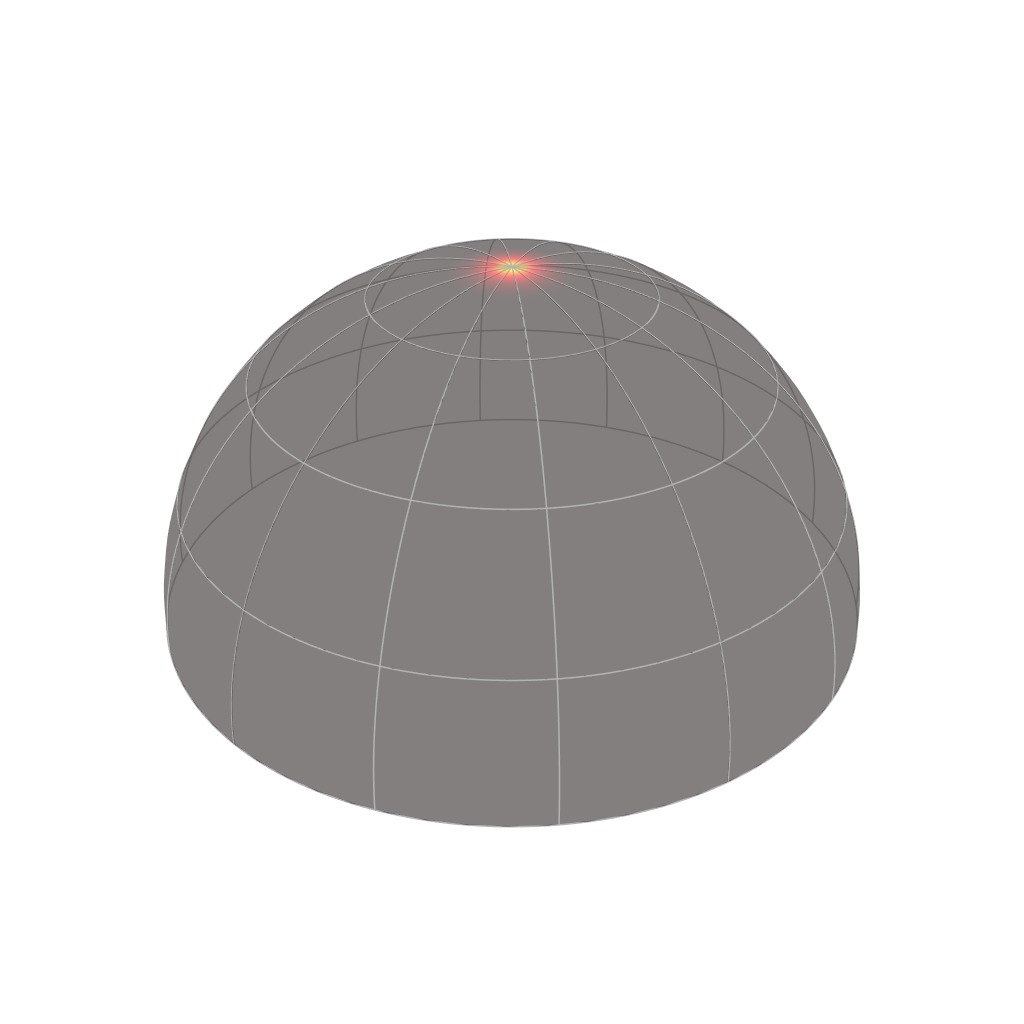

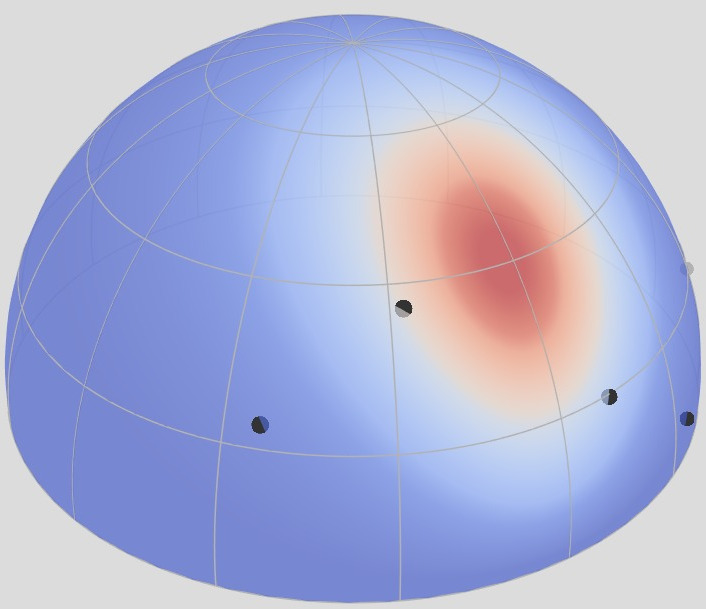

Our Parameterization

NDF

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

Once we have extracted a microfacet NDF from the material we wish to acquire

we then proceed to build our adaptive parameterization that we leverage to

perform 4D measurements at low resolution.

Our Parameterization

NDF

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

Here again, our parameterization is based on insights from microfacet theory.

Our Parameterization

NDF

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

$\boldsymbol{\omega}_m$

$\boldsymbol{\omega}_i$

Specifically, we rely on the notion of projected areas of the microfacets...

Our Parameterization

NDF

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

$\boldsymbol{\omega}_m$

$\boldsymbol{\omega}_i$

$\langle

\boldsymbol{\omega}_i

\cdot

\boldsymbol{\omega}_m

\rangle$

..., which are directly subject to the cosine attenuation law, or Lambert's

attenuation law.

Our Parameterization

NDF

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

$\boldsymbol{\omega}_m$

$\boldsymbol{\omega}_i$

$\langle

\boldsymbol{\omega}_i

\cdot

\boldsymbol{\omega}_m

\rangle$

intuition: sample

$

\propto

\langle

\boldsymbol{\omega}_i

\cdot

\boldsymbol{\omega}_m

\rangle

{\color{blue}D}(\boldsymbol{\omega}_m)

$

Under this intuition, we devise our parameterization such that it importance

samples these projected areas.

Our Parameterization

NDF

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

intuition: sample

$

\propto

\langle

\boldsymbol{\omega}_i

\cdot

\boldsymbol{\omega}_m

\rangle

{\color{blue}D}(\boldsymbol{\omega}_m)

$

$\boldsymbol{\omega}_m$

$\boldsymbol{\omega}_i$

$\langle

\boldsymbol{\omega}_i

\cdot

\boldsymbol{\omega}_m

\rangle$

parametric

BRDF

$\;$

$$g$$

$$\;\;\shortmid\!\longrightarrow\;$$

.

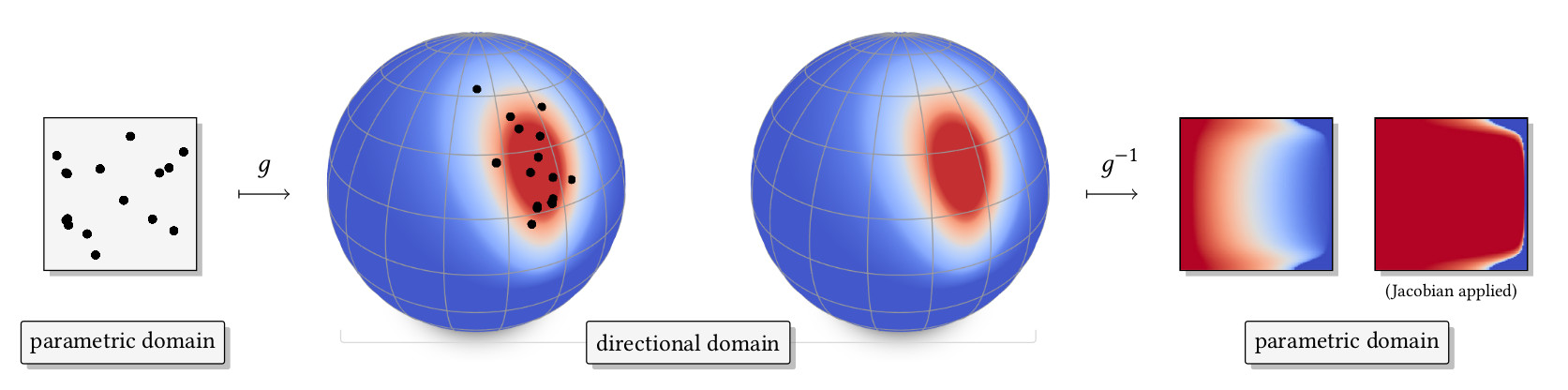

This is the foundation of our adaptive parameterization, which leverages a

bijective mapping between the BRDF's directional space and that of a

unit hypercube.

Our Parameterization

NDF

NDF: ${\color{blue}D}(\boldsymbol{\omega}_m)$

intuition: sample

$

\propto

\langle

\boldsymbol{\omega}_i

\cdot

\boldsymbol{\omega}_m

\rangle

{\color{blue}D}(\boldsymbol{\omega}_m)

$

$\boldsymbol{\omega}_m$

$\boldsymbol{\omega}_i$

$\langle

\boldsymbol{\omega}_i

\cdot

\boldsymbol{\omega}_m

\rangle$

parametric

BRDF

$\;$

$$g$$

$$\;\;\shortmid\!\longrightarrow\;$$

.

Built-in importance sampling

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

For those who are familiar with microfacet theory, this approach is based

exactly on the importance sampling mechanism of Heitz and d'Eon.

[click] an efficient importance sampling

mechanism, because the way we importance sample it is exactly the same as the

one we use to measure it in the first place.

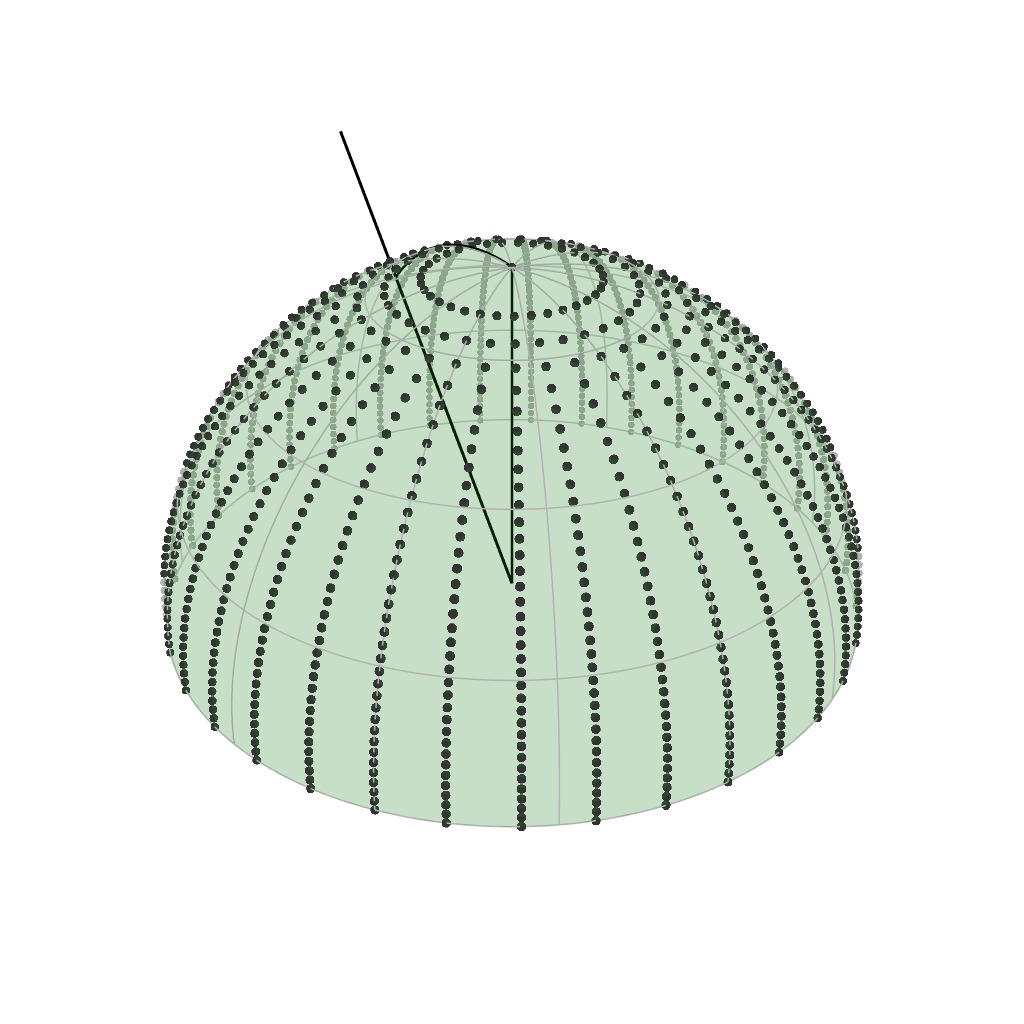

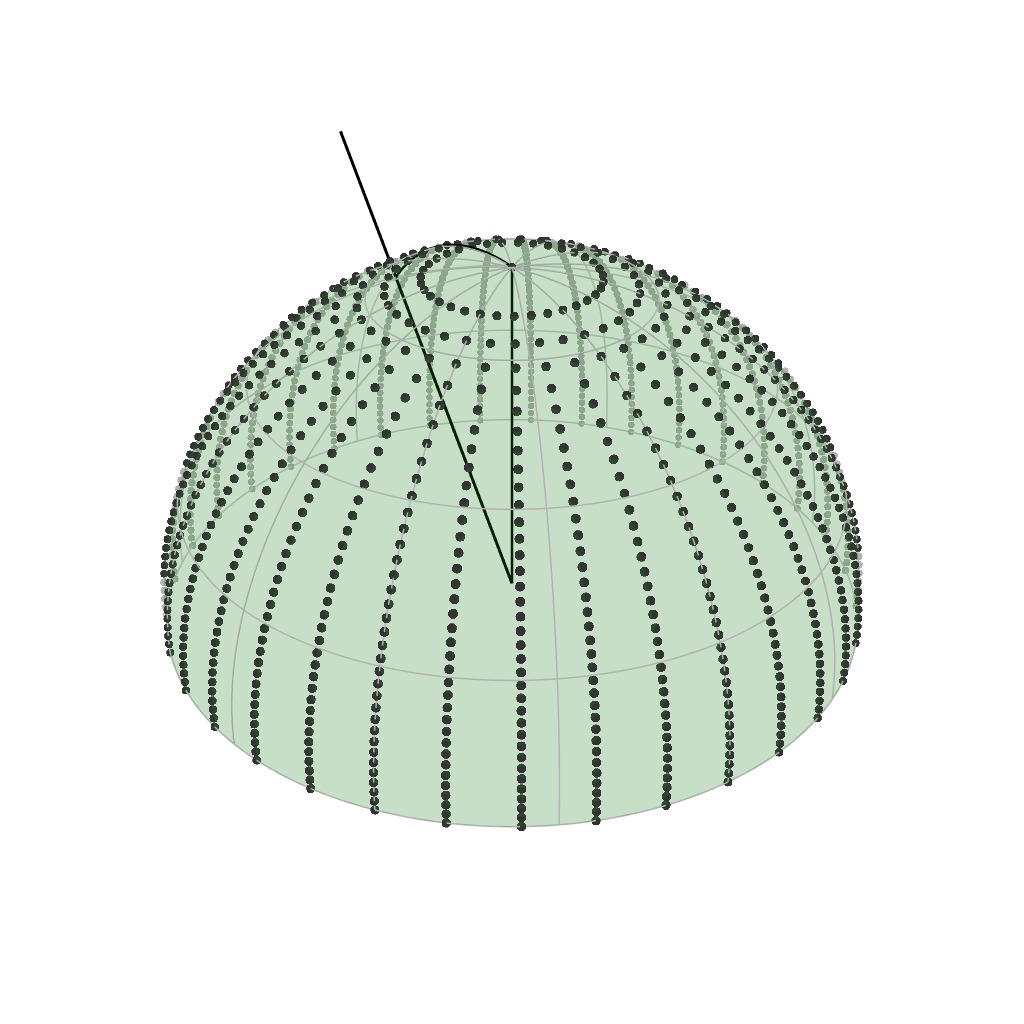

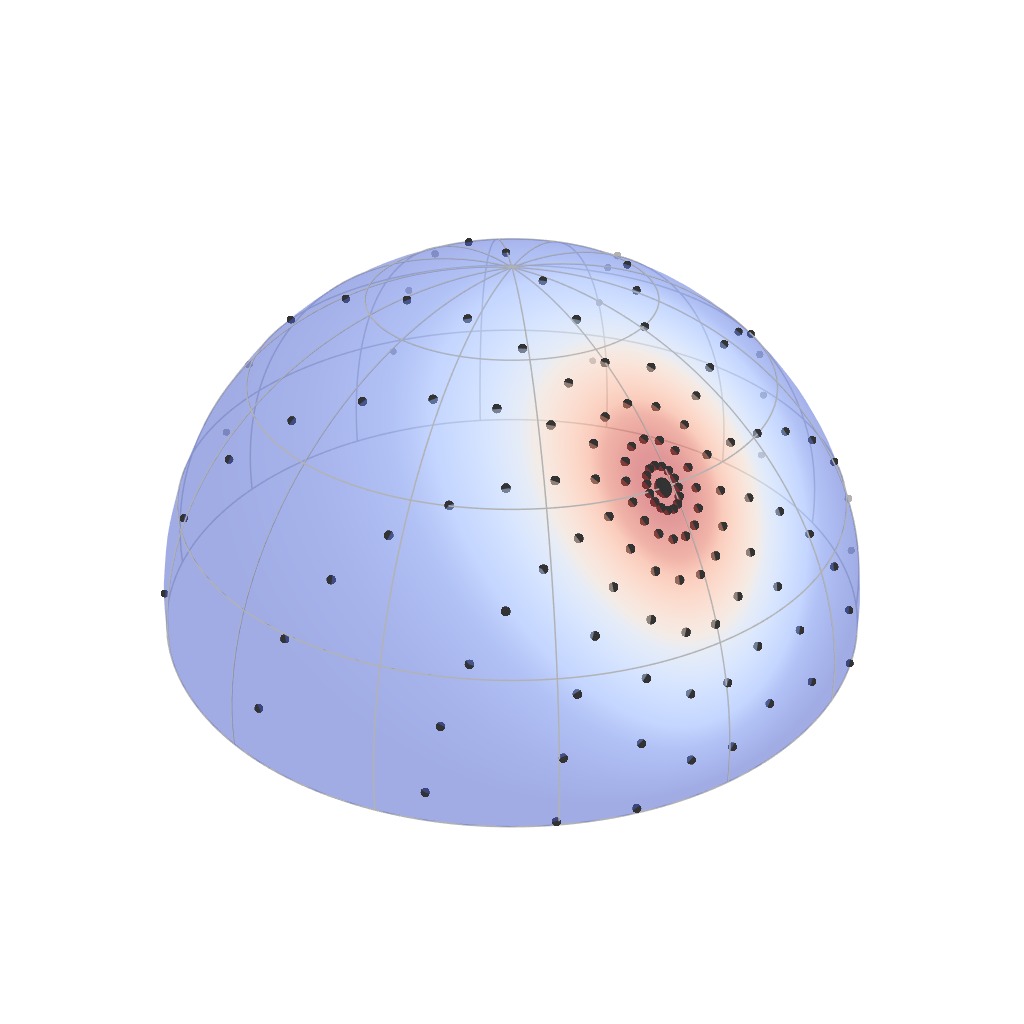

Our Parameterization

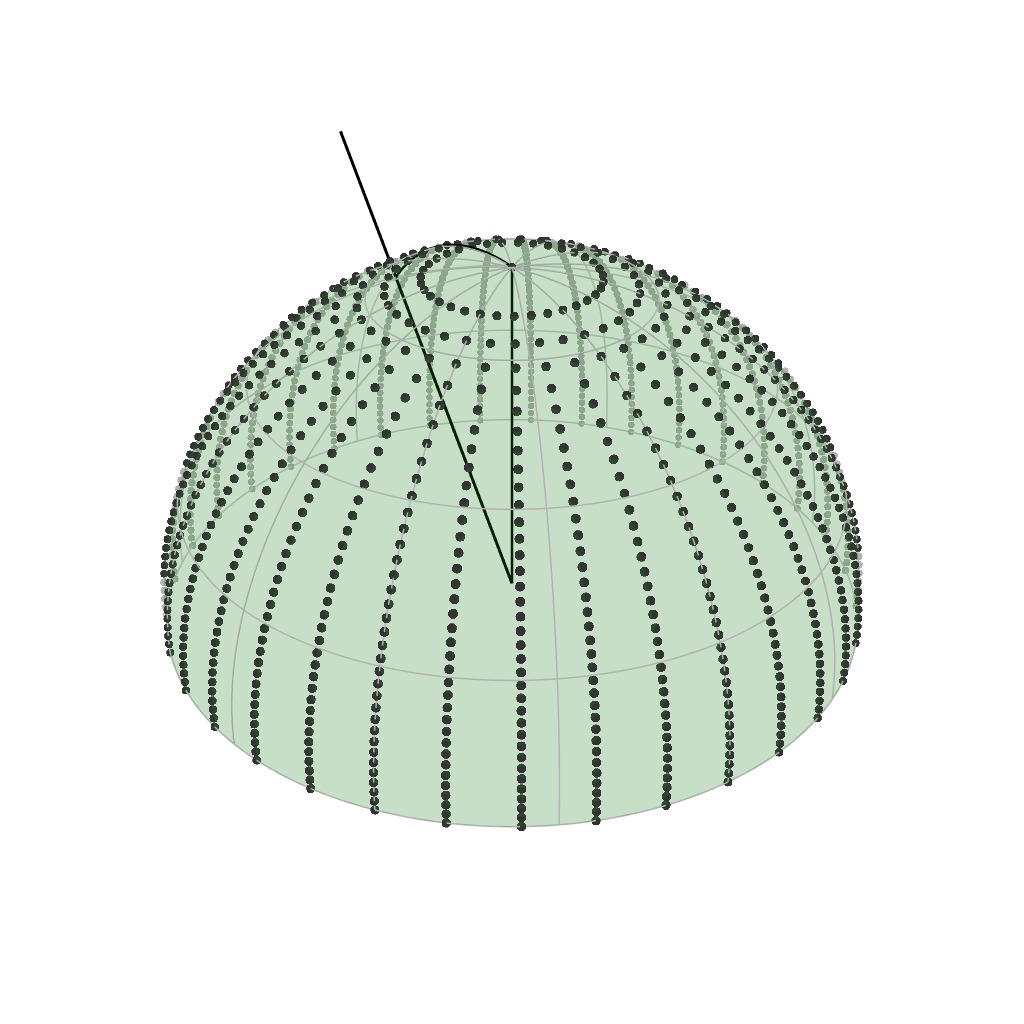

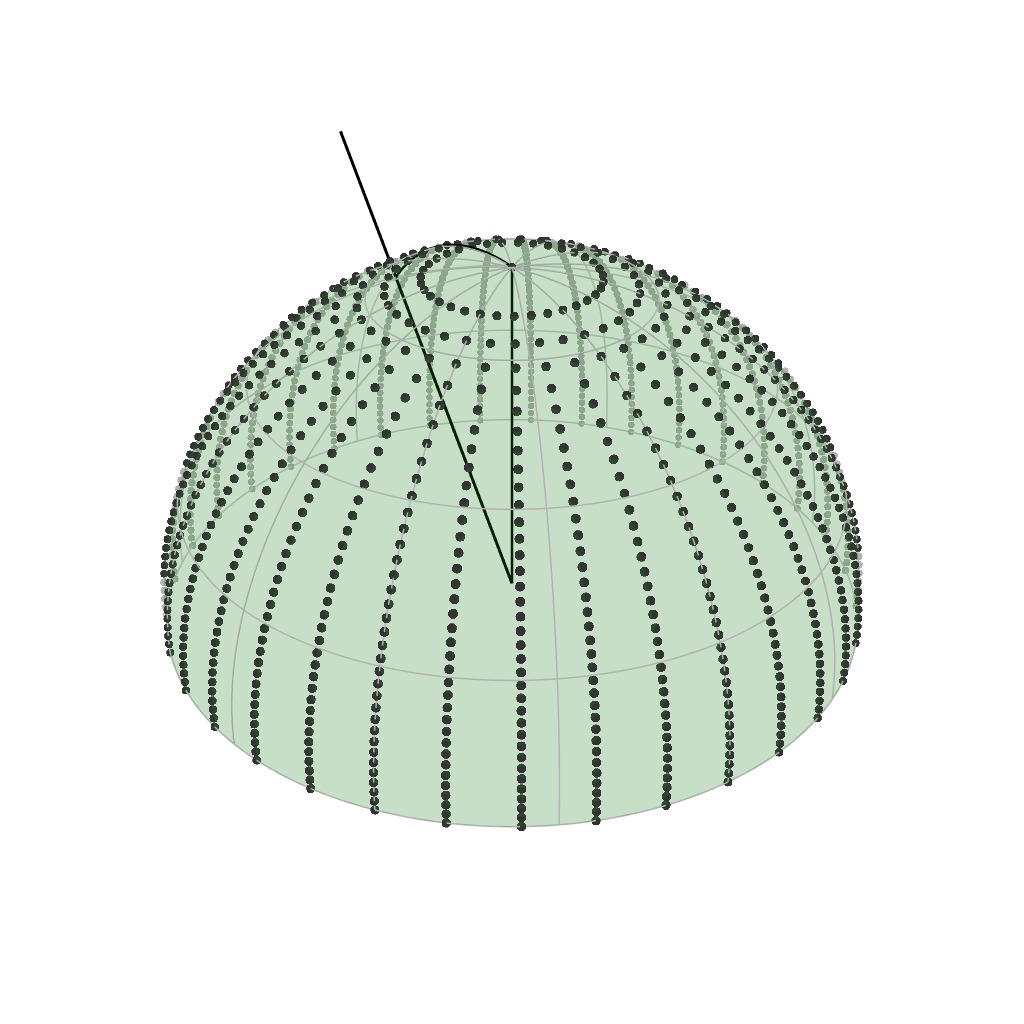

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Prepass, then:

[Importance Sample]

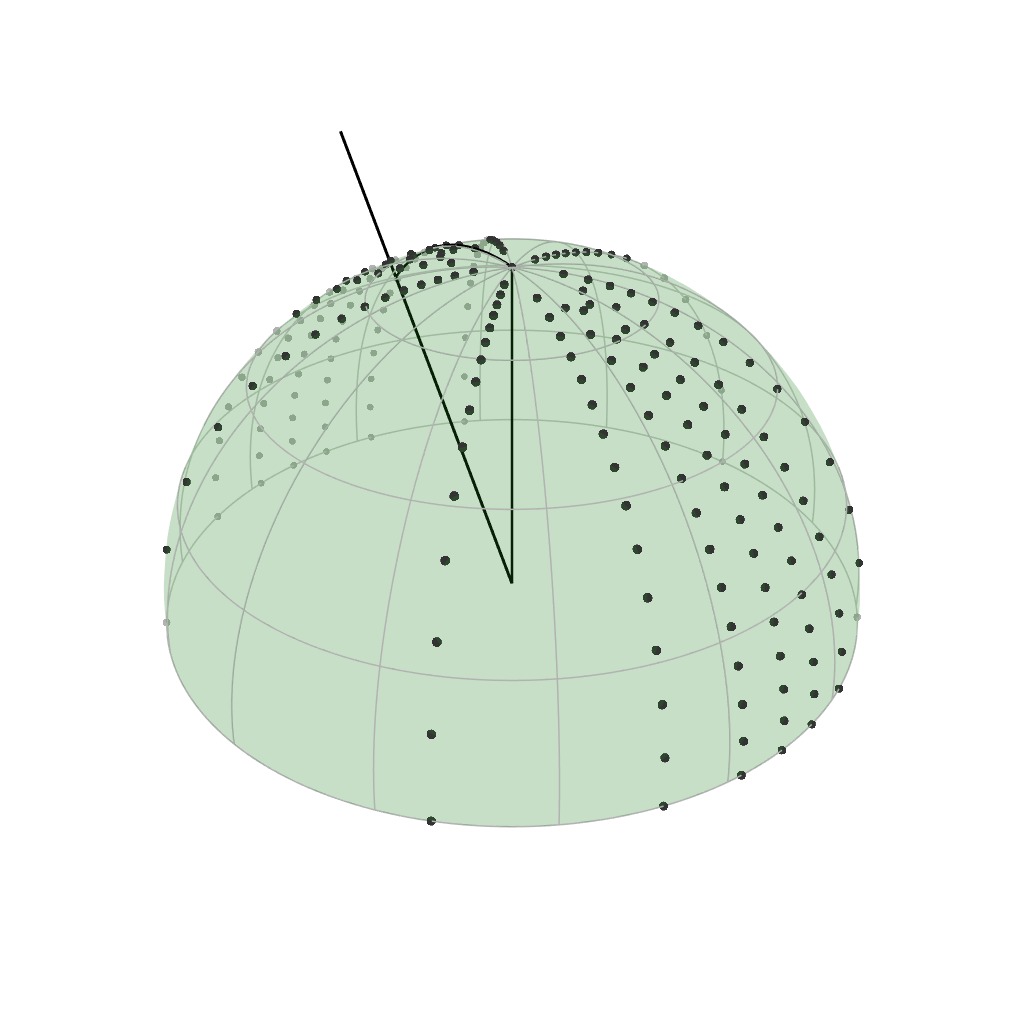

[Importance Sample]

... that effectively importance samples the 4D directional domain of the BRDF.

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Prepass, then:

[Importance Sample]

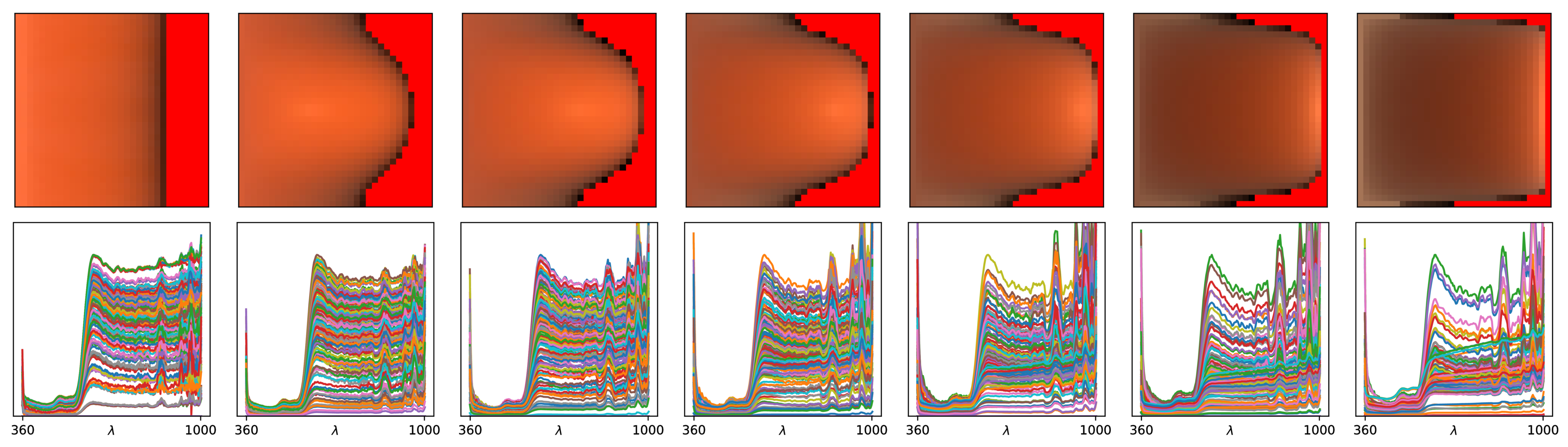

[Importance Sample]

32x32

In practice we discretize the outgoing domain at 32x32 resolution.

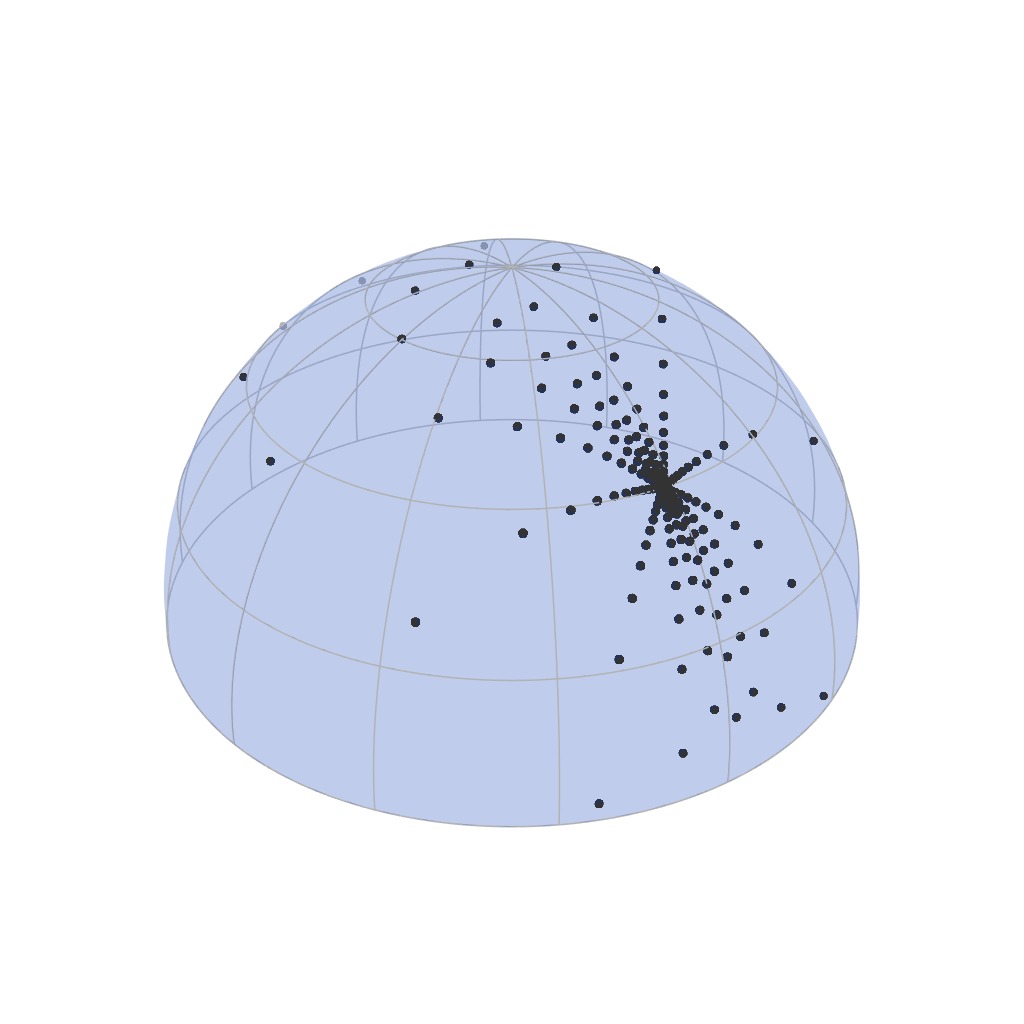

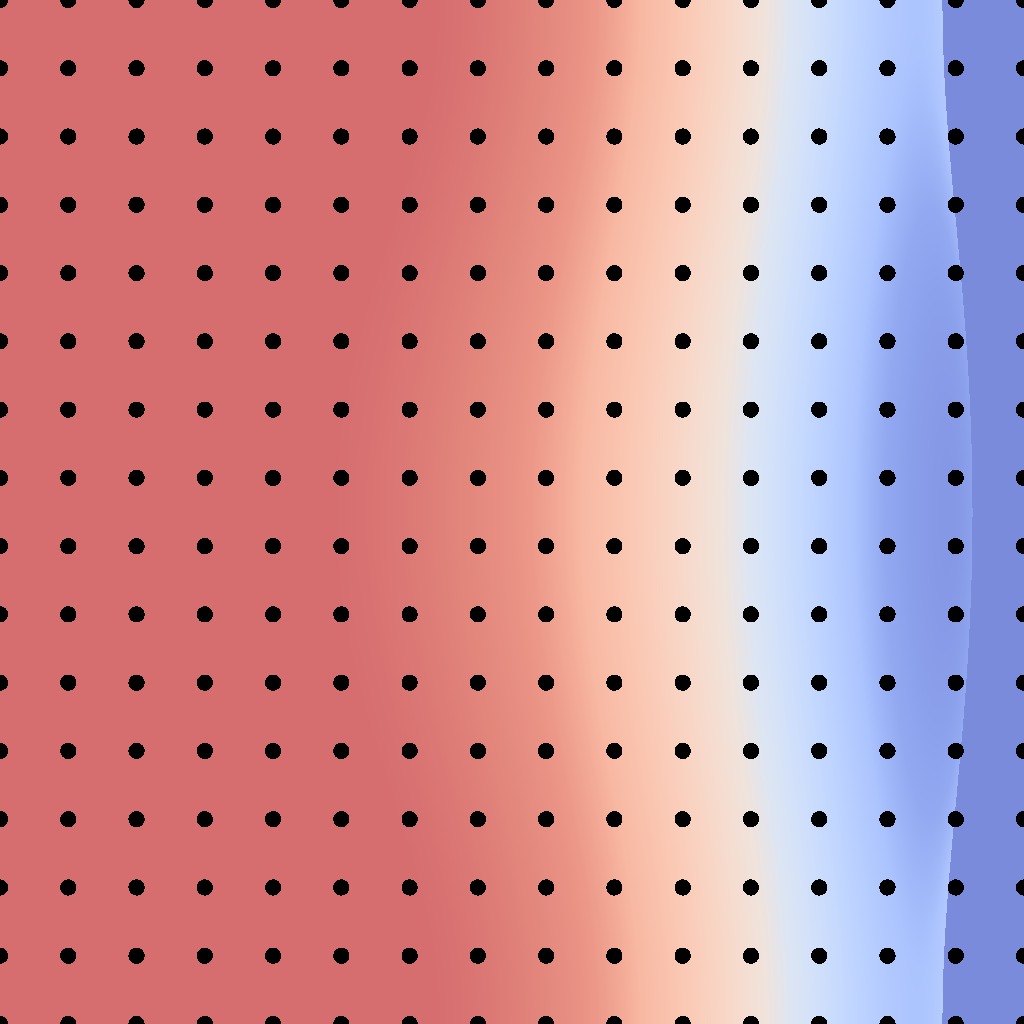

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Shiny Material

Prepass, then:

[Importance Sample]

[Importance Sample]

32x32

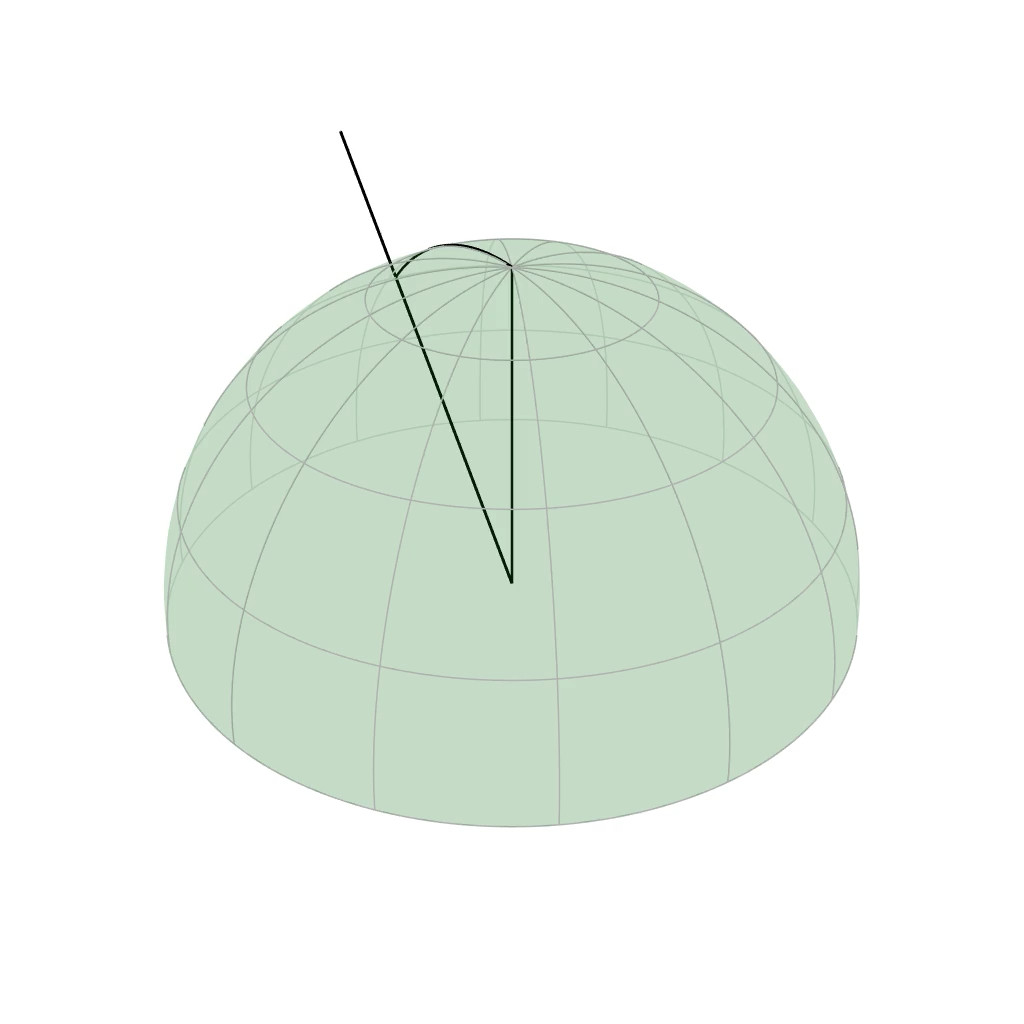

As expected, the samples get more concentrated for shiny materials...

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Rough Material

Prepass, then:

[Importance Sample]

[Importance Sample]

32x32

... and more dilated for rough materials...

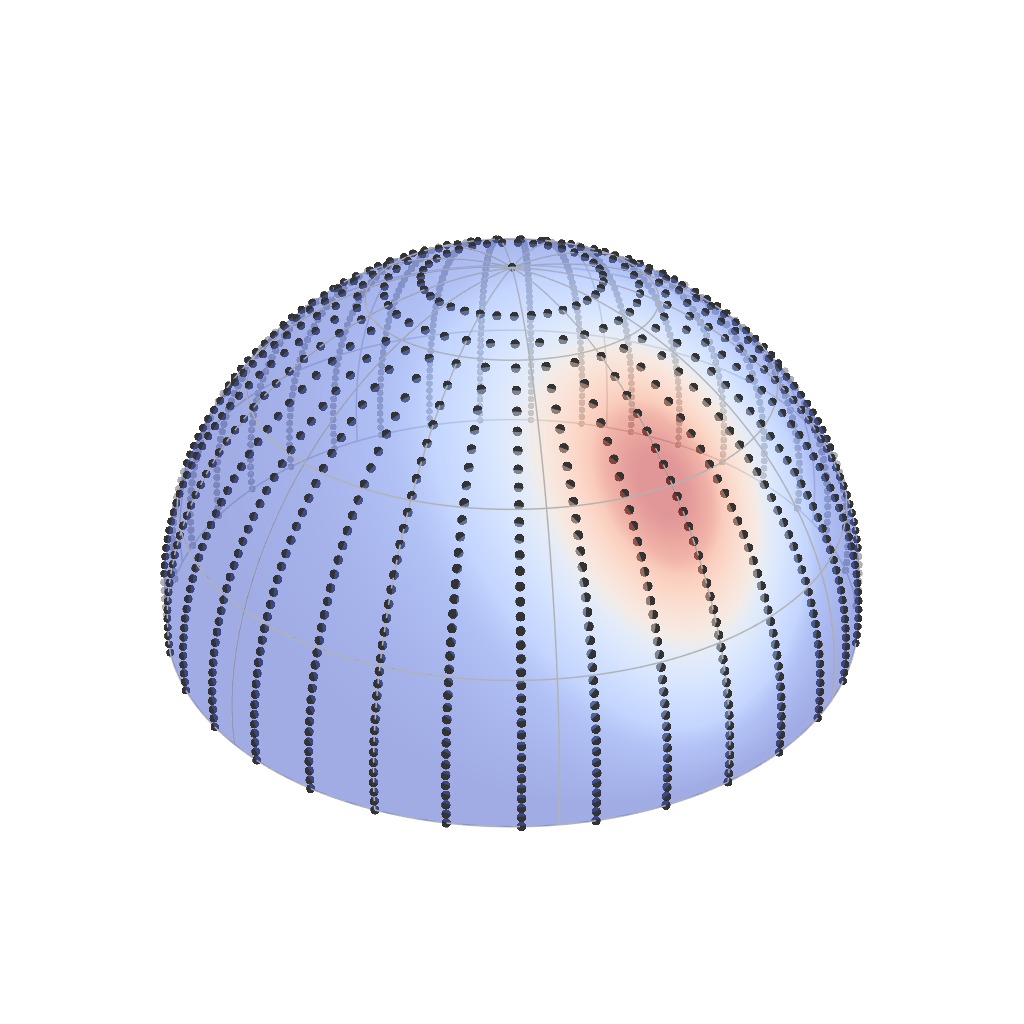

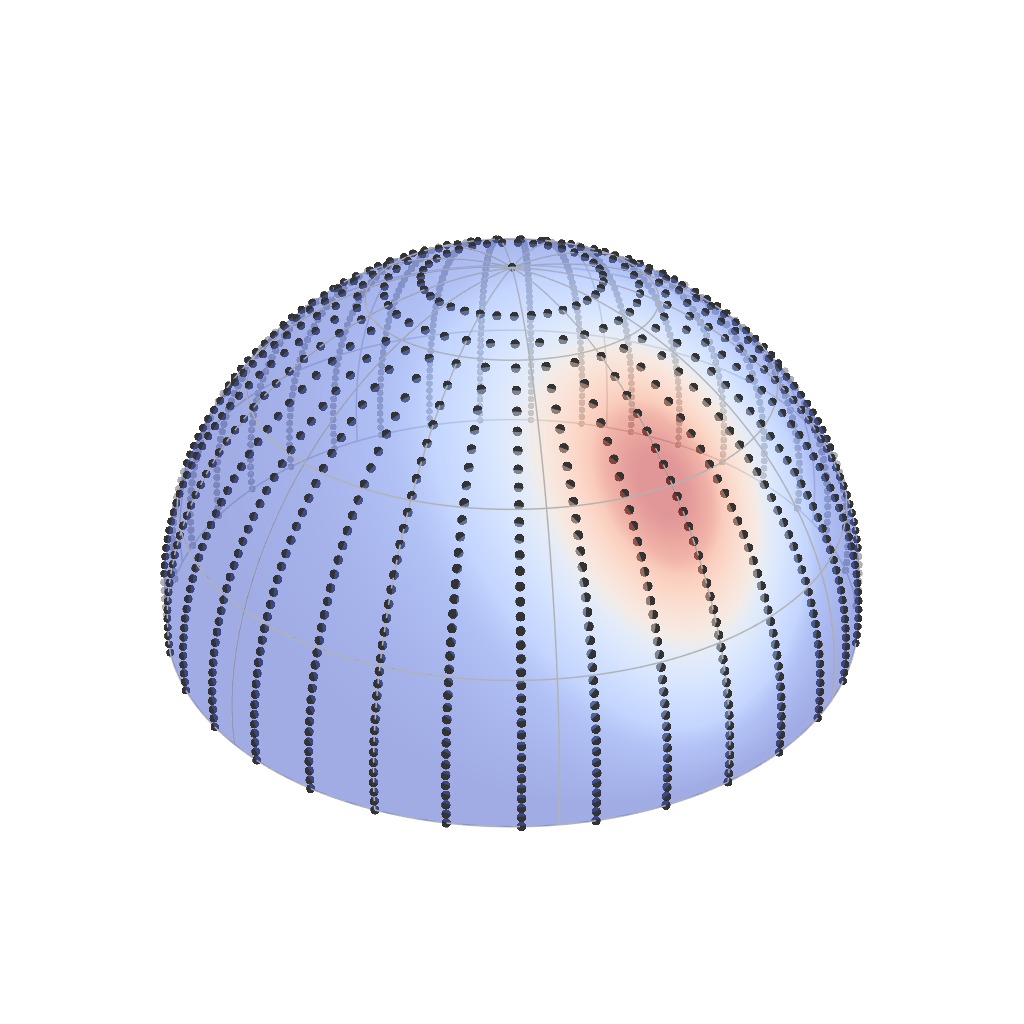

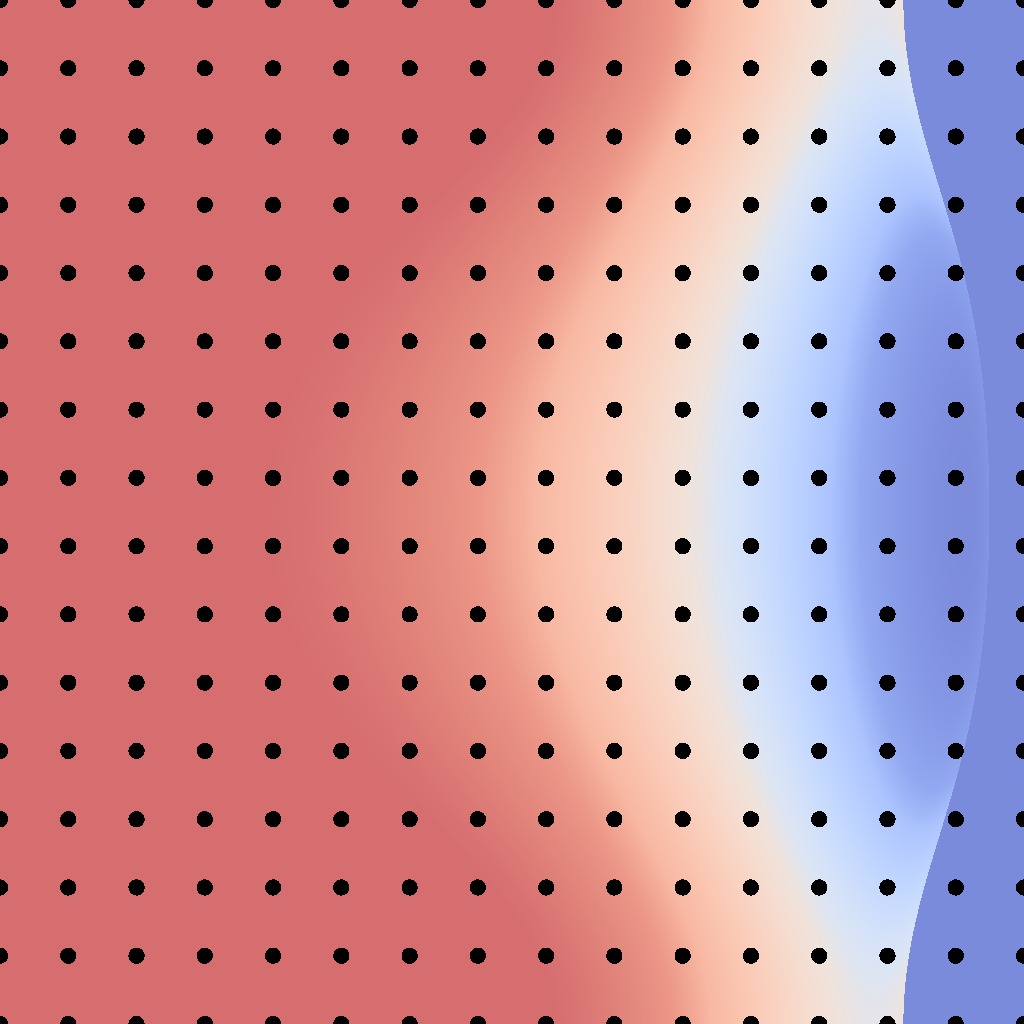

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Anisotropic Material

Prepass, then:

[Importance Sample]

[Importance Sample]

32x32

... If the input material is anisotropic, then the samples are warped along

the main directions of radial asymetry.

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Anisotropic Material

Prepass, then:

[Importance Sample]

[Importance Sample]

32x32

(here is the final BRDF lobe to emphasize that the samples are indeed placed

at efficient locations)

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Anisotropic Material

Prepass, then:

[Importance Sample]

[Importance Sample]

32x32

8x16

100K samples:

xx

2.5 days

x

[1 meas/s]

512 KiB

per wavelength

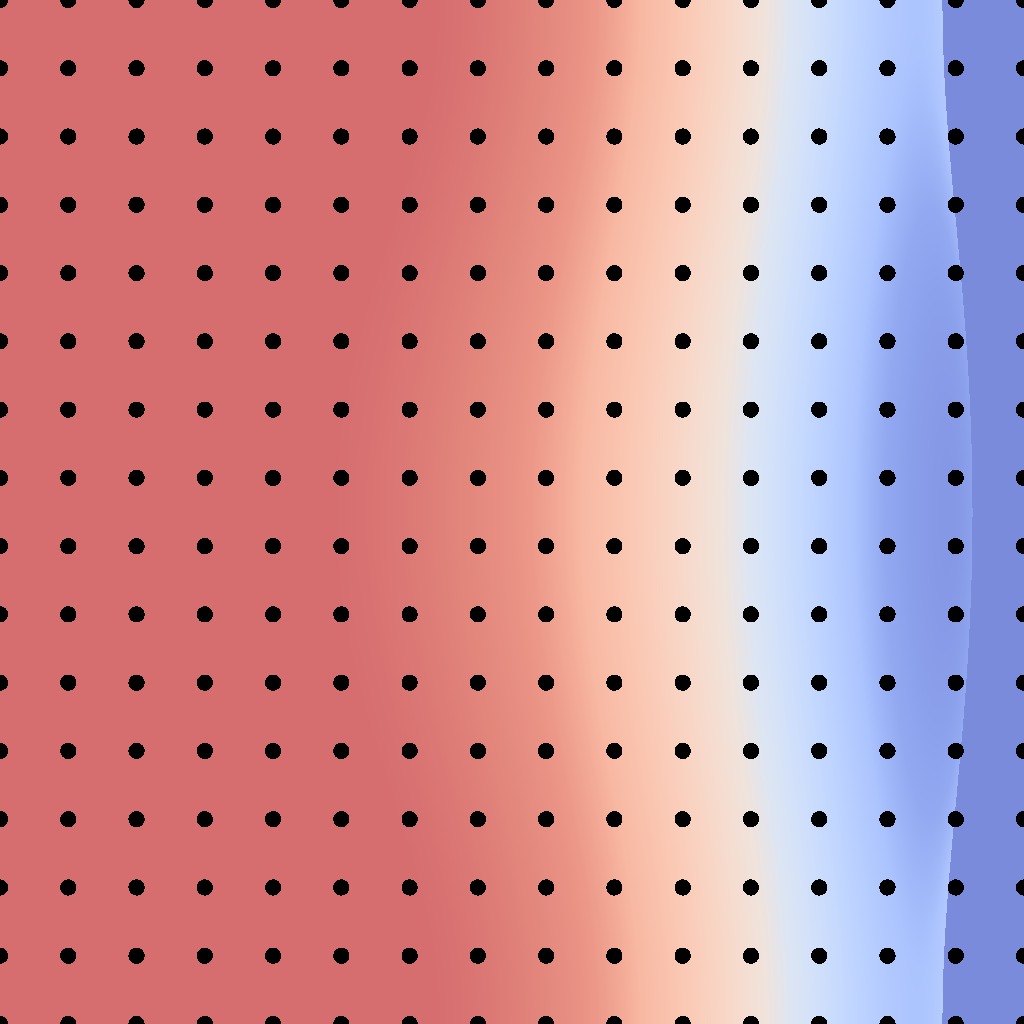

We discretize the incident domain into 8 elevations and 16 azimuthal angles,

so that their distribution also accounts for the characteristics of the

material. For instance, in the case of an anisotropic material, the azimuthal

distribution of incident samples will concentrate around the regions of

high curvature, where anisotropy leads to more dramatic BRDF variations.

[click] 2.5

days in total, recquiring a 512KiB of memory per wavelength.

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Anisotropic Material

Prepass, then:

[Importance Sample]

[Importance Sample]

32x32

8x16

And that's for the case of an anisotropic BRDF.

Our Parameterization

$f_r^\perp(\boldsymbol{\omega}_i = \boldsymbol{\omega}_o)$

Incident domain

Outgoing domain

Isotropic Material

Prepass, then:

[Importance Sample]

[Importance Sample]

32x32

8x1

8K samples:

xx

2.2 hours

x

[1 meas/s]

32 KiB

per wavelength

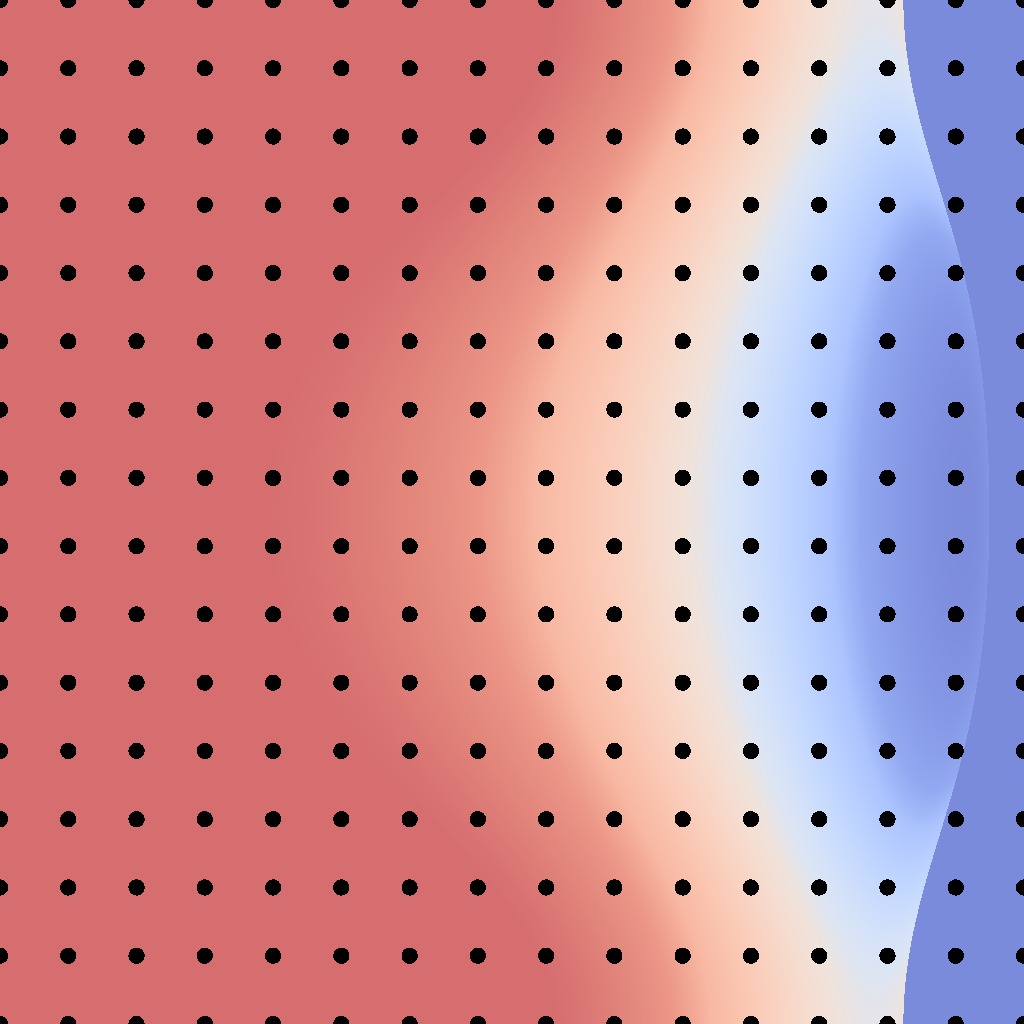

It turns out that for isotropic BRDFs, which we can detect via their

radially symmetric retro-reflective lobes, we can be even faster.

For such materials,

only a single slice of the incident domain is necessary due to radial

symmetry (just as for the MERL database).

[click] 3

hours in total, recquiring a 32KiB of memory per wavelength.

Your browser does not support the video tag.

Our Pipeline

Here is our measurement pipeline again. Showing the retro-reflective response

and the 4D measurements.

OK now let's see some cool acquisition results. Our database

is entirely free and available online at [click] the following

website [website live demo].

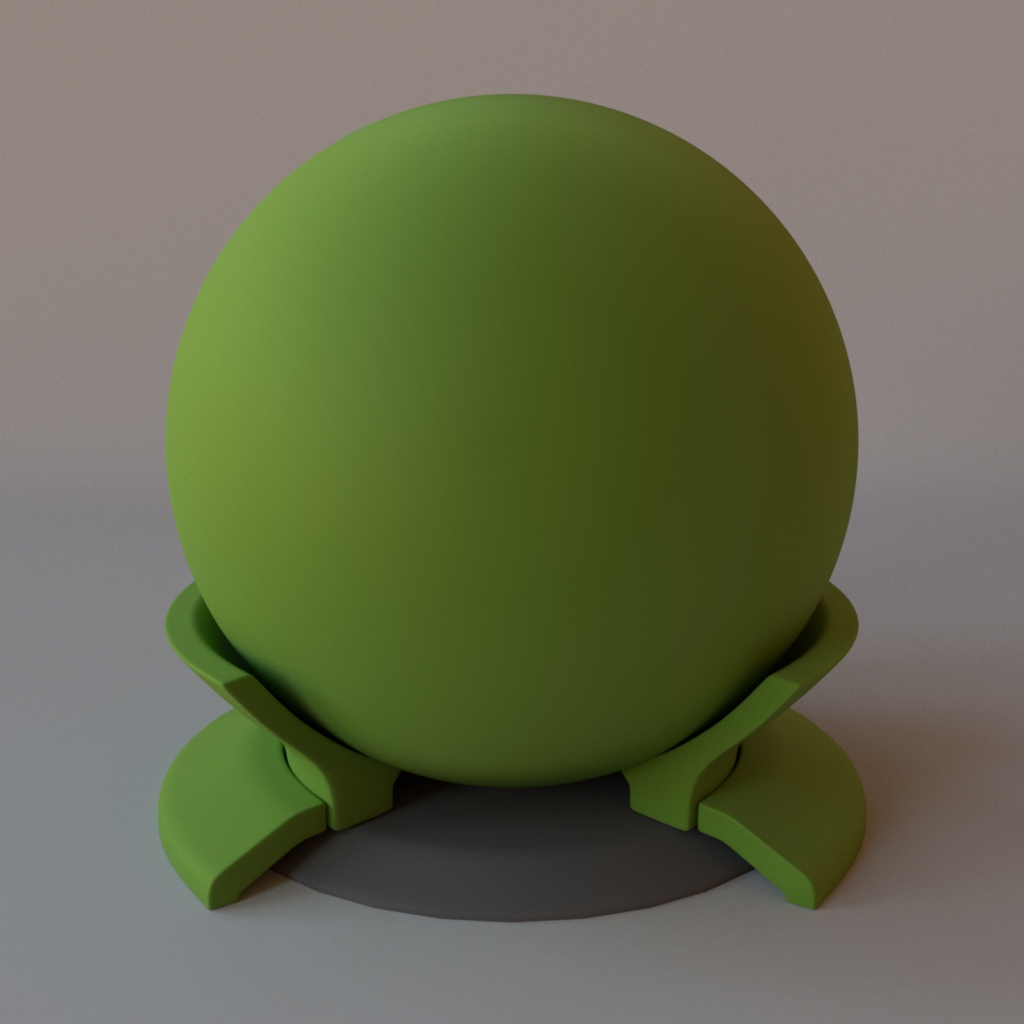

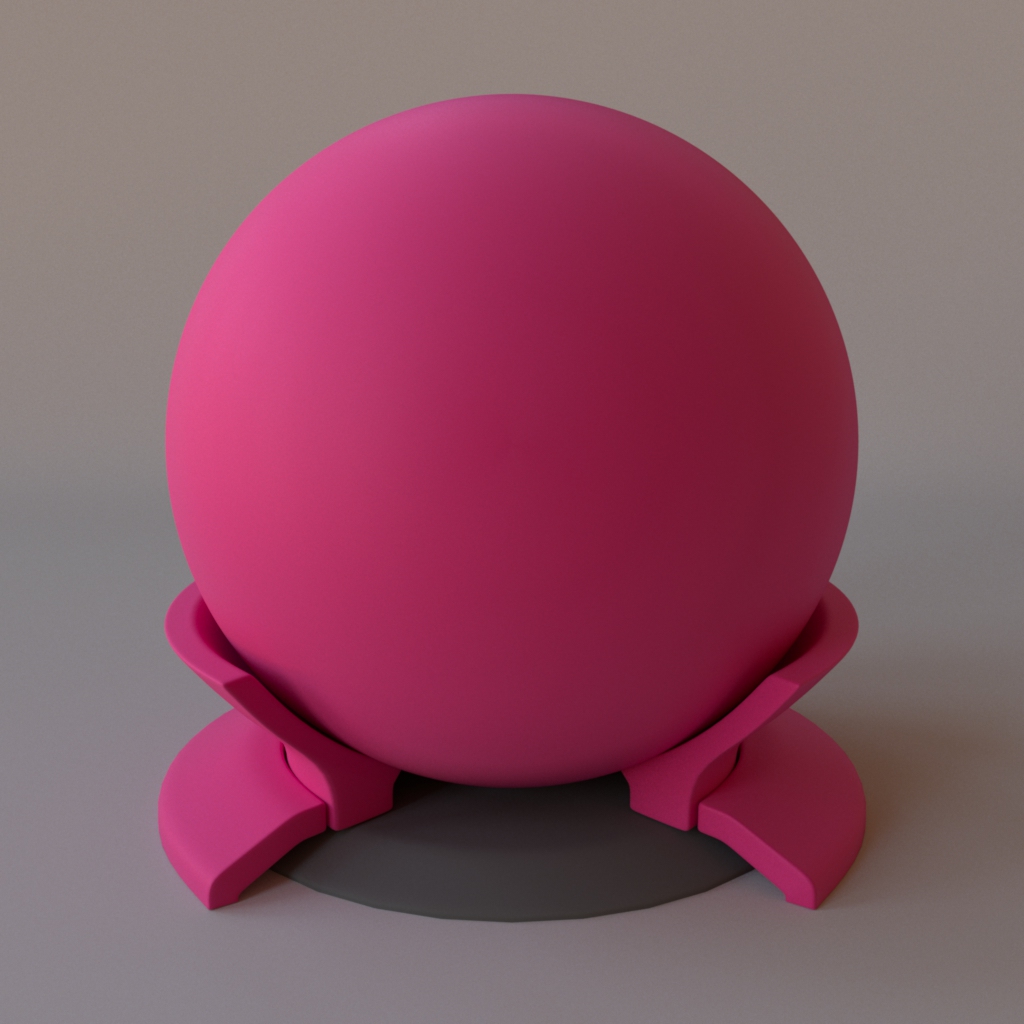

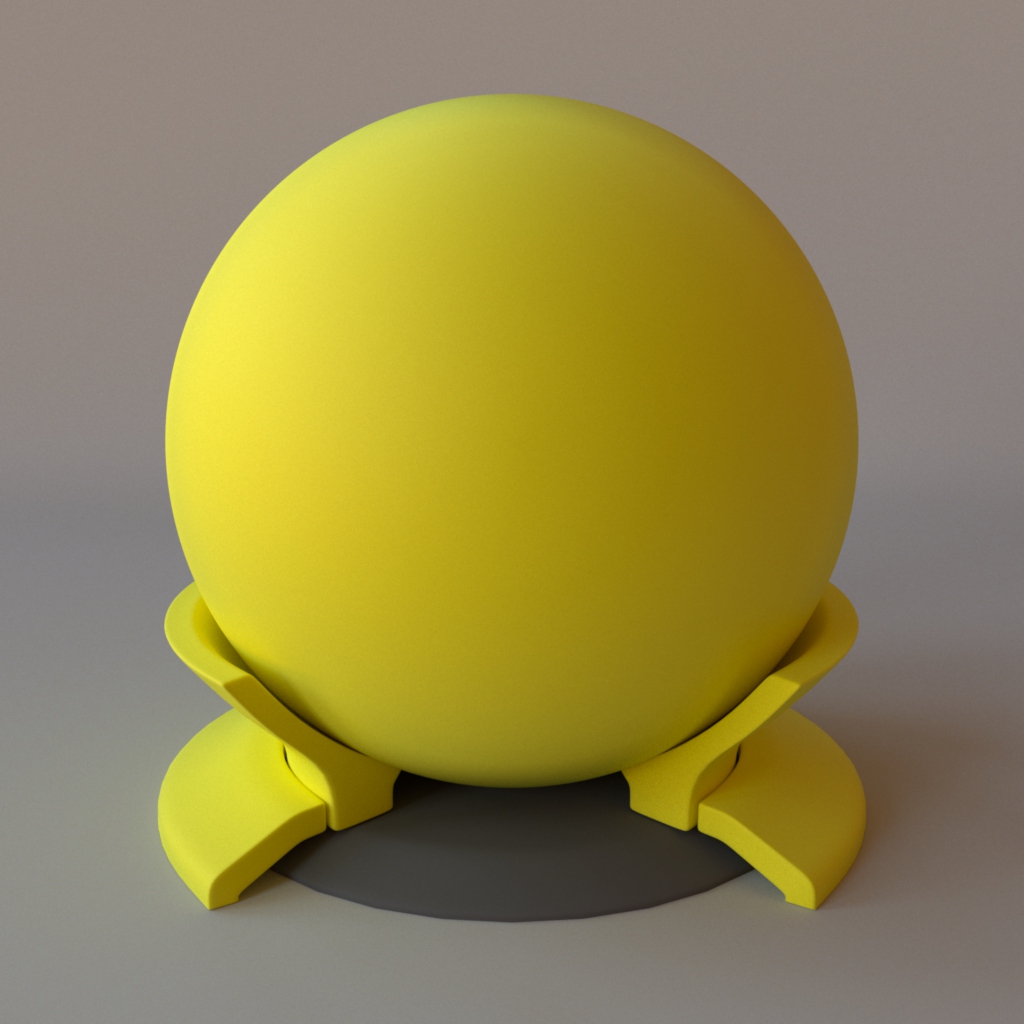

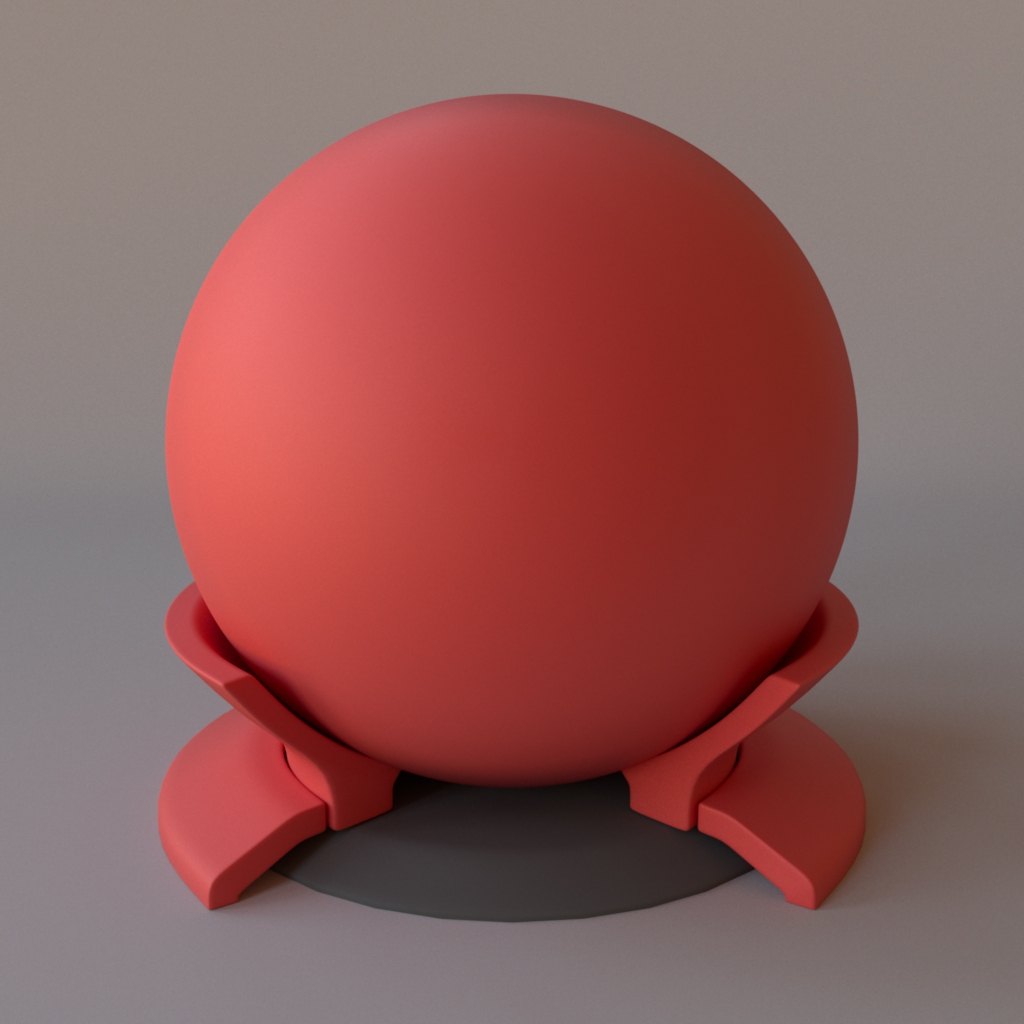

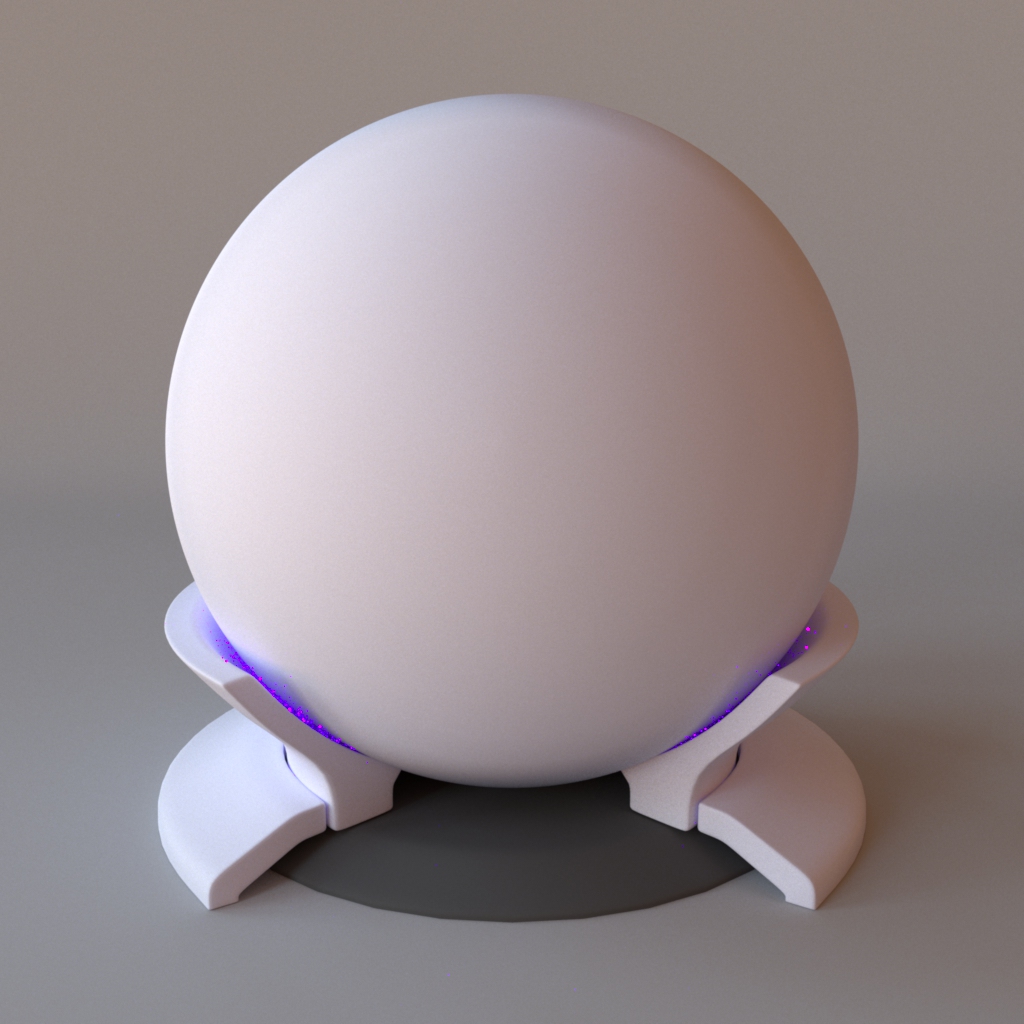

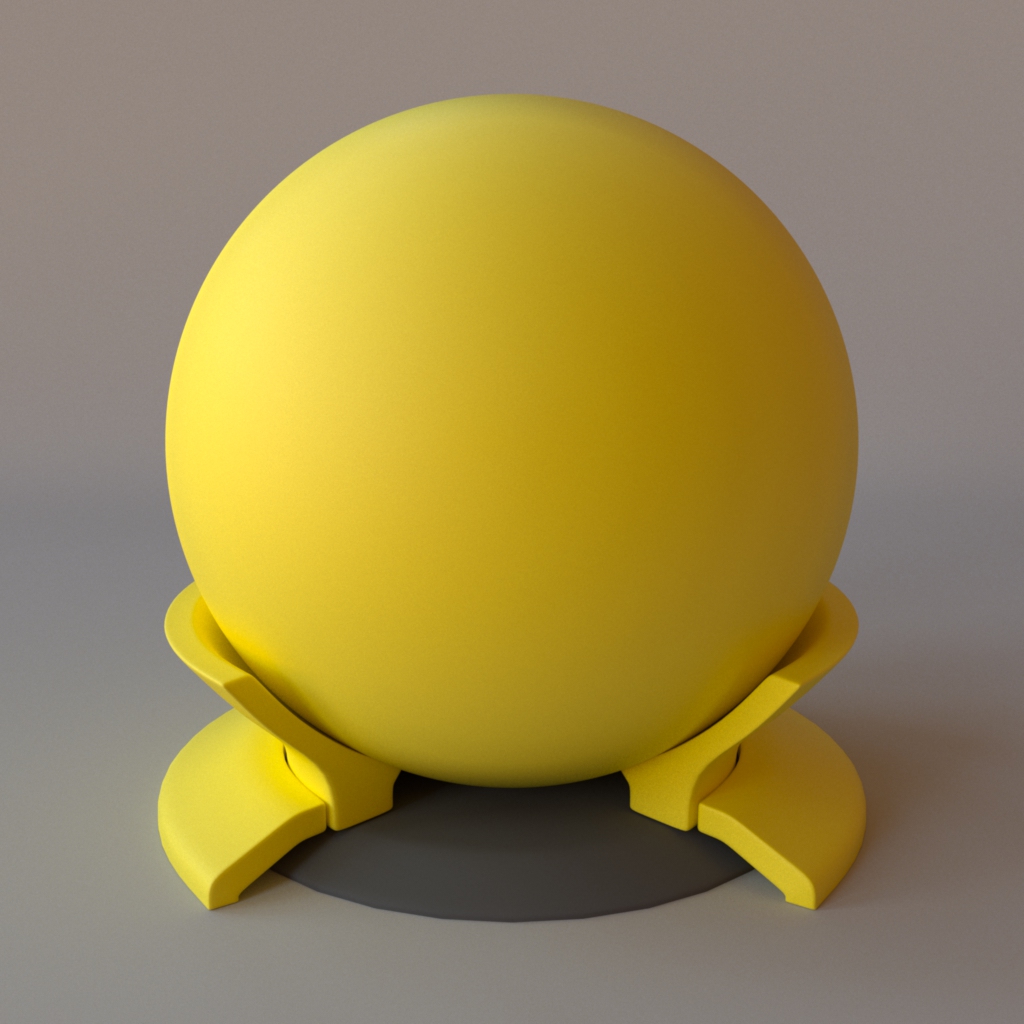

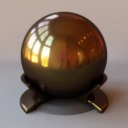

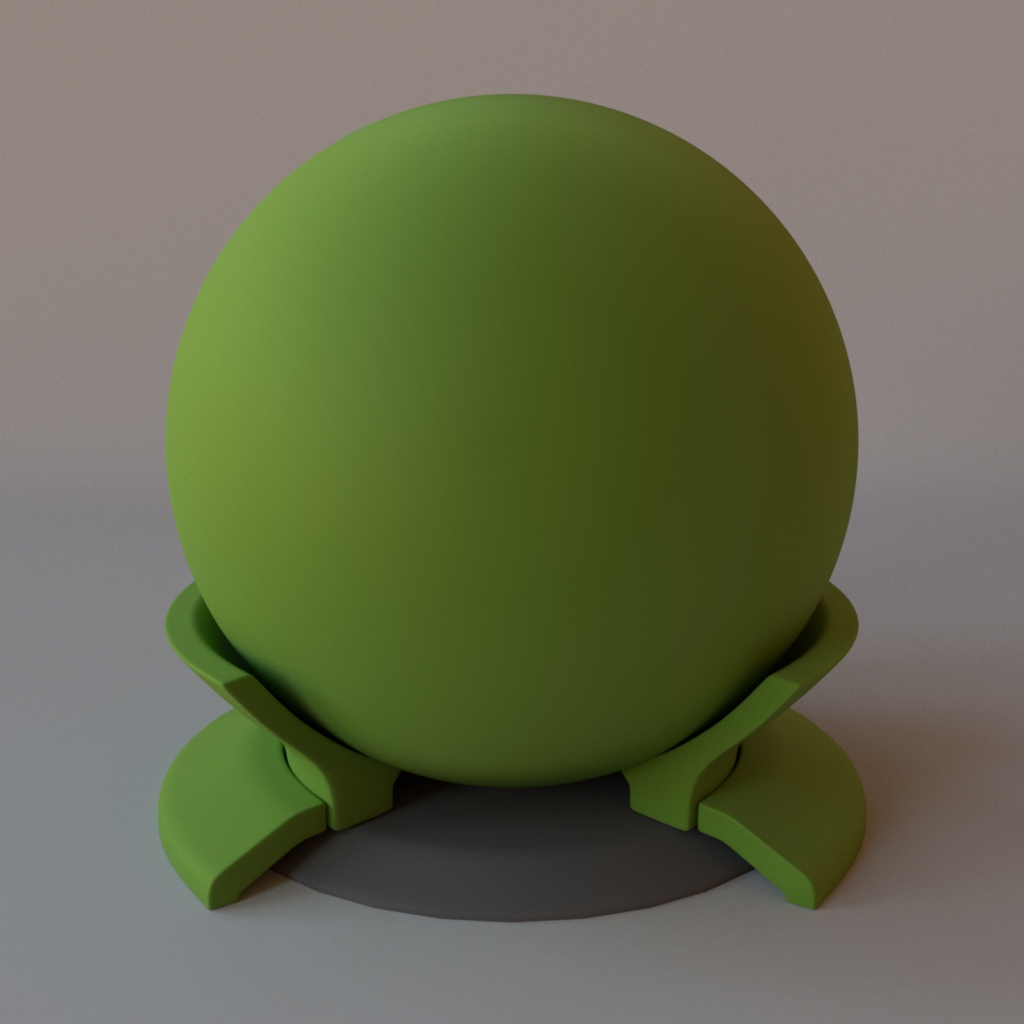

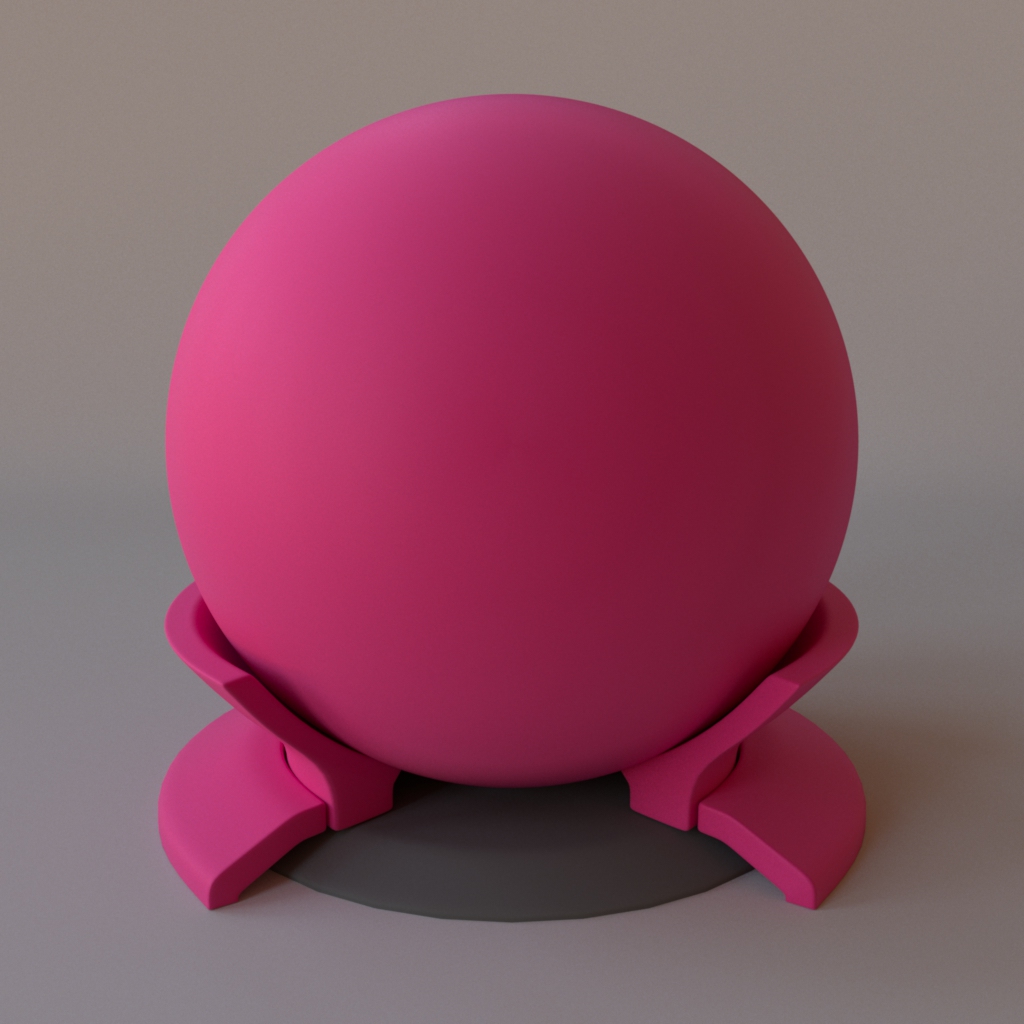

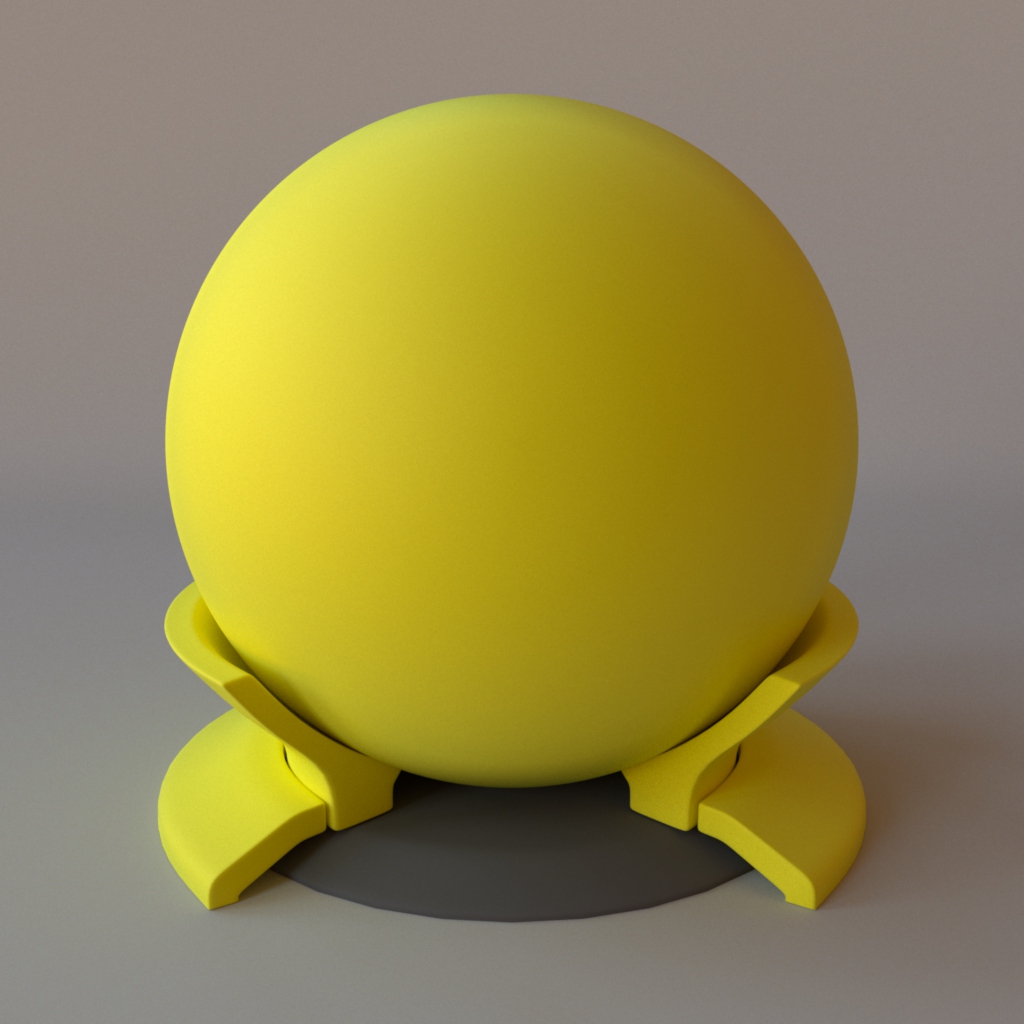

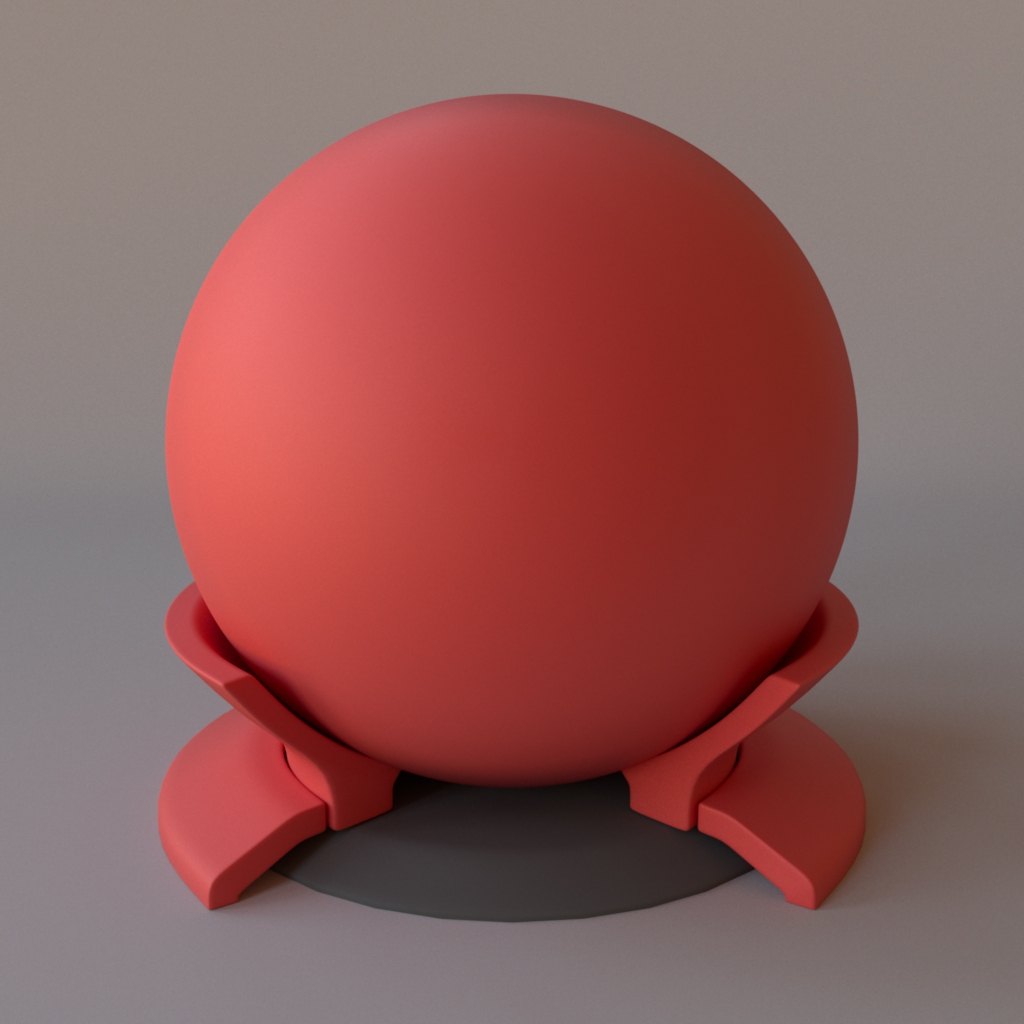

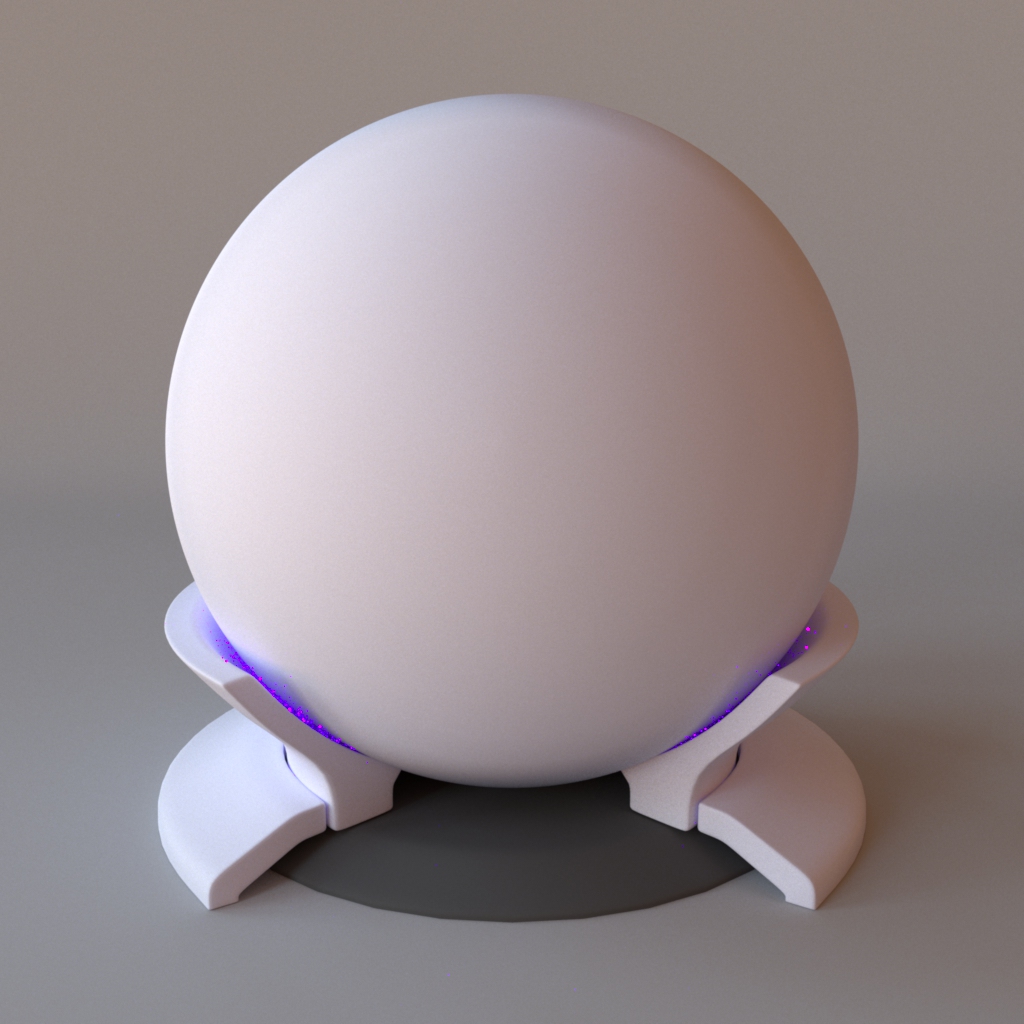

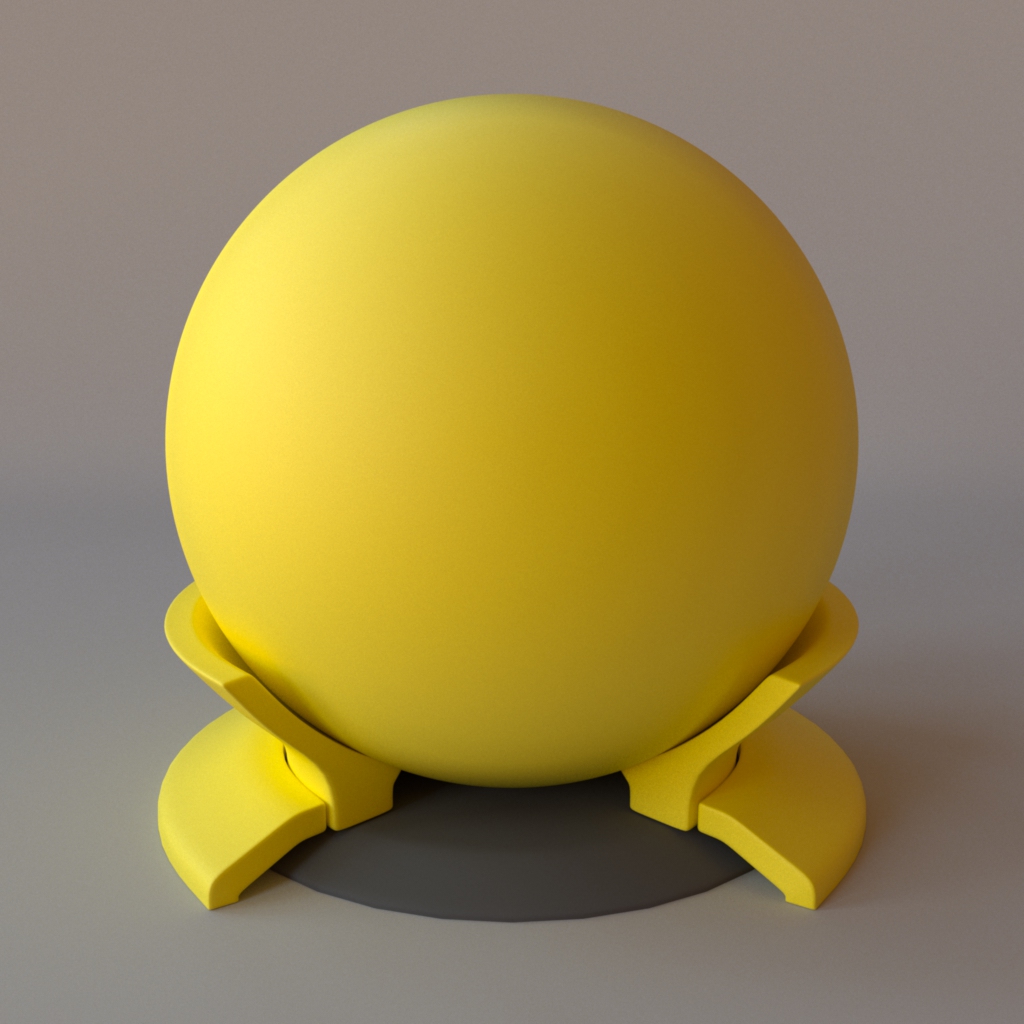

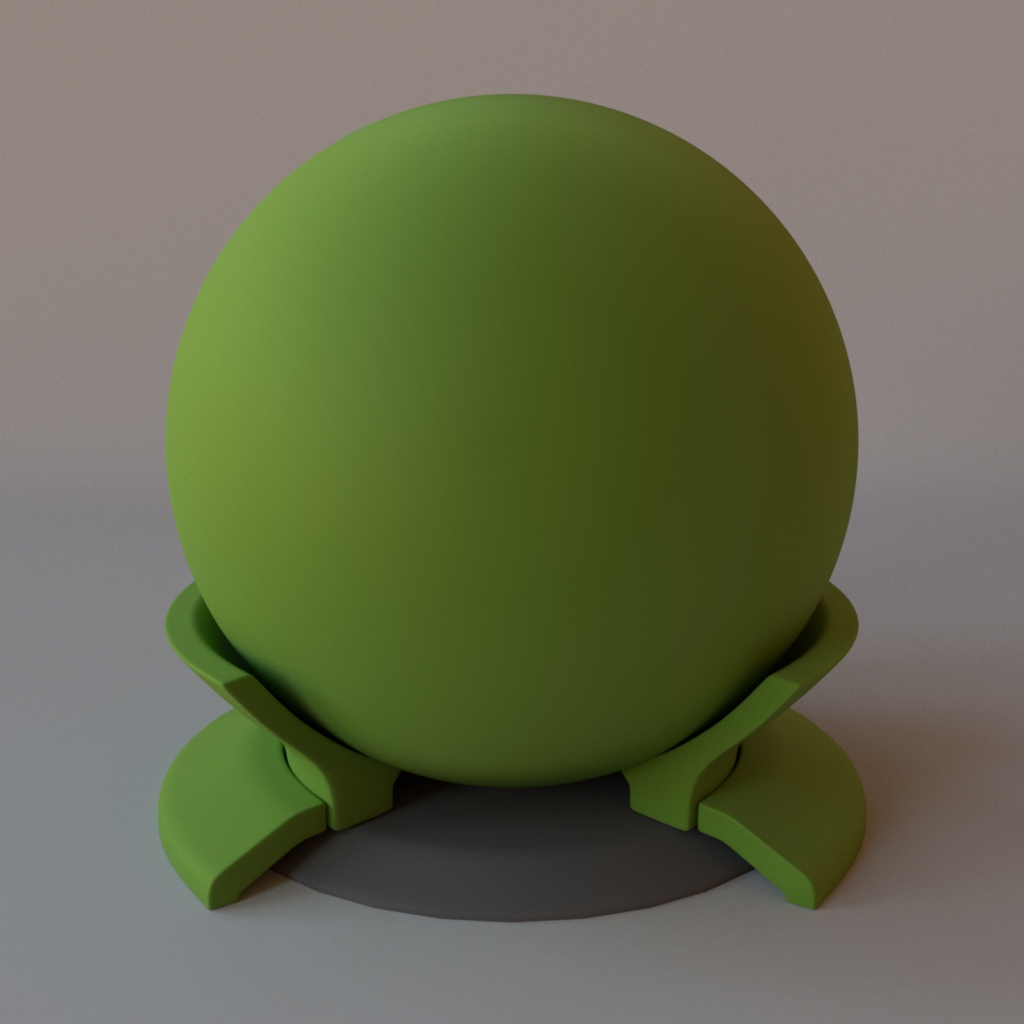

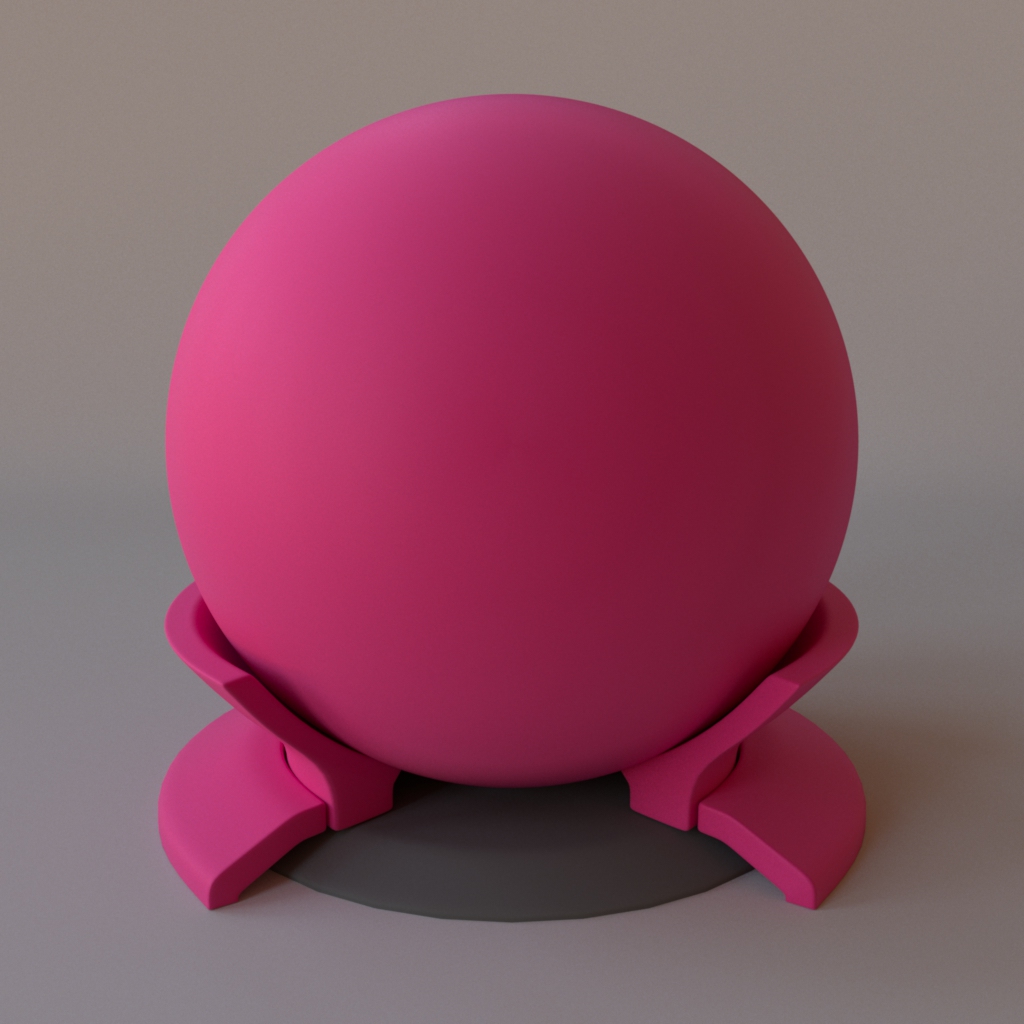

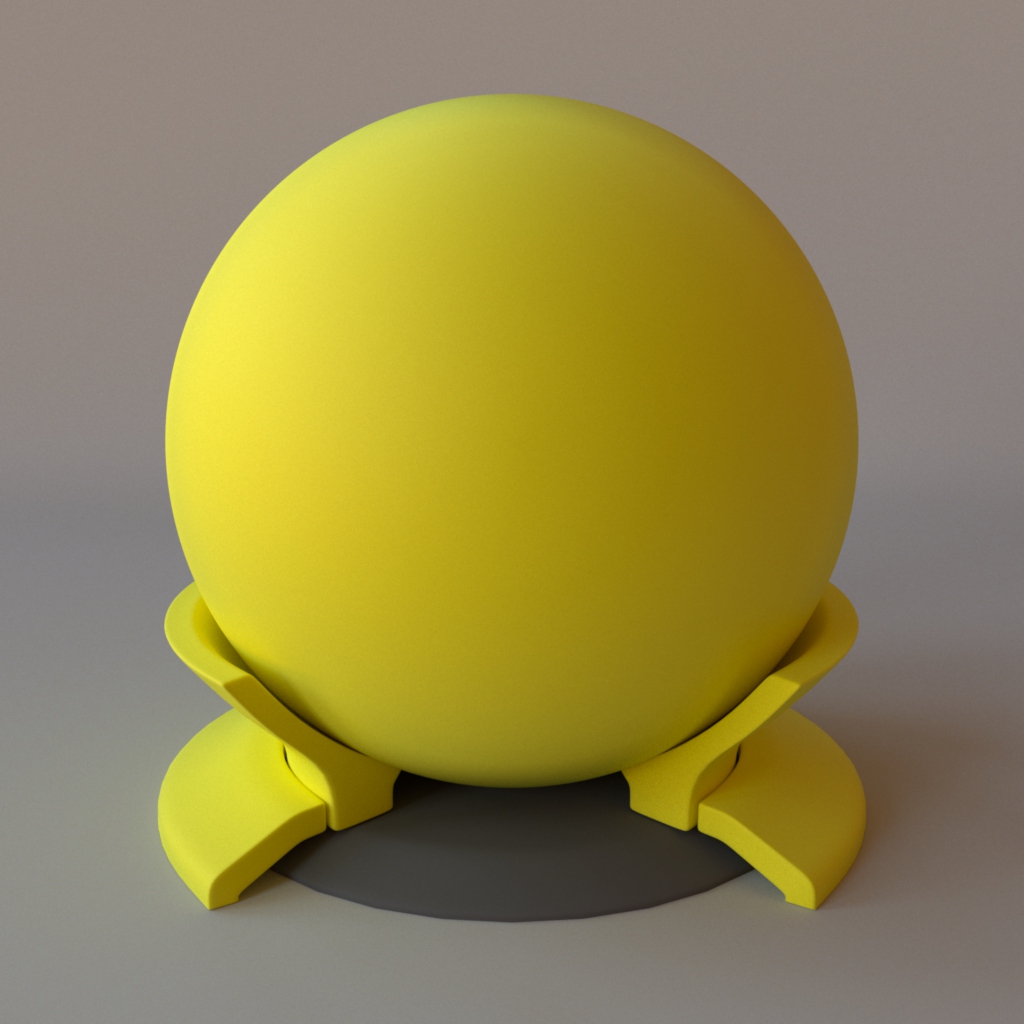

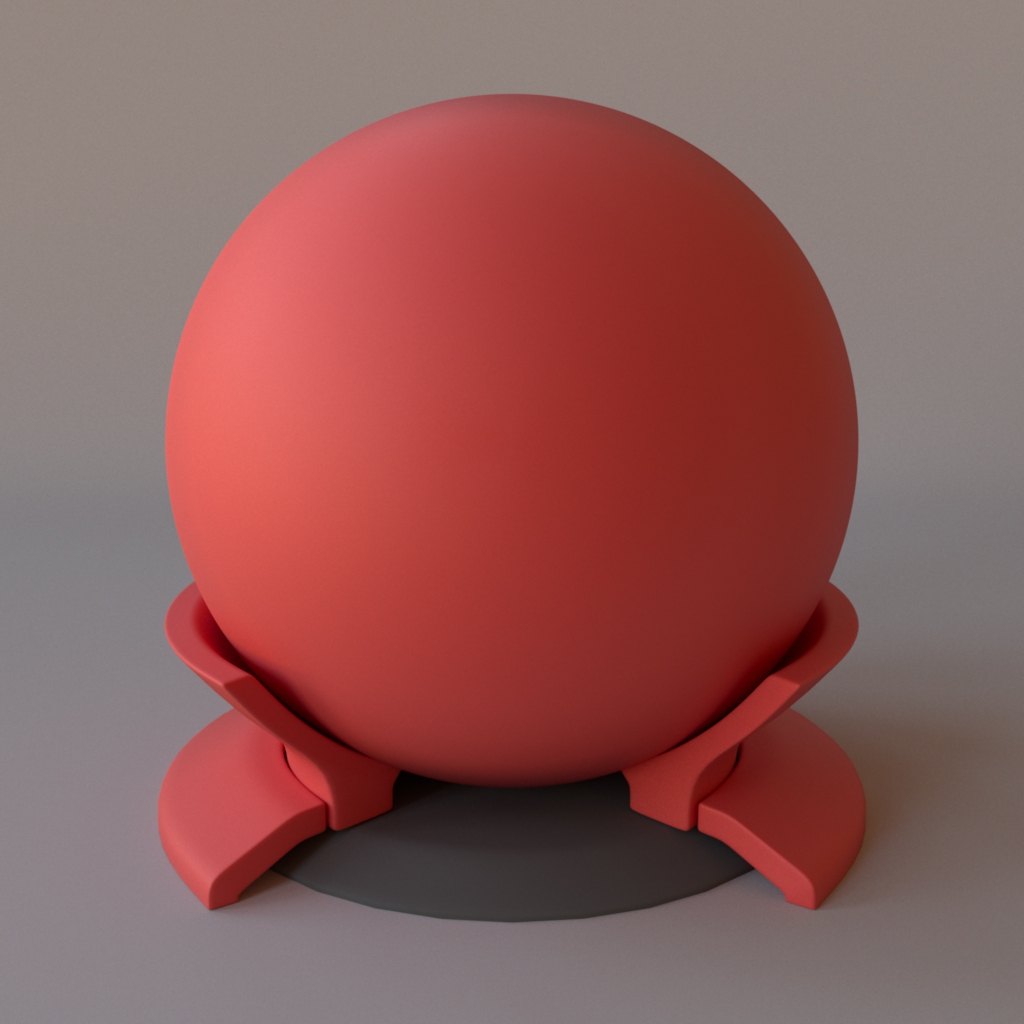

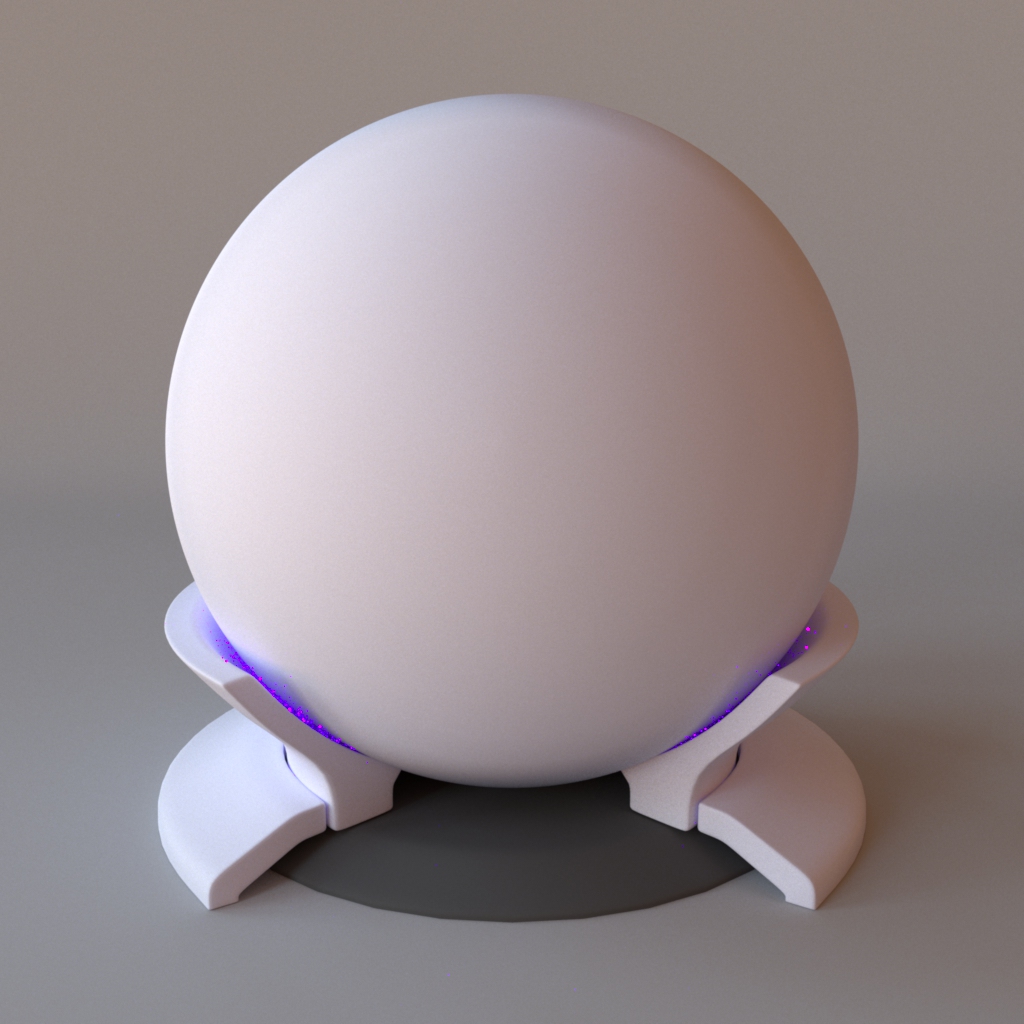

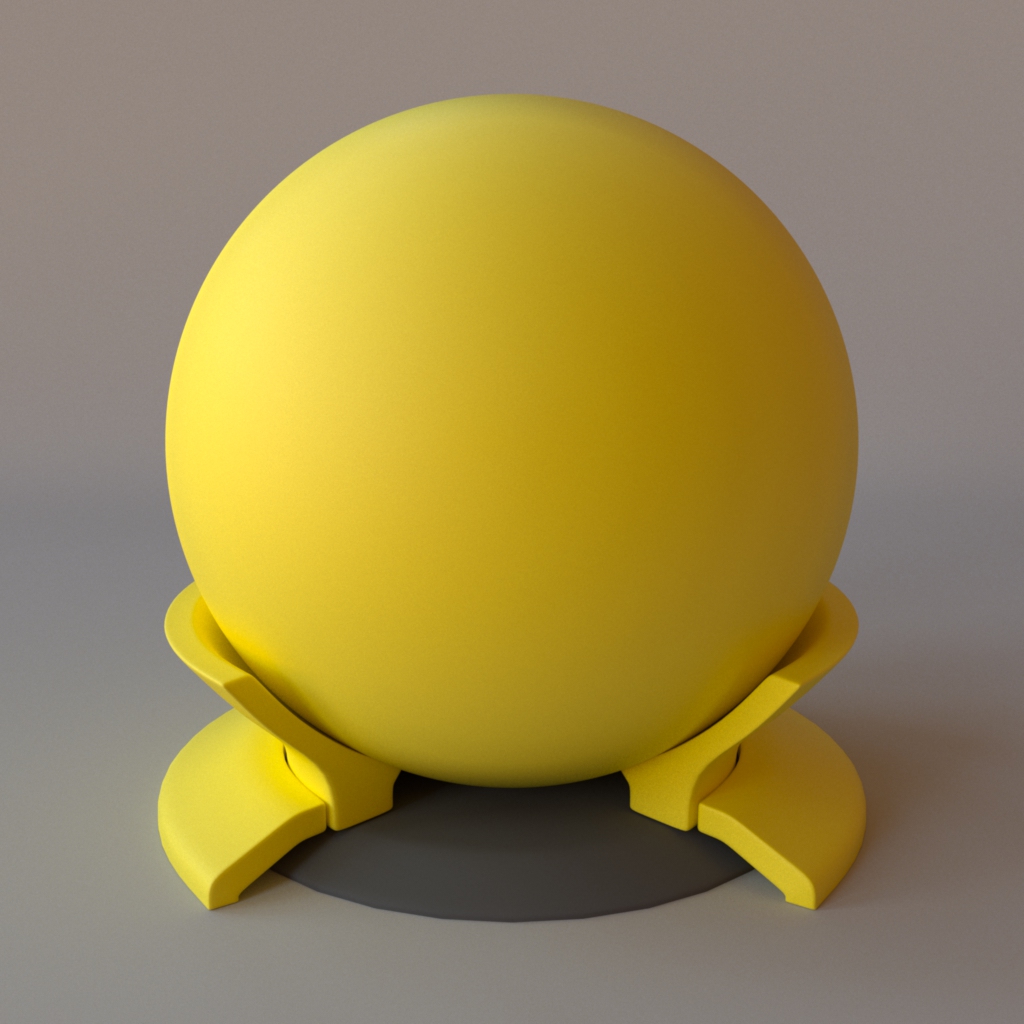

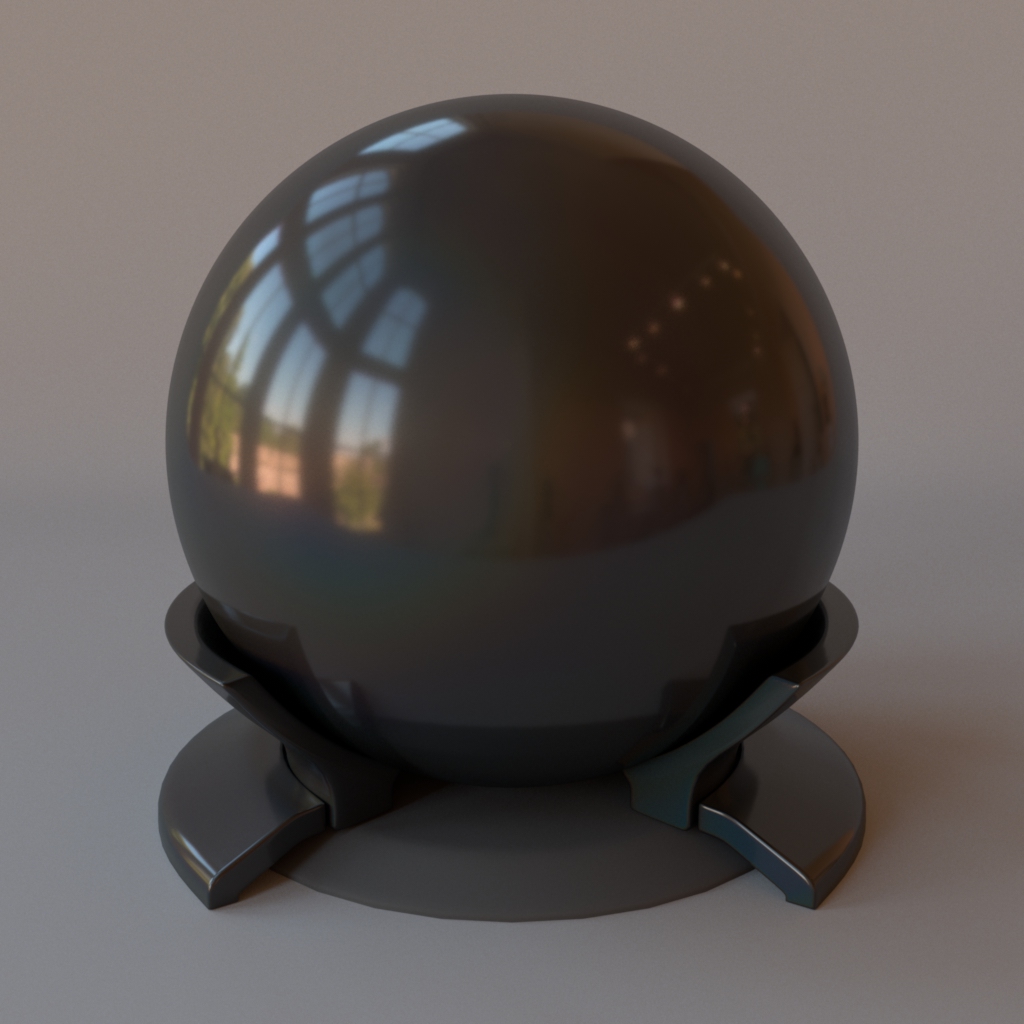

Results (1024 spp)

Microfacet-like

vch_dragon_eye_red

vch_frozen_amethyst

vch_silk_blue

vch_ultra_pink

Here are a few selected materials. Such glossy highlights are typically perfect

candidates for microfacet theory.

Results (1024 spp)

Microfacet-like

aniso_copper_sheet

aniso_metallic_paper_copper

aniso_metallic_paper_gold

aniso_brushed_aluminium

Hazy lobes

Here is another set of good candidates, altough they exhibit anisotropy and

super hazy lobes that are very difficult to model with analytic microfacet

NDFs; such materials could serve as reference for modelling new hazy NDFs.

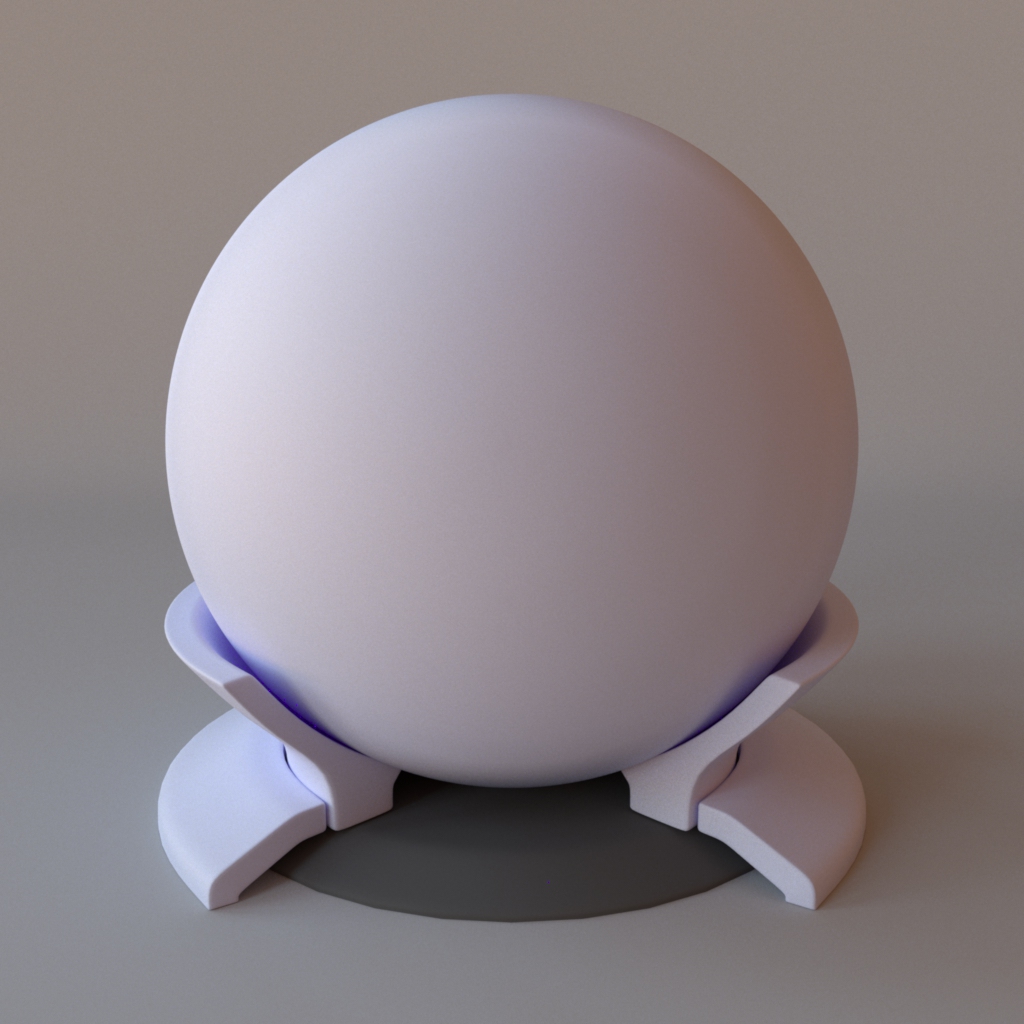

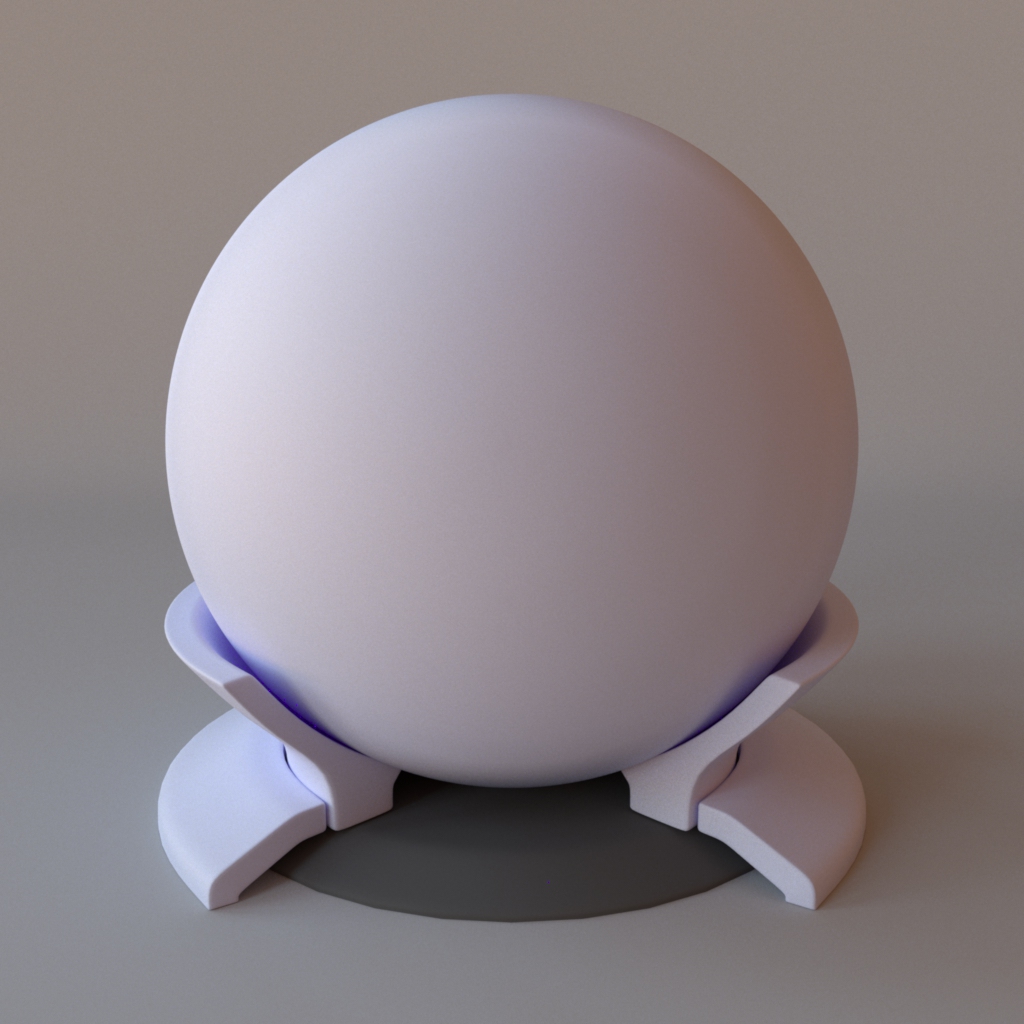

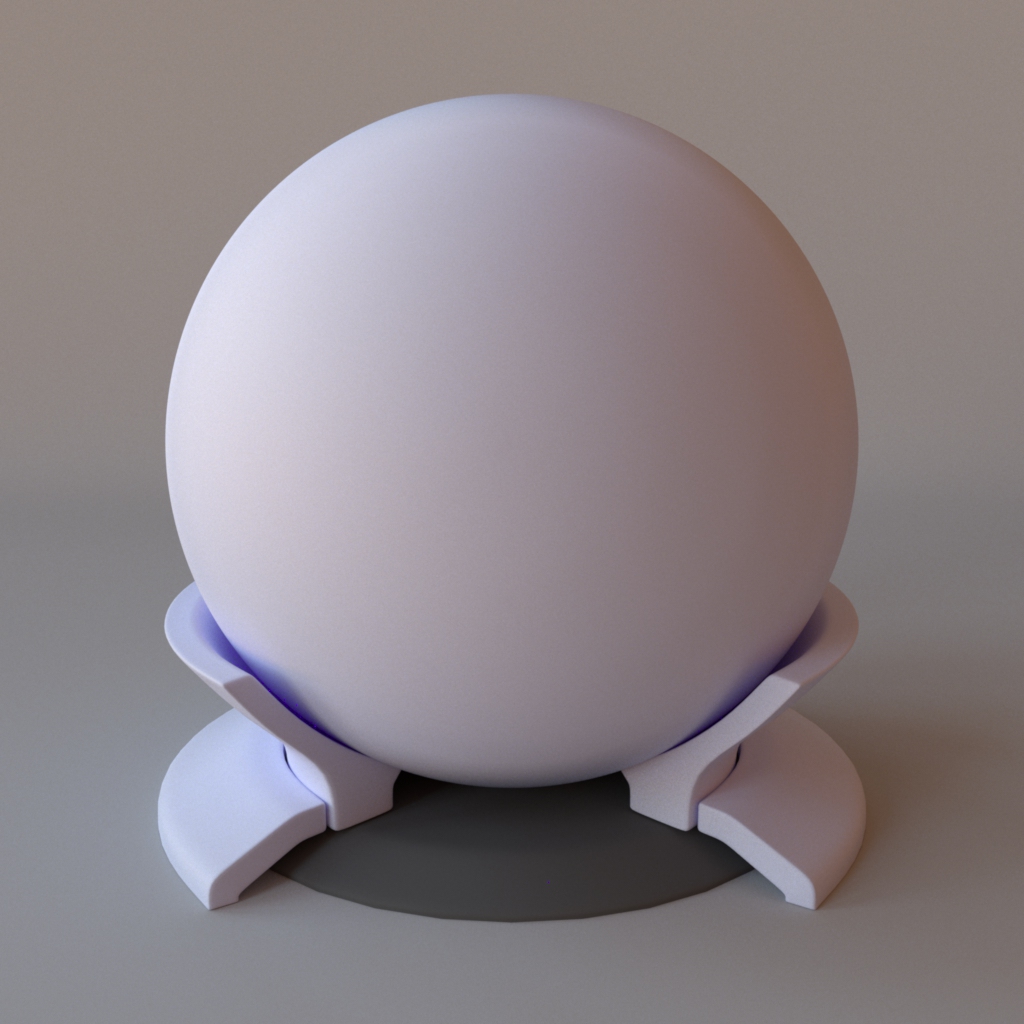

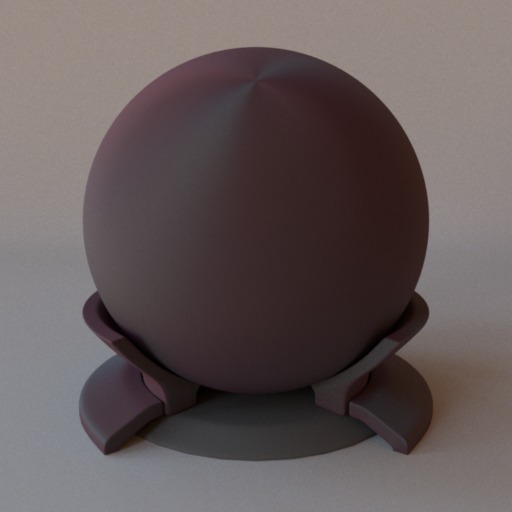

Results (1024 spp)

Microfacet-like ?

satin_white

satin_blue

satin_gold

satin_purple

Coloured-highlights

Moving on to another set of candidates, alreay more complicated as they

exhibit colored highlights that are hard to explain and/or model with

microfacet theory.

Results (1024 spp)

Microfacet-like ?

aurora_white

cc_nothern_aurora

aniso_sari_silk_2color

aniso_morpho_melenaus

Funky!

And finally a set of aliens (!). All these materials exhibit wave-optics

behaviours that are completely alien to microfacet theory, which is a

geometric optics model.

Outline

What makes BRDF measurements difficult ?

A: Curse of dimensionality

How to lower the number of measurements ?

A: Image-based setup ? Use an adaptive parameterization

Is there a way to quickly characterize a material ?

A: We measure retro-reflection

Implementation details + results

Results

Take aways:

(BRDF modelling & rendering) xx

New public spectral BRDF database

(gonio-photometric acquisition) xx

New practical acquisition technique

[Note: this slide is progressive. Press the left key on your keyboard each

time you read [click] to keep the text in sync with the contents of

the slide]

We are now reaching the end of this presentation.

As the exposition has been quite dense, here are [click] two targetted

take-aways to wrap everything up.

[click] First, if you happen to be working on BRDF modelling or

photorealistic rendering, then there is a new spectral database

available online to download.

[click] Second, if you happen to own a BRDF acquisition device, then

there is a new efficient algorithm you can rely on to build your own database.

Acknowledgements

Naty Hoffman (ILM) Andre Mazzone (ILM) Olesya Jakob

Benoit Ruiz

Peter Apian-Bennewitz

Laurent Belcour

Romain Pacanowski

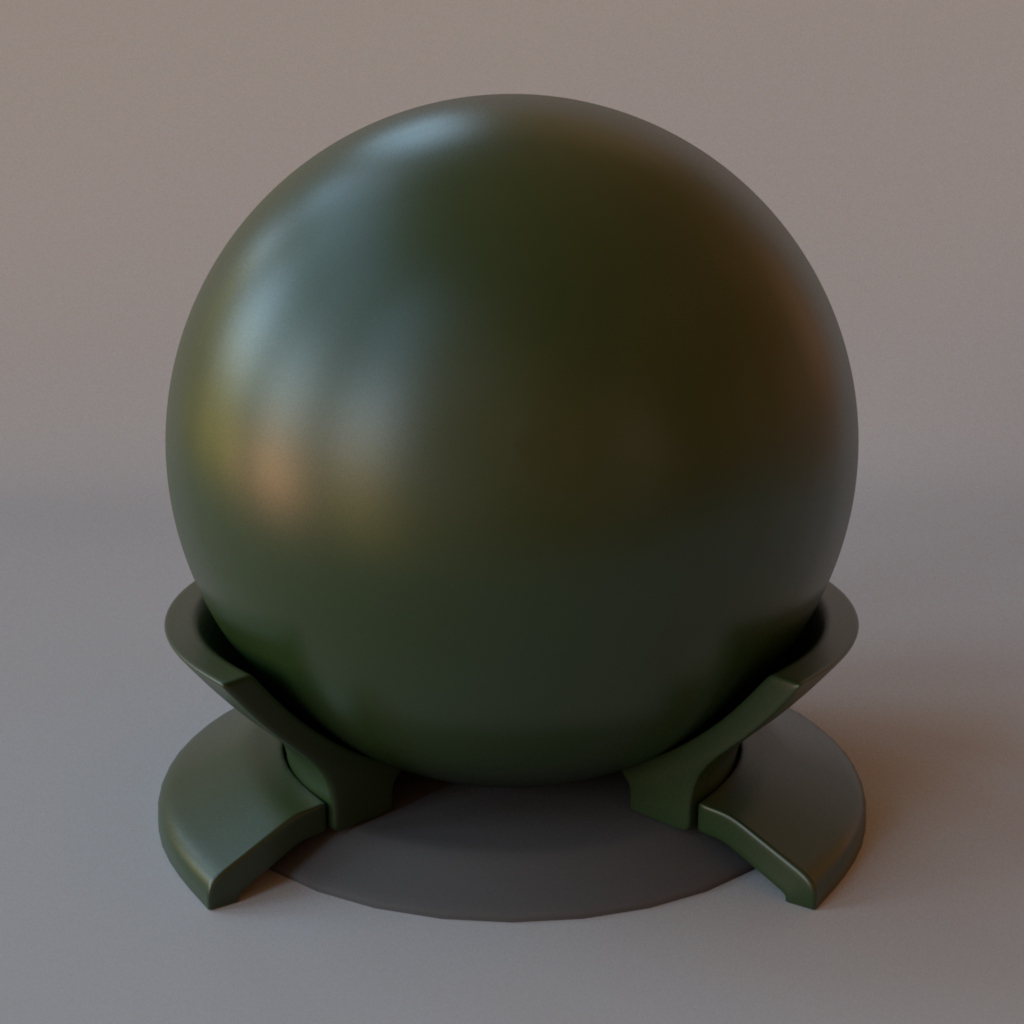

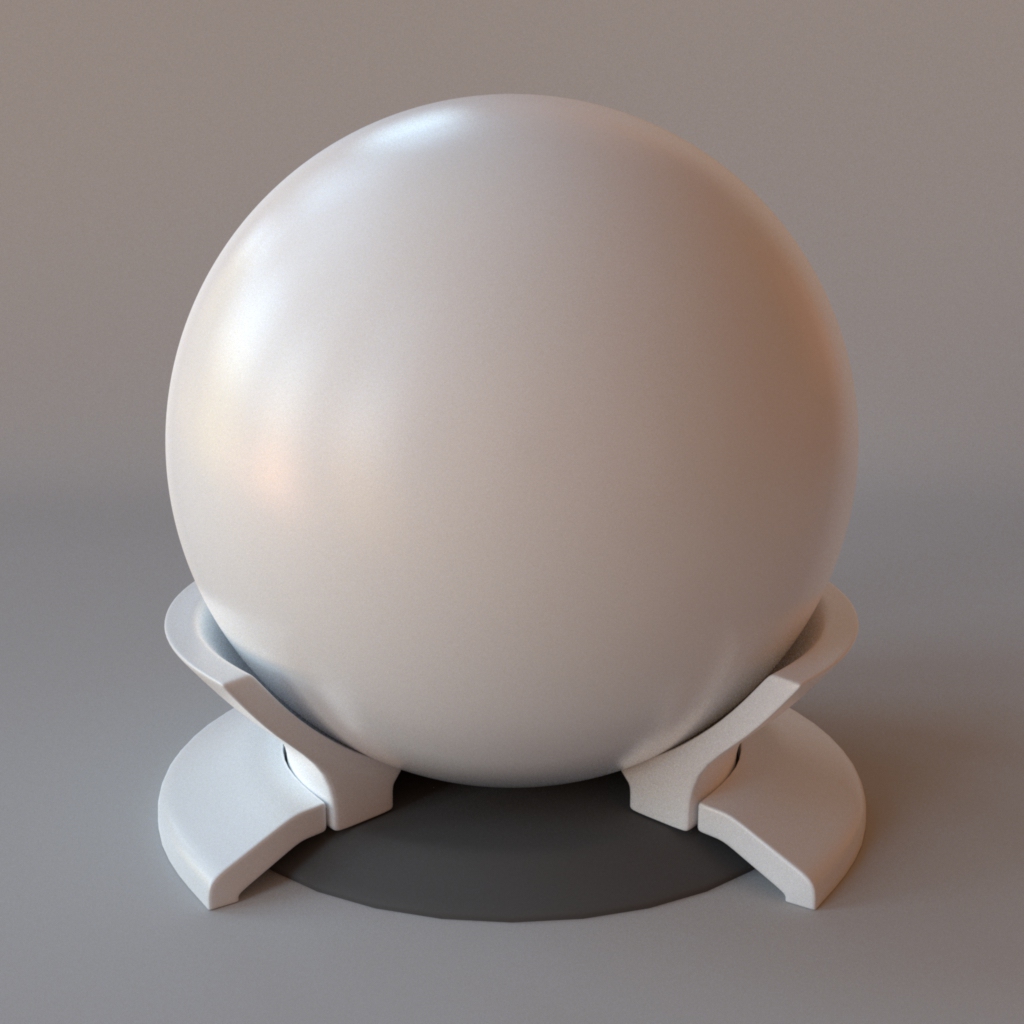

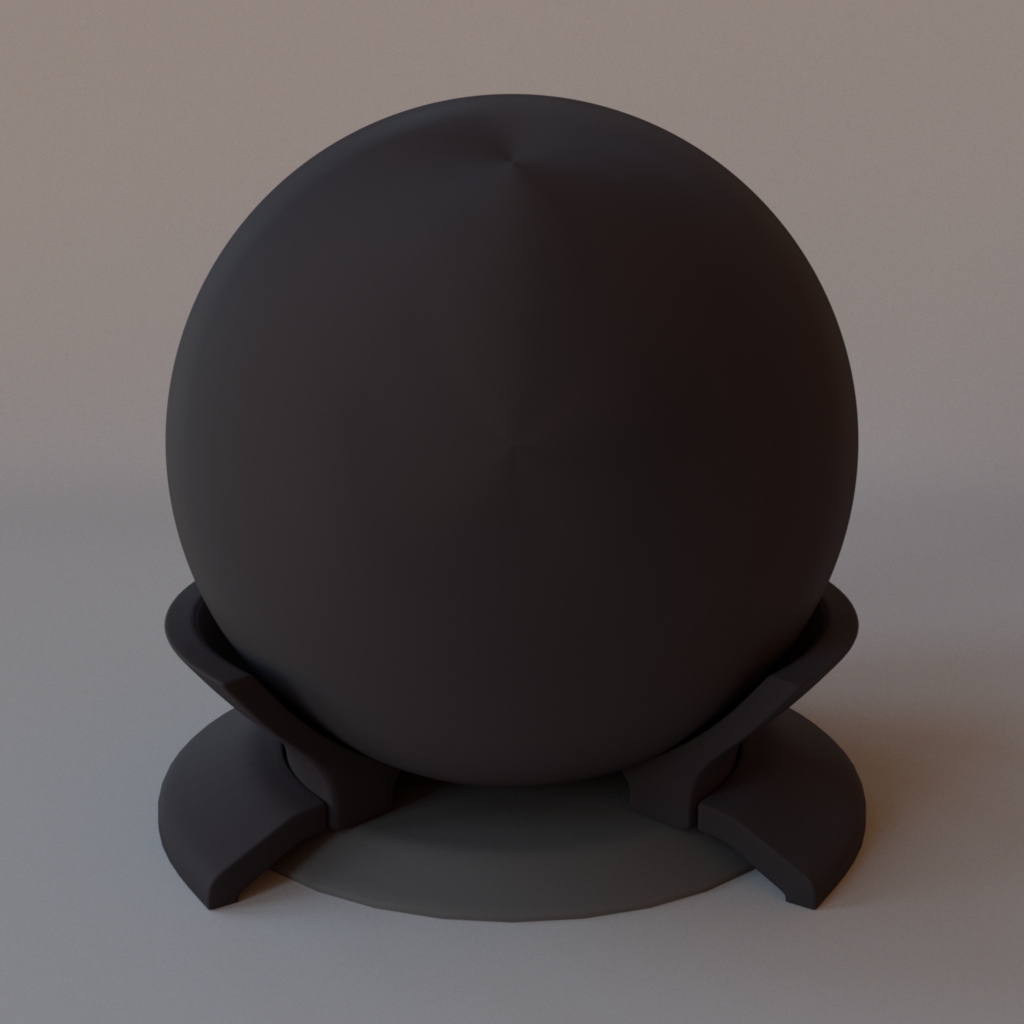

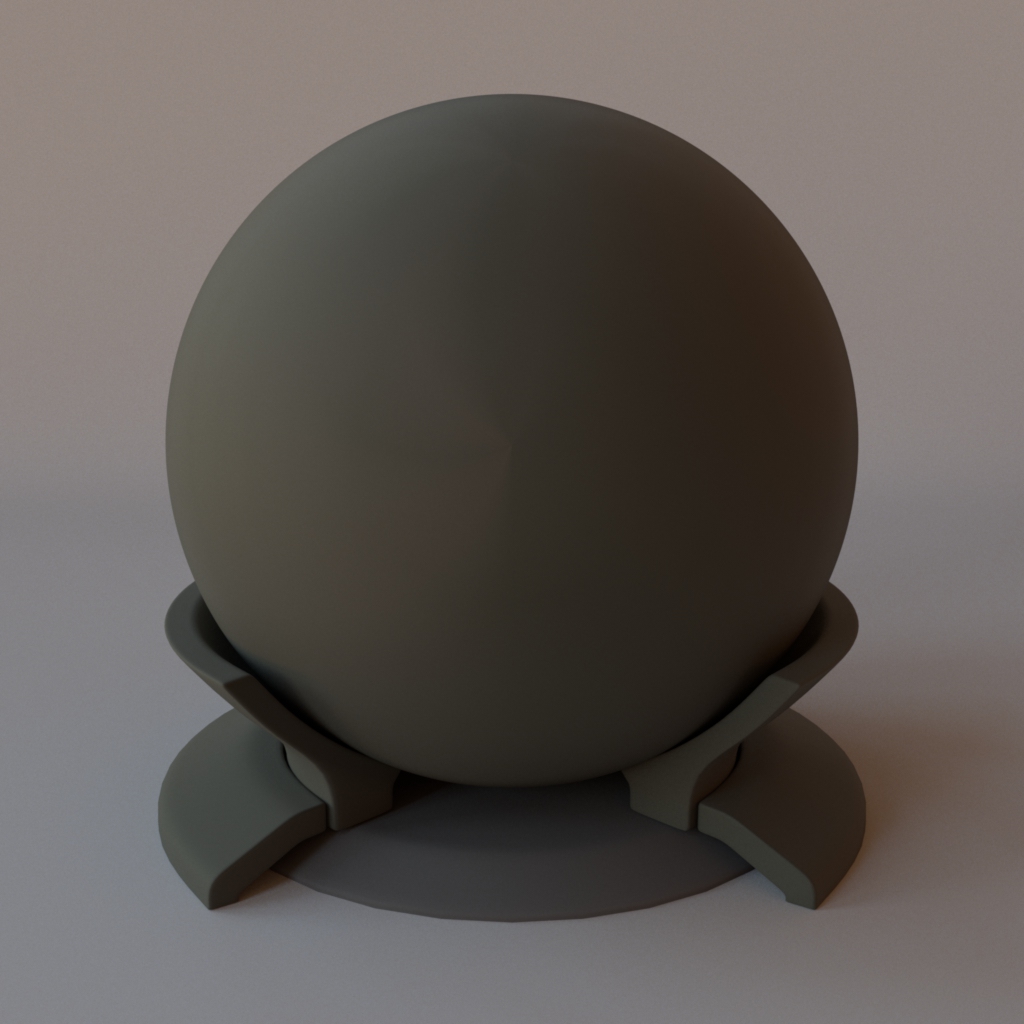

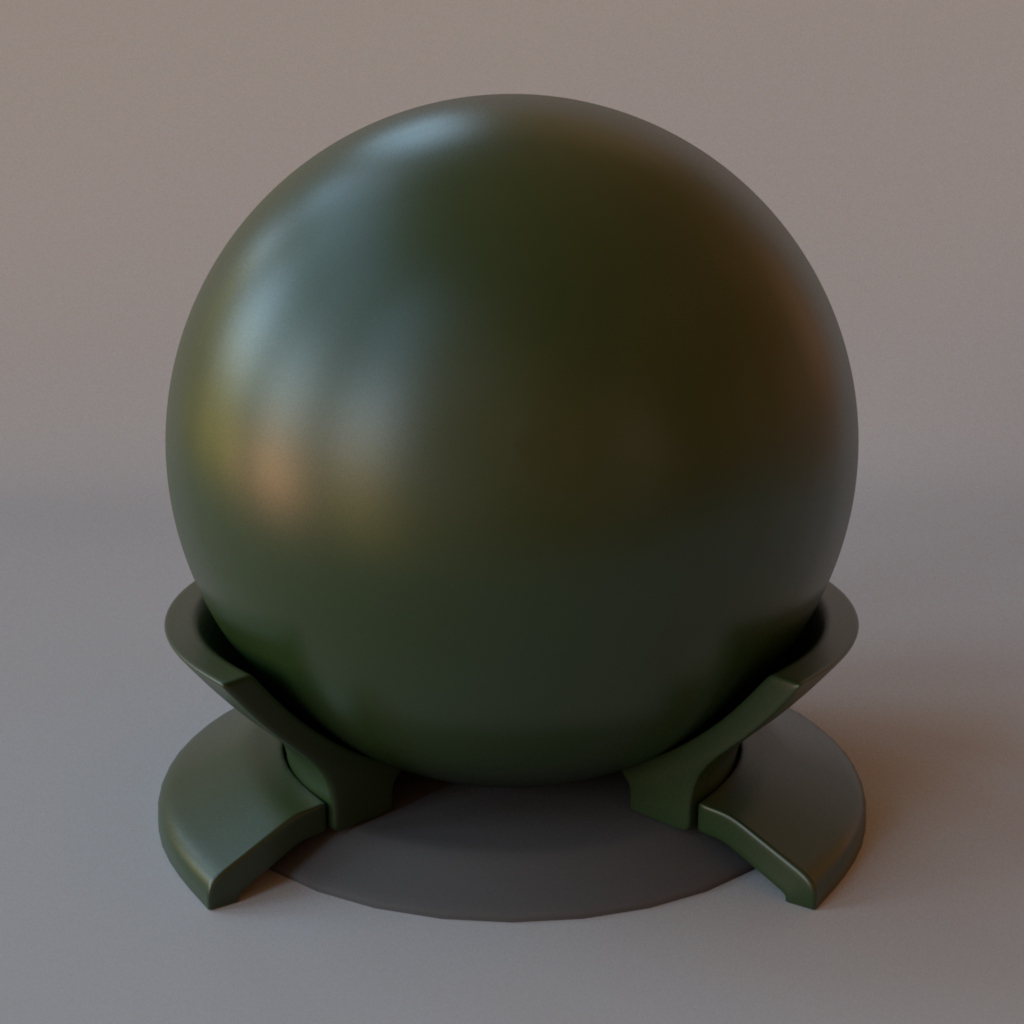

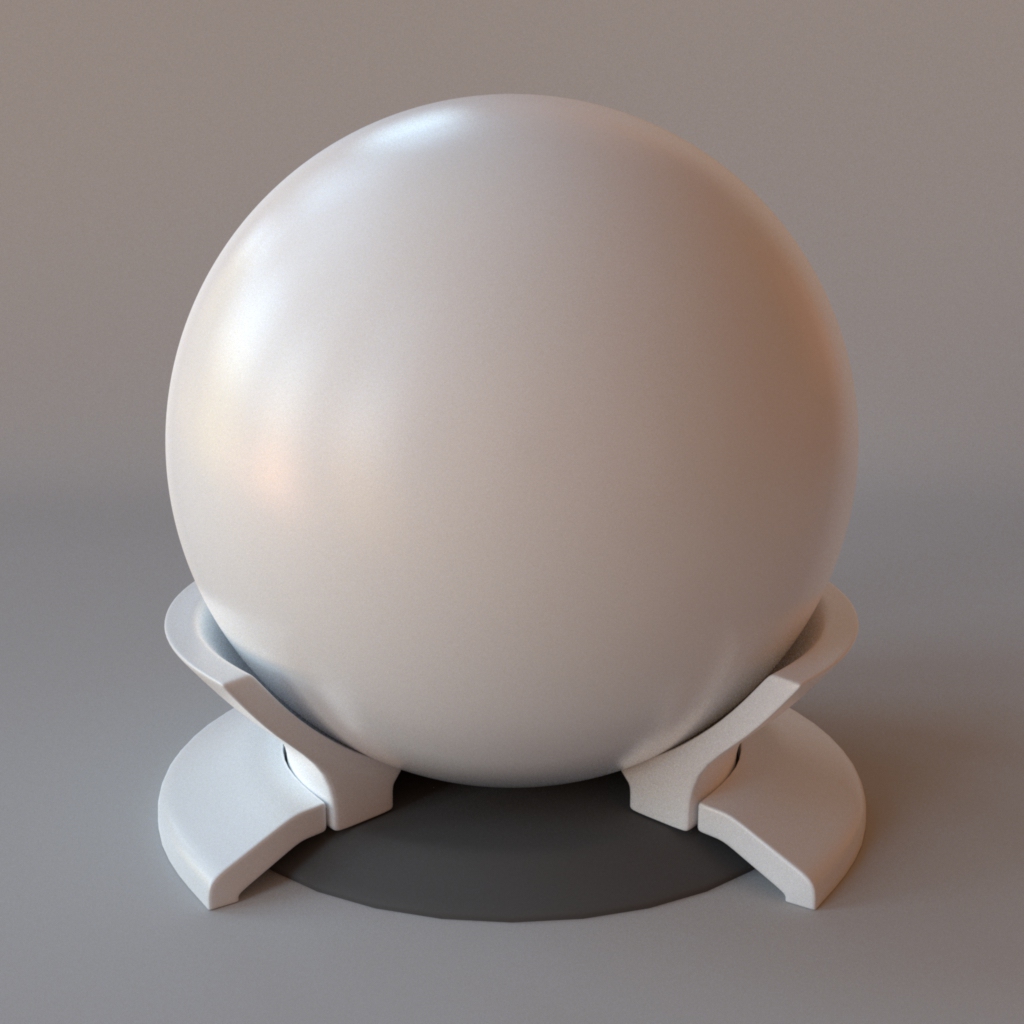

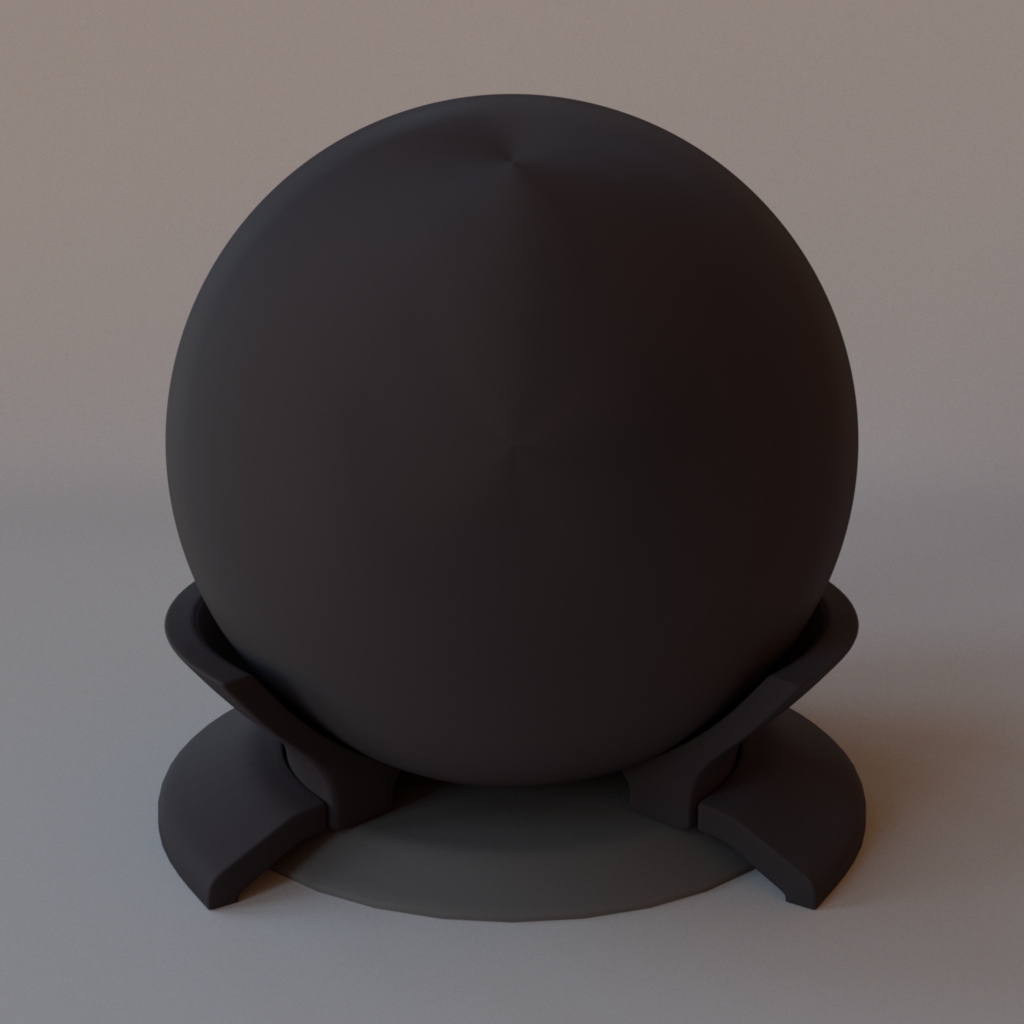

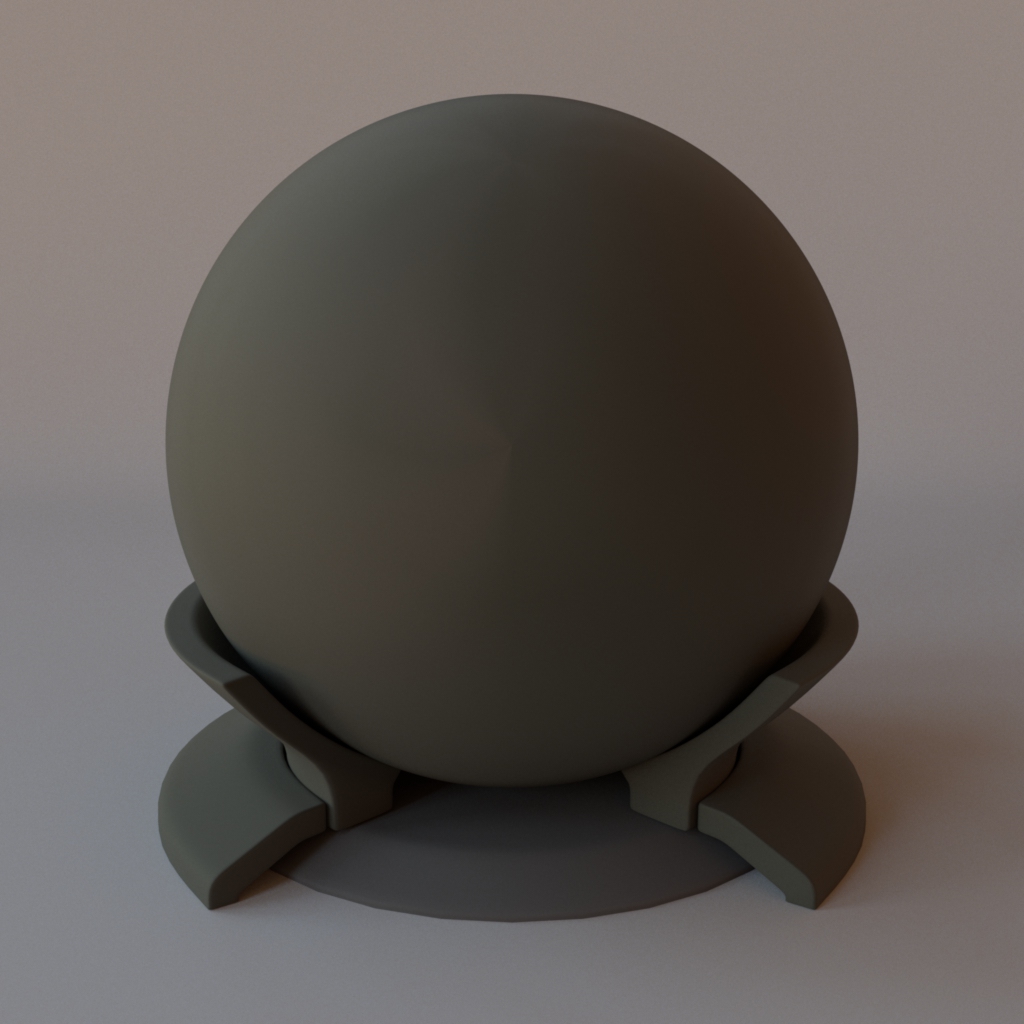

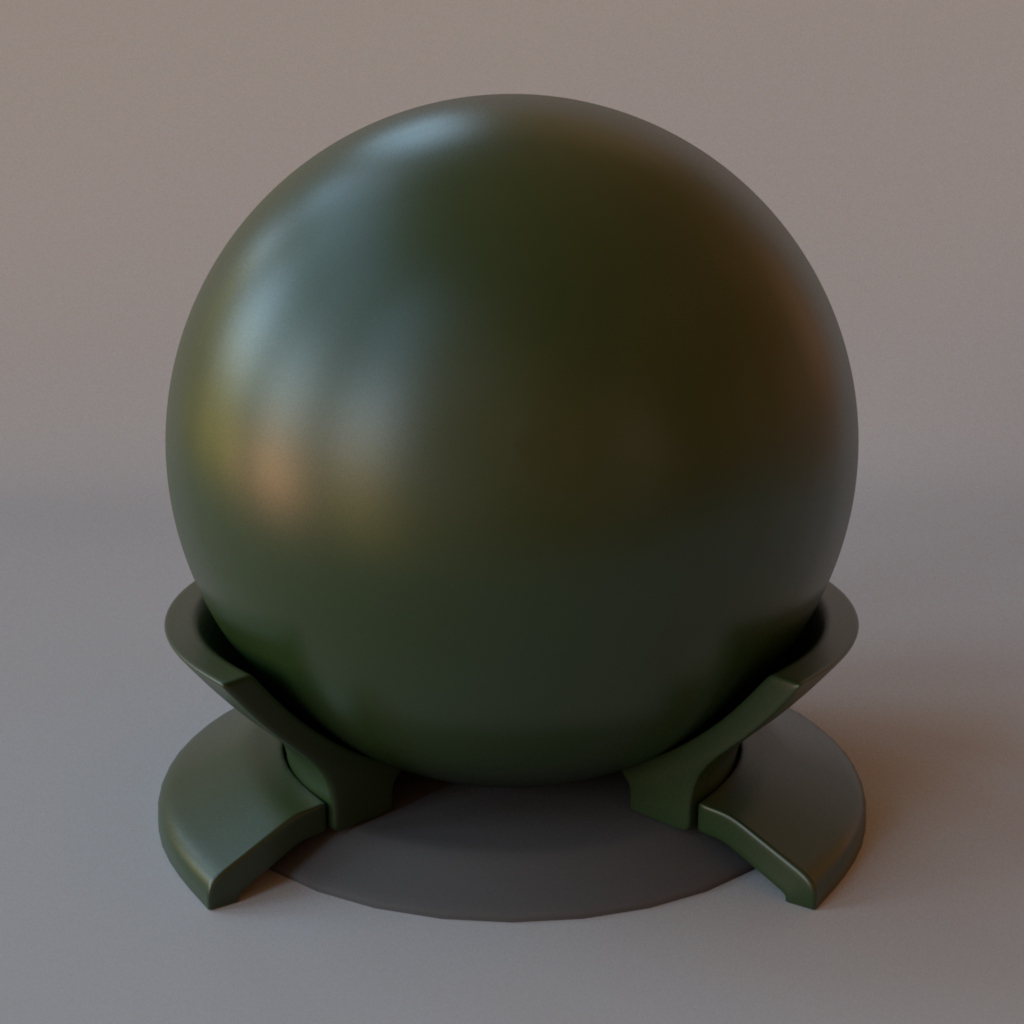

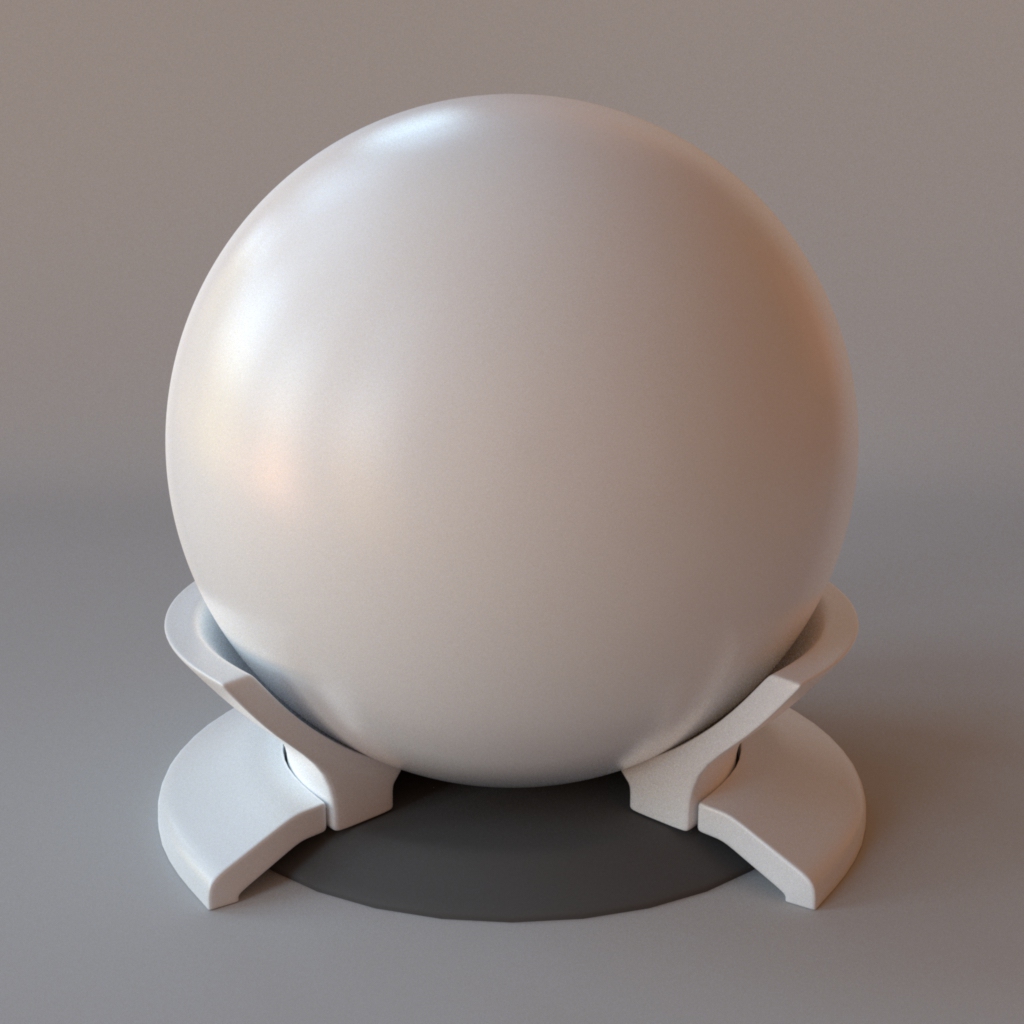

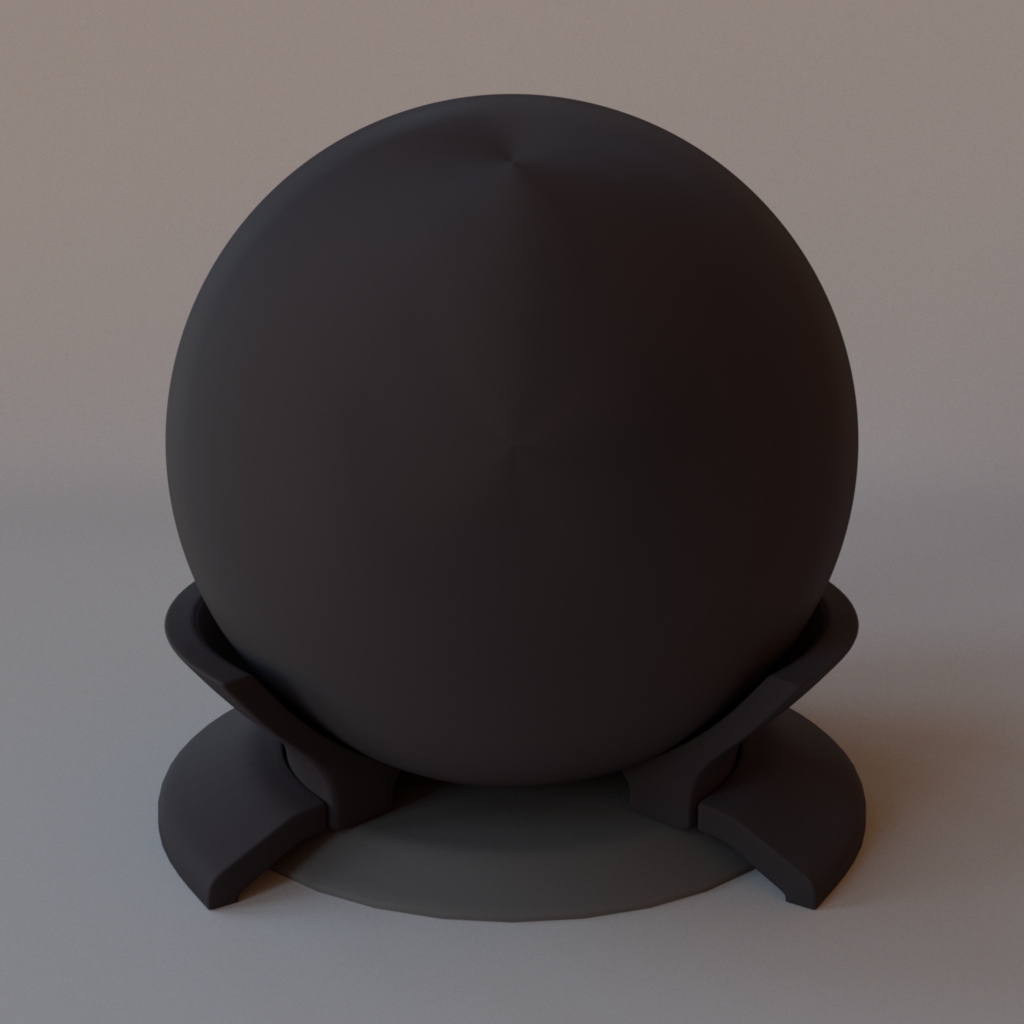

darth_vader_pants

millennium_falcon

tarkin_tunic

solo_m_68

Industrial ? Your material here !

l3_37_dark_green

l3_37_matte

l3_37_metallic

Many thanks to Naty Hoffman and Andre Mazzone from ILM to have provided

us with the Star Wars materials.

Acknowledgements

Naty Hoffman (ILM)

Andre Mazzone (ILM)

Olesya Jakob Benoit Ruiz

Peter Apian-Bennewitz

Laurent Belcour

Romain Pacanowski

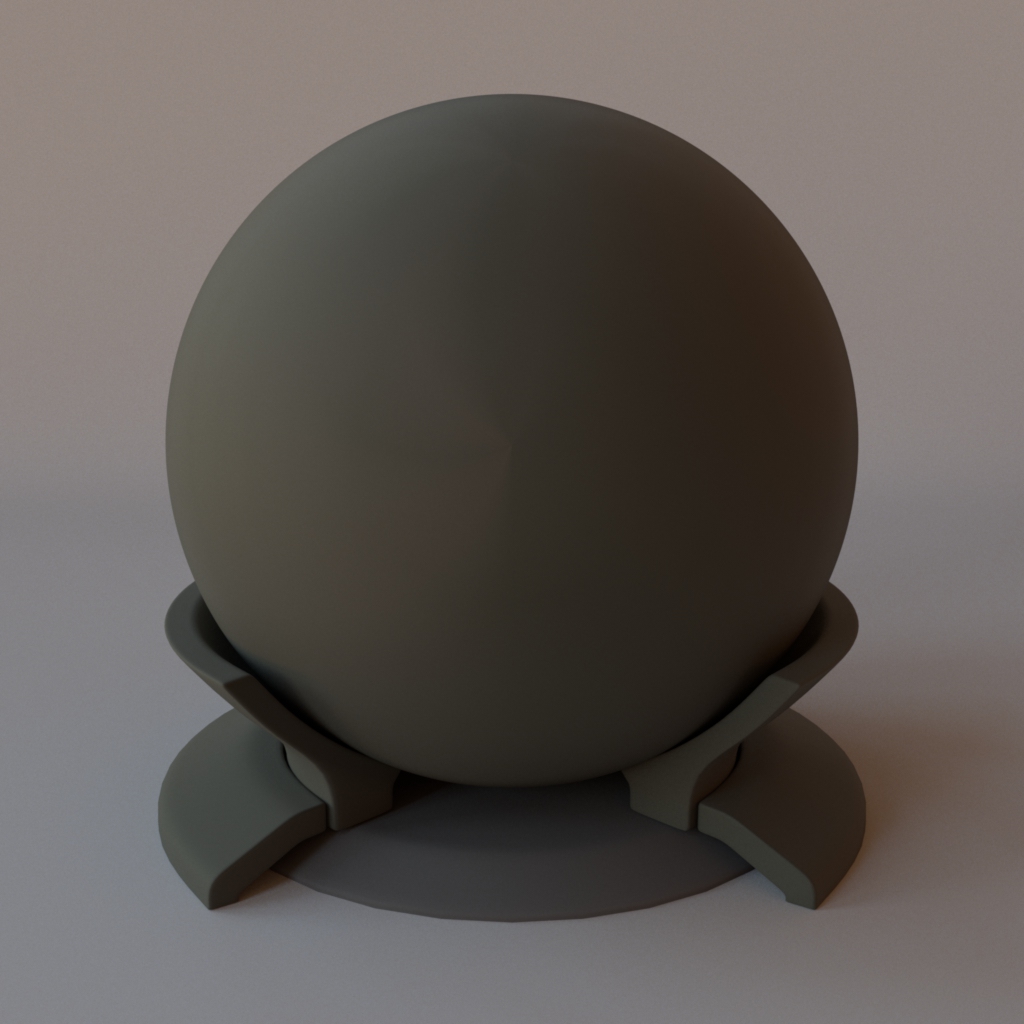

Olesya Jakob created this nice 3D scene that we used in our paper.

Acknowledgements

Naty Hoffman (ILM)

Andre Mazzone (ILM)

Olesya Jakob Benoit Ruiz

Peter Apian-Bennewitz

Laurent Belcour

Romain Pacanowski

Since our acquisitions are spectral, we played with the spectra of the light

sources in the scene. Notice how the materials can take very different

appearances depending on the lighting conditions. This is an area we have not

explored in detail, but believe it to be important as it widens the

range of expressiveness wrt traditional RGB rendering.

Acknowledgements

Naty Hoffman (ILM)

Andre Mazzone (ILM)

Olesya Jakob

Benoit Ruiz Peter Apian-Bennewitz

Laurent Belcour

Romain Pacanowski

Thanks to Benoit Ruiz, a student from EPFL, who implemented the

BRDF viewer that's available online.

Acknowledgements

Naty Hoffman (ILM)

Andre Mazzone (ILM)

Olesya Jakob

Benoit Ruiz

Peter Apian-Bennewitz Laurent Belcour

Romain Pacanowski

Thanks to Peter Apian-Bennewitz who is the builder of the goniophotometer

we used to perform our measurements and provided us with software support.

Acknowledgements

Naty Hoffman (ILM)

Andre Mazzone (ILM)

Olesya Jakob

Benoit Ruiz

Peter Apian-Bennewitz

Laurent Belcour Romain Pacanowski

laser

beam dump

photodiode

beamsplitter

sample

isolator

Finally, thanks to Laurent Belcour and Romain Pacanowski for sharing their

insights on how to measure retro-reflection using a beam splitter.

This is the end of the talk. Here is the URL that will take you to the

database. Enjoy !

Storage

$\;\;\;$

$\;\;\;$

$\;\;\;$

$\;\;\;$

$\;\;\;$

$\;\;\;$

Storage

$\;\;\;$

$\;\;\;$

$\;\;\;$

$\;\;\;$

$\;\;\;$

$\;\;\;$

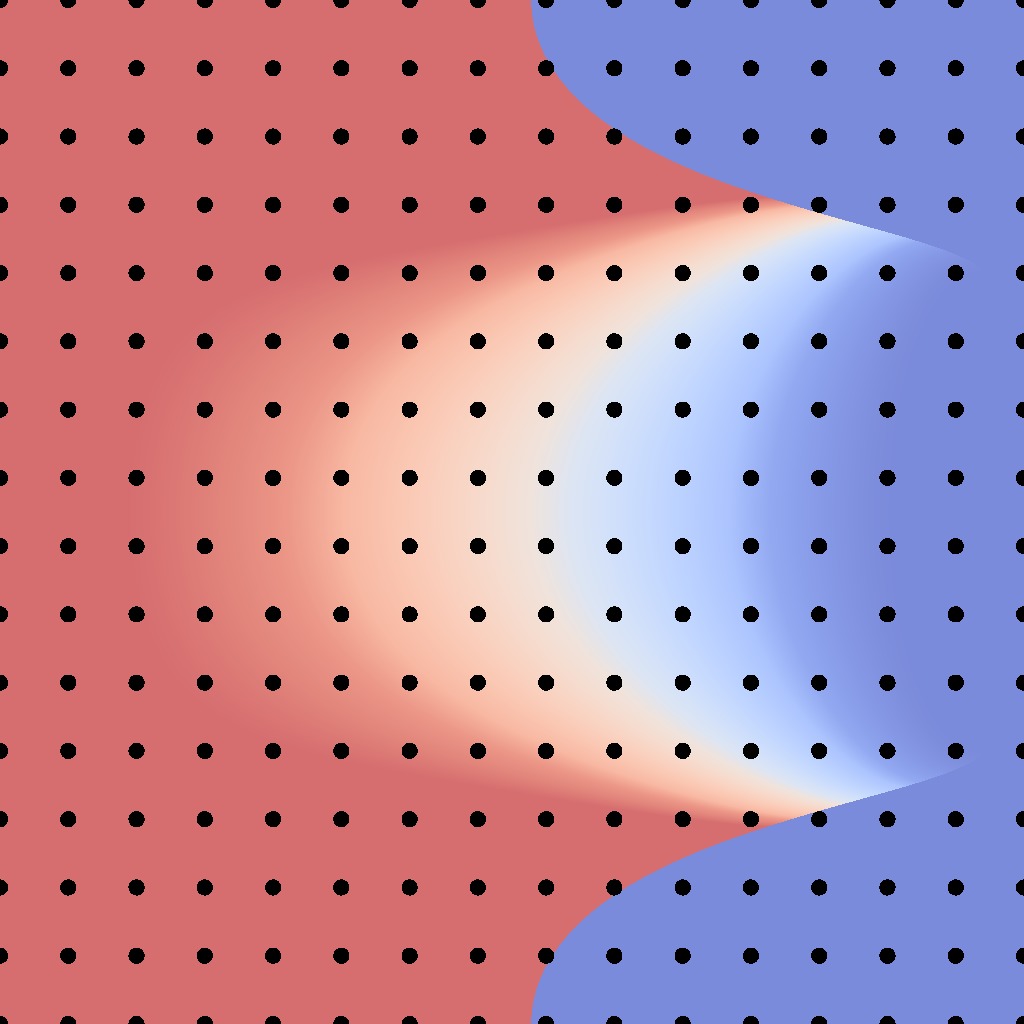

Validation: MERL

Ref (36 MiB)

Ours (96 KiB)

Ref (36 MiB)

Ours (96 KiB)

Importance Sampling

$$L_o = \int_{\mathcal{H}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i$$

In a rendering context, we use importance sampling of the BRDF x cos.

It turns out that this is exactly what we would like to do for a material.

But measured materials don't have builtin importance sampling. So we looked

into microfacet theory. Microfacet theory is a mathematical framework that

has undergone a large evolution due to CG and has been successful at

explaining the behaviour of real world materials and has a good importance

sampling mechanism.

We could devise an importance sampling mechanism for any BRDF, but only

if we know it before hand, which means we need to measure it !

So we simplify the problem to acquiring a microfacet BRDF.

So we decided to simplify our acquisition paper into that of acquiring

a microfacet BRDF.

The equation itself is not very interesting.

Microfacet theory describes the behaviour of

materials as a collection of flakes and blabla, NDF.

Given an NDF, we can build an importance sampling mechanism that consists

in picking a microfacet proportionally visible area; this is called the VNDF

sampling.

Importance Sampling

$$L_o = \int_{\mathcal{H}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i$$

Substitution

$$\boldsymbol{\omega}_i = g(\mathbf{u})$$

$$

\Rightarrow d\boldsymbol{\omega}_i = \left| \frac{dg}{d\mathbf{u}} \right| d\mathbf{u}

$$

$$= \int_{\mathcal{U}^2} L_i \cdot f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right| \cdot d\mathbf{u}$$

parametric domain

BRDF domain

$$g$$ $$\shortmid\!\longrightarrow$$ .

$$\;\;\;\; g^{-1}$$ $$\longleftarrow\!\shortmid$$ .

In a rendering context, we use importance sampling of the BRDF x cos.

It turns out that this is exactly what we would like to do for a material.

But measured materials don't have builtin importance sampling. So we looked

into microfacet theory. Microfacet theory is a mathematical framework that

has undergone a large evolution due to CG and has been successful at

explaining the behaviour of real world materials and has a good importance

sampling mechanism.

We could devise an importance sampling mechanism for any BRDF, but only

if we know it before hand, which means we need to measure it !

So we simplify the problem to acquiring a microfacet BRDF.

So we decided to simplify our acquisition paper into that of acquiring

a microfacet BRDF.

The equation itself is not very interesting.

Microfacet theory describes the behaviour of

materials as a collection of flakes and blabla, NDF.

Given an NDF, we can build an importance sampling mechanism that consists

in picking a microfacet proportionally visible area; this is called the VNDF

sampling.

Importance Sampling

$$L_o = \int_{\mathcal{H}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i$$

Substitution

$$\boldsymbol{\omega}_i = g(\mathbf{u})$$

$$

\Rightarrow d\boldsymbol{\omega}_i = \left| \frac{dg}{d\mathbf{u}} \right| d\mathbf{u}

$$

$$= \int_{\mathcal{U}^2} L_i \cdot f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right| \cdot d\mathbf{u}$$

parametric domain

BRDF domain

$$g$$ $$\shortmid\!\longrightarrow$$ .

$$\;\;\;\; g^{-1}$$ $$\longleftarrow\!\shortmid$$ .

Importance Sampling

$$L_o = \int_{\mathcal{H}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i$$

Substitution

$$\boldsymbol{\omega}_i = g(\mathbf{u})$$

$$

\Rightarrow d\boldsymbol{\omega}_i = \left| \frac{dg}{d\mathbf{u}} \right| d\mathbf{u}

$$

$$= \int_{\mathcal{U}^2} L_i \cdot f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right| \cdot d\mathbf{u}$$

parametric domain

BRDF domain

$$g$$ $$\shortmid\!\longrightarrow$$ .

$$\;\;\;\; g^{-1}$$ $$\longleftarrow\!\shortmid$$ .

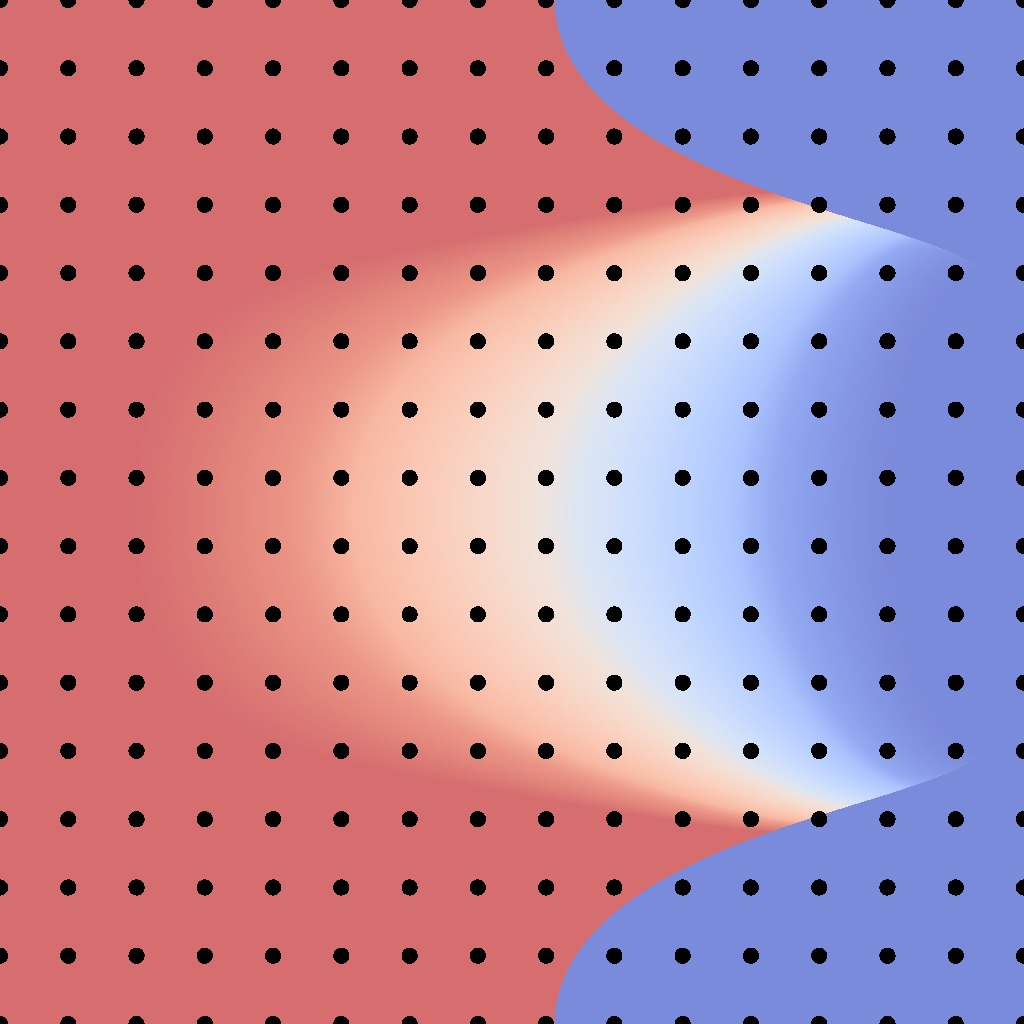

Importance Sampling

$$L_o = \int_{\mathcal{H}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i$$

$$= \int_{\mathcal{U}^2} L_i \cdot f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right| \cdot d\mathbf{u}$$

Substitution

$$\boldsymbol{\omega}_i = g(\mathbf{u})$$

$$

\Rightarrow d\boldsymbol{\omega}_i = \left| \frac{dg}{d\mathbf{u}} \right| d\mathbf{u}

$$

parametric domain

BRDF domain

$$g$$ $$\shortmid\!\longrightarrow$$ .

$$\;\;\;\; g^{-1}$$ $$\longleftarrow\!\shortmid$$ .

low-frequency

Perfect sampling condition:

$$ \left| \frac{dg}{d\mathbf{u}} \right| \propto \frac{1}{f_r^\perp}$$

$$f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right|$$

In a rendering context, we use importance sampling of the BRDF x cos.

It turns out that this is exactly what we would like to do for a material.

But measured materials don't have builtin importance sampling. So we looked

into microfacet theory. Microfacet theory is a mathematical framework that

has undergone a large evolution due to CG and has been successful at

explaining the behaviour of real world materials and has a good importance

sampling mechanism.

We could devise an importance sampling mechanism for any BRDF, but only

if we know it before hand, which means we need to measure it !

So we simplify the problem to acquiring a microfacet BRDF.

So we decided to simplify our acquisition paper into that of acquiring

a microfacet BRDF.

The equation itself is not very interesting.

Microfacet theory describes the behaviour of

materials as a collection of flakes and blabla, NDF.

Given an NDF, we can build an importance sampling mechanism that consists

in picking a microfacet proportionally visible area; this is called the VNDF

sampling.

Importance Sampling

$$L_o = \int_{\mathcal{H}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i$$

$$= \int_{\mathcal{U}^2} L_i \cdot f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right| \cdot d\mathbf{u}$$

Substitution

$$\boldsymbol{\omega}_i = g(\mathbf{u})$$

$$

\Rightarrow d\boldsymbol{\omega}_i = \left| \frac{dg}{d\mathbf{u}} \right| d\mathbf{u}

$$

parametric domain

BRDF domain

$$g$$ $$\shortmid\!\longrightarrow$$ .

$$\;\;\;\; g^{-1}$$ $$\longleftarrow\!\shortmid$$ .

low-frequency

Perfect sampling condition:

$$ \left| \frac{dg}{d\mathbf{u}} \right| \propto \frac{1}{f_r^\perp}$$

$$f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right|$$

In a rendering context, we use importance sampling of the BRDF x cos.

It turns out that this is exactly what we would like to do for a material.

But measured materials don't have builtin importance sampling. So we looked

into microfacet theory. Microfacet theory is a mathematical framework that

has undergone a large evolution due to CG and has been successful at

explaining the behaviour of real world materials and has a good importance

sampling mechanism.

We could devise an importance sampling mechanism for any BRDF, but only

if we know it before hand, which means we need to measure it !

So we simplify the problem to acquiring a microfacet BRDF.

So we decided to simplify our acquisition paper into that of acquiring

a microfacet BRDF.

The equation itself is not very interesting.

Microfacet theory describes the behaviour of

materials as a collection of flakes and blabla, NDF.

Given an NDF, we can build an importance sampling mechanism that consists

in picking a microfacet proportionally visible area; this is called the VNDF

sampling.

Importance Sampling

$$L_o = \int_{\mathcal{H}^2} L_i \cdot f_r^\perp \cdot d\boldsymbol{\omega}_i$$

$$= \int_{\mathcal{U}^2} L_i \cdot f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right| \cdot d\mathbf{u}$$

Substitution

$$\boldsymbol{\omega}_i = g(\mathbf{u})$$

$$

\Rightarrow d\boldsymbol{\omega}_i = \left| \frac{dg}{d\mathbf{u}} \right| d\mathbf{u}

$$

parametric domain

BRDF domain

$$g$$ $$\shortmid\!\longrightarrow$$ .

$$\;\;\;\; g^{-1}$$ $$\longleftarrow\!\shortmid$$ .

low-frequency

Perfect sampling condition:

$$ \left| \frac{dg}{d\mathbf{u}} \right| \propto \frac{1}{f_r^\perp}$$

$$f_r^\perp \cdot \left| \frac{dg}{d\mathbf{u}} \right|$$

Importance sampling

Parameterization

Efficient importance sampling

$\Rightarrow$

Adaptive parameterization

In a rendering context, we use importance sampling of the BRDF x cos.

It turns out that this is exactly what we would like to do for a material.

But measured materials don't have builtin importance sampling. So we looked

into microfacet theory. Microfacet theory is a mathematical framework that

has undergone a large evolution due to CG and has been successful at

explaining the behaviour of real world materials and has a good importance

sampling mechanism.

We could devise an importance sampling mechanism for any BRDF, but only

if we know it before hand, which means we need to measure it !

So we simplify the problem to acquiring a microfacet BRDF.

So we decided to simplify our acquisition paper into that of acquiring

a microfacet BRDF.

The equation itself is not very interesting.

Microfacet theory describes the behaviour of

materials as a collection of flakes and blabla, NDF.

Given an NDF, we can build an importance sampling mechanism that consists

in picking a microfacet proportionally visible area; this is called the VNDF

sampling.

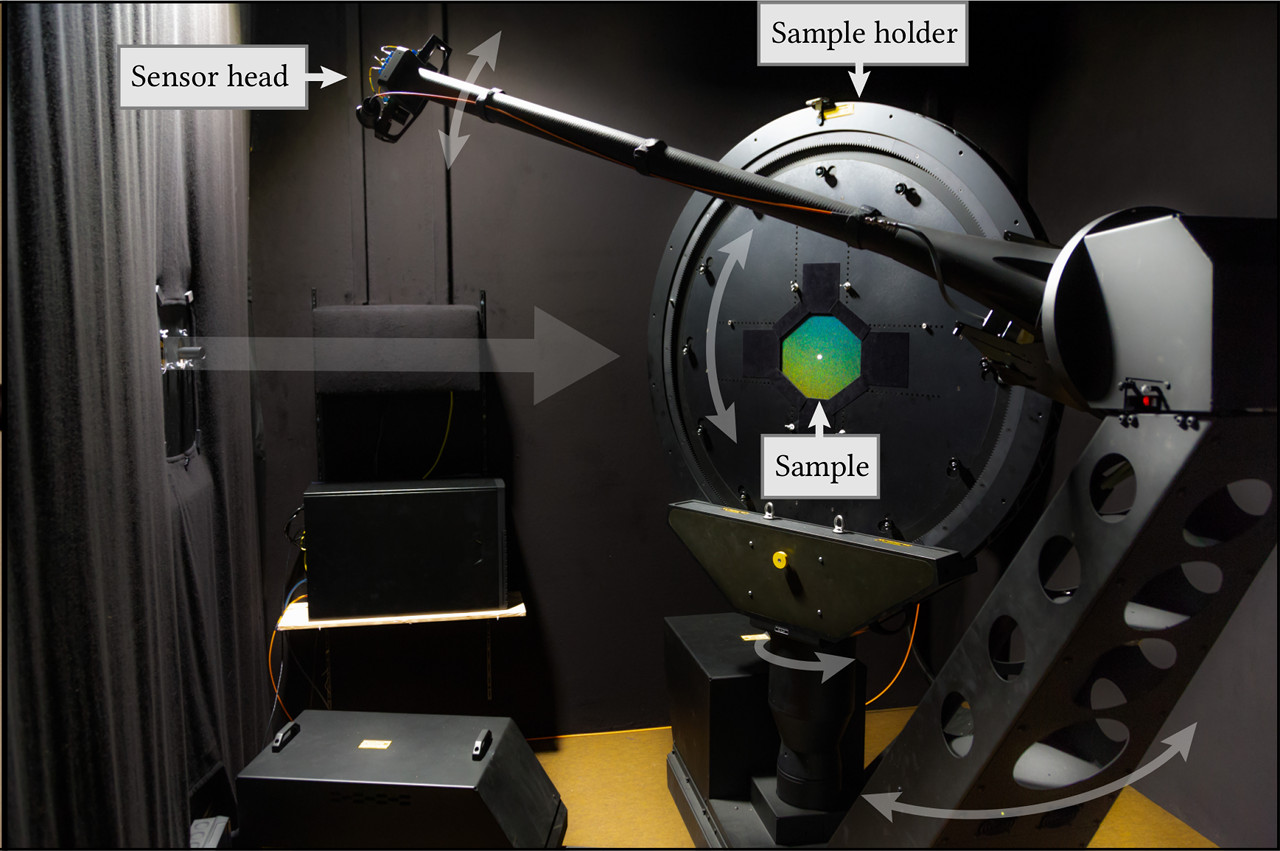

BRDF Acquisition

Gonioreflectometer setup

Pab PGII Retroreflection

BRDF domain

Practical concerns

Shadowing

Symmetries

Validation

BRDF Acquisition

Gonioreflectometer setup

Pab PGII

Retroreflection BRDF domain

Practical concerns

Shadowing

Symmetries

Validation

laser

beam dump

photodiode

beamsplitter

sample

isolator

BRDF Acquisition

Gonioreflectometer setup

Pab PGII

Retroreflection

BRDF domain

Practical concerns

Shadowing

Symmetries

Validation

xenon arc lamp

sample

sensor

collimation

lens

focusing

lens

pinhole

BRDF Acquisition

Shadowed!

$$f_r^\perp = f_r(\boldsymbol{\omega}_i, \boldsymbol{\omega}_o, \lambda) \cos \theta_i$$

Setup for BRDF Acquisition

Overview

To this end, we introduce a novel parameterization for BRDFs.

A parameterization provides a mapping, say

$g$, that transforms a parametric domain

--typically the unit hypercube-- into a domain of interest --here

the directional domain. This mapping is invertible, meaning that

any signal on the domain of interest can be warped to the parametric

domain. In this work, we make sure that the warped signal is as low

frequency as possible. Now, there are plenty of ways to design such

parameterizations, but what makes ours special is that

Overview

There are two key features that our parameterization provides.

First, it is adaptive: it produces a smmoth signal in

the parametric domain, indepently from that of the

original signal expressed in the domain of interest.

Overview

Second, it is predictive. This means that our parameterization adapts to

the material without having full knowledge of the input signal. This is

crucial in the context of acquisition since we don't want to have to

acquire a full 5D BRDF beforehand.